Preparation method of semisolid-state AZ61 magnesium alloy

A technology of AZ61 and magnesium alloy, which is applied in the field of preparation of semi-solid alloy slurry, can solve the problems of high temperature strength, low creep performance, poor corrosion resistance of magnesium alloy, and difficult production of magnesium alloy, and achieve the improvement of mechanical properties and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

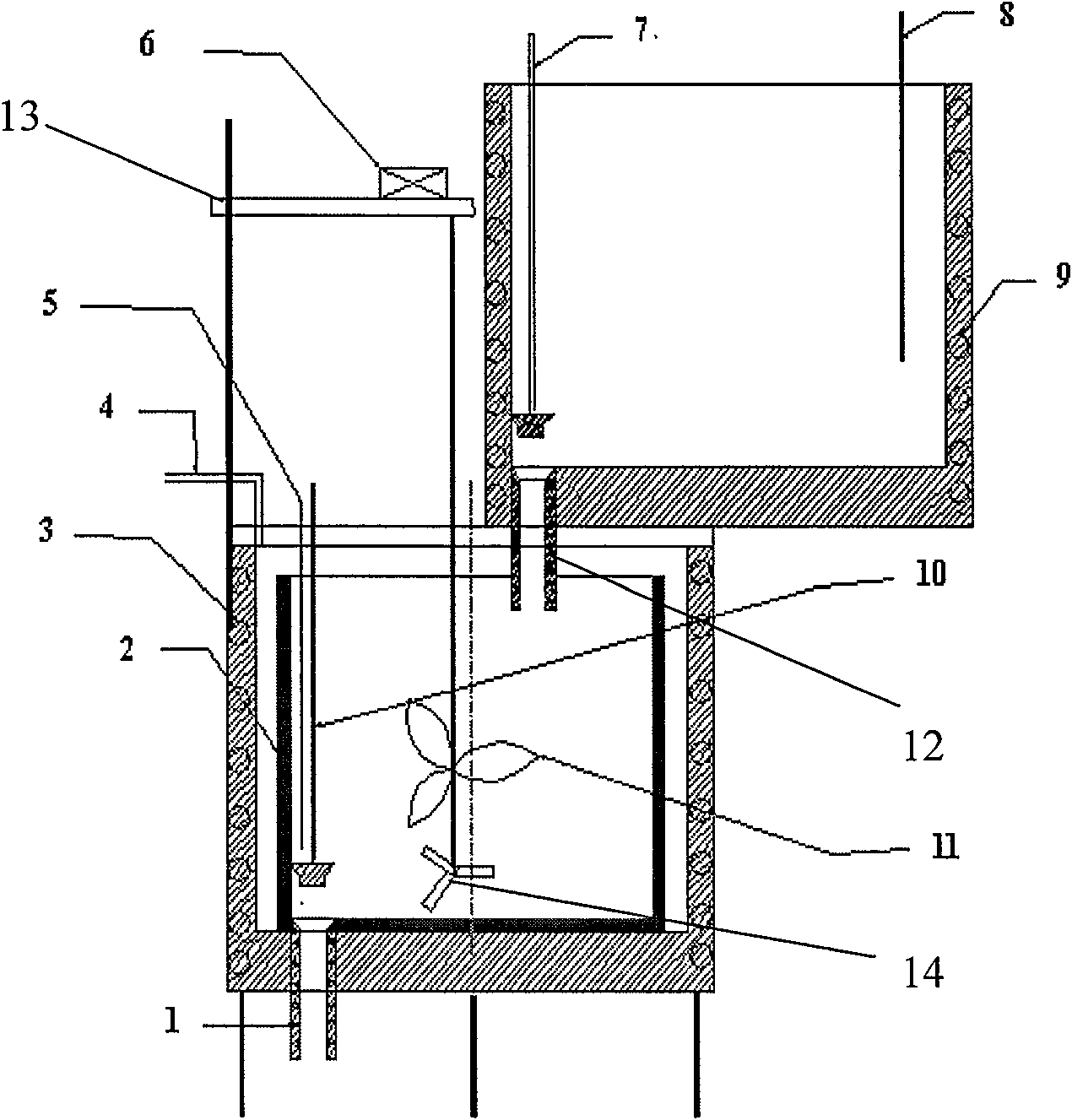

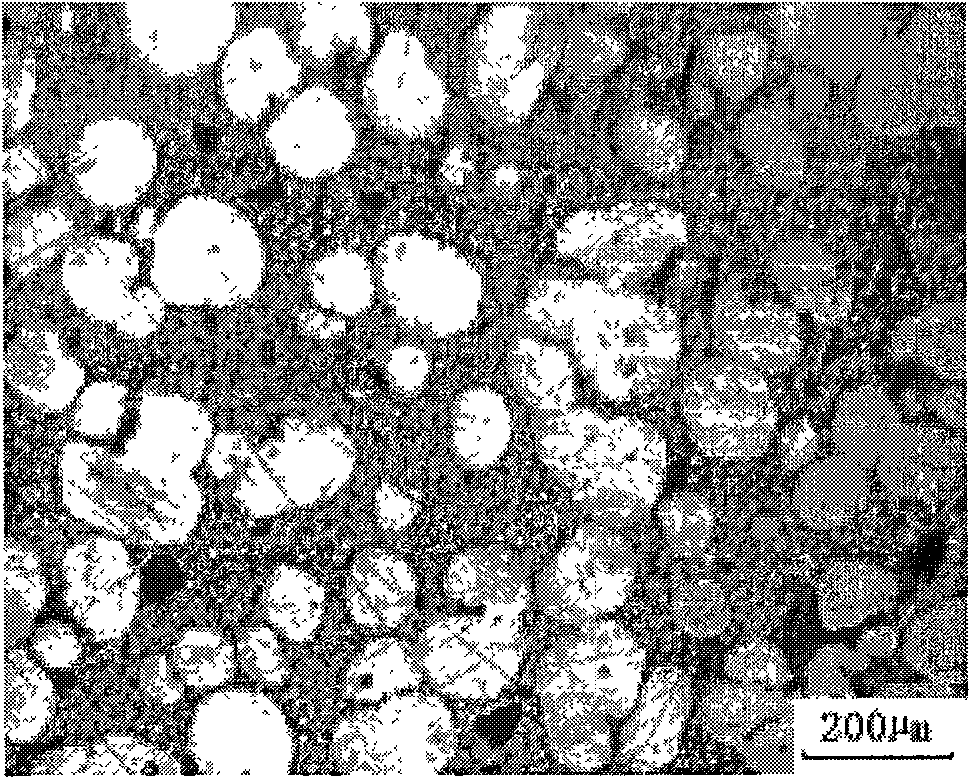

[0022] Put the raw material AZ61 magnesium alloy into the melting furnace, heat and refine under the protection of covering flux, let stand, and then cool down to the liquidus temperature (620°C). Then pour the liquid magnesium alloy into an argon-protected stirring furnace, and stir at a stirring speed of 500r / min for 3 minutes while cooling down to lower the temperature of the liquid magnesium alloy to 600°C to obtain a semi-solid slurry for pouring. Its organizational structure is that the white and nearly round particles are the semi-solid solid phase, and the light black is the dendrite structure after the liquid phase in the semi-solid slurry is partially solidified, and the spherical grains are relatively small, round and evenly distributed.

Embodiment 2

[0024] Put the raw material AZ61 magnesium alloy into the melting furnace, heat and refine under the protection of covering flux, let stand, and then cool down to the liquidus temperature (620°C). Then pour the liquid magnesium alloy into an argon-protected stirring furnace, and stir at a stirring speed of 500r / min for 5 minutes while cooling down to lower the temperature of the liquid magnesium alloy to 600°C to obtain a semi-solid slurry for pouring. Its organizational structure is that the white and nearly round particles are the semi-solid solid phase, and the light black is the dendrite structure after the liquid phase in the semi-solid slurry is partially solidified, and the spherical grains are relatively small, round and evenly distributed.

Embodiment 3

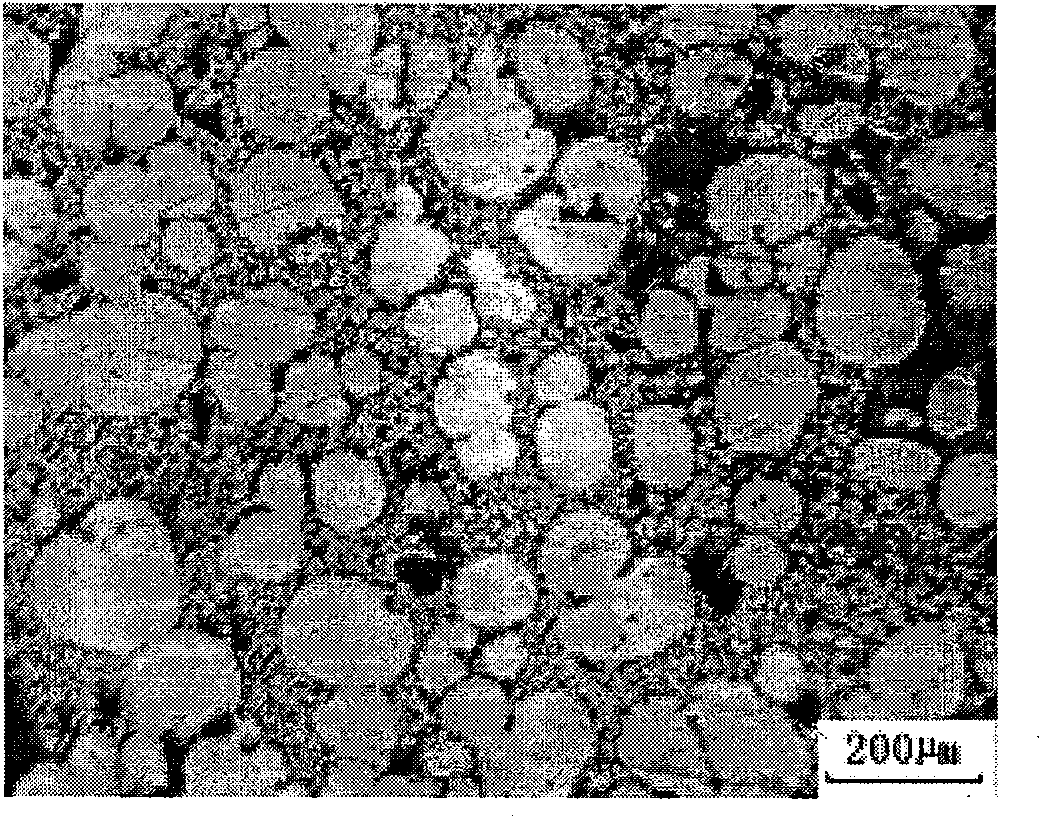

[0026] Put the raw material AZ61 magnesium alloy into the melting furnace, heat and refine under the protection of covering flux, let stand, and then cool down to the liquidus temperature (620°C). Then pour the liquid magnesium alloy into an argon-protected stirring furnace, and stir for 3 minutes while cooling at a stirring speed of 500 r / min, so that the temperature of the liquid magnesium alloy drops to 605° C. to obtain a semi-solid slurry and pour it. Its organizational structure is that the white and nearly round particles are the semi-solid solid phase, and the light black is the dendrite structure after the liquid phase in the semi-solid slurry is partially solidified, and the spherical grains are relatively small, round and evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com