Semi-solid state flexible extrusion molding technique for shaped complex parts

A semi-solid extrusion and extrusion forming technology, applied in the field of extrusion and semi-solid forming, can solve the problems of high production cost, high energy consumption, low production efficiency, etc., achieve less cost input, reduce energy consumption, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] ① Preparation of semi-solid slurry

[0036] The preparation of semi-solid billets with uniform composition, structure and properties, and round and fine particles is the prerequisite for flexible extrusion of complex parts. For semi-solid thixotropic extrusion, it is easy to obtain a billet with semi-solid structure characteristics (such as a blank obtained by the SIMA method) by using an induction heating furnace for secondary heating, so that the blank becomes a semi-solid billet with a certain solid fraction. , and then to the research content ③Flexible extrusion forming; for semi-solid rheological extrusion forming, first use a resistance furnace to heat the dried block commercial alloy ingot (for magnesium alloy materials, argon is used as the shielding gas, use The foamed magnesium alloy covering agent protects the molten magnesium alloy liquid), and after reaching the complete melting temperature, keep the heat preservation and stand for 30 minutes.

[0037] ②De...

Embodiment 1

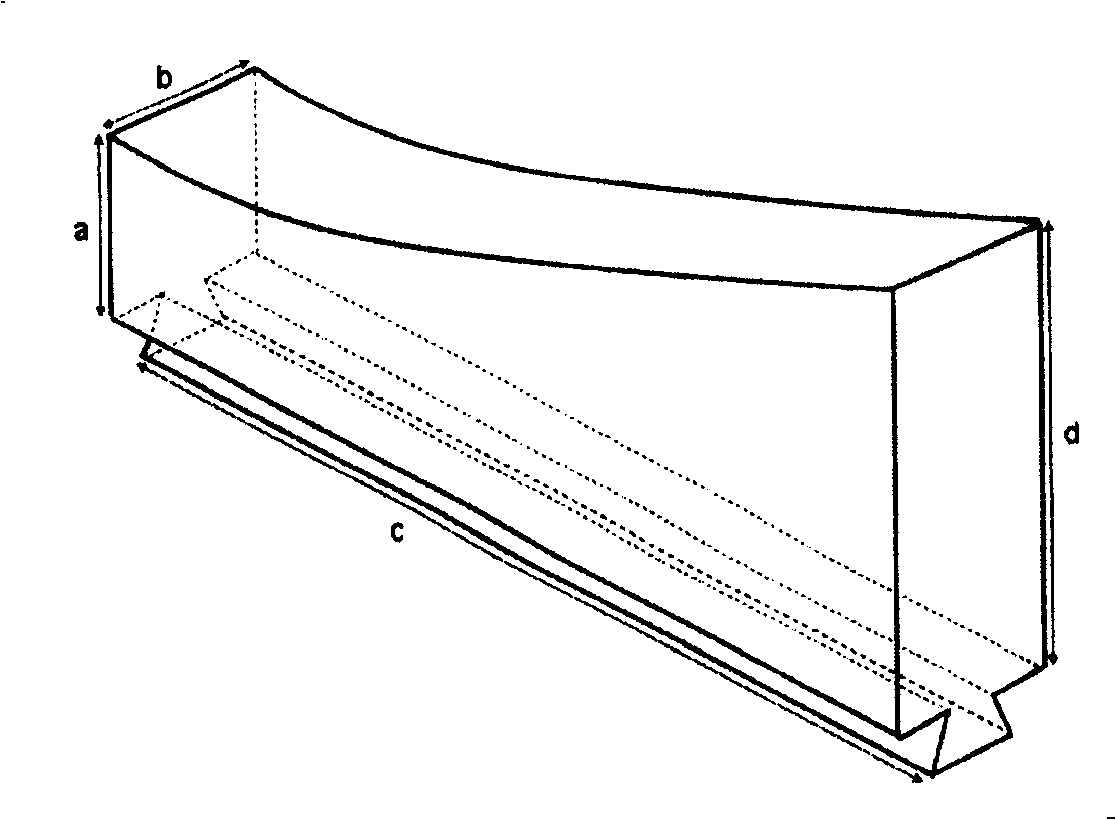

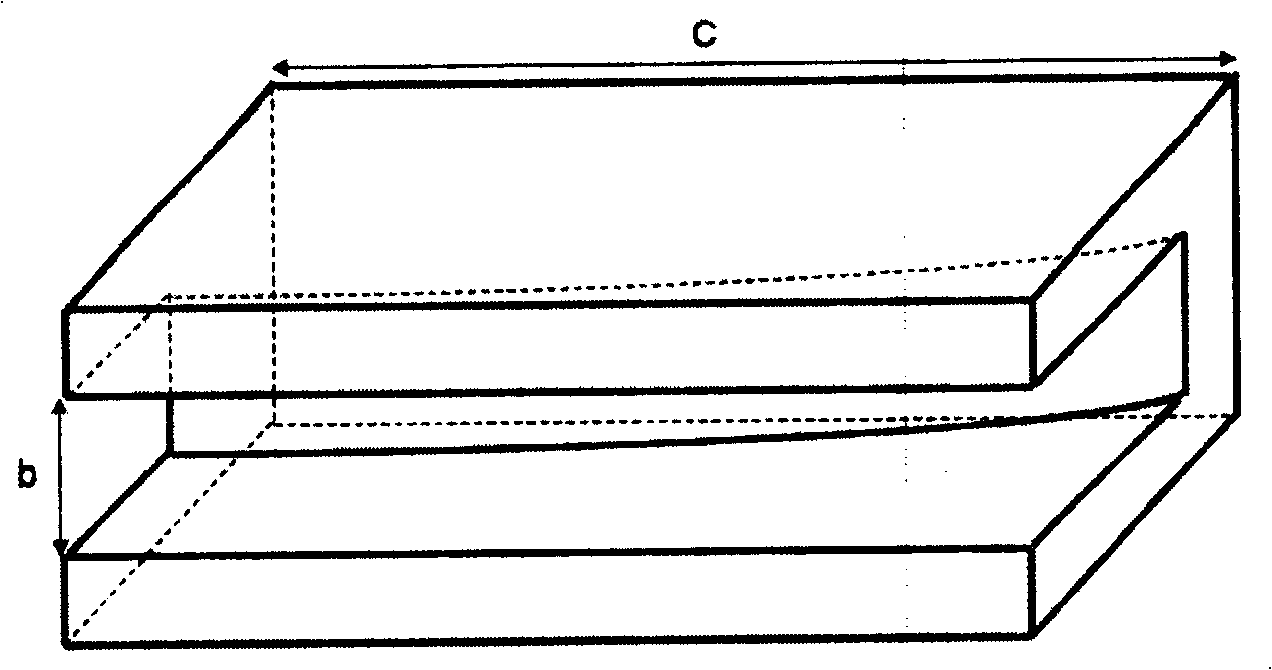

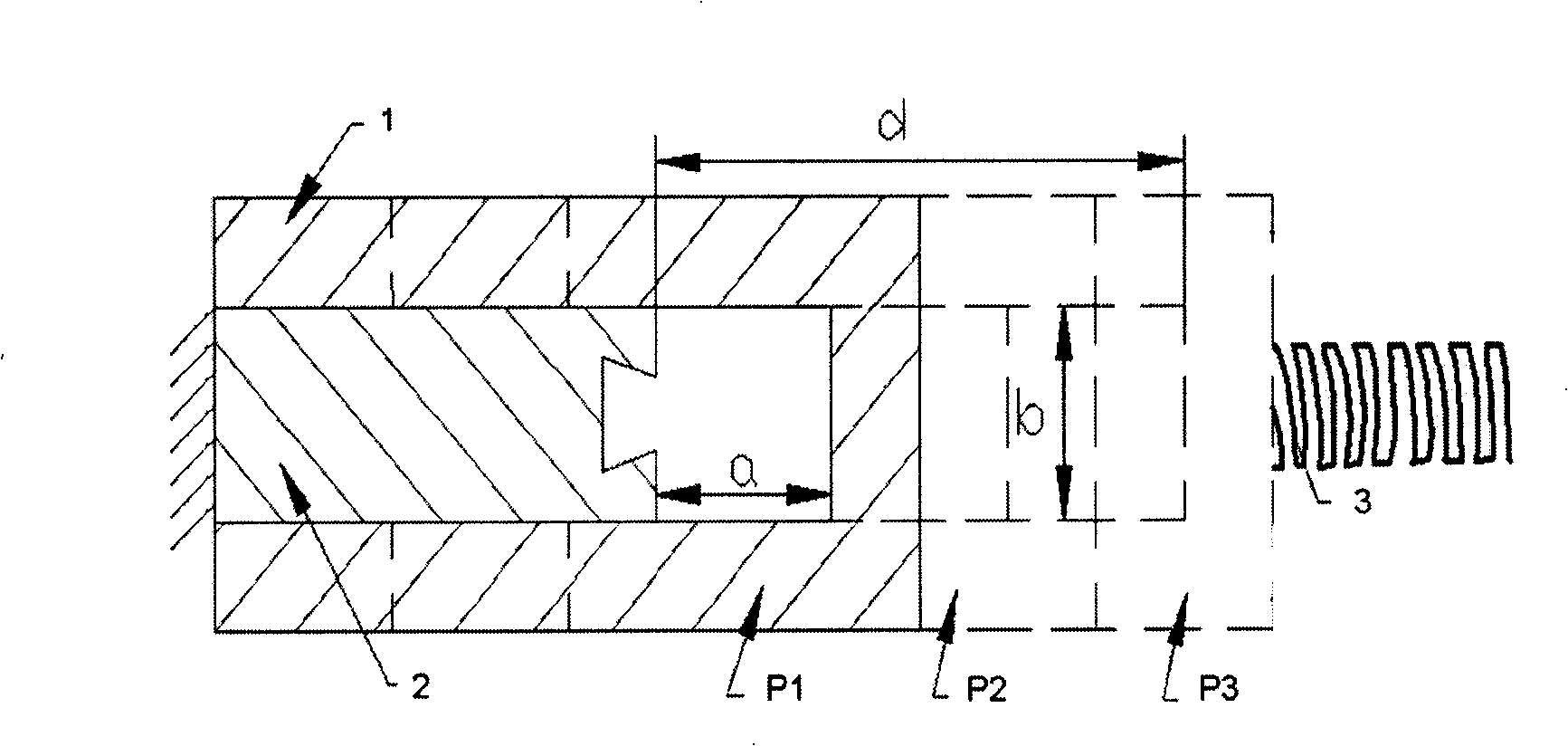

[0048] Semi-solid thixotropic flexible extrusion using A356 aluminum alloy to form complex parts in Fig.-1.

[0049] Assume that the diameter of the blank bar is φ56mm, the length is 60mm, and the material is A356 aluminum alloy. The raw material for semi-solid forming can be purchased from the Duralcan company. First, the induction heating furnace is used to quickly and uniformly heat the semi-solid temperature range that is most suitable for extrusion forming: 577°C-581°C, and then the heated semi-solid billet is quickly put into the lower die of the extrusion die with a clamp (die pre-set The heat temperature is set at 200°C-300°C). The extrusion speed of the press is adjusted to 50mm / s-90mm / s, graphite release agent is used, the forming pressure is set to 400KN-600KN, and the holding time is set to 5-10 seconds. The three-dimensional variable cross-section complex parts shown in Figure-1 can be flexibly extruded using the above parameters.

Embodiment 2

[0051] Semi-solid thixotropic flexible extrusion using AZ91 magnesium alloy to form complex parts in Figure-1.

[0052] Assume that the diameter of the blank bar is φ56mm, the length is 60mm, and the material is AZ91 magnesium alloy. The raw material for semi-solid forming can be purchased from the Duralcan company. First, use an induction heating furnace to quickly and uniformly heat to the most suitable semi-solid temperature range for extrusion: 579°C-584°C, and use argon as a protective gas at the same time. The heated semi-solid billet is quickly put into the lower die of the extrusion die with a clamp (the preheating temperature of the die is set at 200° C.-300° C.). The extrusion speed of the press is adjusted to 60mm / s-100mm / s, graphite release agent is used, the forming pressure is set to 400KN-600KN, and the holding time is set to 5-8 seconds. The three-dimensional variable cross-section complex parts shown in Figure-1 can be flexibly extruded using the above param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com