High-uniformity short-process forming method for large metal component

A technology of metal components and uniformity, which is applied in the field of high-uniformity and short-process forming of large metal components, can solve the problems that forgings are difficult to meet the use requirements, the performance of large forgings is insufficient, and the performance requirements of forgings are extremely high, so as to reduce dendrite segregation defects, Good comprehensive mechanical properties, shortening the processing cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 7075 aluminum alloy is a typical representative alloy in the Al-Zn-Mg-Cu series aluminum alloy, and it is an indispensable material in the aerospace industry. Wide, high aging strengthening effect, good fracture toughness and other characteristics, 7075 aluminum alloy forgings are widely used in aircraft components and aerospace structural components, such as aviation blades, aircraft landing gear and so on. The chemical composition of 7075 aluminum alloy in embodiment 1 is as follows (weight percent, %)

[0032] element

Zn

Mg

Cu

Cr

mn

Fe

Al

Measured ingredients

5.57

2.57

1.45

0.21

0.3

0.5

Remain

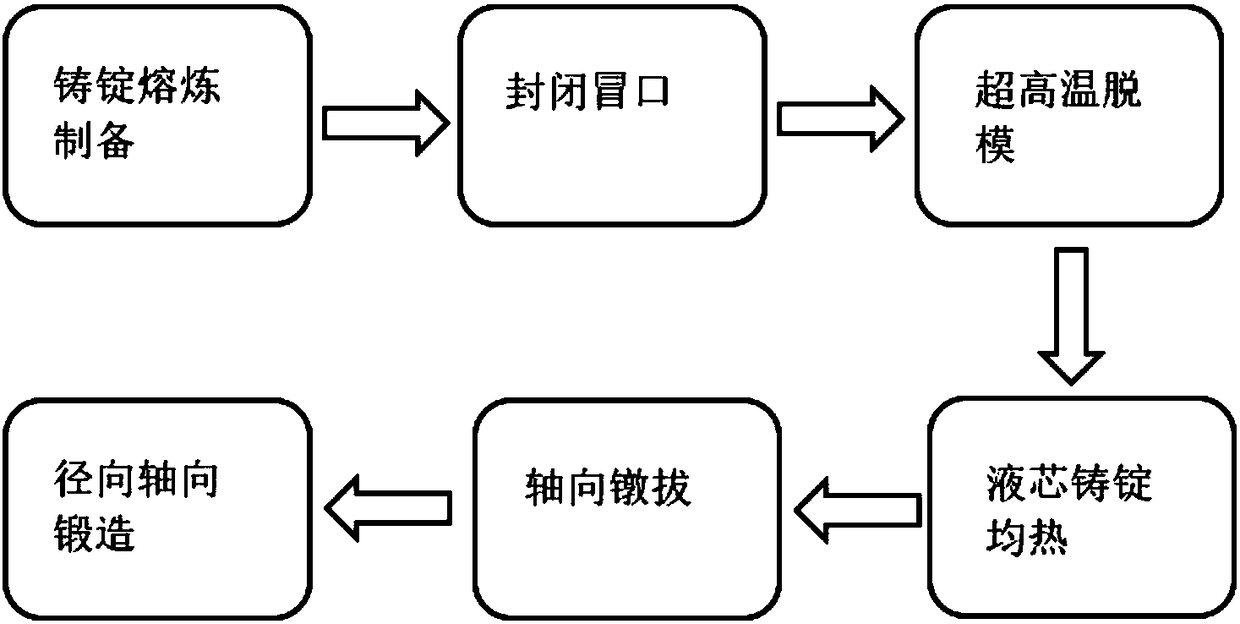

[0033] In this example, a large-scale metal component is manufactured using a 7075 aluminum alloy round ingot as a raw material, and a semi-solid liquid core forging method is adopted. The process flow is as follows figure 1 As shown, the steps are as follows:

[0034] 1. Melting the molten aluminum alloy,...

Embodiment 2

[0041]S34MnV steel is a special type of steel for marine combined crankshafts. It is a medium-carbon low-alloy structural steel. Mn is added to strengthen the ferrite and refine pearlite to improve the strength of the steel. A small amount of V is added to eliminate manganese steel. Sensitivity to overheating. The chemical composition of S34MnV steel in embodiment 2 is as follows (weight percent, %):

[0042] element

C

mn

Ni

V

Mo

Cr

Si

Fe

Measured ingredients

0.35

1.3

0.28

0.10

0.12

0.28

0.15

Remain

[0043] In this example, S34MnV steel round ingots are used as raw materials to manufacture large-scale metal components, and a semi-solid liquid core forging method is adopted. The process flow is as follows figure 1 As shown, the steps are as follows:

[0044] 1. Melting molten steel, casting molten steel according to the process of casting temperature 1550 ℃ and casting speed 50mm / min;

[0045] 2. Spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com