Patents

Literature

43 results about "Semisolid microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

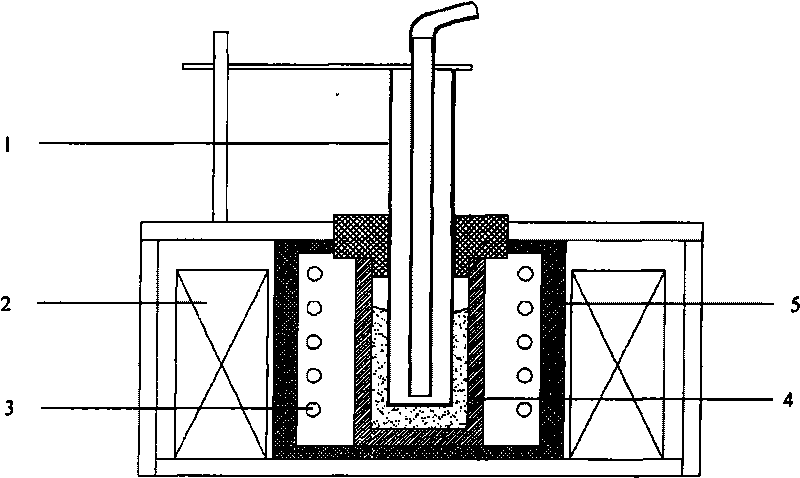

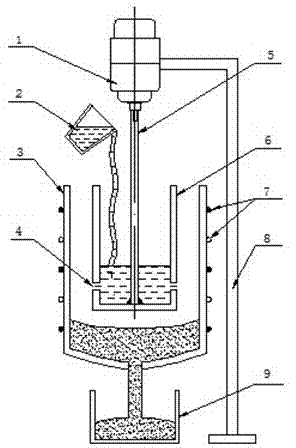

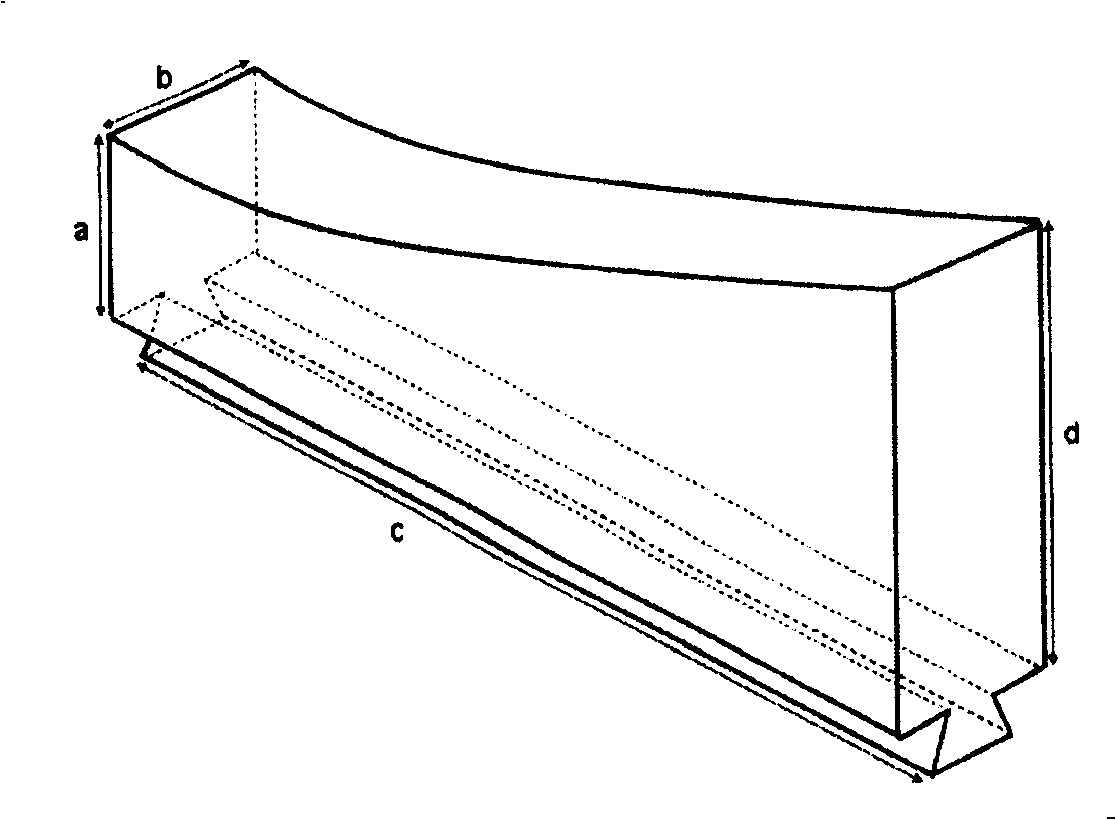

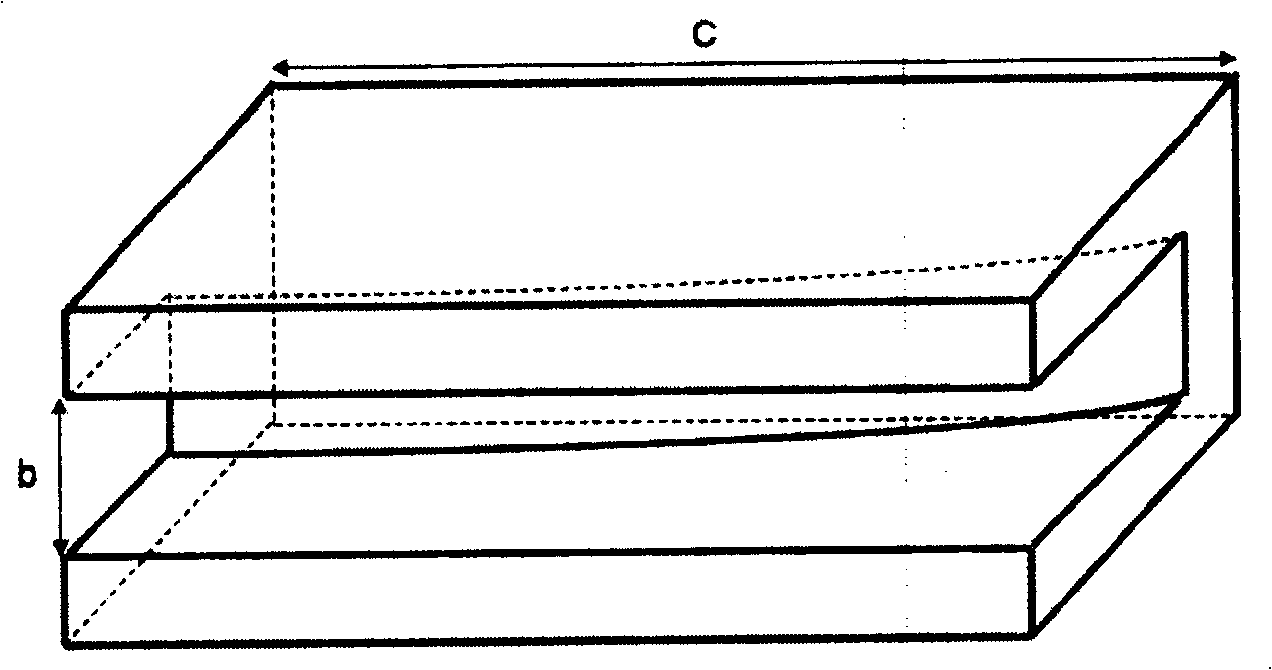

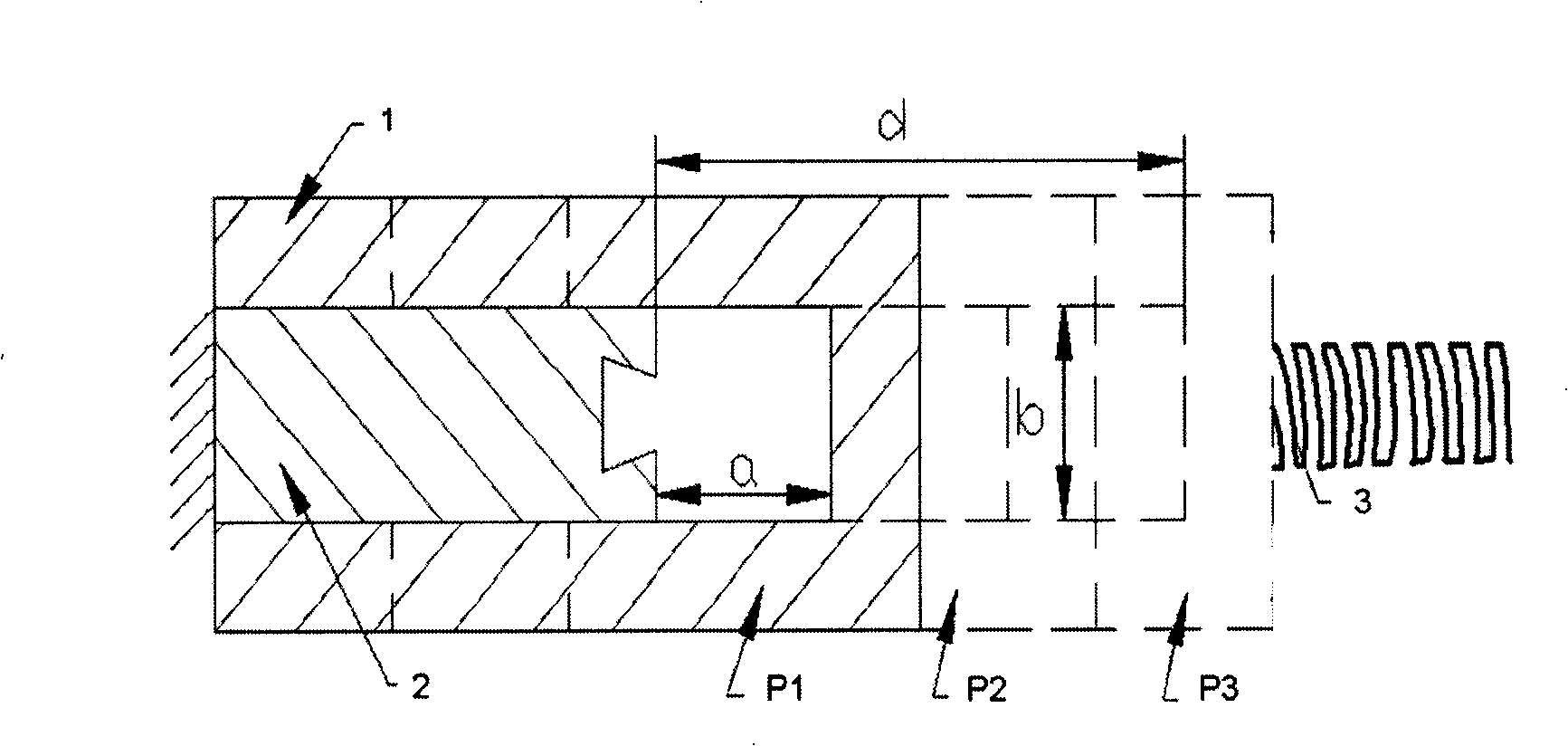

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

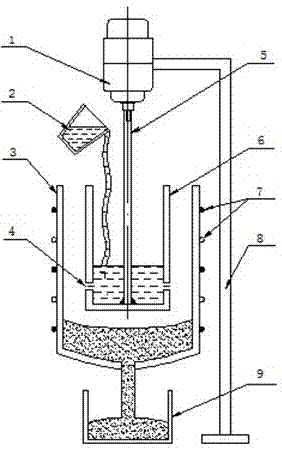

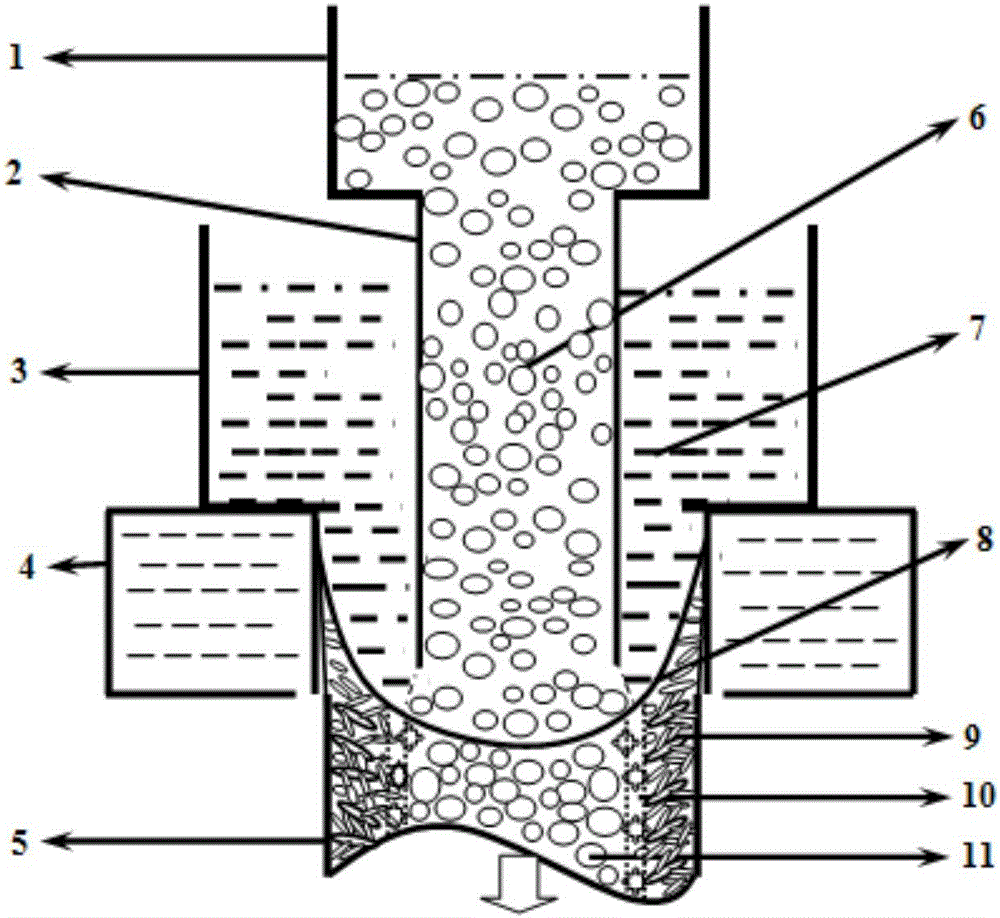

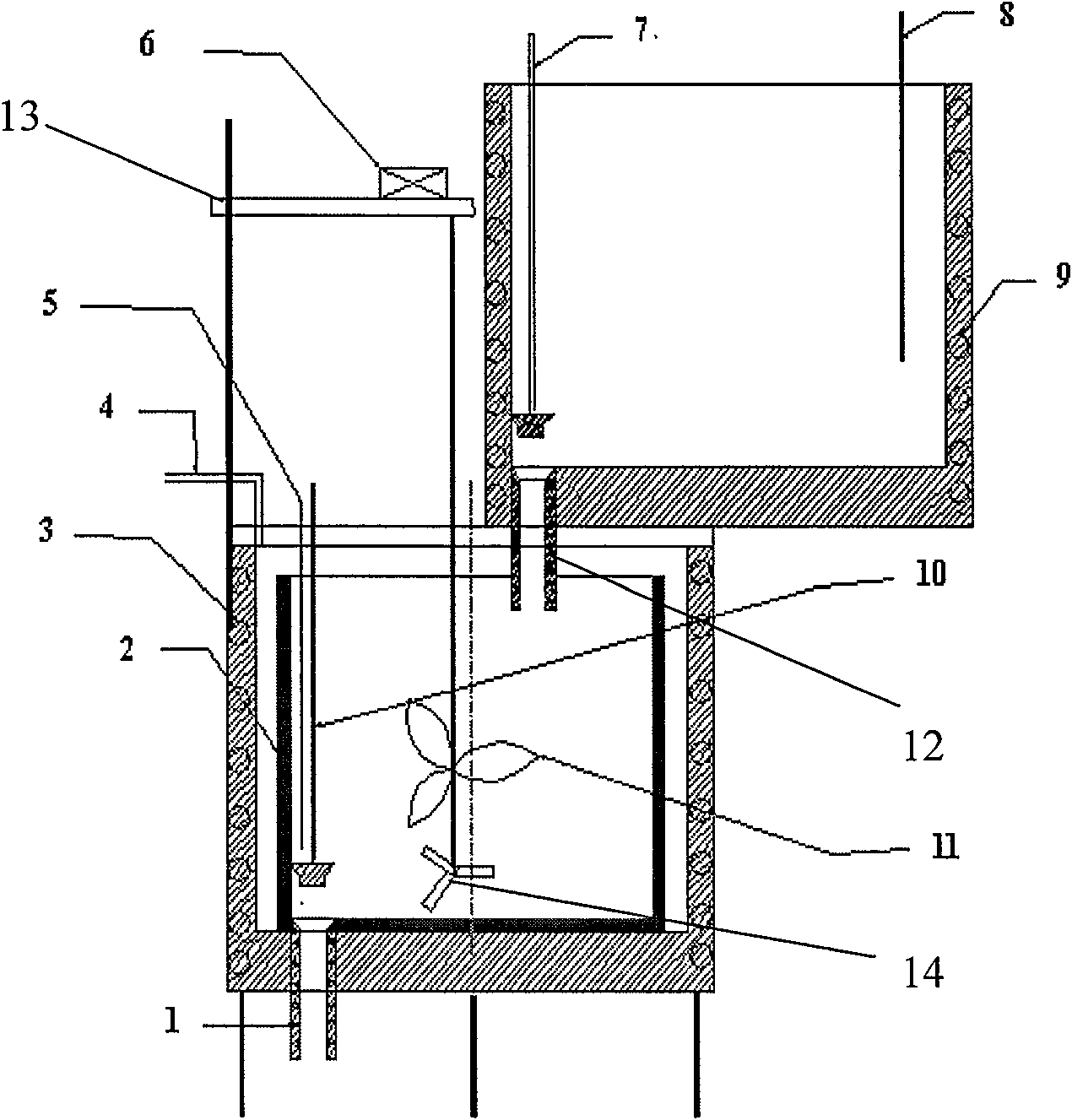

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

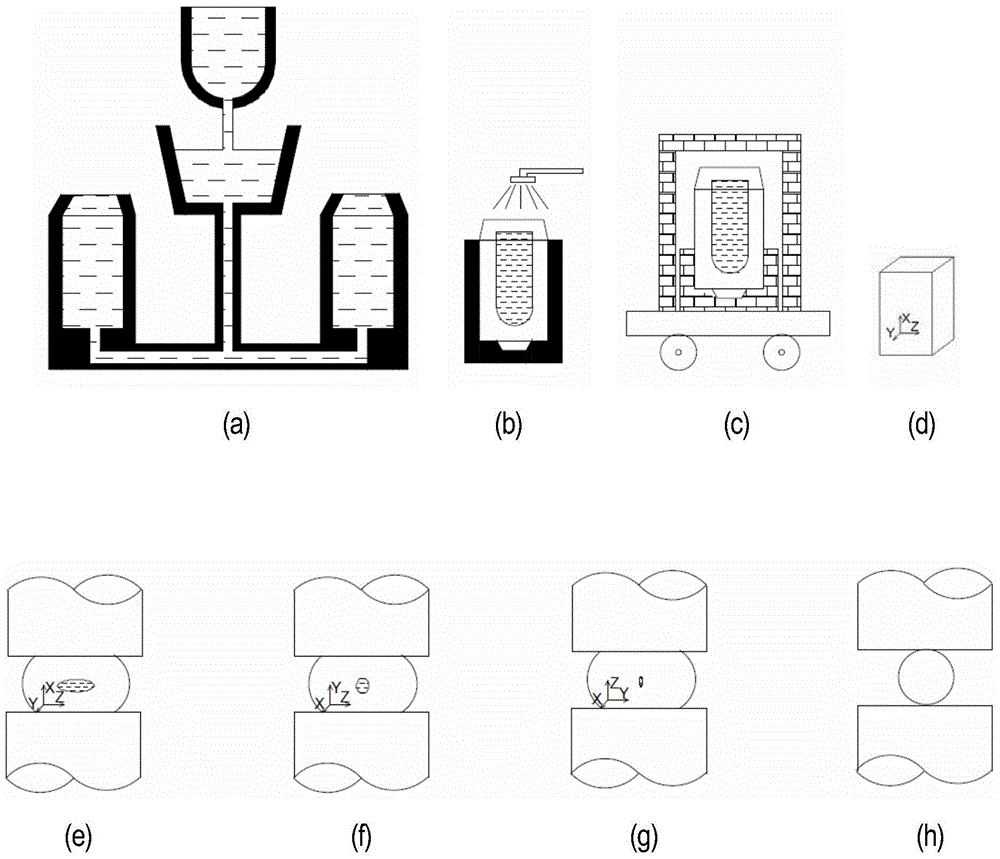

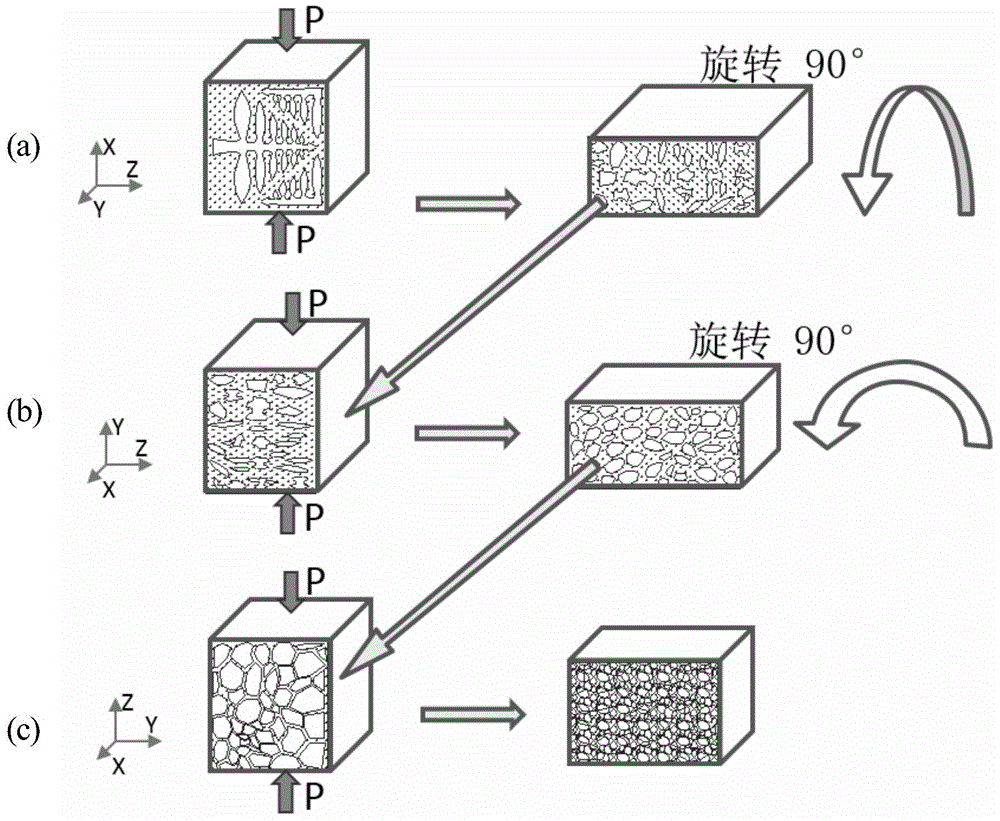

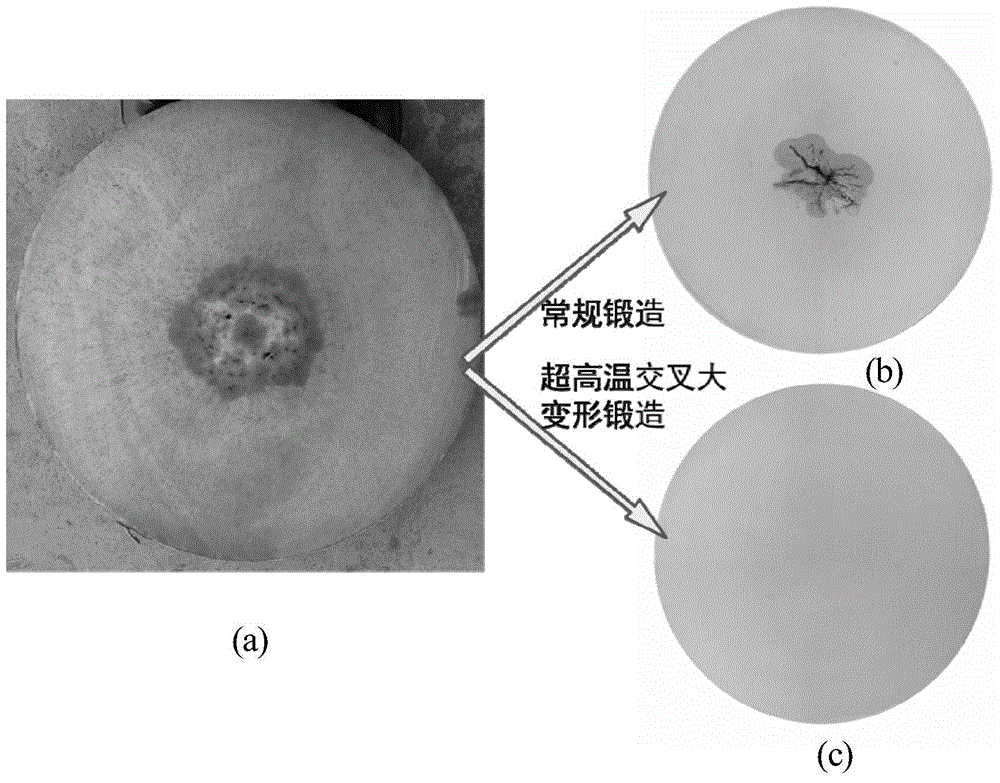

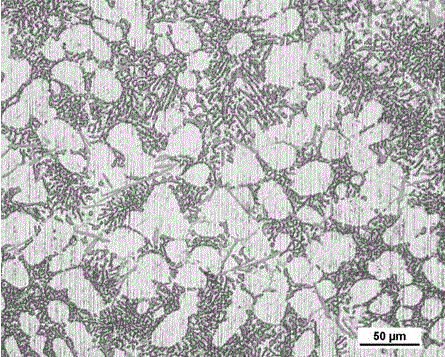

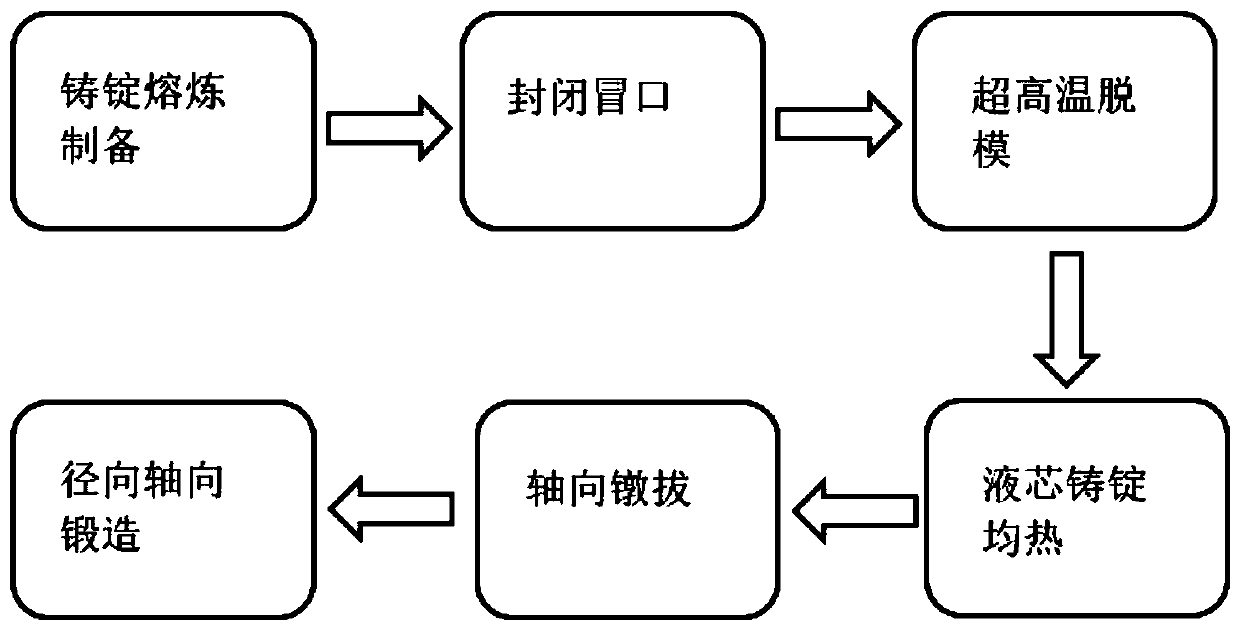

Superhigh-temperature crossed large-deformation forging method for improving structure uniformity of tool and mold steel

ActiveCN105436368AImprove liquiditySolve the shrinkage cavityMetal-working apparatusRefrigerator carCore temperature

The invention relates to the field of forging of tool and mold steel, in particular to a superhigh-temperature crossed large-deformation forging method for improving the structure uniformity of tool and mold steel. The superhigh-temperature crossed large-deformation forging method for improving the structure uniformity of the tool and mold steel comprises the steps that firstly, superhigh-temperature demolding is conducted on a poured steel ingot belt liquid core; secondly, the steel ingot belt liquid core is placed in a insulated van for temperature uniformization and conveyed to a forging press, and three-direction crossed large-deformation forging is conducted on the steel ingot belt liquid core, so that branch crystals formed at the tail stage of solidification are sufficiently crushed, a large quantity of isometric crystal structures are formed, shrinkage cavities and looseness are eliminated, and dendritic segregation is relieved; and finally, conventional forging formation including upsetting, drawing-out and the like is conducted. According to the superhigh-temperature crossed large-deformation forging method for improving the structure uniformity of the tool and mold steel, a conventional method that forging is conducted after a die-cast steel ingot is completely solidified is broken, and a semi-solid structure with the steel ingot core having excellent fluidity and a huge surface and core temperature difference are created through superhigh-temperature demolding of the belt liquid core; forced feeding and pressure solidification are achieved through a three-direction crossed large-deformation method, and the developed branch crystals formed at the tail stage of the solidification of a tool and mold steel ingot are effectively crushed; central hole defects are overcome through welding, the problems of shrinkage cavities, looseness, segregation and the like are completely solved, and the metallurgical quality of products is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing semisolid alloy through centrifuging and chilling

The invention relates to a semisolid alloy preparation method, in particular a method for preparing a spherical primary crystal semisolid alloy through centrifuging and chilling. The method comprises the following steps of: first, melting the alloy to a certain temperature; and then pouring the melt in a centrifugal barrel; throwing the melt to the inner wall of a chilling barrel after rotating the melt through centrifugal force; carrying out mixed convection on the melt in the centrifugal barrel under the double effects of centrifugal force and chilling force; and finally, obtaining a non-dendritic semisolid alloy blank or slurry with spherical or granular primary phase under the mutual effect of numerous nucleation and dendrite breaking of the outer barrel. The method for preparing the spherical primary crystal semisolid alloy through centrifuging and chilling, provided by the invention, has the characteristics of simple equipment, high production efficiency, wide application range of alloy, fine and rounded primary phase with semi-solid structure and the like, and can be used for the preparation and molding production of the metal semisolid alloy.

Owner:NANCHANG HANGKONG UNIVERSITY

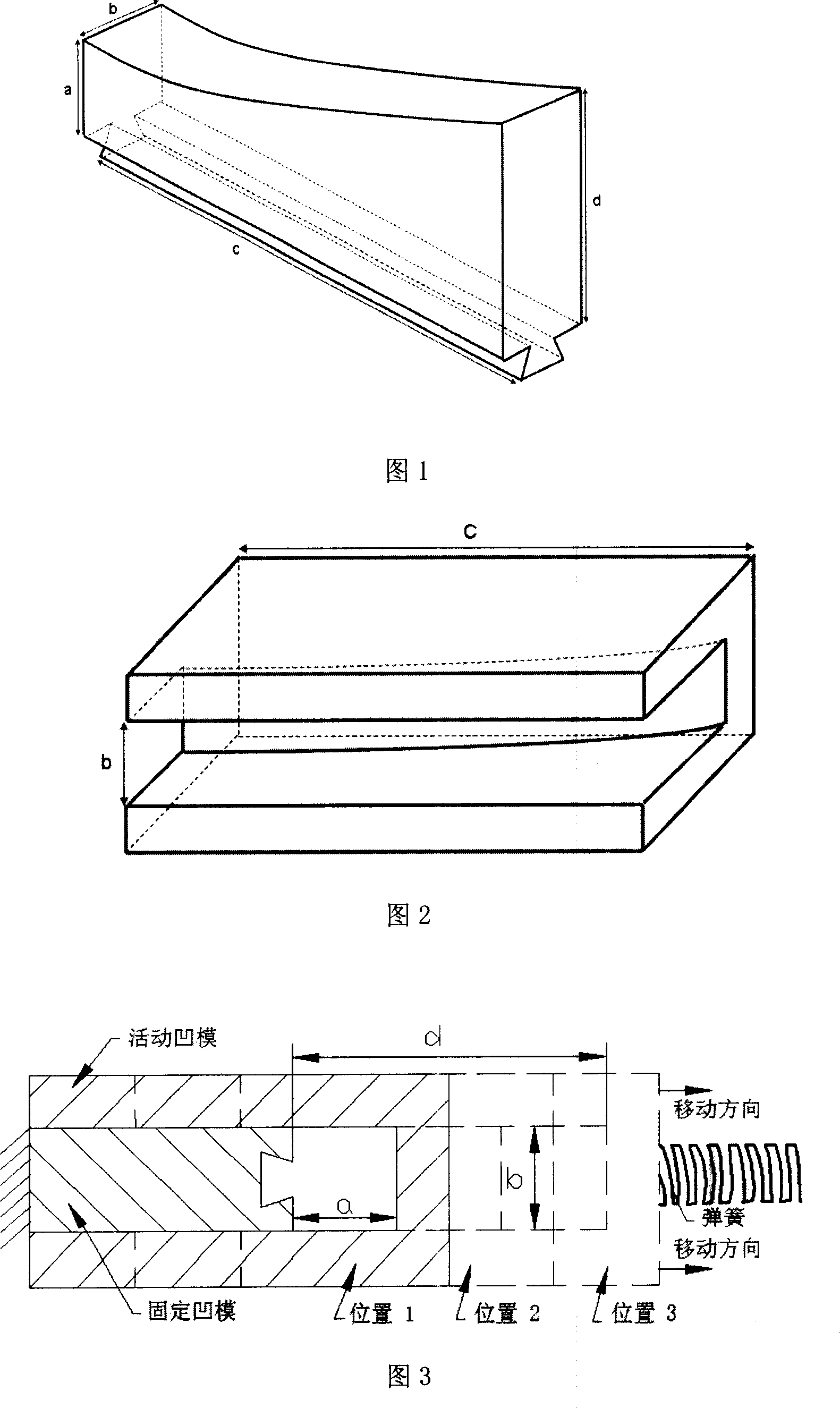

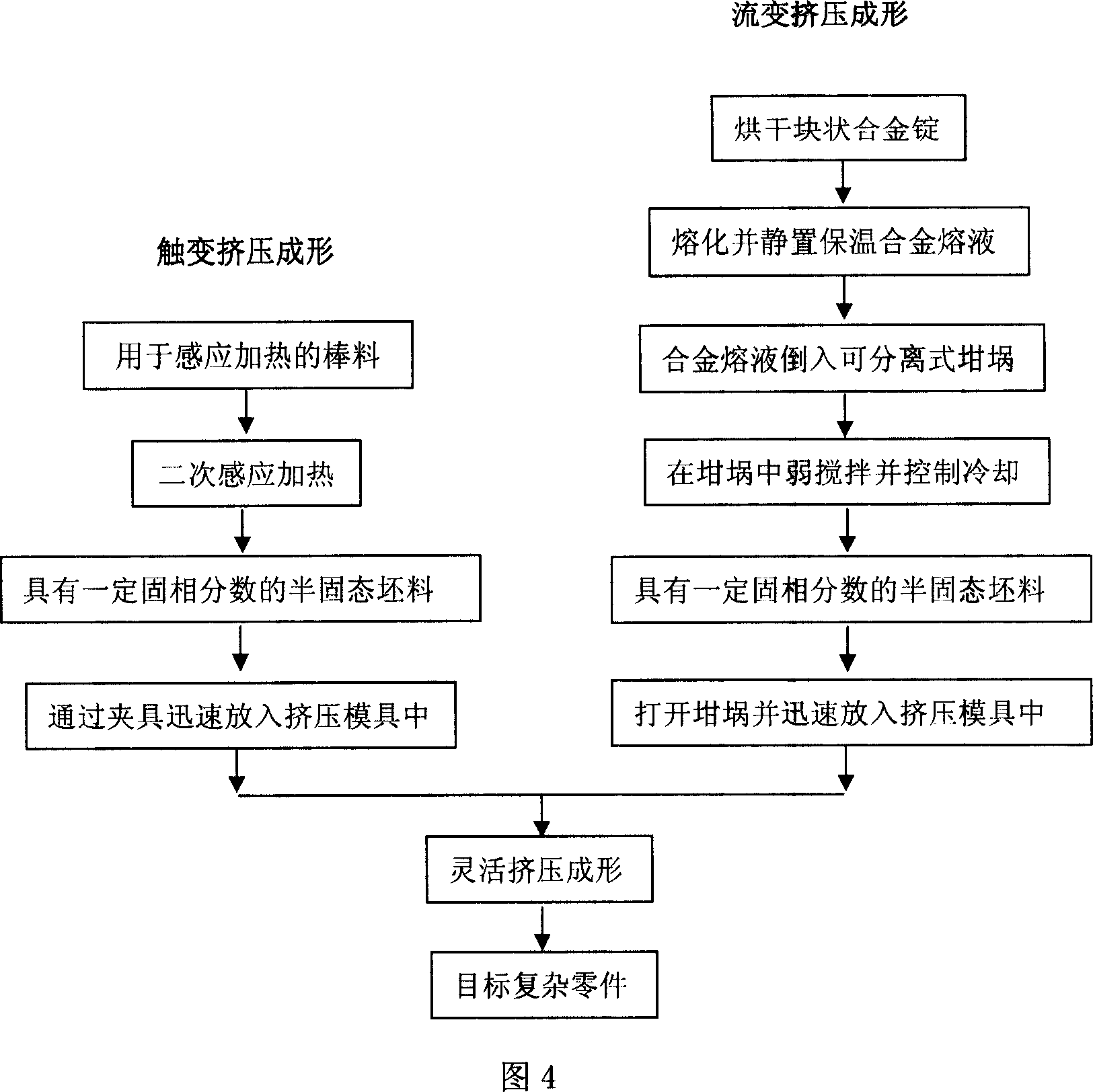

Semi-solid state flexible extrusion molding technique for shaped complex parts

The invention relates to a semi-slid flexible extruding shaping method for obtaining complex element. And the method comprises that preparing semi-solid slurry, designing the device for constantly quickly feeding semi-solid slurry, and extruding and shaping complex element. For semi-solid touch extruding shaping, the invention uses sensitive heating furnace secondary heating to obtain the blank of semi-solid organism character, and for semi-solid flow extruding shaping, the invention first uses resistance furnace to heat the dried alloy ingot, and laid thermal-insulated at fusing temperature. The invention can realize complex element in short process, reduce energy consumption and improve product quality.

Owner:TSINGHUA UNIV

Graphene reinforced aluminum matrix composite material and preparation method

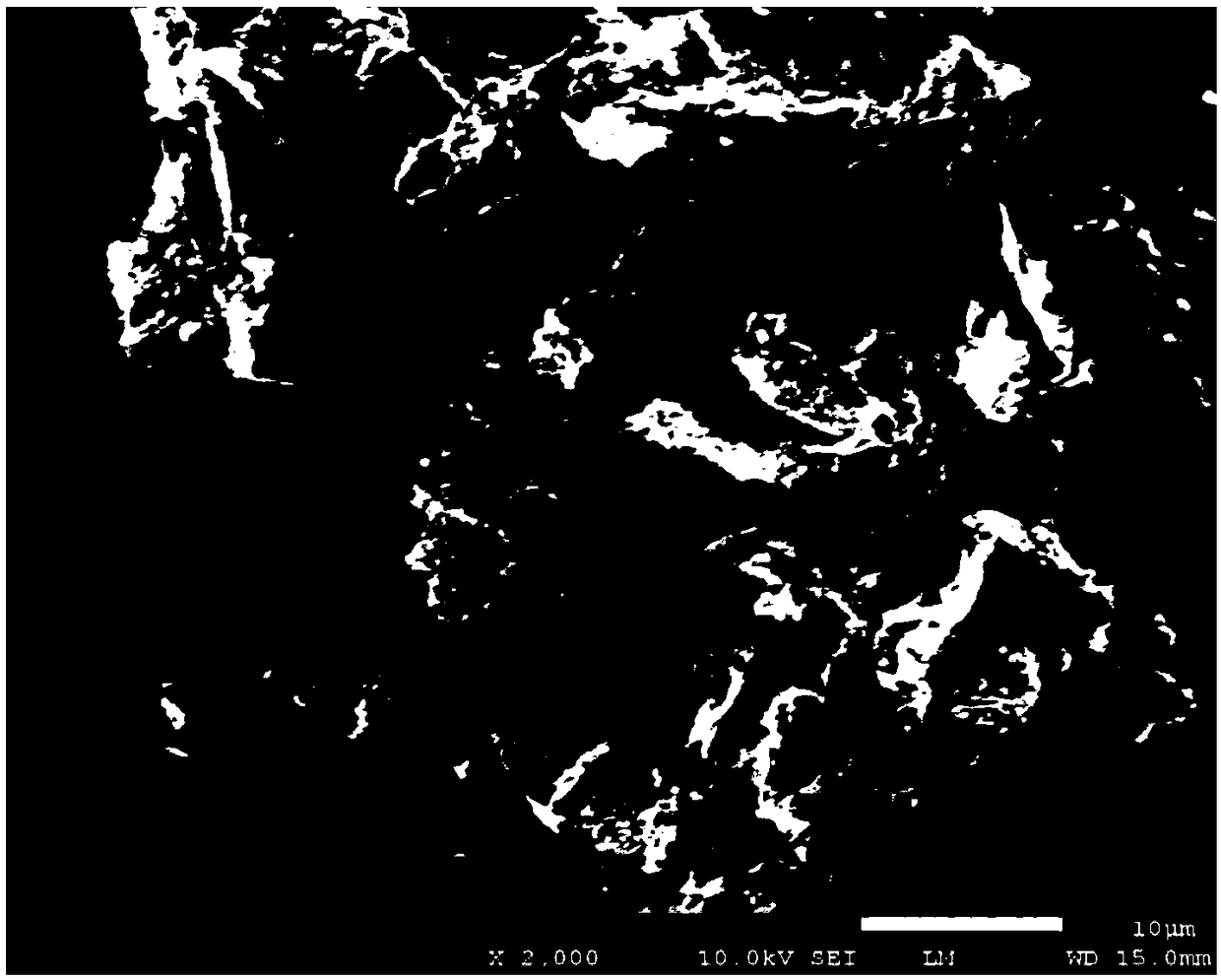

The invention provides a graphene reinforced aluminum matrix composite material and a preparation method. The preparation method comprises the following steps that S1, graphene is subjected to metal plating treatment; S2, the graphene after metal plating treatment and metal powder are subjected to ball-milling treatment, and a surfactant is added during the ball-milling process to obtain a uniformly-mixed mixture; and S3, the mixture is added into aluminum or aluminum alloy melt under the action of air flow and ultrasonic, the flow rate of the mixture and the temperature of the melt are controlled, and the graphene reinforced aluminum matrix composite material is obtained after cooling and solidifying. The graphene reinforced aluminum matrix composite material prepared by the preparation method has semi-solid structure characteristics, the graphene is relatively complete in structure, and the material performance is excellent. The tensile strength of the aluminum matrix composite material prepared by the preparation method is improved by 30%-70% compared with that of a matrix, and is improved by 10%-30% compared with a graphene reinforced aluminum matrix composite material with non-semi-solid structure characteristics.

Owner:SHANGHAI JIAO TONG UNIV

Rare earth-containing aluminum alloy used for semisolid state rheoforming and preparation method of semisolid state slurry thereof

InactiveCN101705398ASpherical fine particlesUniform spherical particlesRare-earth elementMetal forming

The invention belongs to the technical field of semisolid state metal forming and aims at providing a rare earth-containing aluminum alloy used for semisolid state rheoforming and a preparation method of semisolid state slurry thereof. The ingredients of the alloy include: 6.5-7.5wt. percent of Si, 0.25-0.45wt. percent of Mg, 0.1-0.8wt. percent of Er and the balance of aluminum and unavoidable impurities. Compared with the alloy without adding element Er, the aluminum alloy has finer and more uniform spherical particles of the semisolid state tissue due to the addition of rare earth element Er and the refining of primary alpha-Al phase. The characteristic that the given alloy is suitable for the semisolid state forming is mainly represented in the following aspects: 1) the primary alpha-Al phase is fine and uniform spherical non-arborescent tissue; and 2) during the semisolid state rheoforming, the control accuracy on temperature is reduced and a complicated preparation device is not needed, thus reducing technological control cost.

Owner:BEIJING UNIV OF TECH

Method for preparing bimetallic composite material through pouring continuous casting

The invention provides a method for preparing a bimetallic composite material through pouring continuous casting. The method comprises the steps: (a) cooling liquid-state metal melt in a crystallizer, and forming an inverted-conical coagulating liquid hole under the action of a continuous casting dummy bar; (b) adding semi-solid-state metal slurry into the coagulating liquid hole through a diversion system, and carrying out coagulation, thereby obtaining a bimetallic composite cast ingot. The invention further provides equipment for preparing the bimetallic composite material through pouring continuous casting. According to the method and the equipment, firstly, the coagulating liquid hole with certain depth is formed by using the traditional continuous casting principle, and then, the semi-solid-state metal slurry is poured into the coagulating liquid hole through the diversion system, so that heterogeneous metal fluid coating composite casting is achieved; during coagulation, the internal semi-solid-state metal slurry and the outer-layer metal melt are subjected to convective mass transfer at an interface, and metal in the crystallizer is subjected to gradual coagulation from outside to inside, so that the bimetallic composite material, of which gradient transition of alloy composition to semi-solid-state texture to dendrite texture is formed between metal of inner and outer layers, is obtained.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

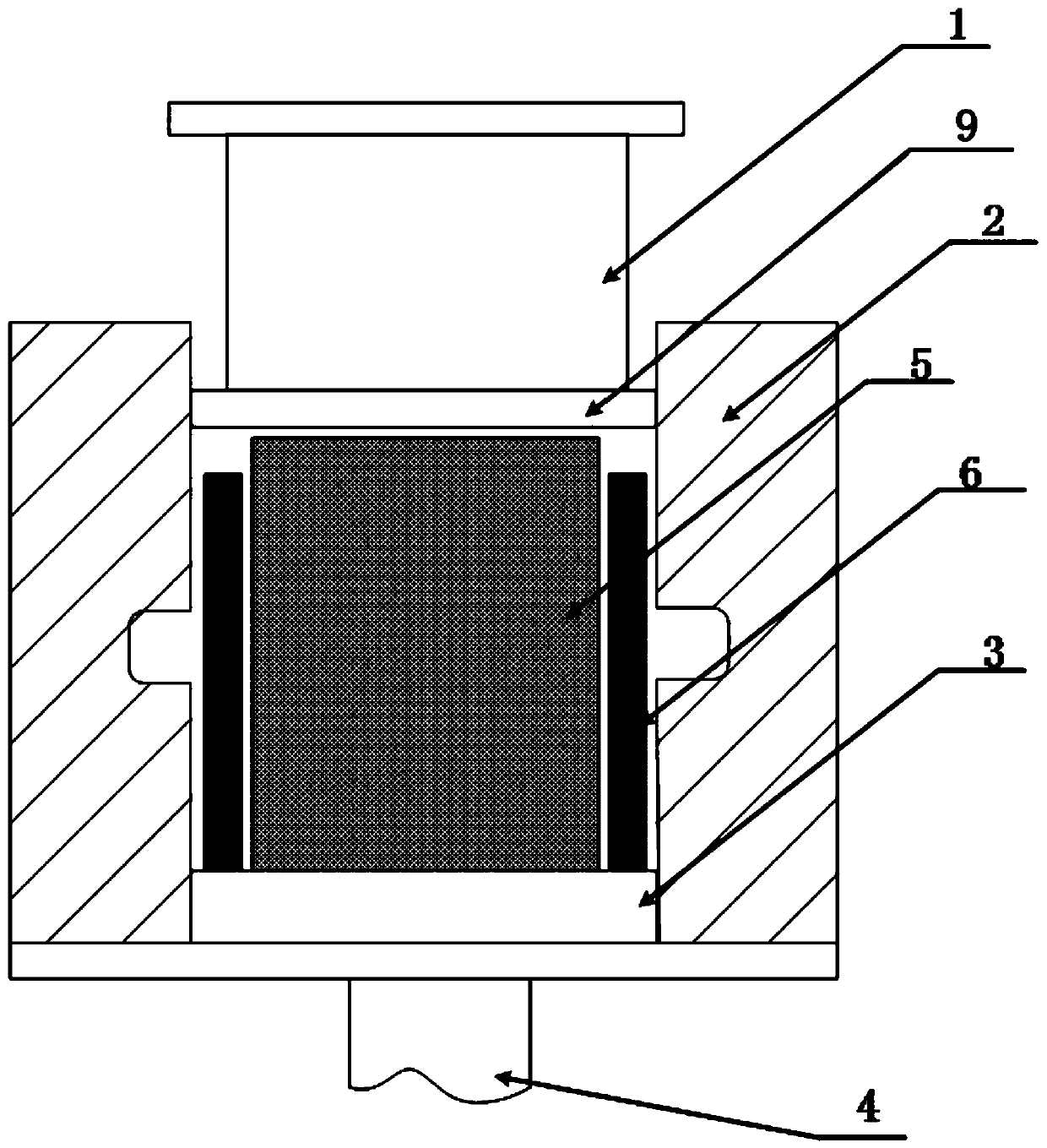

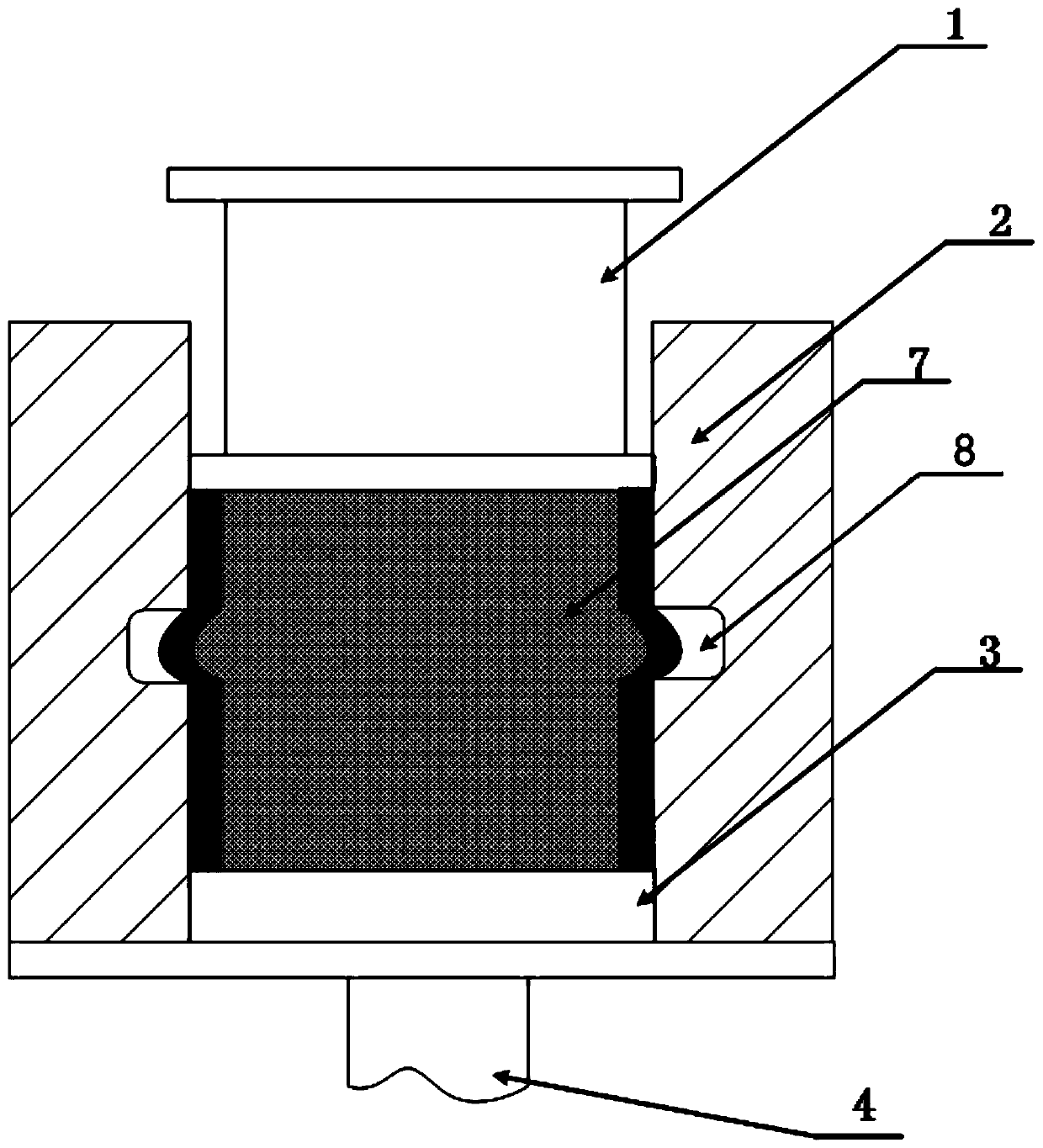

Method of forming thixotropic soft core of aluminum-steel bimetal member through composite forging

ActiveCN109807272AAvoid instabilityAvoid foldingForging/hammering/pressing machinesSemi solidUltimate tensile strength

The invention discloses a method of forming a thixotropic soft core of an aluminum-steel bimetal member through composite forging. The method comprises the following steps of: firstly manufacturing analuminum alloy core body and a steel sleeve which have certain sizes and shapes, heating the aluminum alloy core body and carrying out heat preservation until the aluminum alloy core body is in a semi-solid texture state, heating the steel sleeve until the steel sleeve is in a thermoplastic state, quickly guiding the aluminum alloy core body and the steel sleeve into a mold, and assembling to complete the composite forging. By utilizing the good fluidity of the aluminum alloy in the semi-solid state, the coordinated deformation of the aluminum alloy core body and the steel sleeve is realized,so that the composite member is more precisely formed; in addition, a liquid phase portion in the semi-solid aluminum alloy core body reacts with the steel sleeve to form a stable interface with highbonding strength. The metallurgical combination of aluminum-steel bimetal coordinated deformation and interface reliability is realized; and the high-performance advantage of steel and the lightweight advantage of the aluminum alloy are effectively integrated.

Owner:HARBIN INST OF TECH AT WEIHAI

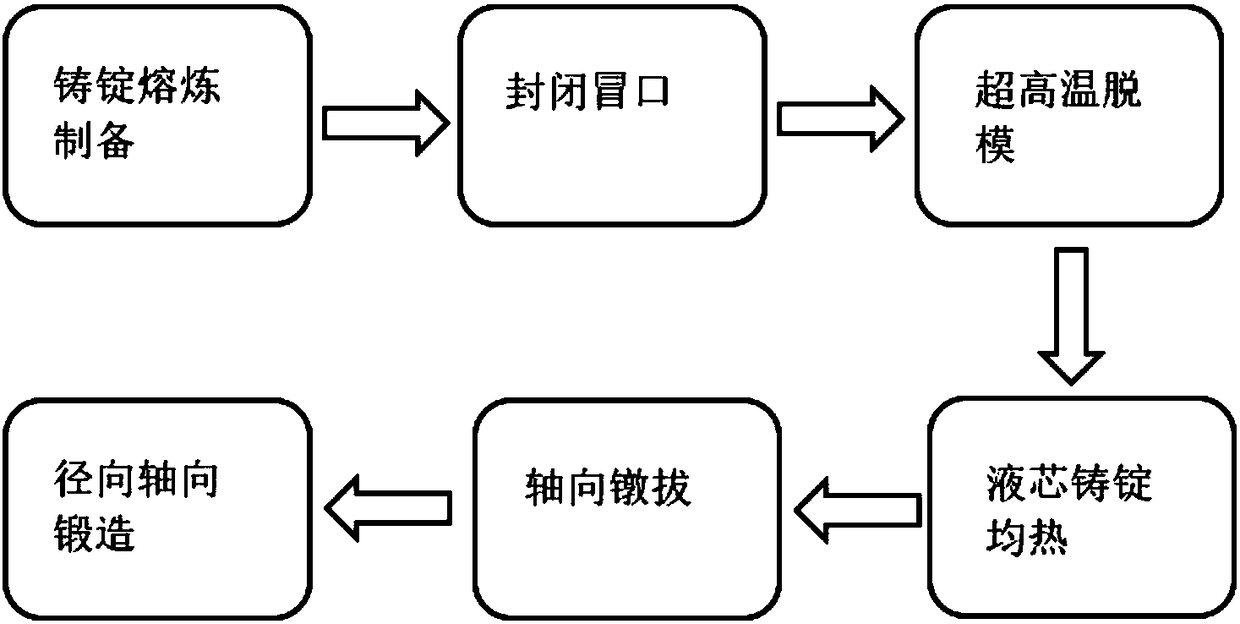

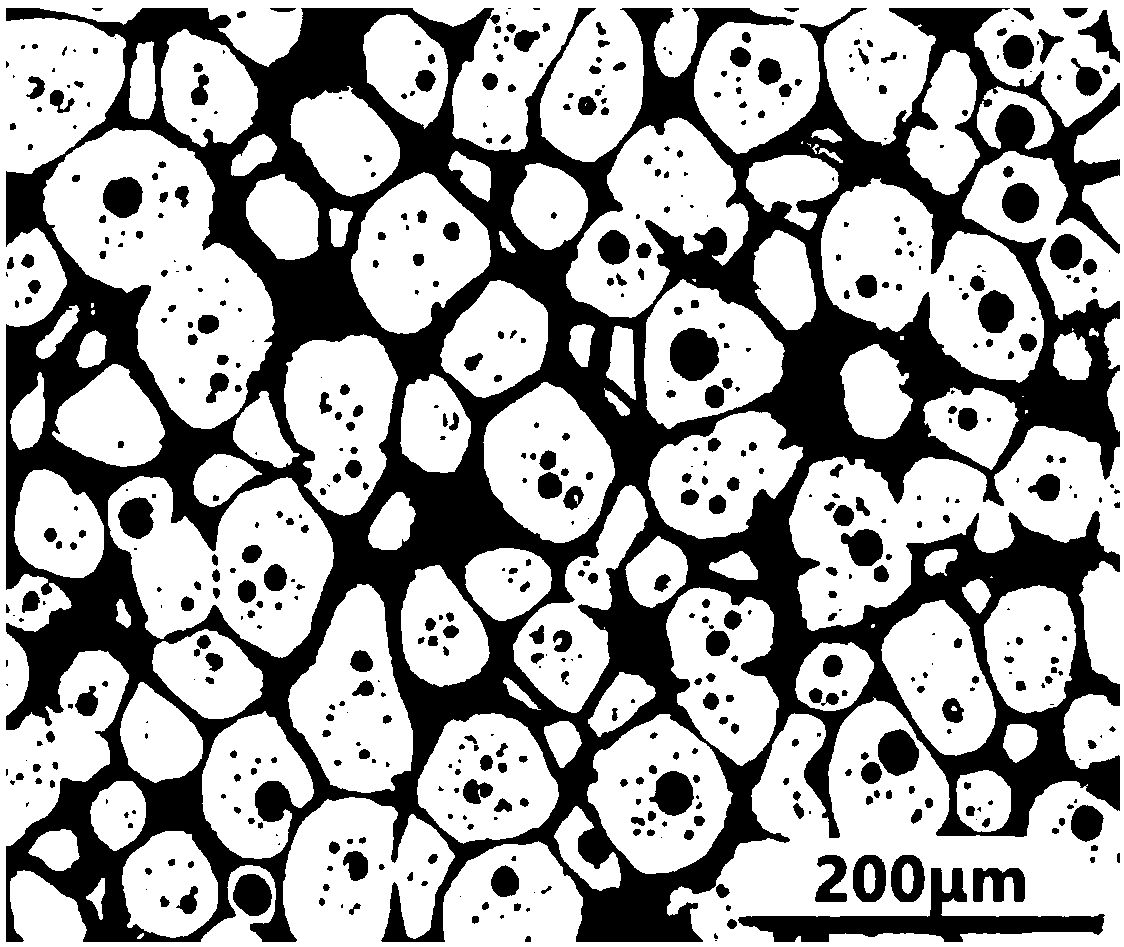

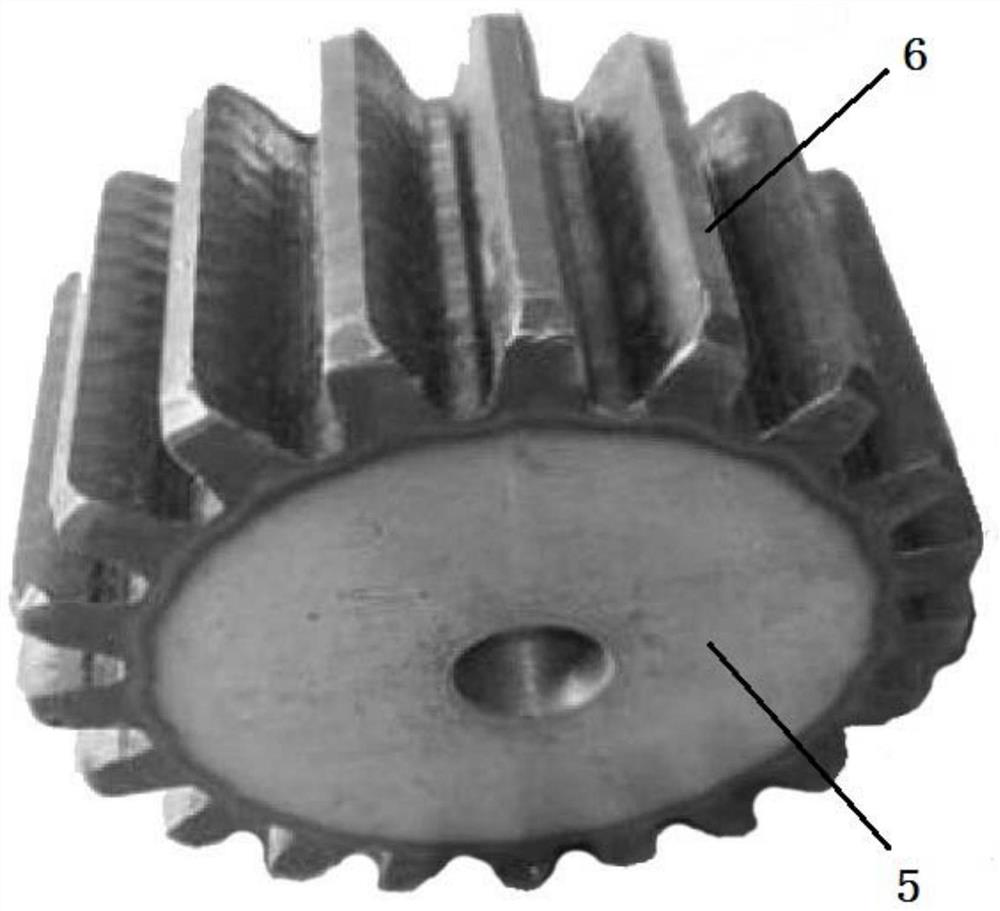

High-uniformity short-process forming method for large metal component

The invention relates to the field of metal forming, in particular to a high-uniformity short-process forming method for a large metal component. Firstly, a cast alloy cast ingot is subjected to superhigh temperature demolding; then soaking is conducted on the liquid core cast ingot, precise control of the liquid fraction of the core part of the cast ingot is achieved, axial upsetting and rollingare conducted on the cast ingot under a forging press, dendrite at the liquid core of the cast ingot is fully crushed and balled, and a uniform and tiny semisolid structure is formed; and finally radial and axial forging is conducted on the cast ingot, and the cast ingot is forged into the needed large metal component structure. Through the high-uniformity short-process forming method, the problems such as shrinkage cavity and porosity and dendritic segregation in the cast ingot are solved, the central mechanical performance of the large metal component can reach the surface performance level,and uniformity of the overall performance of the component is improved. The core part of the cast ingot forms the uniform and tiny semisolid structure, and thus the final forge piece has good comprehensive performance. Forming pressure is small, the requirement for ability of forging equipment is lowered, the technological process is shortened, and production cost can be lowered effectively.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for aluminum alloy semi-solid slurry induced and impregnated by modificator

A preparation method for aluminum alloy semi-solid slurry induced and impregnated by a modificator comprises the following steps that (1) an Al-Si-Cu alloy ingot is placed into a graphite crucible to be subjected to fusion, refining and slag removal; (2) small pieces of Al-Sr intermediate alloy are added into the fondant, the mass fraction of Sr in the Al-Sr intermediate alloy is 9 wt.%-11 wt.%, and the mass fraction of the Sr in the fondant is 0.01 wt.%-0.09 wt.%; (3) the temperature is increased to 760-770 DEG C, heat preservation is conducted for 15-20 min, then a preheated ultrasonic amplitude-change pole probe is placed in the fondant, ultrasounds are released intermittently, the ultrasound interval of each time is 1-2 s, the ultrasounds are released for 2.0-2.5 s each time, the power is 1.0-2.0 kw, the frequency is 20 kHz, the total ultrasound time is 3-5 min, then the temperature is decreased to 585-610 DEG C, and standing and heat preservation are conducted for 8-10 min; and (4) intermittent ultrasound treatment is conducted on the fondant again, the ultrasound conditions are identical to those in the step (3), the total ultrasound time is 60-100 s, and water quenching is conducted immediately after the ultrasound treatment is completed. Grains of semi-solid structures obtained through the method are finer, rounder, more complete and more uniform in distribution and fully meet the requirements for semi-solid rheoforming, operation is easy and convenient, safety and reliability are achieved, and three-waste pollution is avoided.

Owner:江西剑发铝型材有限公司

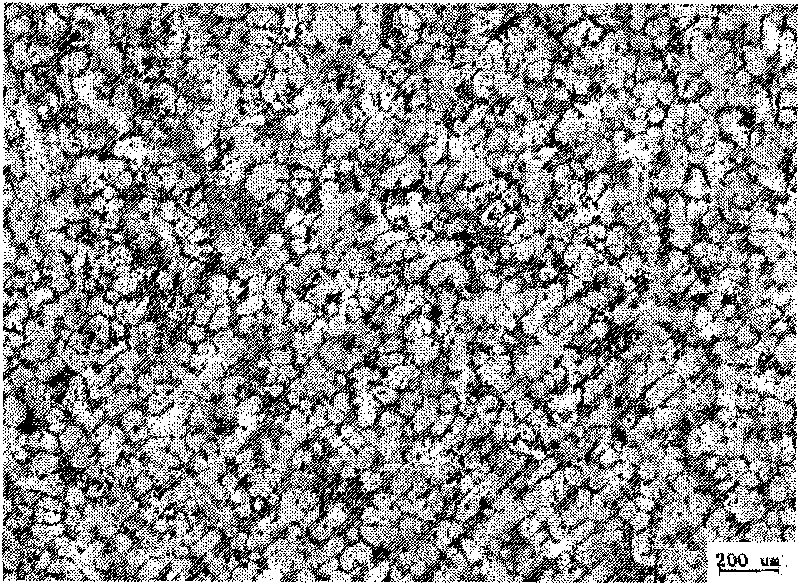

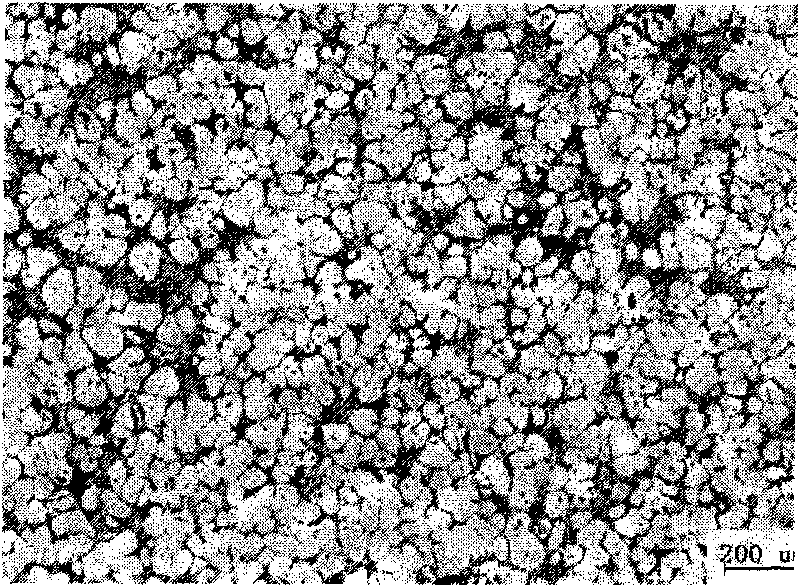

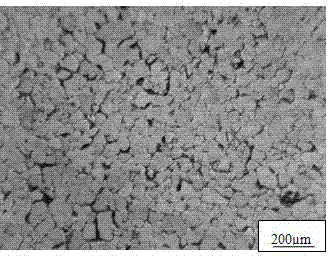

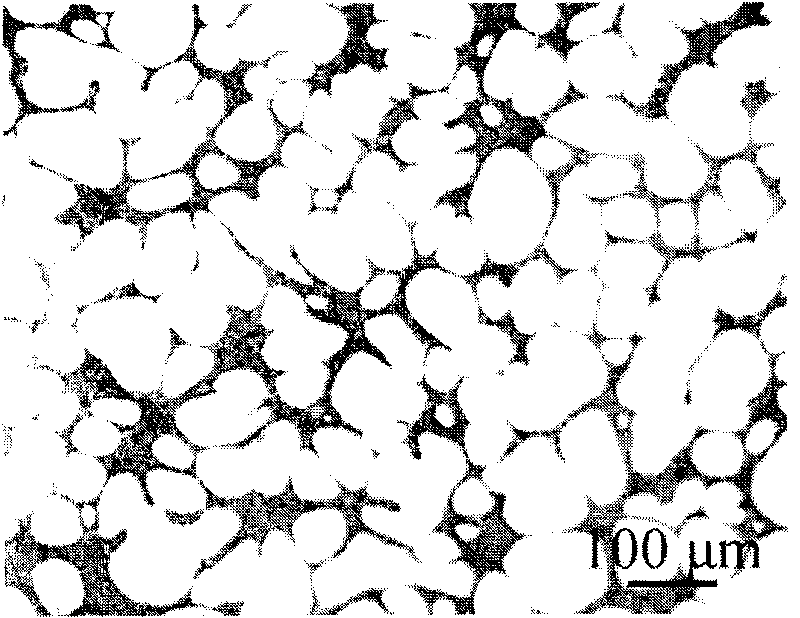

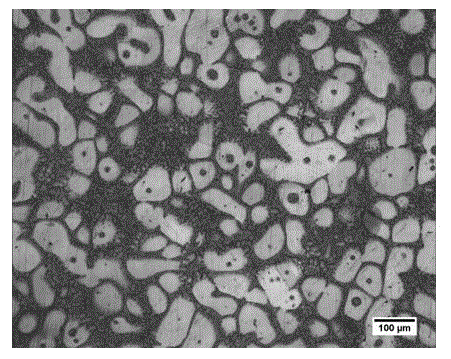

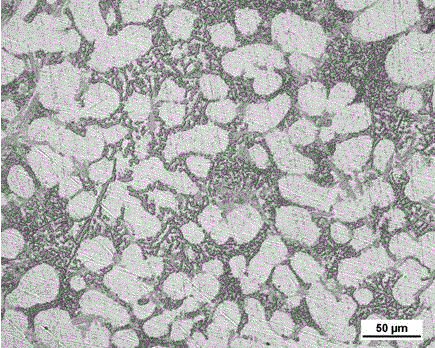

Preparation method of semisolid-state AZ61 magnesium alloy

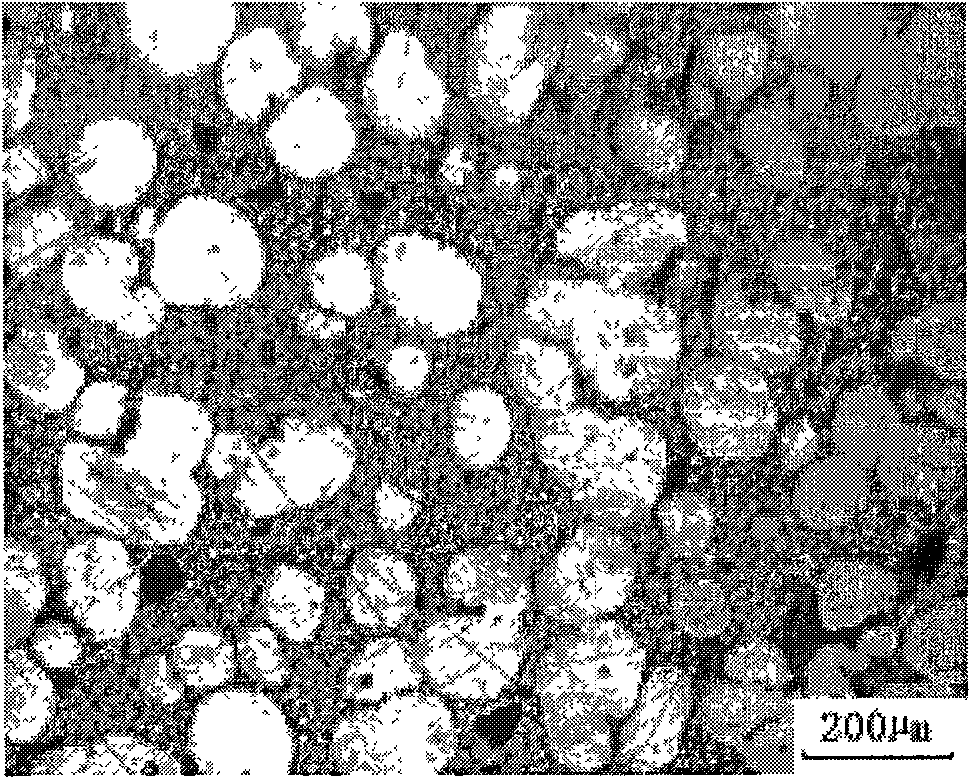

InactiveCN101623753AEvenly distributedImprove mechanical propertiesMechanical propertySemisolid microstructure

The invention discloses a preparation method of a semisolid-state AZ61 magnesium alloy, which is characterized by comprising the following steps: firstly placing AZ61 magnesium alloy into a melting furnace, heating, refining and standing under protection of covering flux, and then cooling to liquidus temperature; then pouring liquid magnesium alloy into an argon protection stirring furnace to be stirred for 3 min to 5 min when being cooled with the stirring speed of 300 to 600 r / min until temperature of the liquid magnesium alloy is lowered to 595 DEG C to 610 DEG C; and pouring the liquid magnesium alloy. The invention can obtain fine, round, even and uniformly distributed semisolid spherical particles, and the mechanical performance of a semisolid structure thereof is greatly enhanced compared with a conventional cast structure.

Owner:NANCHANG UNIV

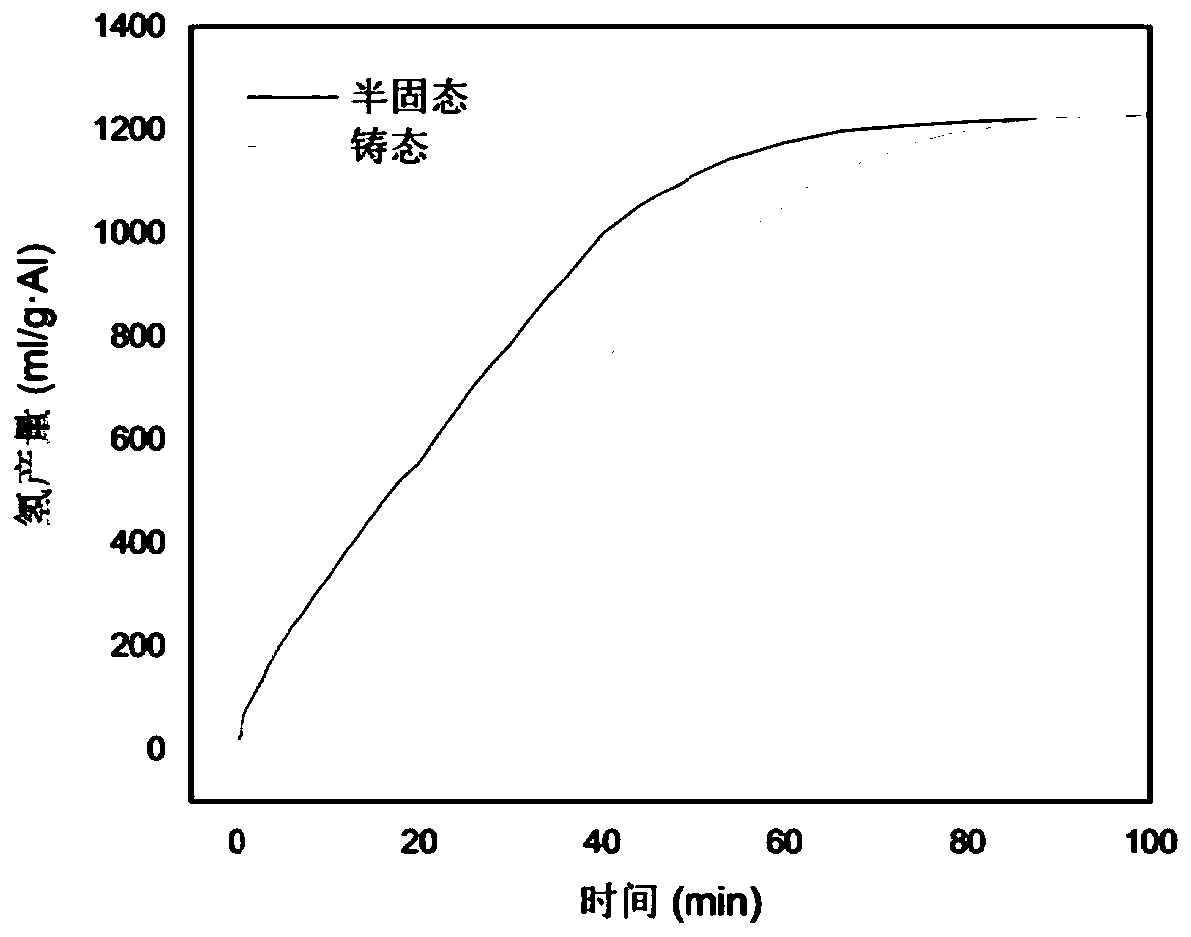

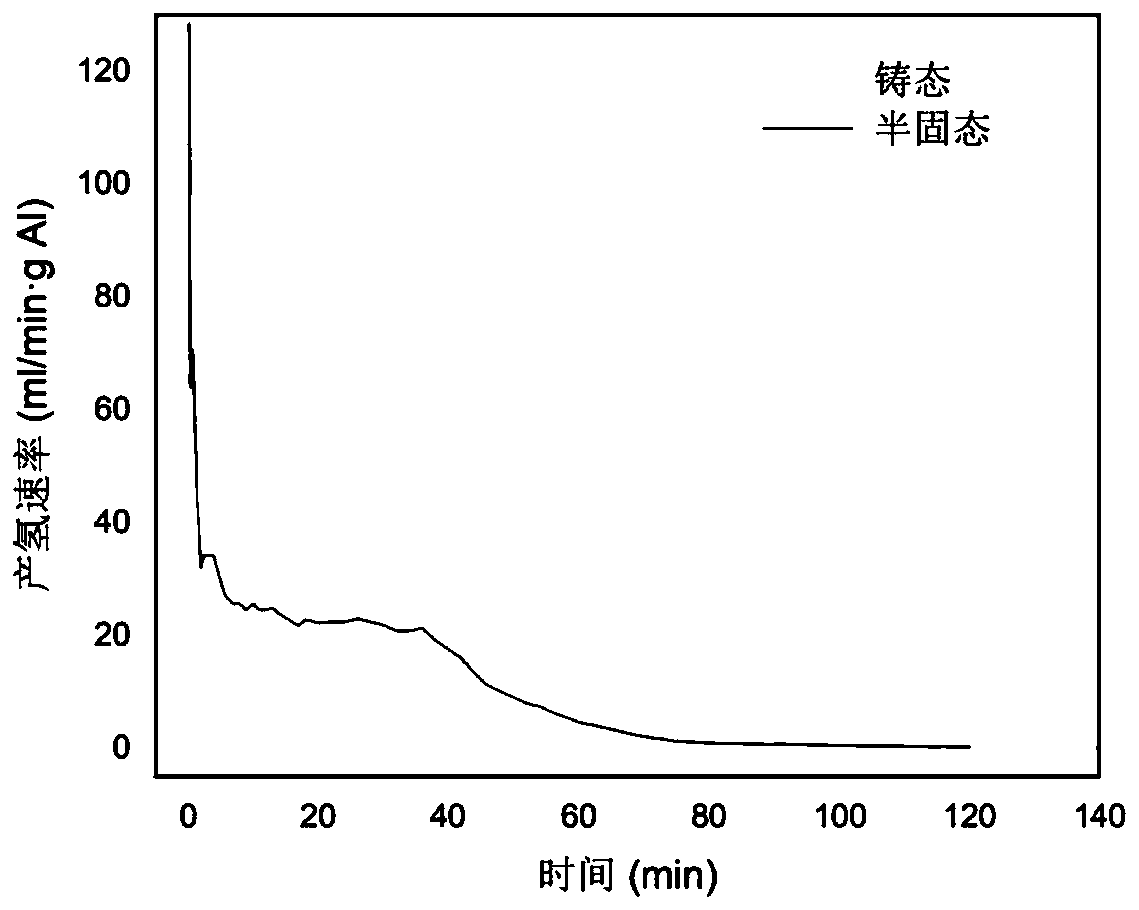

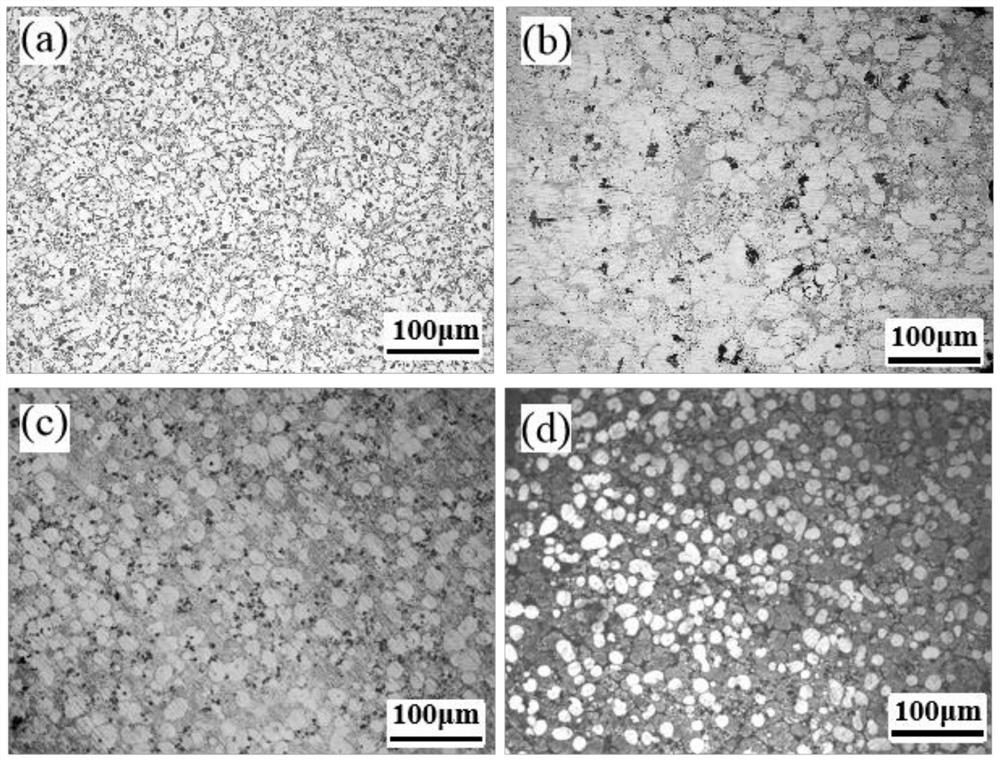

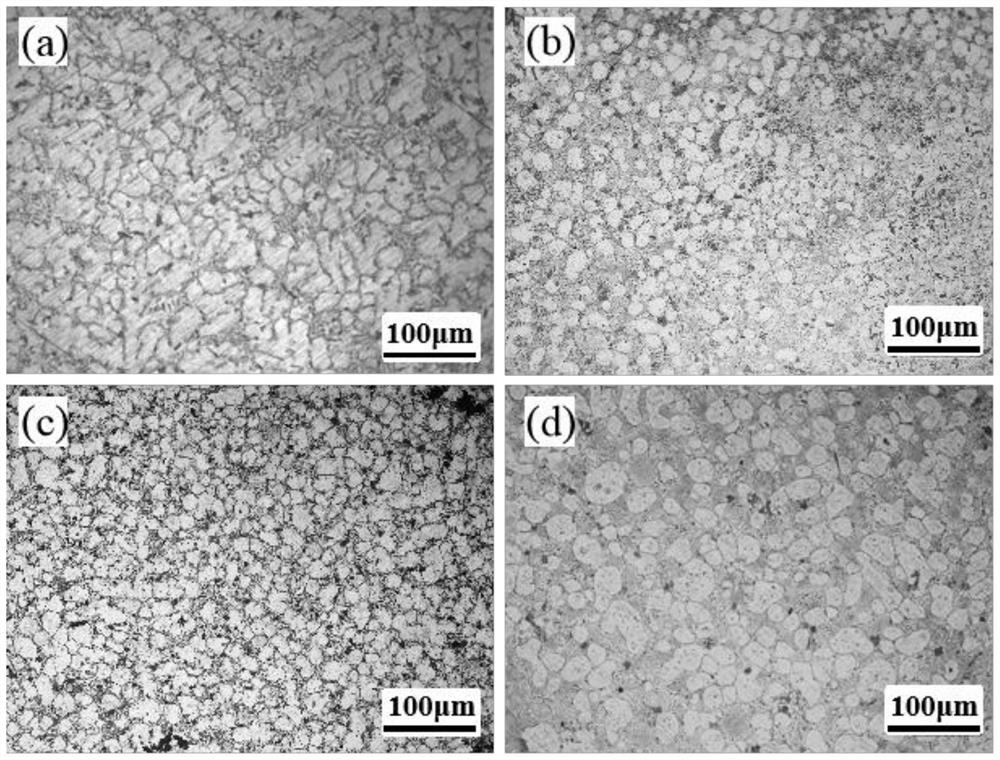

Semi-solid metal-based hydrolysis hydrogen production material and preparation method thereof

ActiveCN110592433AEasy to achieve complete hydrolysisHigh yieldHydrogen productionSemi solidHydrolysis

The invention provides a semi-solid metal-based hydrolysis hydrogen production material and a preparation method thereof. The material has semi-solid tissue, the semi-solid tissue comprises sphericalor near-spherical primary phases containing metal matrix elements and meshy secondary solidified tissue containing active elements, wherein the spherical or near-spherical primary phases containing the metal matrix elements are uniformly dispersed in the meshy secondary solidified tissue containing the active elements; and the metal matrix elements and the active elements are prefabricated into ablank, the blank is subjected to semi-solid pulping, and then the semi-solid metal-based hydrolysis hydrogen production material is obtained after cooling. Compared with other existing tissue block materials with the same components, the metal-based block hydrolysis hydrogen production material prepared through the method has the advantages that the hydrogen production rate is 20%-500% higher thanprevious hydrogen production rate, and the yield is nearly 100%.

Owner:SHANGHAI JIAO TONG UNIV

High-entropy alloy isothermal heat treatment method

ActiveCN114214579AImprove performanceGood spherical effectIncreasing energy efficiencyHigh entropy alloysSemi solid

The invention provides a high-entropy alloy isothermal heat treatment method which comprises the following steps: carrying out isothermal heat treatment on a high-entropy alloy at the temperature of 420-440 DEG C for 16-22 minutes, and putting the high-entropy alloy subjected to the isothermal heat treatment into water for water quenching. According to the isothermal heat treatment method for the light high-entropy alloy, the high-entropy alloy is placed in the box-type resistance furnace to be subjected to isothermal heat treatment, water quenching is conducted after isothermal heat treatment is completed, the isothermal heat treatment method achieves a non-dendritic crystal spherical structure in the secondary heating process before semi-solid thixoforming, the process is simple, special equipment is not needed, cost is low, and the method is suitable for industrial production. According to the isothermal heat treatment method for the high-entropy alloy, the semi-solid structure with the good spheroidizing effect is obtained in the isothermal heat treatment process through changes of the heat treatment time and the heat treatment temperature, and the alloy performance is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

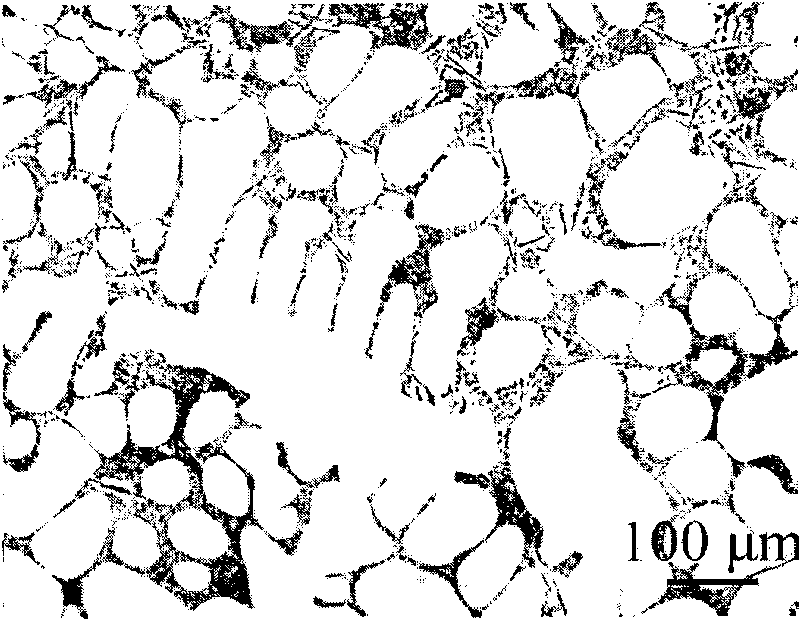

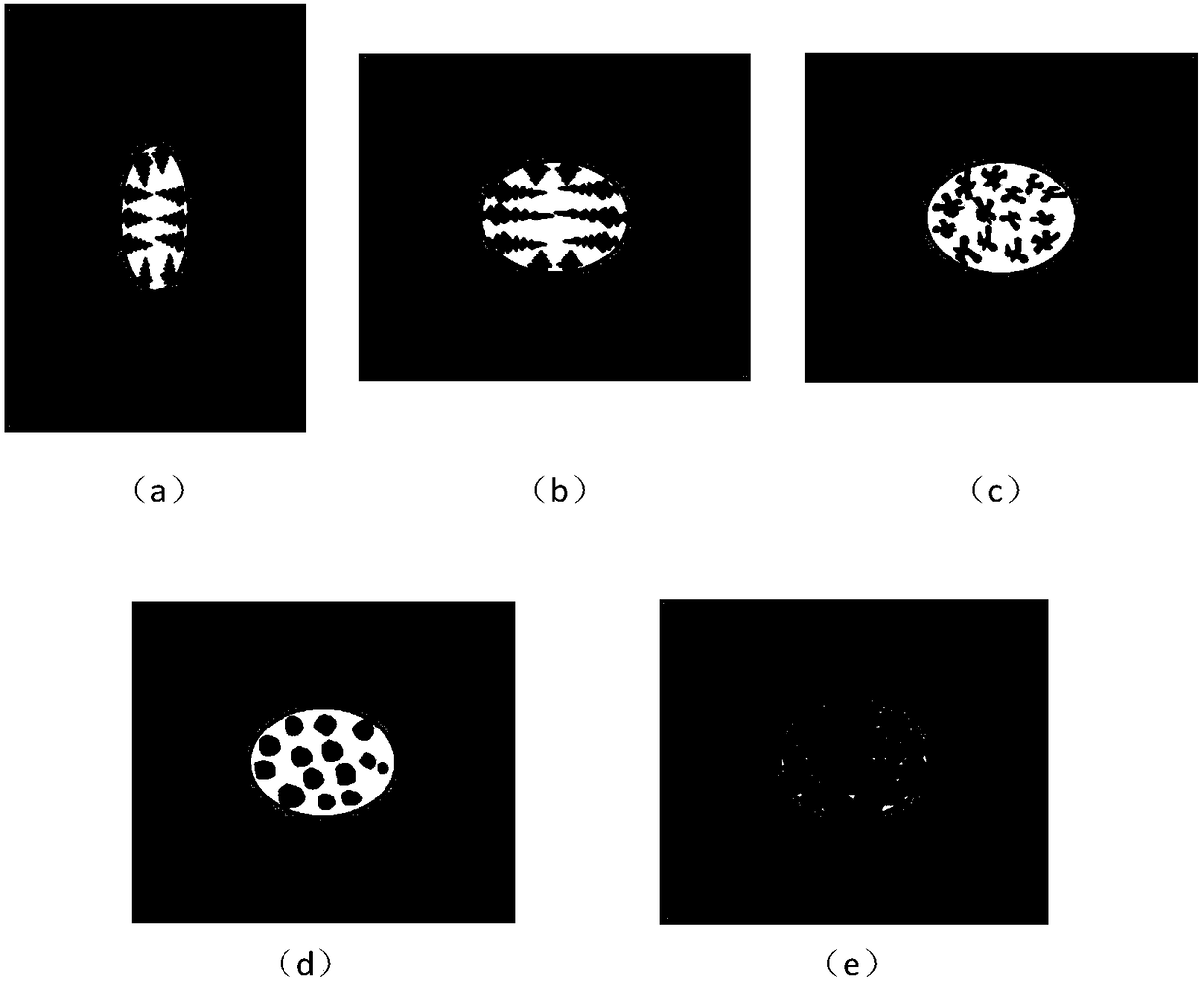

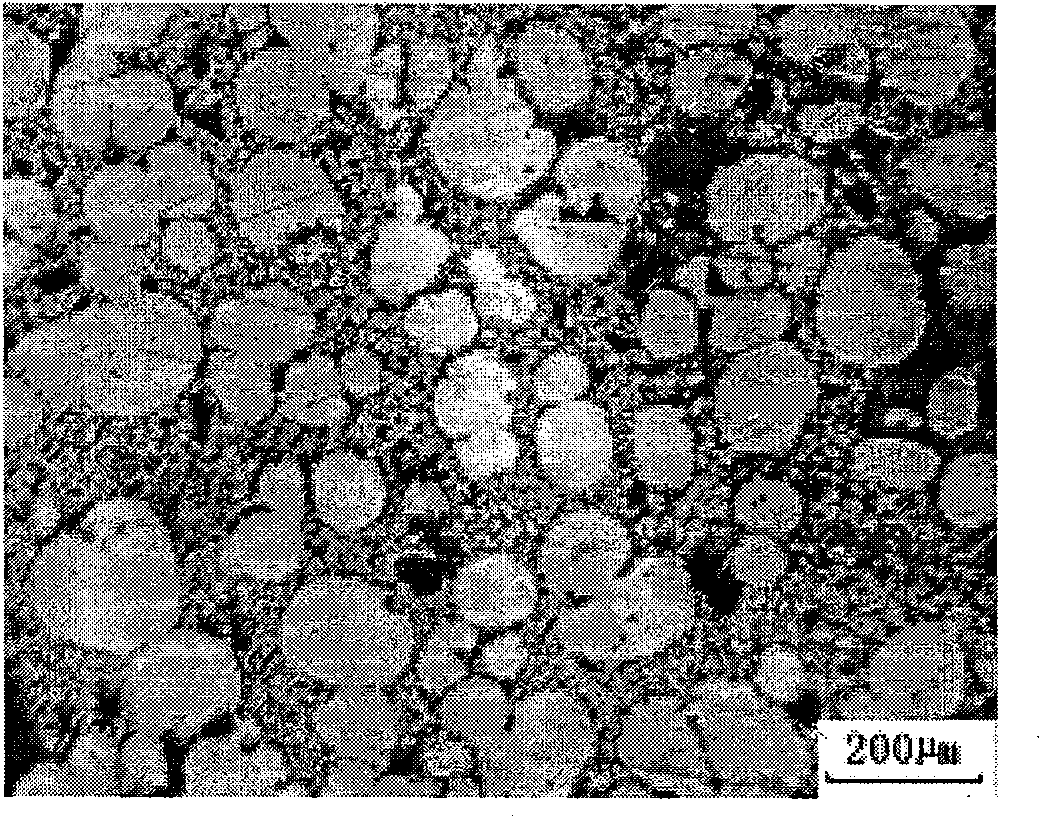

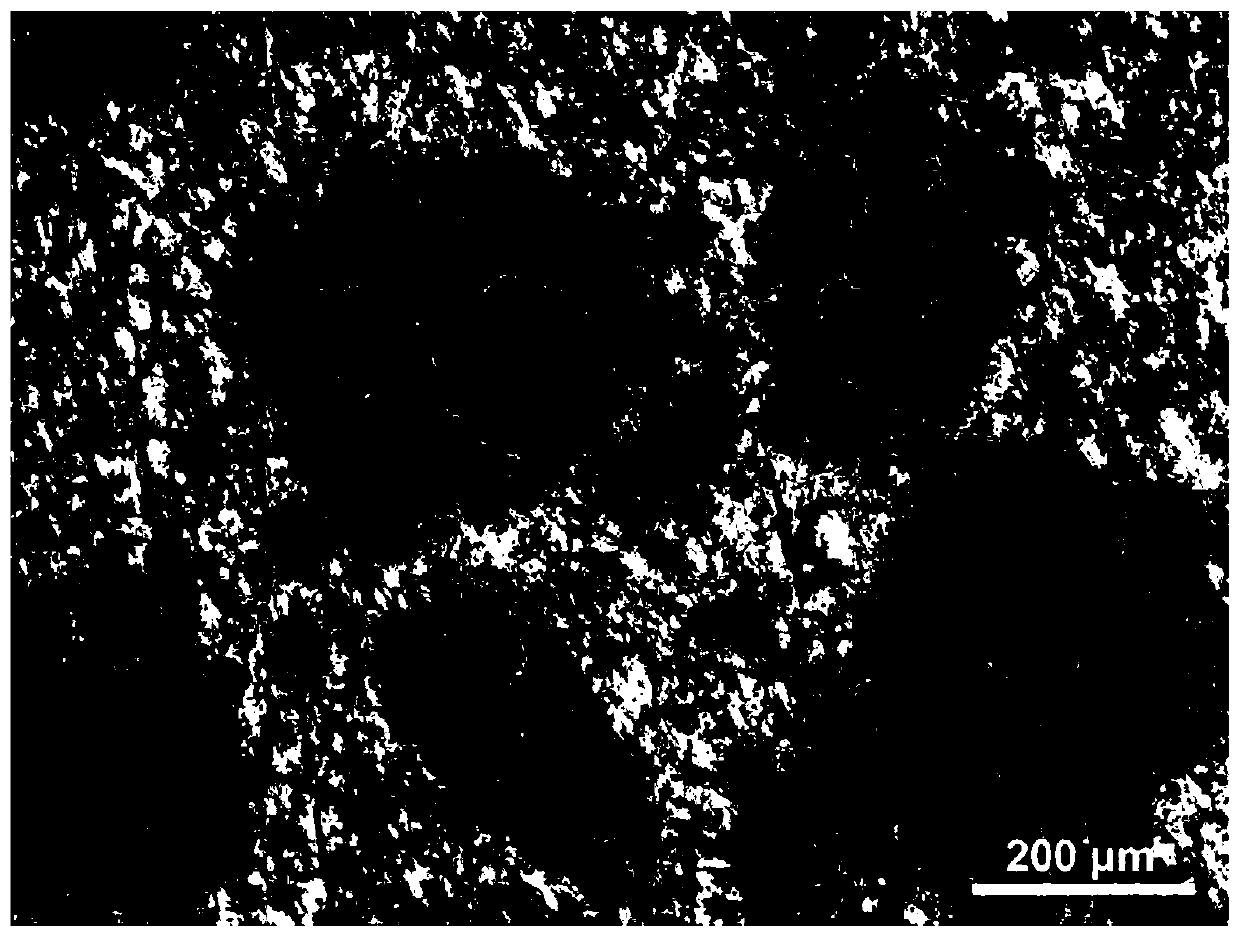

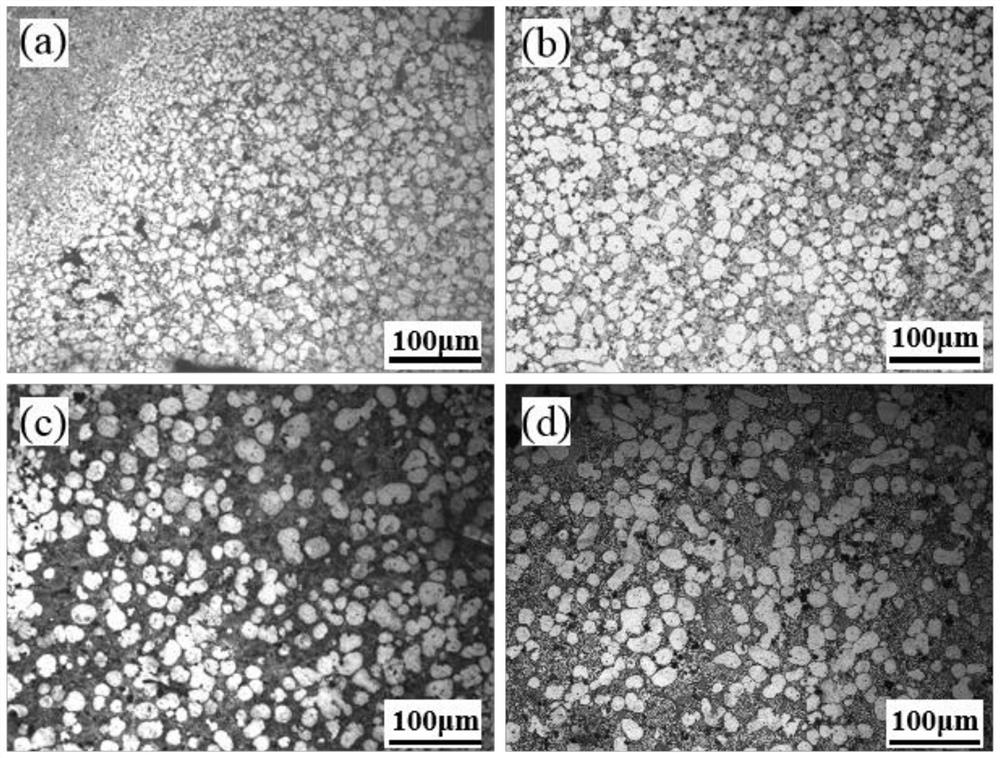

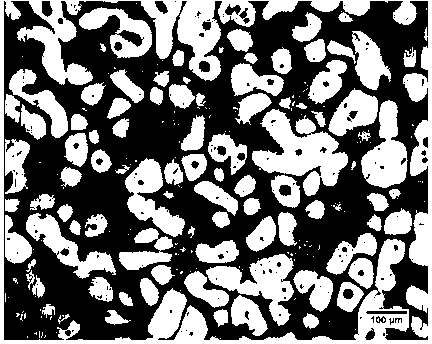

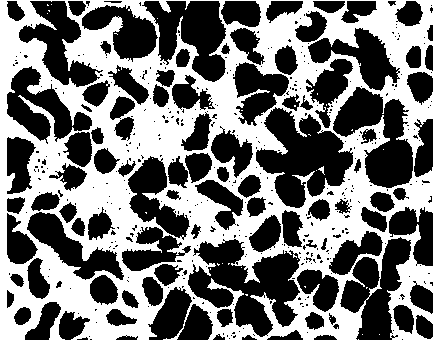

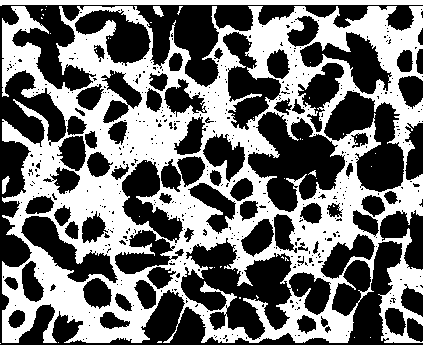

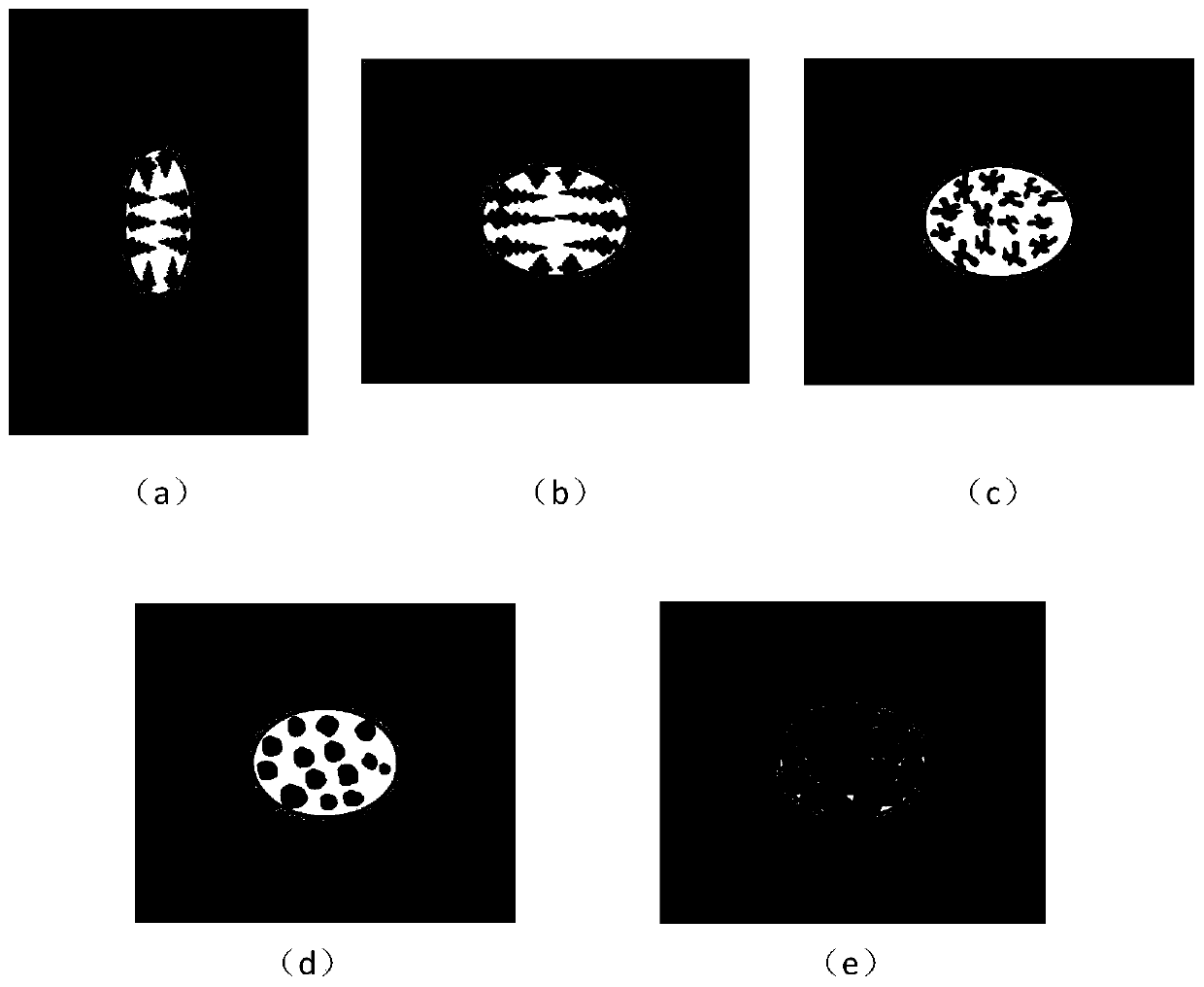

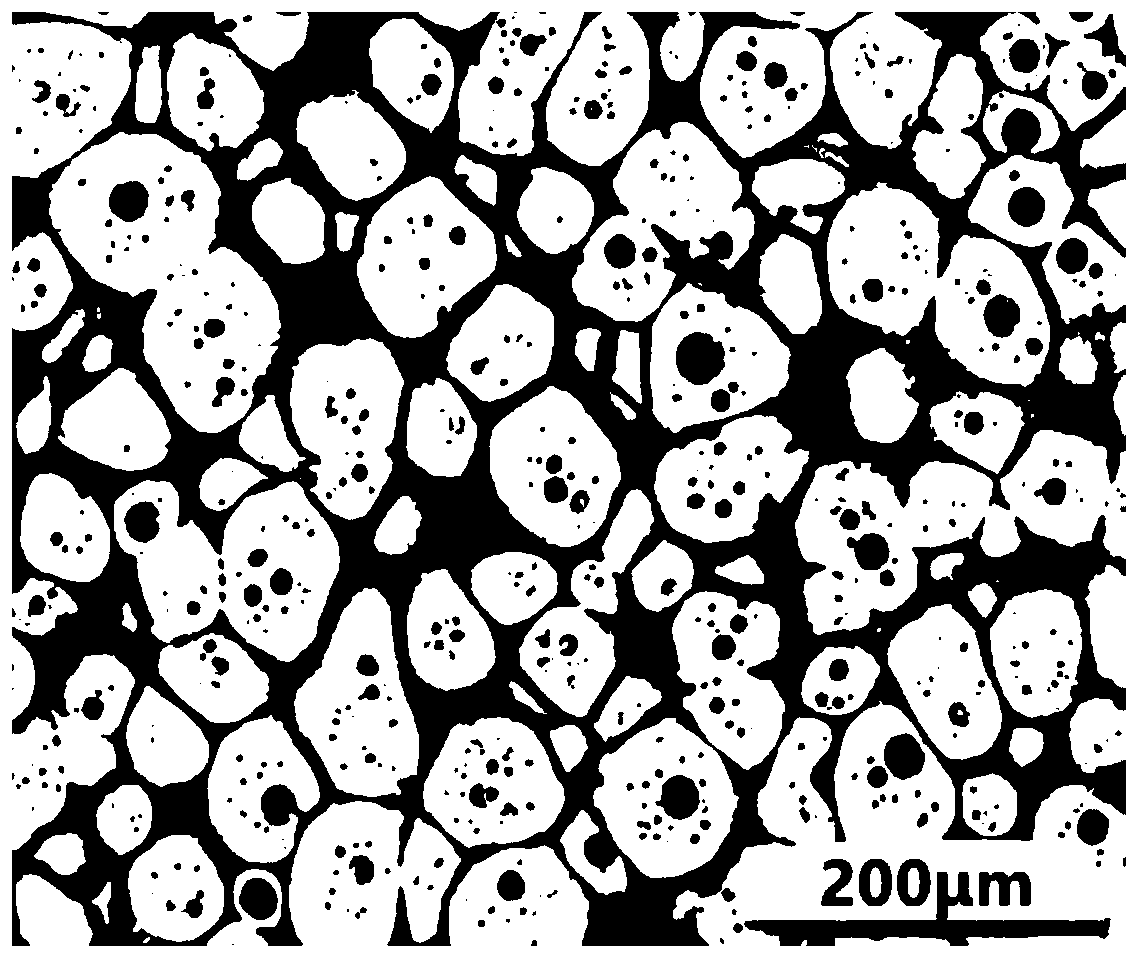

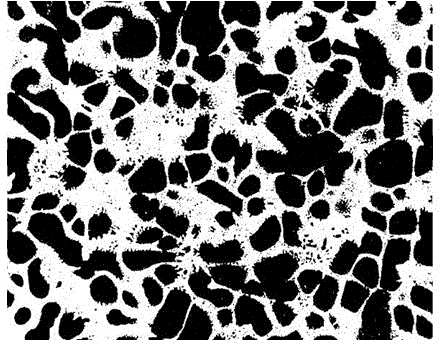

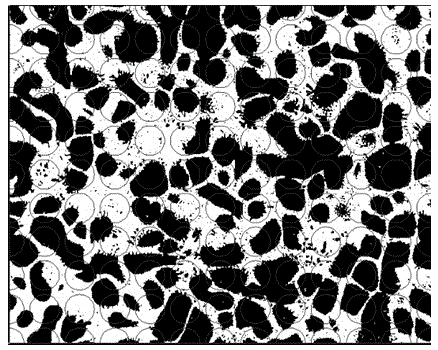

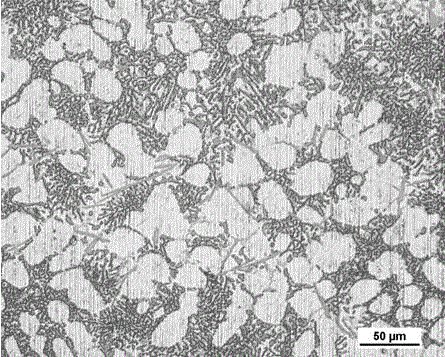

Method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue

InactiveCN103106342AImprove performanceEvenly distributedSpecial data processing applicationsSemi solidSlurry

The invention relates to a method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue and belongs to the field of metal semi-solid slurry tissue performance analysis. The method includes separating solid phase in the semi-solid slurry tissue out, calculating the total size of the solid phase, calculating and drawing an ideal dispersion degree distribution pattern of the solid phase, and calculating and obtaining dispersion distribution degree coefficient through comparing an ideal distribution state with a real distribution state of the solid phase. With the method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue, dispersion distribution degree of the solid phase in the semi-solid tissue can be given quantitatively and the range of the dispersion distribution degree is greater than 0 and smaller than 1. A greater number indicates more even distribution degree of the solid phase in the semi-solid tissue and better performance of the semi-solid tissue. The method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue is simple to operate and convenient to use.

Owner:KUNMING UNIV OF SCI & TECH

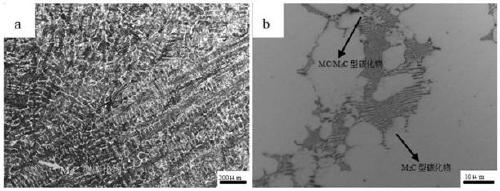

Preparation method of high-speed tool steel

The invention relates to the field of hot working of steel and relates to a preparation method of high-speed tool steel. The preparation method of the high-speed tool steel comprises the following technological steps that (1) a to-be-treated ledeburite high-speed tool steel billet material is heated to a temperature above TL (liquidus temperature), and is molten fully; (2) the ledeburite high-speed tool steel billet material is cooled to a temperature in a solid-liquid two-phase region between the TL and TS (solidus temperature), heat preservation is carried out, and thus a semisolid structurewith the solid-phase rate being above 70% is obtained; (3) the ledeburite high-speed tool steel billet material is subjected to deformation with the forging ratio being above 1.5 in the solid-liquidtwo-phase region; and (4) the ledeburite high-speed tool steel billet material is cooled to a temperature below the TS, an operator continues to carry out the deformation with the forging ratio beingabove 1.5, and thus the high-speed tool steel is obtained. By carrying out the deformation in the solid-liquid two-phase region, nascent dendritic crystals in the high-speed tool steel solidificationprocess can be broken effectively, dendritic segregation is relieved, precipitation of liquation carbides is inhibited, and the purposes of obtaining a homogenized structure, improving comprehensive mechanical properties and prolonging the service life are achieved.

Owner:NORTHEASTERN UNIV

Method for preparing metal-matrix composite material by using recovering scrap metal through semi-solid state technology

The invention provides a method for preparing a metal-matrix composite material by using recovering scrap metal through a semi-solid state technology. The method for preparing the metal-matrix composite material by using the recovering scrap metal through the semi-solid state technology is adopted, a reinforced phase-metal sweeping mixed solution is used for conducting ultrasonic dispersion and mechanical stirring, then CO2 atmosphere during is carried out, and the reinforced phase wrapping metal sweeping metal-matrix composite material is obtained in cooperation with semi-solid state isothermal treatment. Compared with a traditional method for preparing the metal-matrix composite material through powder metallurgy, the method for preparing the metal-matrix composite material in cooperation with ultrasonic dispersion mechanical stirring and semi-solid state extrusion is simple in process, meanwhile, in the composite material preparing method, wee semi-solid state textures with the goodballing effect can be obtained after semi-solid state isothermal treatment, and wetting, compounding and interface bonding promoting of a matrix and a reinforced phase are facilitated.

Owner:HARBIN UNIV OF SCI & TECH

Thixotropic plasticity forming method of metal-based composite material

InactiveCN102189207APromote the practical processReduce consumptionMetal-working apparatusMetal matrix compositeApplication areas

The invention relates to a thixotropic plasticity forming method of a metal-based composite material. The method is characterized by comprising the following steps of: preheating a die to 280-300 DEG C; spraying lubricant into the die; preserving the temperature of the metal-based composite material with high-solid-phase-rate semisolid texture characteristics at 10-25 DEG C above a solidus curve for 16-45 minutes; and then placing the metal-based composite material in the preheated die; and finally performing thixotropic plasticity forming in a die forging hydraulic press. By the method disclosed by the invention, the application field of the semisolid technology can be widened, the energy consumption can be reduced, the product quality can be improved, and the practicability progress of the semisolid forming technology can be promoted.

Owner:NANCHANG UNIV

A kind of preparation method of high-speed tool steel

The invention relates to the field of hot processing of steel, and to a method for preparing high-speed tool steel. A method for preparing high-speed tool steel, which method includes the following process steps: 1) heating the ledeburite high-speed tool steel billet material to be processed to the liquidus line T L above, to completely melt it; 2) Cool the material to T L ~T S Insulate the solid-liquid two-phase zone between them to obtain a semi-solid structure with a solid phase ratio of more than 70%; 3) Deform the material in the solid-liquid two-phase zone with a forging ratio of more than 1.5; 4) Cool the material to the solidus line T S At the following temperatures, continue to implement deformation with a forging ratio of 1.5 or more, and it will be obtained. By implementing deformation in the solid-liquid two-phase region, the present invention can effectively break dendrites formed during the solidification process of high-speed tool steel, reduce dendrite segregation, inhibit the precipitation of liquid carbides, achieve a homogenized structure, and improve comprehensive mechanical properties. , the purpose of extending service life.

Owner:NORTHEASTERN UNIV LIAONING

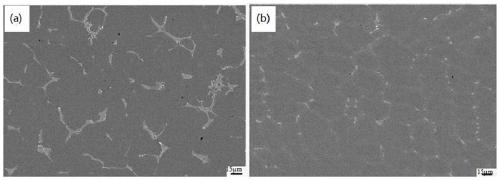

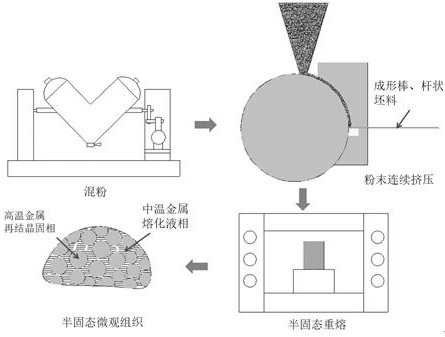

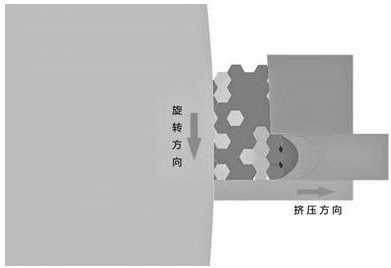

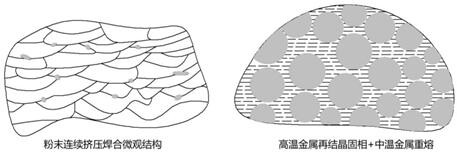

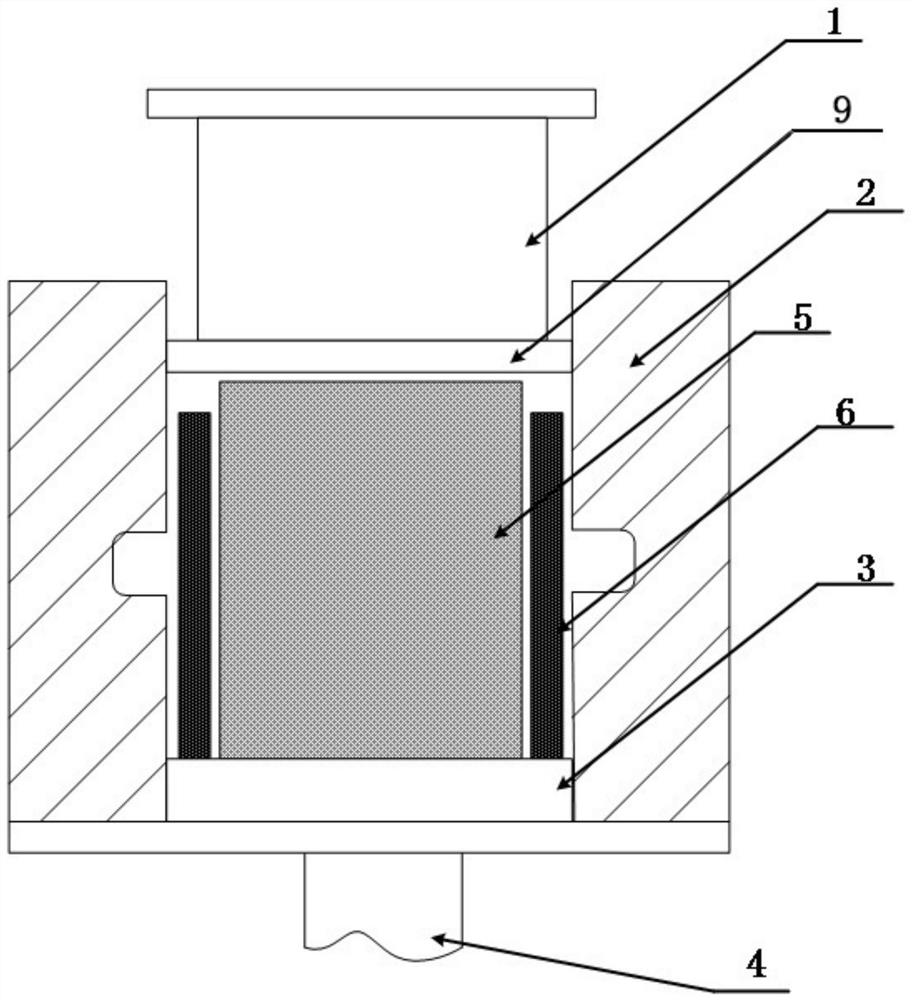

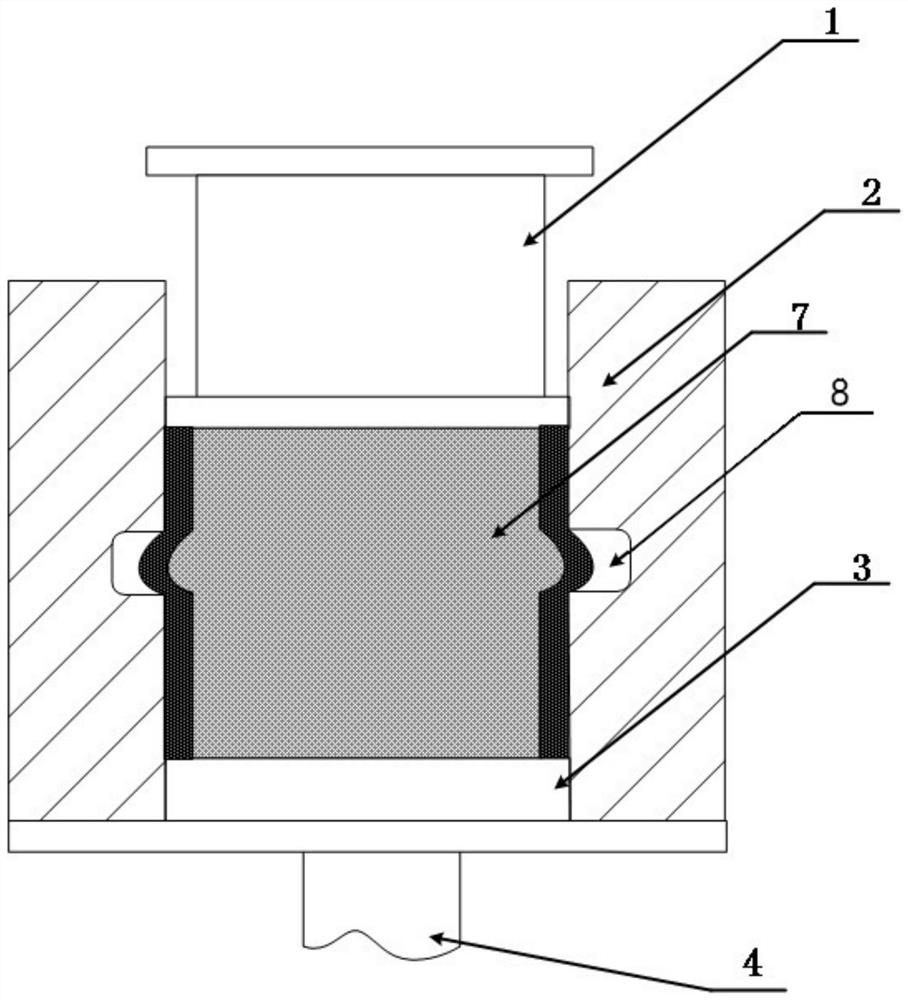

Method for preparing alloy semi-solid thixotropic blank by continuously extruding elementary substance mixed powder

ActiveCN113000842AReduce manufacturing costShorten the production cycleIncreasing energy efficiencySolid structureSemi solid

The invention discloses a method for preparing an alloy semi-solid thixotropic blank by continuously extruding elementary substance mixed powder, and belongs to the technical field of material processing. According to the method, two or more kinds of elementary substance mixed powder is evenly mixed and conveyed into a groove of a continuous extrusion wheel, the powder in a female die is crushed, rubbed, extruded and welded to form a block material after passing through the female die, the block material is cut out according to the equal volume of a target part, heat preservation is carried out for a certain time near the melting point of low-melting-point elementary substance metal, the low-melting-point powder begins to melt, recovery recrystallization occurs in a welding area of the high-melting-point powder, and a semi-solid structure with a high-melting-point solid phase as a framework and a low-melting-point liquid phase distributed between is formed. According to the method, metal powder continuous extrusion and a strain-induced melting activation method are combined, the short-process and batch semi-solid alloy blank making method is achieved, the semi-solid thixotropic temperature of the alloy can be reduced, and energy consumption and the cost of a tool mold are reduced.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of carbon nanotube reinforced aluminum alloy semi-solid slurry

The invention provides a preparation method of carbon nanotube reinforced aluminum alloy semi-solid slurry, and belongs to the technical field of metal material manufacturing. The preparation method of the carbon nanotube reinforced aluminum alloy semi-solid slurry comprises the following steps of under the casting condition, enabling Al-Mg-Si alloy to be refined and subjected to slag removal, pressing an Al-CNTs-KAlF4 intermediate precast block into an alloy melt through a bell jar in the argon protection state, applying 2.1-3.2 kW high-energy ultrasound in the adding process, then rapidly reducing the temperature to 610-650 DEG C, performing heat preservation, performing short-time secondary high-energy ultrasonic treatment, then performing rapid water quenching, and finally preparing a semi-solid structure which is uniformly spheroidized under an optimal process condition. The preparation method is safe to operate and stable in process, the structure of the prepared semi-solid slurry is obviously refined compared with the structure of a matrix without an intermediate precast block under the original same condition, the interface bonding of the carbon nanotubes and the alloy matrix is good, and the distribution of a secondary phase is more uniform.

Owner:NANCHANG UNIV

Thixotropic soft core composite forging forming method for aluminum-steel bimetal component

ActiveCN109807272BForming accuratelyGood thixotropic fluidityForging/hammering/pressing machinesSemi solidUltimate tensile strength

The invention discloses a thixotropic soft core composite forging molding method for an aluminum-steel bimetallic component. Firstly, an aluminum alloy core body and a steel sleeve of a certain size and shape are made, and the aluminum alloy core body is heated and kept in a semi-solid state. The sleeve is heated to a thermoplastic state, and the aluminum alloy core and steel sleeve are quickly introduced into the mold and assembled to complete the composite forging. Utilizing the good fluidity of the aluminum alloy in the semi-solid state, the coordinated deformation of the aluminum alloy core and the steel sleeve is realized, making the molding of the composite component more precise; in addition, using the liquid phase part in the semi-solid aluminum alloy core and the steel The set reaction forms a stable interface with high bonding strength. Realize the metallurgical combination of aluminum-steel double-metal coordinated deformation and reliable interface, and effectively integrate the high-performance advantages of steel and the lightweight advantages of aluminum alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

A kind of preparation method of carbon nanotube reinforced aluminum alloy semi-solid slurry

The invention provides a method for preparing carbon nanotube reinforced aluminum alloy semi-solid slurry, which belongs to the technical field of metal material manufacturing. A method for preparing carbon nanotube reinforced aluminum alloy semi-solid slurry, comprising the following steps: under the condition of melting and casting, after refining Al-Mg-Si alloy to remove slag, under argon protection state, use a bell jar to place Al-CNTs ‑KAlF 4 The intermediate prefabricated block is pressed into the alloy melt, and 2.1-3.2kW high-energy ultrasound is applied during the addition process, and then the temperature is quickly lowered to 610-650°C for heat preservation, and a second high-energy ultrasound is performed for a short time, followed by rapid water quenching. A semi-solid structure with uniform spheroidization is obtained under the process conditions. The invention is safe in operation and stable in process. The structure of the prepared semi-solid slurry is obviously finer than that of the matrix structure without adding the intermediate prefabricated block under the same conditions. The interface between the carbon nanotube and the alloy matrix is well combined, and the distribution of the secondary phase is also more uniform. .

Owner:NANCHANG UNIV

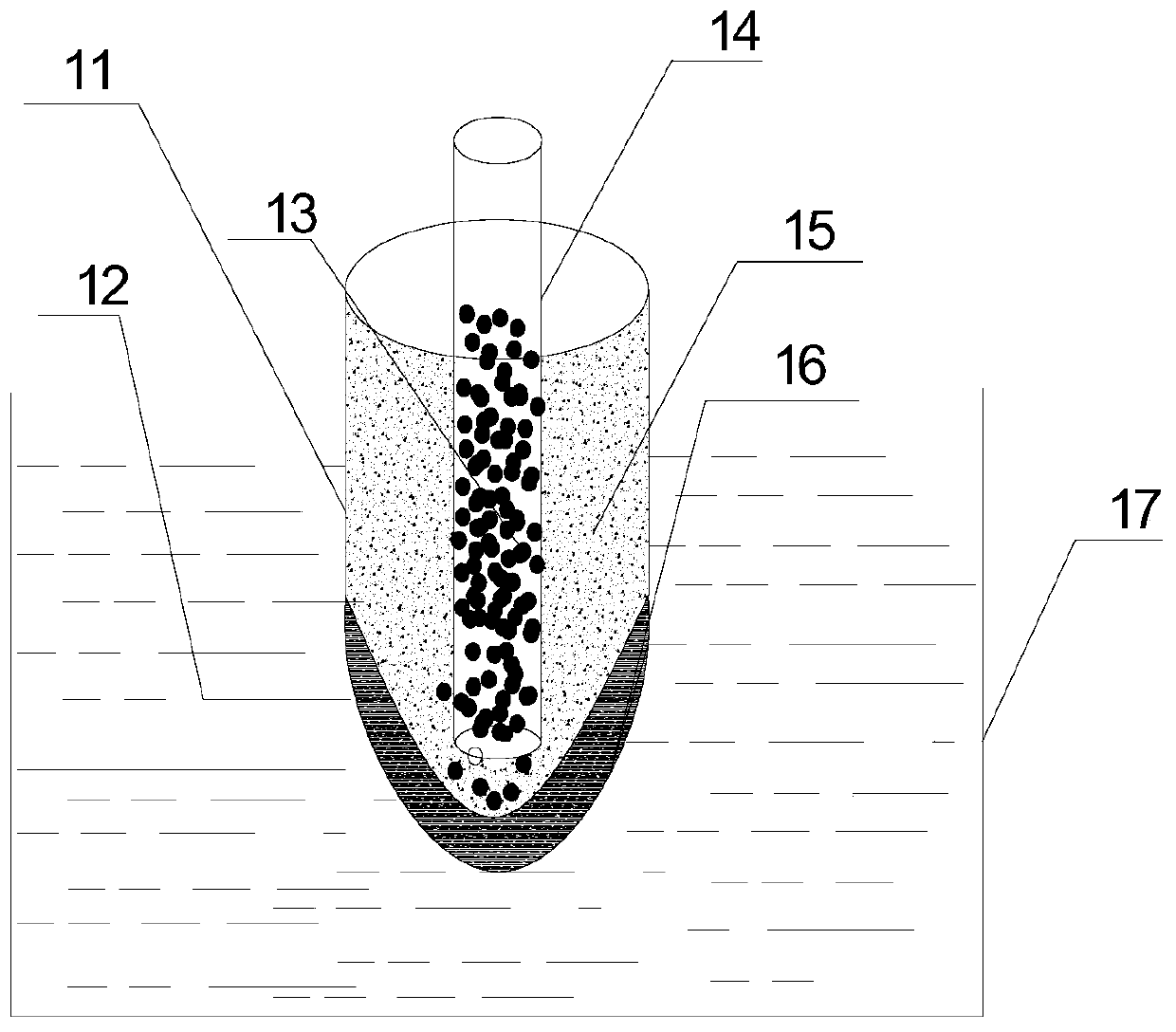

A method for preparing bimetal composite ingot by using solidified liquid cavity

The invention provides a method for preparing a bimetal composite cast ingot through a solidified liquid pool. The method comprises the following steps: a) cooling an inverted cone-shaped crucible containing first molten metal so that the first molten metal forms the solidified liquid pool; and b) adding second semisolid metal paste into the solidified liquid pool, and obtaining the bimetal composite cast ingot after the second semisolid metal paste is solidified, wherein the first molten metal and the second semisolid metal paste are different metals. The invention further provides a preparation device for the bimetal composite cast ingot. Through the method and the device provided by the invention, the solidified liquid pool with a certain thickness and height can be obtained, mutual diffusion between the inner-layer semisolid paste and the outer-layer melt is effectively slowed down, effective combination of the semisolid paste and the melt is realized, and a continuous and stable high-strength metallurgical bonding interface free of scale or inclusion can be obtained so as to obtain the high-performance bimetal composite cast ingot with the feature that a semisolid structure and a dendritic structure are in gradient distribution on a macroscopic interface.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A high-uniformity short-process forming method for large metal components

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing carbon nanotubes reinforced AZ61 magnesium alloy semi-solid slurry

The invention discloses a method for preparing carbon nanotubes reinforced AZ61 magnesium alloy semi-solid slurry. The method comprises the following steps that ZrO2 coating is carried out on the surfaces of the carbon nanotubes, and the carbon nanotubes are prepared into an Mg-Al-Zn-ZrO2@CNTs intermediate precast block; under the casting condition, after AZ61 magnesium alloy is refined, a bell jar is used for pressing the intermediate precast block into an alloy melt in the argon protection state; high-energy ultrasound is applied in the adding process; then the temperature is rapidly reduced to 560-620 DEG C, heat preservation is carried out, short-time secondary high-energy ultrasound is applied, and then rapid water quenching is carried out; and finally, a semi-solid structure in which the carbon nanotubes are uniformly dispersed and magnesium alloy grains are fully spheroidized is prepared under an optimized process condition. The preparation method is safe to operate and stable in process, the structure of the prepared semi-solid slurry is obviously refined, and the interface bonding of the carbon nanotubes and the AZ61 magnesium alloy melt is good.

Owner:NANCHANG UNIV

A Method for Quantitative Analysis of Solid Phase Dispersion Distribution in Semi-solid Slurry Structure

InactiveCN103106342BImprove performanceEvenly distributedImage analysisSpecial data processing applicationsSemi solidSlurry

The invention relates to a method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue and belongs to the field of metal semi-solid slurry tissue performance analysis. The method includes separating solid phase in the semi-solid slurry tissue out, calculating the total size of the solid phase, calculating and drawing an ideal dispersion degree distribution pattern of the solid phase, and calculating and obtaining dispersion distribution degree coefficient through comparing an ideal distribution state with a real distribution state of the solid phase. With the method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue, dispersion distribution degree of the solid phase in the semi-solid tissue can be given quantitatively and the range of the dispersion distribution degree is greater than 0 and smaller than 1. A greater number indicates more even distribution degree of the solid phase in the semi-solid tissue and better performance of the semi-solid tissue. The method for quantitatively analyzing solid phase dispersion distribution in semi-solid slurry tissue is simple to operate and convenient to use.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of modified agent induced impregnated aluminum alloy semi-solid slurry

A preparation method for aluminum alloy semi-solid slurry induced and impregnated by a modificator comprises the following steps that (1) an Al-Si-Cu alloy ingot is placed into a graphite crucible to be subjected to fusion, refining and slag removal; (2) small pieces of Al-Sr intermediate alloy are added into the fondant, the mass fraction of Sr in the Al-Sr intermediate alloy is 9 wt.%-11 wt.%, and the mass fraction of the Sr in the fondant is 0.01 wt.%-0.09 wt.%; (3) the temperature is increased to 760-770 DEG C, heat preservation is conducted for 15-20 min, then a preheated ultrasonic amplitude-change pole probe is placed in the fondant, ultrasounds are released intermittently, the ultrasound interval of each time is 1-2 s, the ultrasounds are released for 2.0-2.5 s each time, the power is 1.0-2.0 kw, the frequency is 20 kHz, the total ultrasound time is 3-5 min, then the temperature is decreased to 585-610 DEG C, and standing and heat preservation are conducted for 8-10 min; and (4) intermittent ultrasound treatment is conducted on the fondant again, the ultrasound conditions are identical to those in the step (3), the total ultrasound time is 60-100 s, and water quenching is conducted immediately after the ultrasound treatment is completed. Grains of semi-solid structures obtained through the method are finer, rounder, more complete and more uniform in distribution and fully meet the requirements for semi-solid rheoforming, operation is easy and convenient, safety and reliability are achieved, and three-waste pollution is avoided.

Owner:江西剑发铝型材有限公司

A preparation method of modified carbon nanotube reinforced aluminum alloy semi-solid slurry

ActiveCN113088744BEvenly dispersedImprove distributionProcess efficiency improvementModified carbonSolid structure

The invention provides a method for preparing a modified carbon nanotube reinforced aluminum alloy semi-solid slurry: by performing ZrO on the surface of the carbon nanotube 2 modified, and made carbon nanotubes into Al‑ZrO 2 @CNTs‑KAlF 4 Intermediate precast blocks. Under the conditions of melting and casting, after the Al-Si alloy is refined, the intermediate prefabricated block is pressed into the melt with a bell jar under the protection of argon, and a 2.1-3.2kW high-energy ultrasonic is applied during the addition process, and then the temperature is dropped rapidly. Perform high-energy ultrasonication for 60‑90s twice in the semi-solid temperature range, followed by rapid water quenching. Finally, a semi-solid structure with uniform dispersion of carbon nanotubes and fully spheroidized grains was obtained under the optimal process conditions. The invention has the advantages of safe operation, stable process, obviously refined structure of the prepared semi-solid slurry, and good interface bonding between the carbon nanotube and the alloy melt.

Owner:NANCHANG UNIV

Method for preparing semi-solid slurry of Al-Si-Cu alloy induced and inoculated by misch rare earth

Disclosed is a method for preparing semi-solid slurry of Al-Si-Cu alloy induced and inoculated by misch rare earth. The method includes the following steps that (1) an Al-Si-Cu alloy ingot is put in a graphite crucible for overheating melting, refining and deslagging; (2) Al-5Pr-5Ce intermediate alloy coated with aluminum foil paper is added into a melt, the adding amount accounts for 3wt%-9wt% of the amount of the melt, then the furnace temperature is increased to 760-770 DEGC, and heat preservation is conducted for 15-20 min; (3) a preheated ultrasound amplitude transformer probe is put in the melt for intermittent ultrasound treatment, the ultrasound interval is 1-2s each time, the ultrasound releasing time is 2.0-2.5s each time, the ultrasound power is 1.0-2.0kw, the ultrasound frequency is 20kHz, and the total ultrasound treatment time is 3-5 min; and (4) the furnace temperature is decreased to 585-610 DEG C, heat preservation is conducted for 8-10 min, the intermittent ultrasound treatment is performed again under the same conditions for 60-100s, and water quenching is performed immediately after ultrasound treatment is finished. The crystal grains of the obtained semi-solid structure are thinner, round and uniformly distributed, the demand for semi-solid rheoforming is completely met, the operation is simple and convenient, the method is safe and reliable, and three-waste pollution is avoided.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com