Method of forming thixotropic soft core of aluminum-steel bimetal member through composite forging

A forging forming, bi-metal technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of uncoordinated deformation of aluminum-steel, interface cracks of aluminum-steel, inability to obtain metallurgical interface, etc. Element diffusion and reaction, improving the uniformity of microstructure and properties, and the effect of reliable and stable metallurgical interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

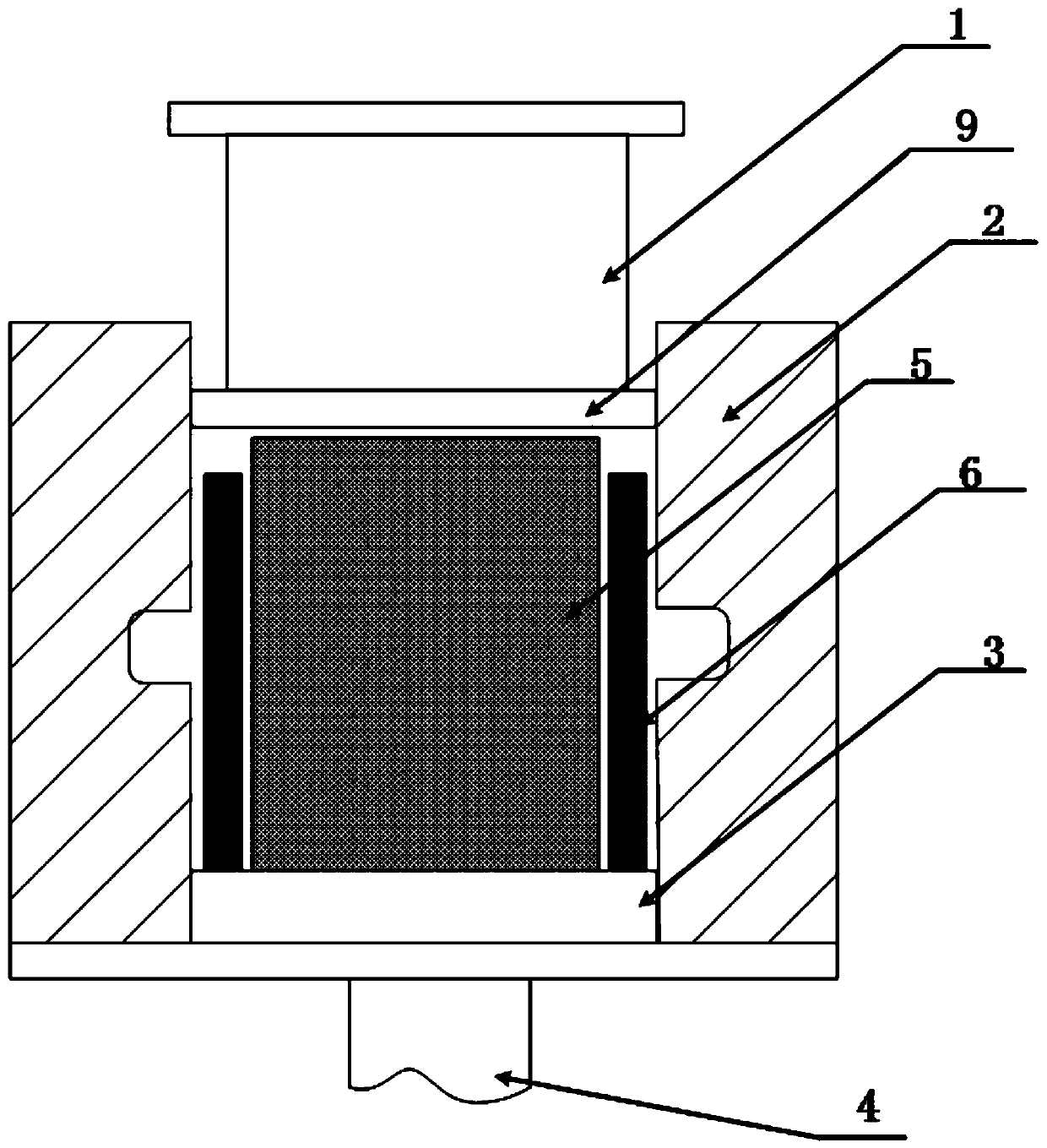

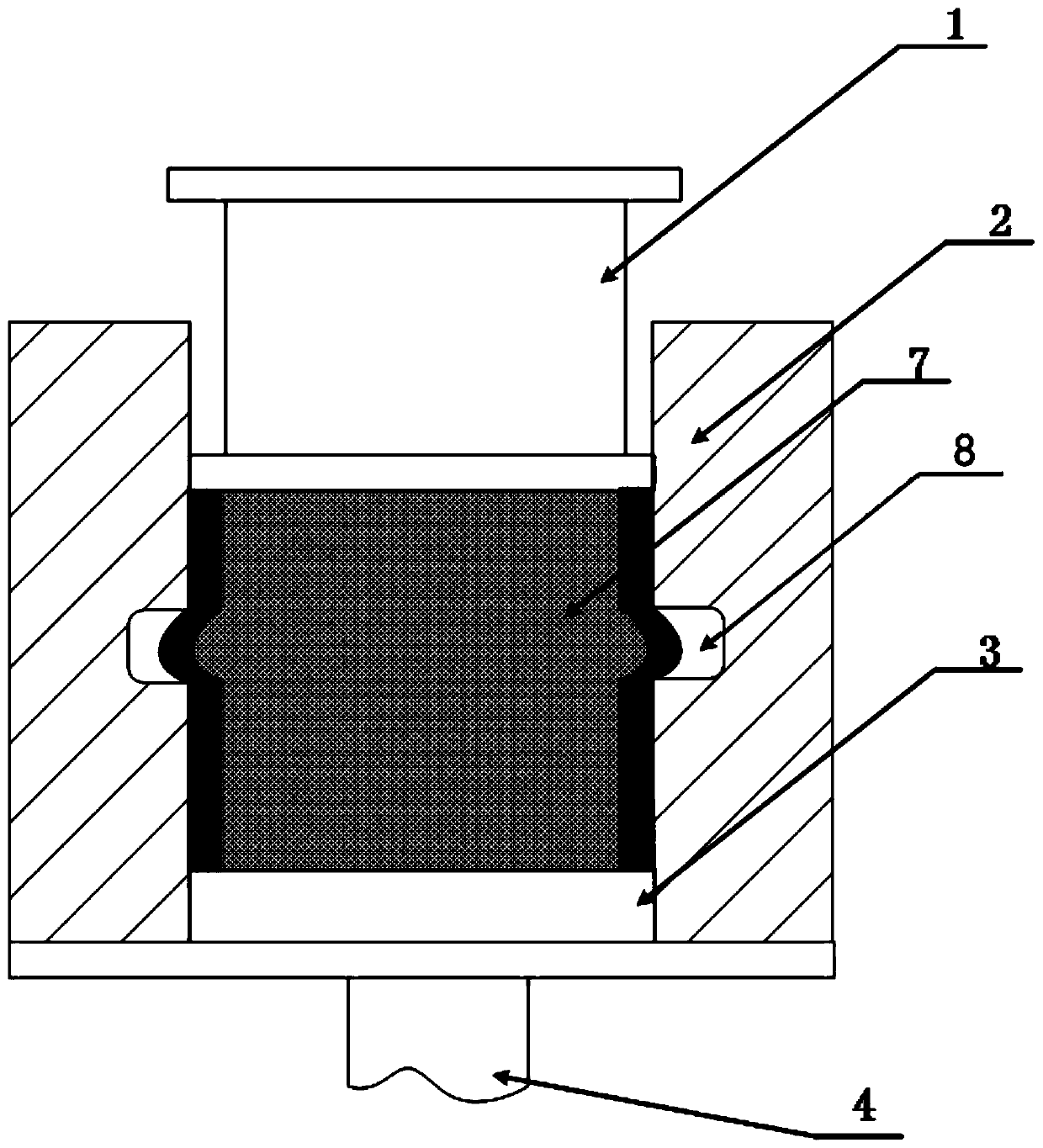

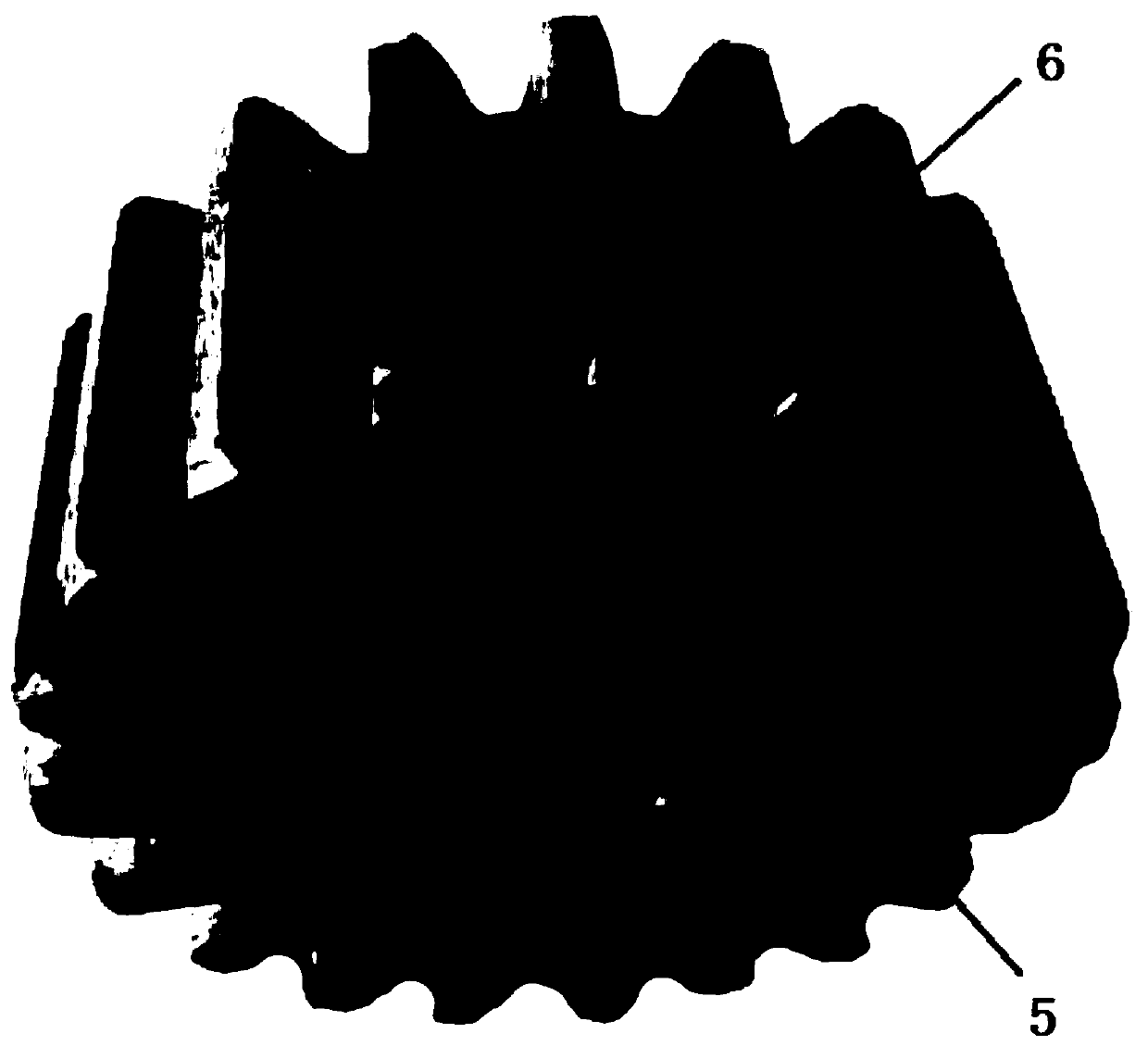

[0048] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0049] Step 2: Process the 7075 aluminum alloy bar stock into a cylinder with a diameter of 35 mm and a height of 58 mm, as the aluminum alloy core 5, process the 45# steel pipe into an outer diameter of 45 mm, a wall thickness of 4 mm, and a height of 50 mm The torus of millimeter, as steel sleeve 6;

[0050] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 620°C and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase rate of 40%;

[0051] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 1000°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the tem...

Embodiment 2

[0056] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0057] Step 2: Process the 2024 aluminum alloy bar into a cylinder with a diameter of 35 mm and a height of 58 mm as the aluminum alloy core 5, and process the 304 stainless steel pipe into an outer diameter of 45 mm, a wall thickness of 4 mm, and a height of 50 mm The torus, as the steel sleeve 6;

[0058] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 630° C. and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase ratio of 40%;

[0059] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 900°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the temp...

Embodiment 3

[0064] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0065] Step 2: Process the 6061 aluminum alloy bar stock into a cylinder with a diameter of 35 mm and a height of 58 mm as the aluminum alloy core 5, and process the 40CrMo pipe into a cylinder with an outer diameter of 45 mm and a wall thickness of 4 mm and a height of 50 mm. Torus, as steel sleeve 6;

[0066] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 630° C. and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase ratio of 40%;

[0067] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 1000°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com