Thixotropic soft core composite forging forming method for aluminum-steel bimetal component

A forging and bimetallic technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as uncoordinated deformation of aluminum and steel, cracks at the interface between aluminum and steel, and inability to obtain metallurgical interfaces, etc., to promote Diffusion and reaction of elements, improvement of uniform structure and performance, reliable and stable metallurgical interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

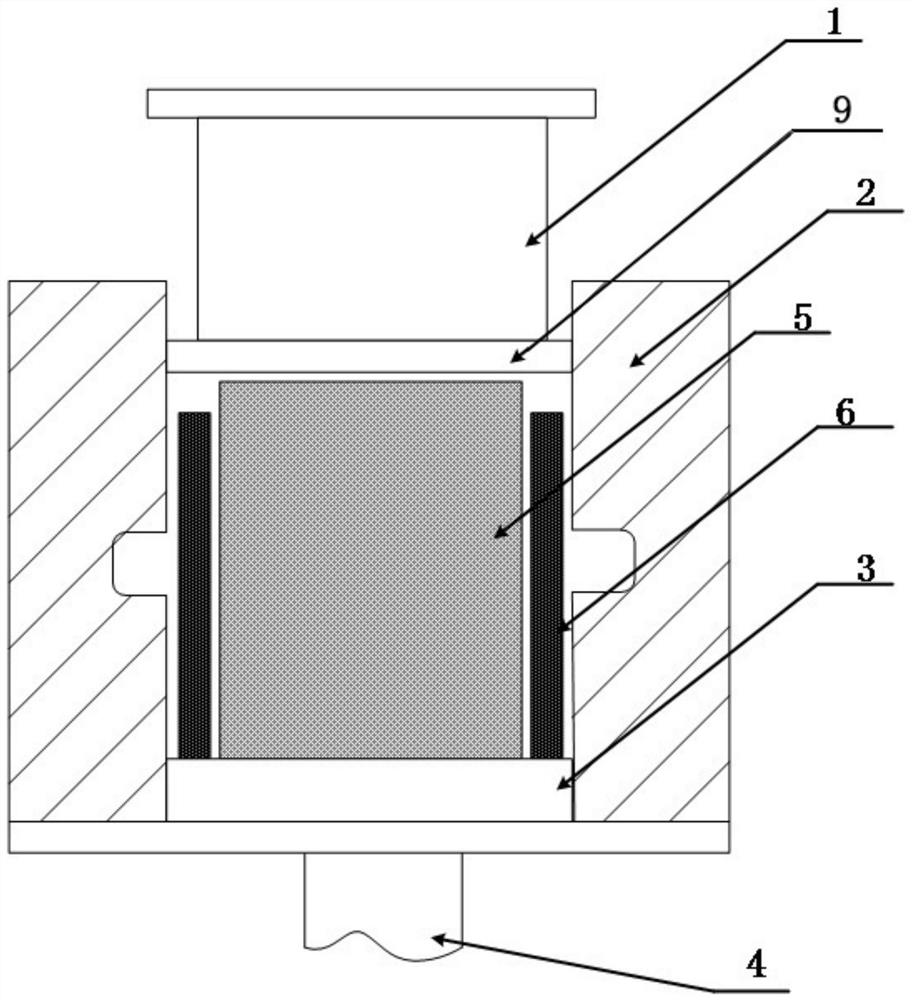

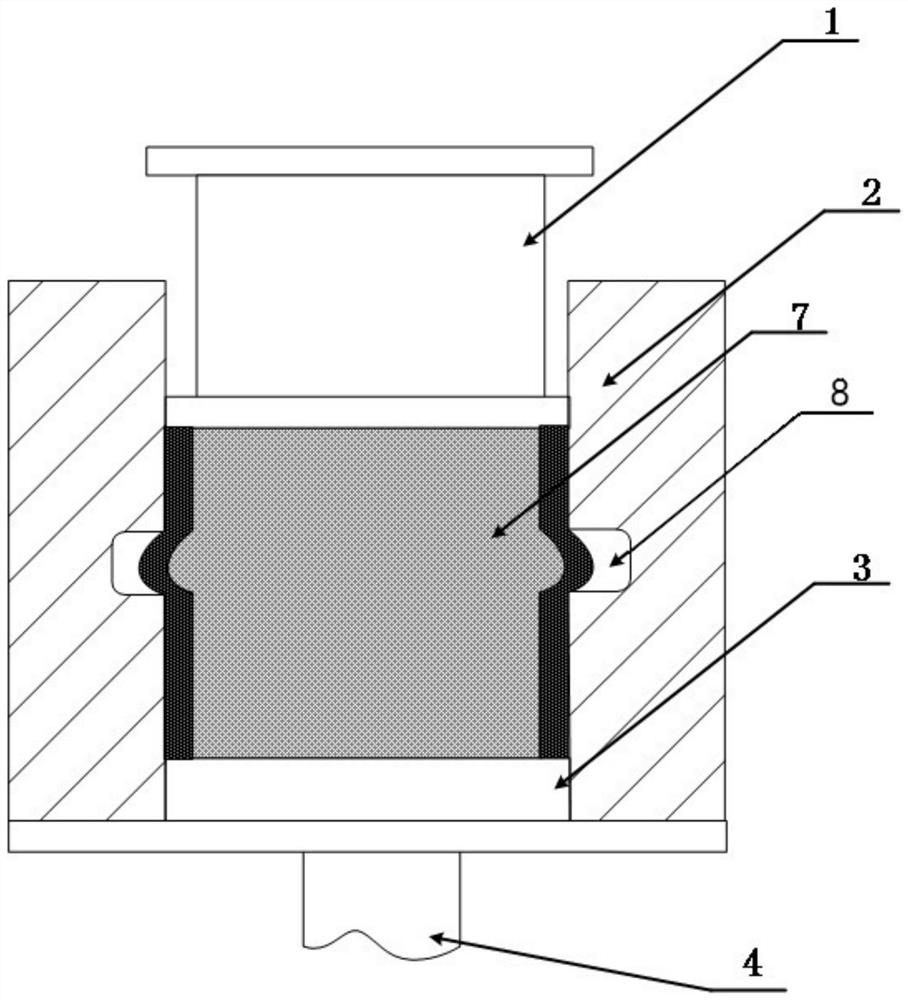

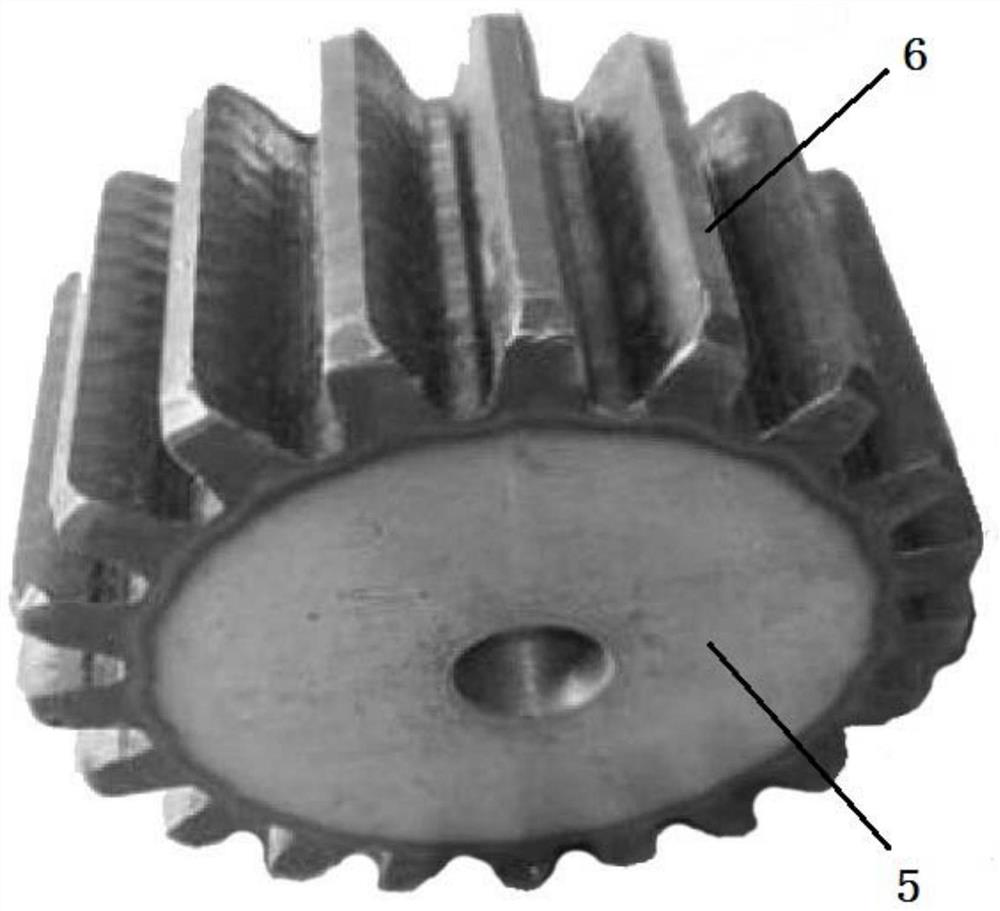

[0048] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0049] Step 2: Process the 7075 aluminum alloy bar stock into a cylinder with a diameter of 35 mm and a height of 58 mm, as the aluminum alloy core 5, process the 45# steel pipe into an outer diameter of 45 mm, a wall thickness of 4 mm, and a height of 50 mm The torus of millimeter, as steel sleeve 6;

[0050] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 620°C and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase rate of 40%;

[0051] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 1000°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the tem...

Embodiment 2

[0056] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0057] Step 2: Process the 2024 aluminum alloy bar into a cylinder with a diameter of 35 mm and a height of 58 mm as the aluminum alloy core 5, and process the 304 stainless steel pipe into an outer diameter of 45 mm, a wall thickness of 4 mm, and a height of 50 mm The torus, as the steel sleeve 6;

[0058] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 630° C. and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase ratio of 40%;

[0059] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 900°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the temp...

Embodiment 3

[0064] Step 1: Prepare a mold for composite forging and forming aluminum-steel bimetal components, the mold includes a mold cavity 8, and the shape of the mold cavity 8 is gear-shaped;

[0065] Step 2: Process the 6061 aluminum alloy bar stock into a cylinder with a diameter of 35 mm and a height of 58 mm as the aluminum alloy core 5, and process the 40CrMo pipe into a cylinder with an outer diameter of 45 mm and a wall thickness of 4 mm and a height of 50 mm. Torus, as steel sleeve 6;

[0066] Step 3: using an infrared heating furnace to heat the aluminum alloy core body 5 to 630° C. and keep it warm for 30 minutes, so that the aluminum alloy core body 5 is transformed into a semi-solid state with a liquid phase ratio of 40%;

[0067] Step 4: During the heat preservation in step 3 for about 25 minutes, use an electromagnetic induction heating furnace to heat the steel jacket 6 to 1000°C, use an infrared thermometer to monitor the steel jacket 6 in real time, and feed back the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com