A kind of preparation method of high-speed tool steel

A high-speed tool steel and steel billet technology, applied in metal processing equipment, etc., can solve the problems of material processing cracks and mechanical property degradation, and achieve the effects of reducing liquid carbides, refining grains, and uniform mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The weight of the experimental material M2 tool steel billet is 1 ton, and the specification is φ500×700mm. After chemical analysis, its specific composition is shown in Table 1.

[0048] The chemical composition of high-speed tool steel M2 in table 1 * embodiment 1 (weight percent, %)

[0049] element C Si mn S P Ni Cr Mo Cu V W Fe Measured ingredients 0.85 0.035 0.25 ≤0.03 ≤0.04 ≤0.03 4.10 5.0 0.1 1.90 6.40 Remain

[0050] *Liquidus T of this component L at 1445°C, the solidus T S It is 1245°C.

[0051] Semi-solid processing of M2 steel billet, the specific steps are as follows:

[0052] 1) Place a φ500×700mm billet in a crucible, heat up to 1465°C at a heating rate of 60°C / h, keep it warm for 1.5 hours, and then pour it out of the furnace into an iron mold.

[0053] 2) Cool the billet temperature to 1265°C at a cooling rate of 50°C / h, take it out of the iron mold when the billet temperature has cooled to 1265°C, ...

experiment example 1

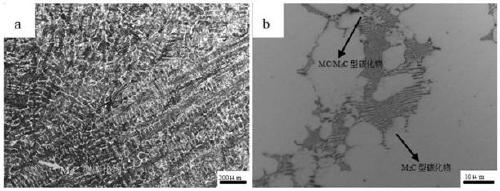

[0065] For Example 1 and Comparative Example 1, the metallographic microscope is used to analyze the sample structure state of the as-cast billet central region (250mm position below the surface), and the specific metallographic structure is shown in figure 1 (a), it can be seen that due to solidification segregation, there are a large number of dendrites and liquid carbides in the as-cast structure, and the specific morphology of carbides figure 1 (b), the main carbide types are MC, M6C and M2C.

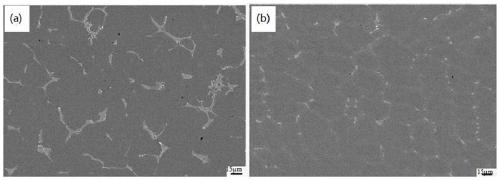

[0066] Analyze the microstructure of the sample in the central area of the billet after forging (150mm below the surface). For the specific metallographic structure, see figure 2 , it can be seen that after the conventional forging process is adopted, a large amount of liquid precipitated carbides still remain in the high-speed tool steel, and they are distributed in a network shape ( figure 2 (a)), while using the large deformation process in the solid-liquid two-phase region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com