High-entropy alloy isothermal heat treatment method

An isothermal heat treatment and high-entropy alloy technology, applied in the field of alloys, can solve the problems of high porosity, low plasticity of high-entropy alloys, uneven composition, etc., and achieve the effects of improving alloy performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

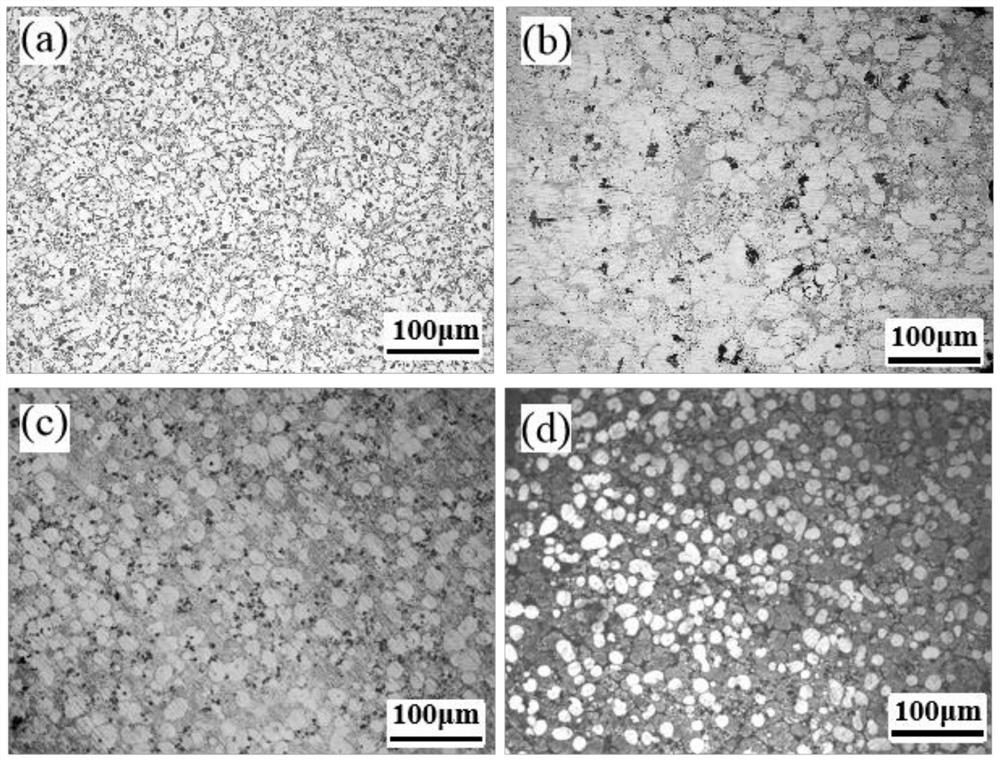

[0033] This embodiment provides a high-entropy alloy isothermal heat treatment method, comprising the following steps:

[0034] S1, the high entropy alloy Al 15 Mg 45 Li 39 Ca 0.5 Si 0.5 Place in a box-type resistance furnace, and use No. 5 flux to cover the high-entropy alloy, and pass through argon protection;

[0035] S2. At a temperature of 420°C, heat treatment isothermally for 16 minutes, 18 minutes, 20 minutes and 22 minutes respectively;

[0036] S3, then the high-entropy alloy Al after isothermal heat treatment 15 Mg 45 Li 39 Ca 0.5 Si 0.5 Put into water for water quenching treatment.

Embodiment 2

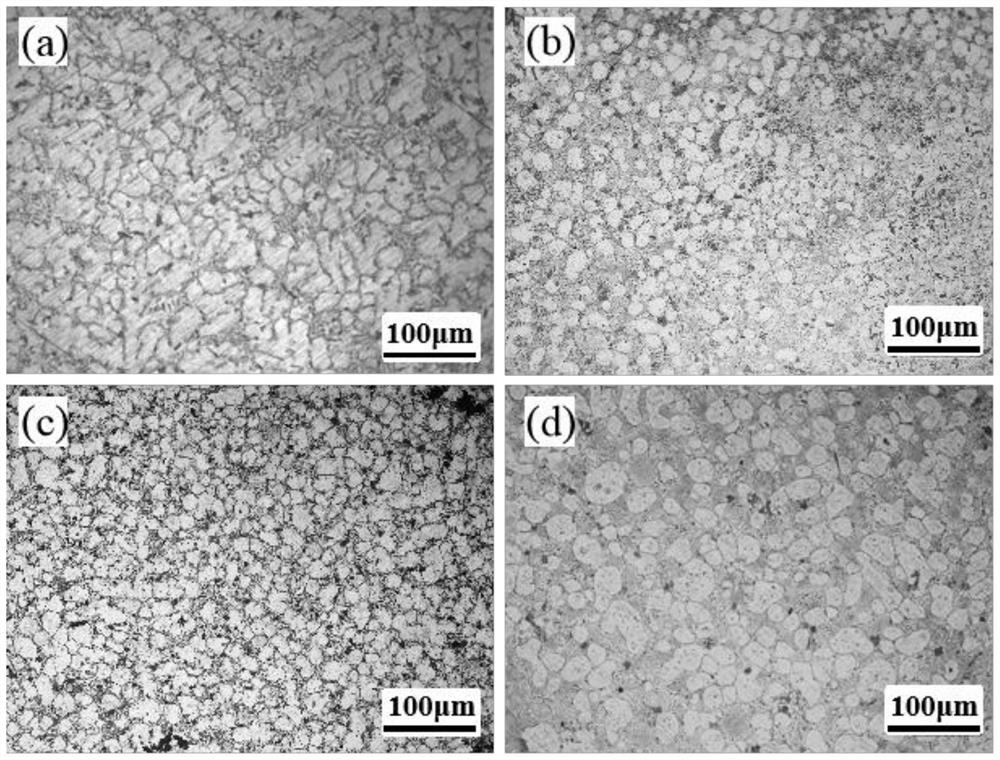

[0038] This embodiment provides a high-entropy alloy isothermal heat treatment method, comprising the following steps:

[0039] S1, the high entropy alloy Al 15 Mg 45 Li 39 Ca 0.5 Si 0.5 Place in a box-type resistance furnace, and use No. 5 flux to cover the high-entropy alloy, and pass through argon protection;

[0040] S2. At a temperature of 425°C, heat treatment isothermally for 16 minutes, 18 minutes, 20 minutes and 22 minutes respectively;

[0041] S3, then the high-entropy alloy Al after isothermal heat treatment 15 Mg 45 Li 39 Ca 0.5 Si 0.5 Put into water for water quenching treatment.

Embodiment 3

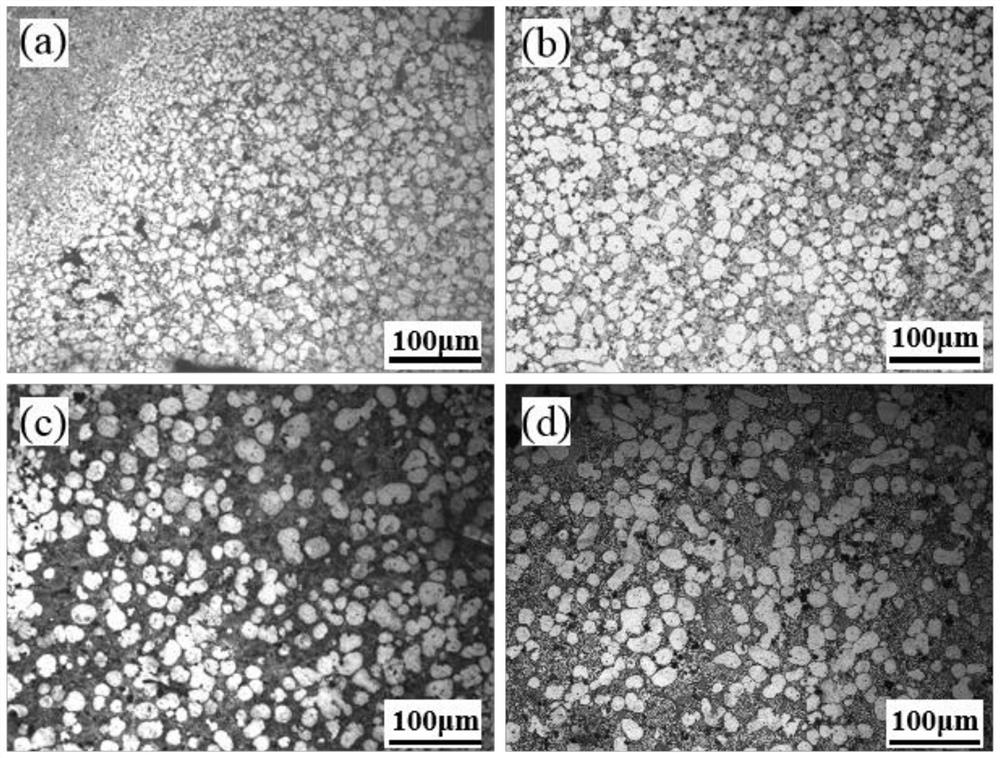

[0043] This embodiment provides a high-entropy alloy isothermal heat treatment method, comprising the following steps:

[0044] S1, the high entropy alloy Al 15 Mg 45 Li 39 Ca 0.5 Si 0.5 Place in a box-type resistance furnace, and use No. 5 flux to cover the high-entropy alloy, and pass through argon protection;

[0045] S2. At a temperature of 430°C, heat treatment isothermally for 16 minutes, 18 minutes, 20 minutes and 22 minutes respectively;

[0046] S3, then the high-entropy alloy Al after isothermal heat treatment 15 Mg45 Li 39 Ca 0.5 Si 0.5 Put into water for water quenching treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com