Patents

Literature

36results about How to "Improve tissue performance uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified EH550 super-thick steel plate for marine engineering and manufacturing method thereof

The invention discloses a modified EH550 super-thick steel plate for marine engineering and a manufacturing method thereof. The steel contains 0.08% to 0.15% of C, 0.20% to 0.55% of Si, 0.80% to 1.35%of Mn, less than or equal to 0.01% of P, less than or equal to 0.03% of S, 0.04% to 0.08% of V, 0.015% to 0.45% of Als, 0.003-0.015% of N, 0.50-0.90% of Ni, 0.20-0.40% of Cr, 0.002-0.03% of Mo, 0.02%to 0.05% of Nb, 0.20-0.40% of Cu, less than or equal to 0.04% of Ti, and the balance of Fe and unavoidable impurities. The method employs two-stage controlled rolling, the first-stage rolling temperature is 1100-1150 DEG C, the one-stage finishing rolling temperature is 990-1130 DEG C, the second-stage rolling temperature is 700-780 DEG C, and the final rolling temperature is 680-750 DEG C. The heat treatment method of quenching before sub-quenching is used, and after quenching, the steel plate is tempered, and the steel plate having a thickness of 80-100 mm is obtained. The impact toughnessof a core is more than 200J, and the comprehensive performance is uniform at different positions.

Owner:ANGANG STEEL CO LTD

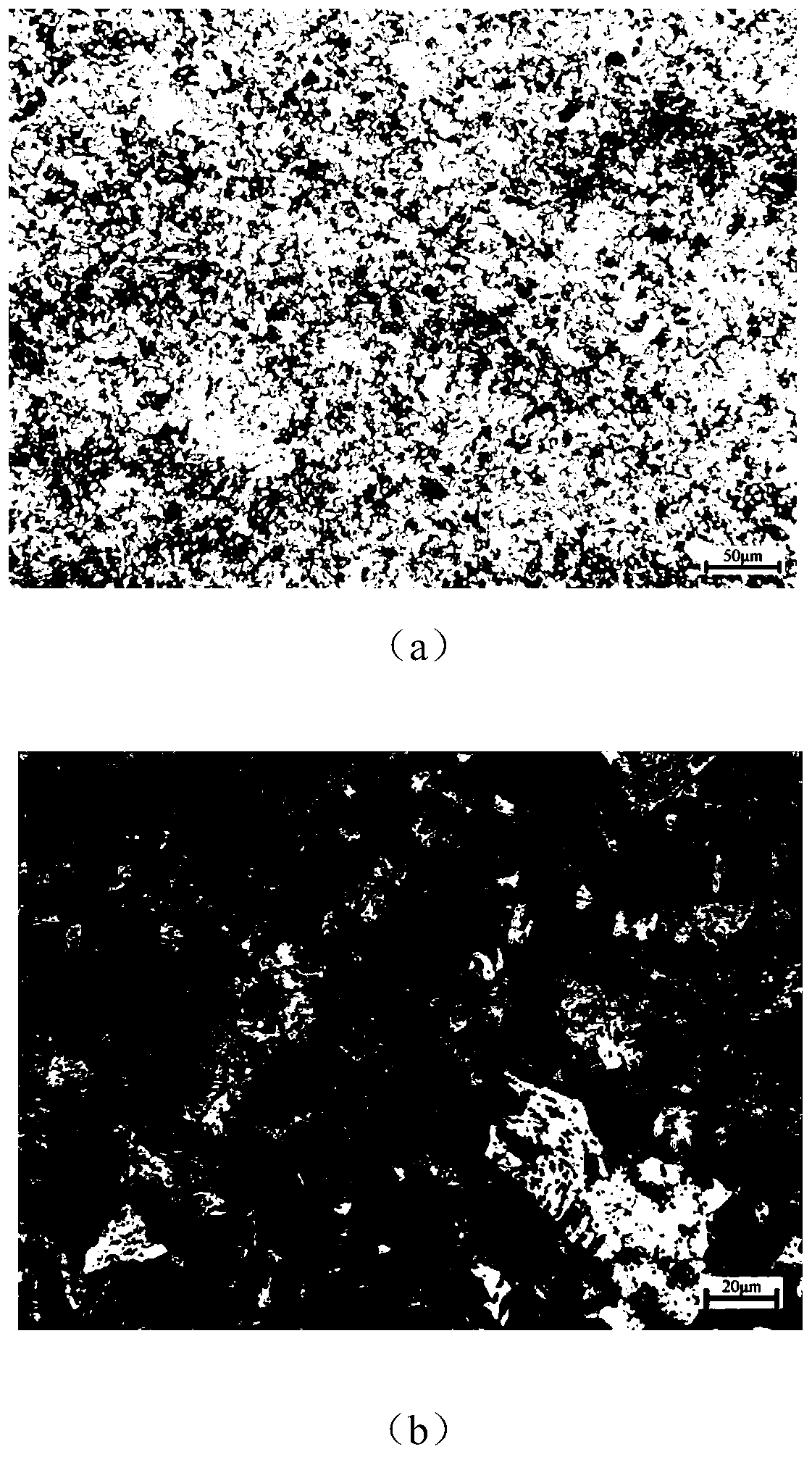

Aggregation-type composite powder for high-temperature abradable seal coating layer and preparing method of aggregation-type composite powder

The invention relates to aggregation-type composite powder for a high-temperature abradable seal coating layer and a preparing method of the aggregation-type composite powder. The aggregation-type composite powder which has good spraying technology adaptability is prepared through the method of mechanical milling, room-temperature binding and aggregation. The powder comprises MCrAlY alloy powder, alloy powder with beta-NiAl intermetallic compounds as a main phase, polybenzoate powder, boron nitride, binding agents and the like. Raw materials can be the combination of the materials, and the binding agents can be inorganic matter or organic matter. The powder comprises beta-NiAl intermetallic compound high-temperature-resisting components, heat-resisting temperature of an existing metal-based seal coating layer can be raised, and compared with a ceramic seal coating layer, the coating layer has great thermal shock resistance and can be used under the working condition of the high temperature of 1000 DEG C for a long time. The powder has wide application in gas channel sealing of a combustion gas turbine high-temperature part, especially of a high-pressure turbine.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

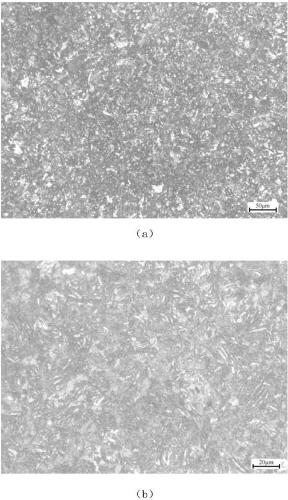

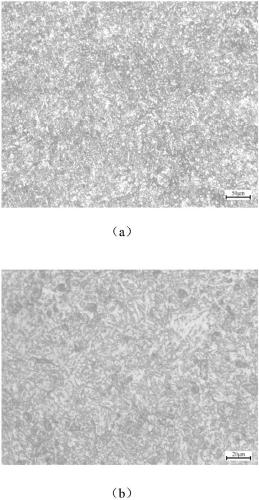

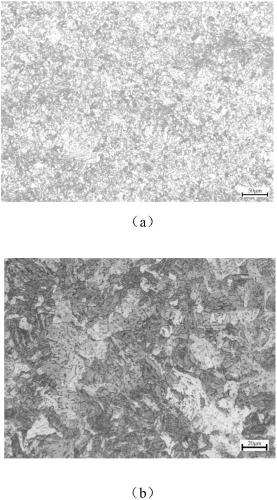

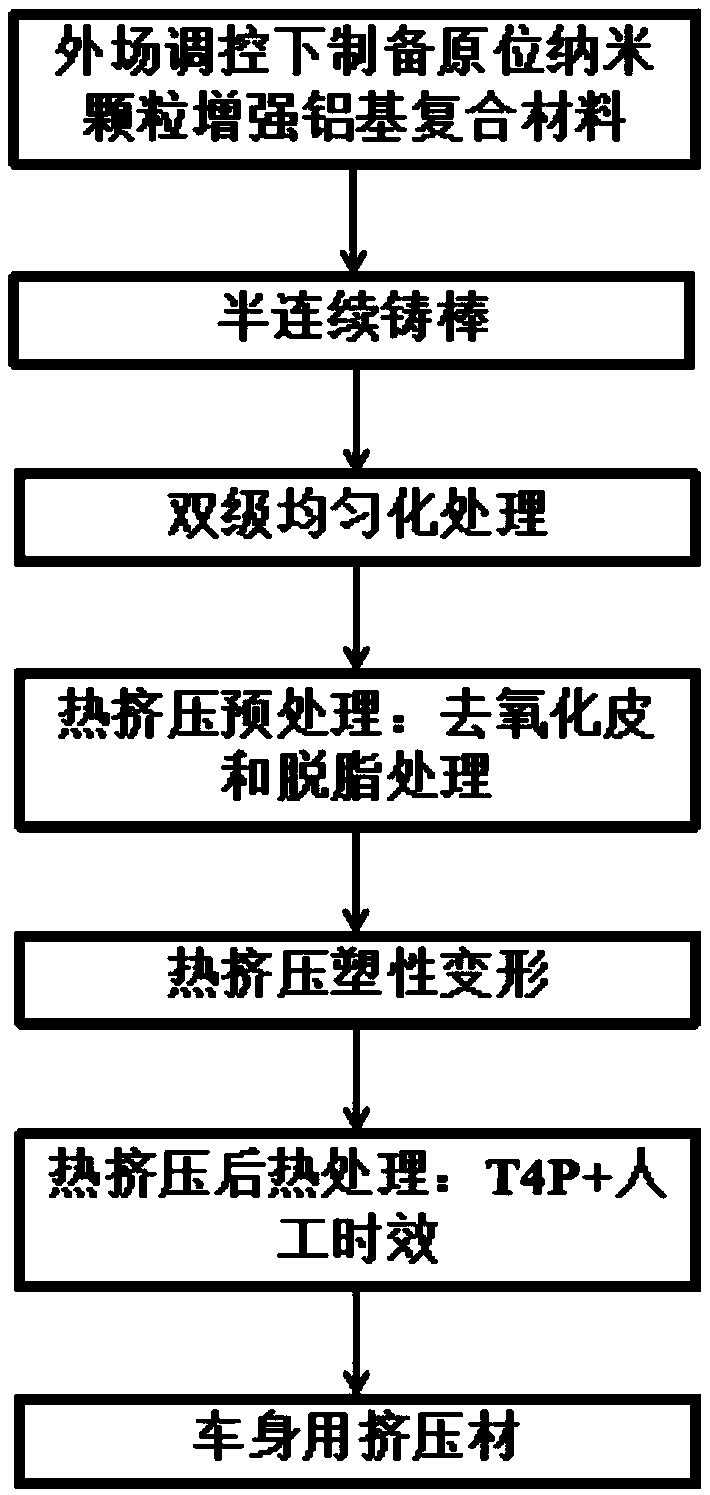

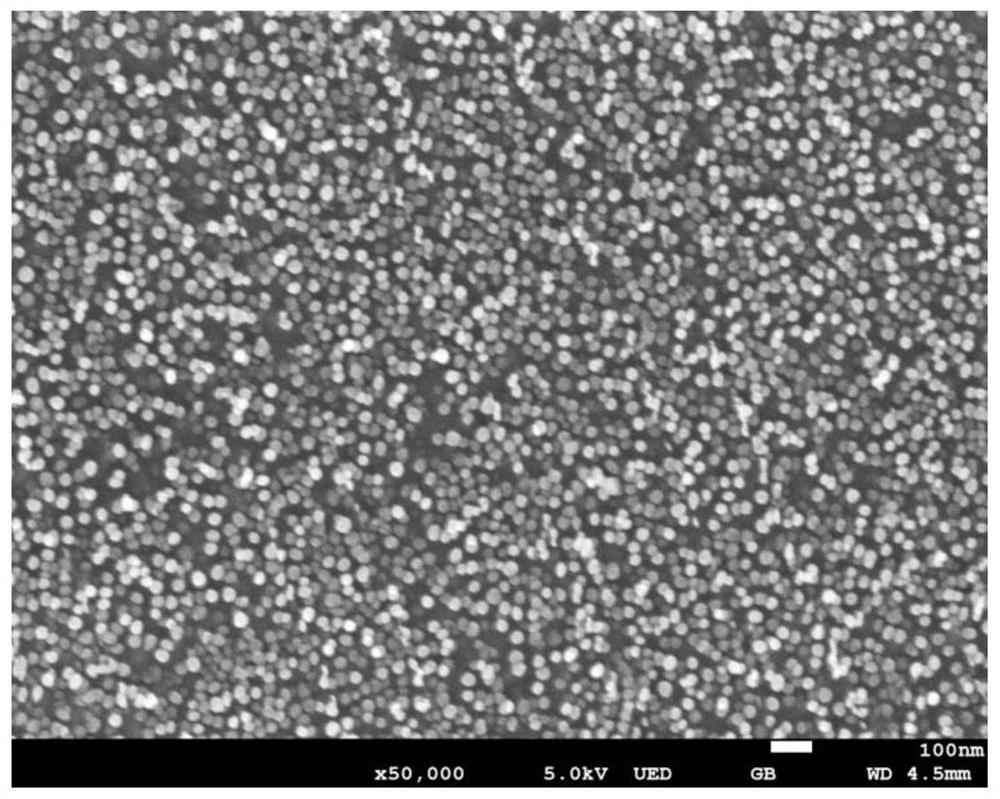

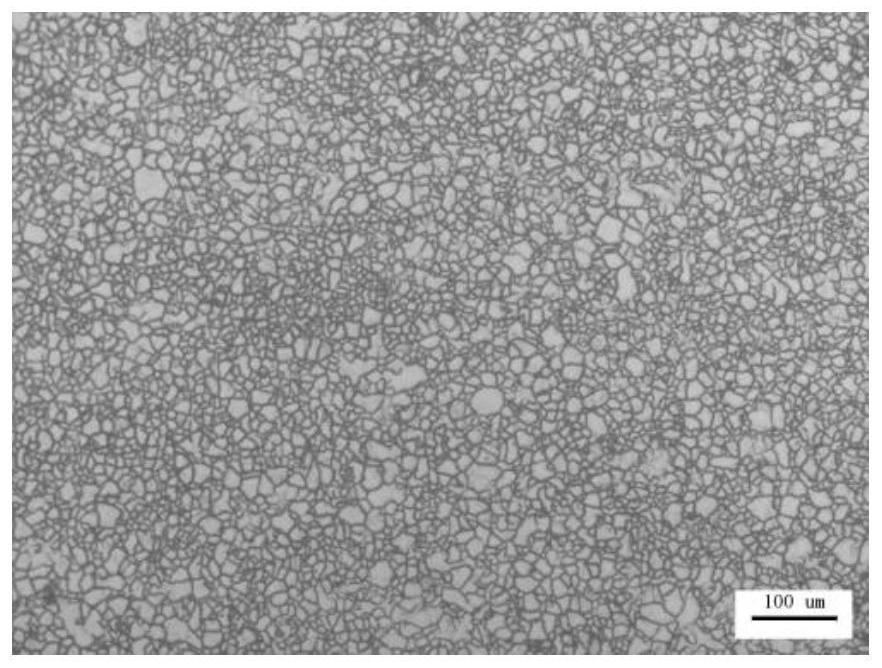

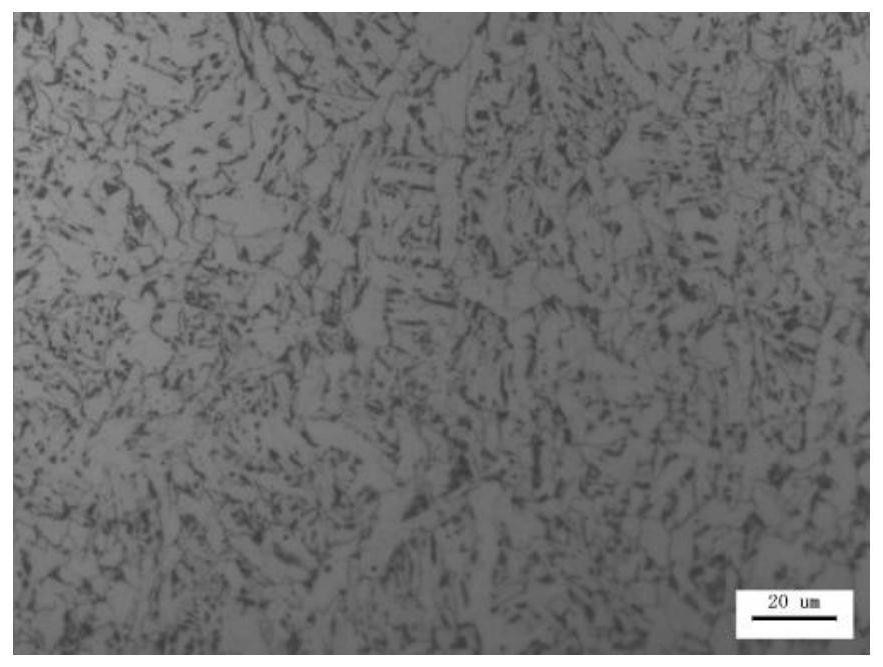

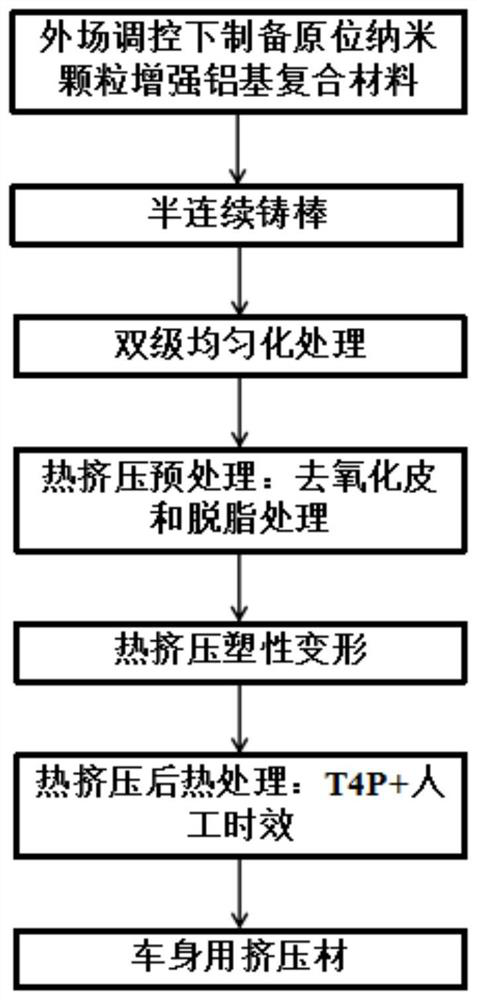

Extrusion process for vehicle body in-situ nanoparticles enhancing aluminum base composite material

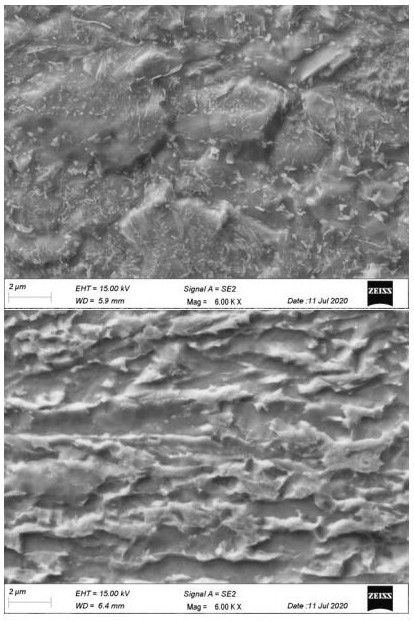

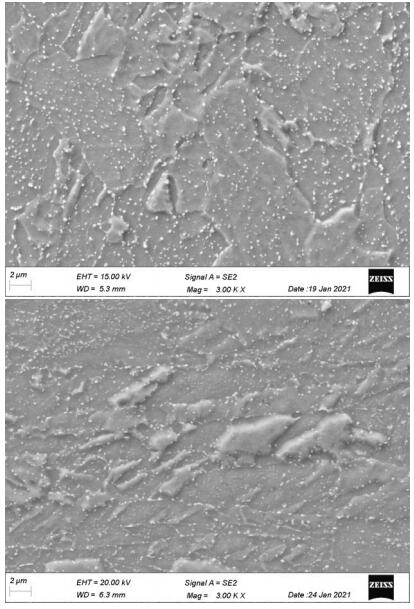

ActiveCN108796404AImprove tissue performance uniformityImprove strong plasticityResearch ObjectThermal expansion

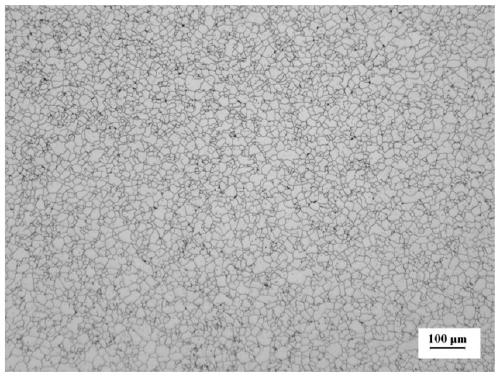

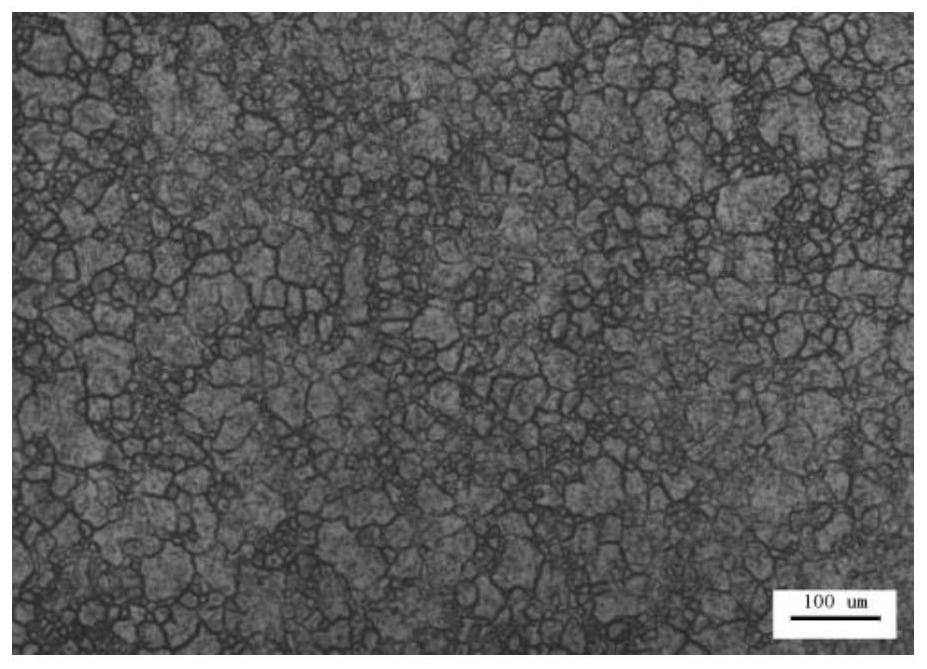

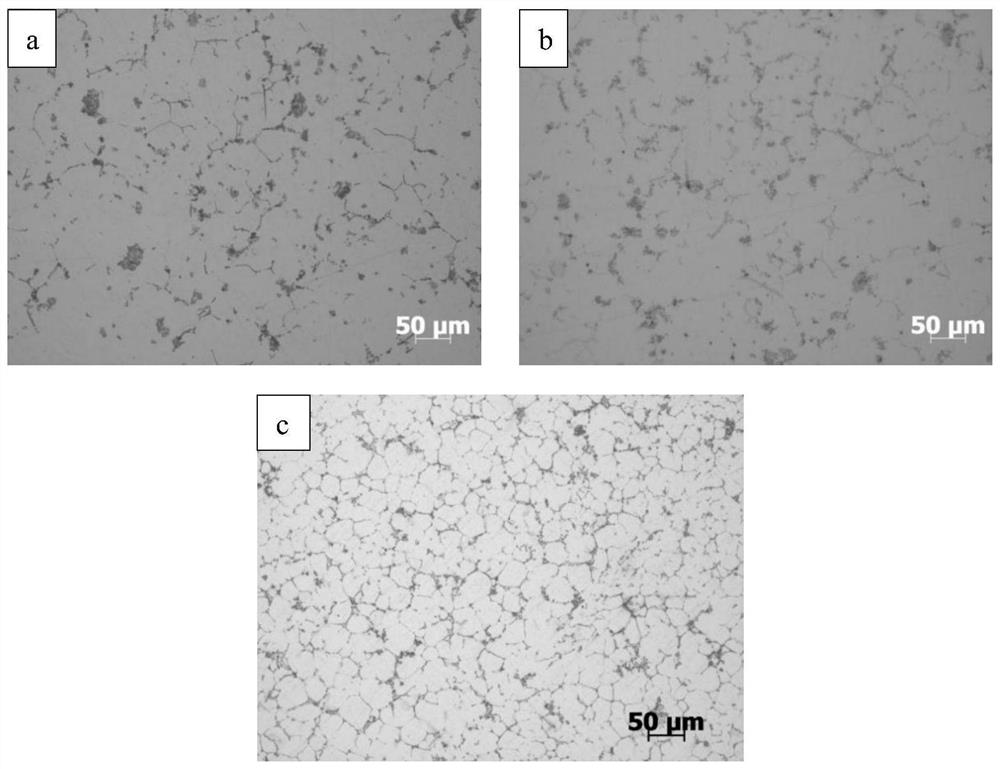

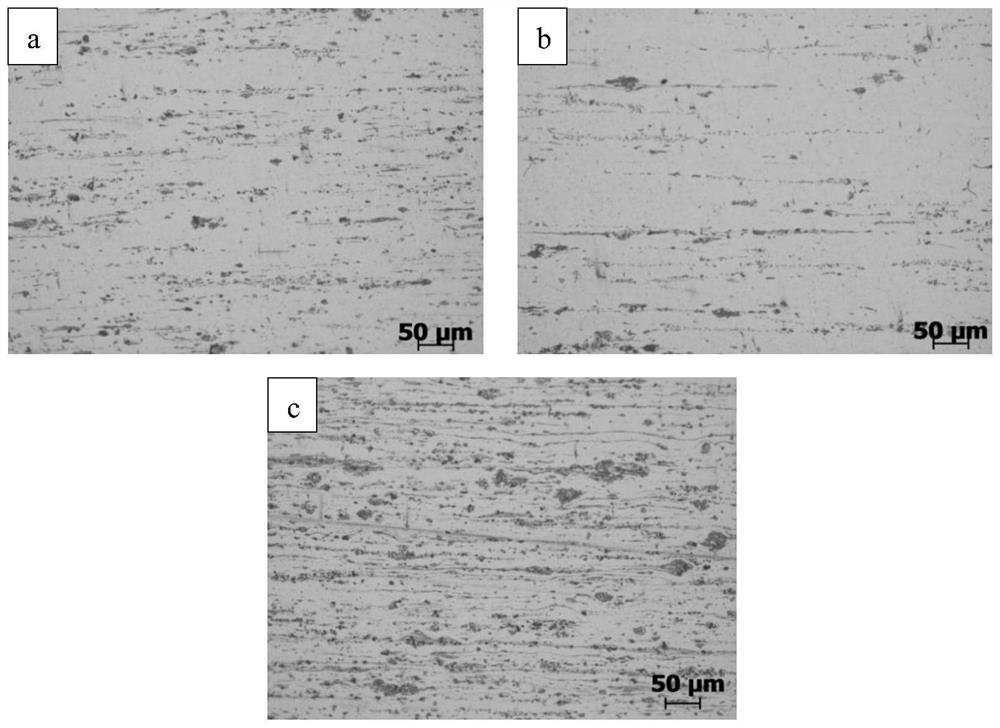

The invention relates to the field of aluminum base composite material processing, in particular to an extrusion process for a vehicle body in-situ nanoparticles enhancing aluminum base composite material. The vehicle body in-situ nanoparticles enhancing aluminum base composite material synthesized in situ under the outer field control is used as a research object, the casting defects such as holes and loosening are eliminated by adopting the hot extrusion plasticity, so that the texture is refined and dense, the extruded grains are uniform and small, and the mechanical properties are obviously improved; meanwhile, under the action of the extrusion pressure, the agglomeration particles are dispersed and dispersed in a matrix, the bonding force with the matrix is higher, a lot of dislocation is generated, a high-density dislocation mesh is formed, and dislocation enhancement is produced accordingly. The T4P+ artificial aging heat treatment of the follow-up extrusion material can eliminate the thermal residual stress caused by the different thermal expansion coefficients of nanoparticles and matrix in the process of the hot extrusion, the plasticity of the vehicle body extrusion material is further improved, and the vehicle body in-situ nanoparticles enhancing aluminum base composite material extrusion material which can replace the steel plate is obtained.

Owner:JIANGSU UNIV

Preparation method of easy-cutting aluminum alloy extrusion rod without coarse grain rings

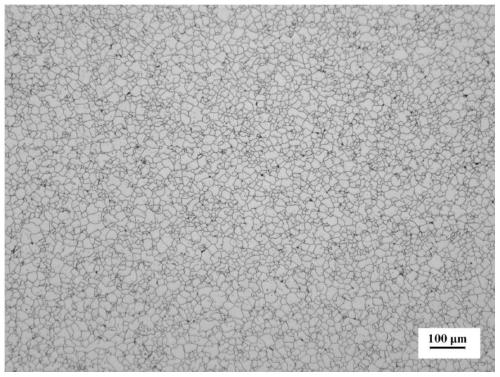

ActiveCN111304473AImprove tissue performance uniformityInhibit the growth of recrystallized grainsUltrasonic vibrationGrain structure

The invention provides a preparation method of an easy-cutting aluminum alloy extrusion rod without coarse grain rings. The preparation method comprises the following steps of conducting material mixing according to the composition and mass percentages of components of an aluminum alloy; conducting electromagnetic stirring, and melting the mixture into an aluminum alloy solution; conducting in-furnace powder spraying, refining, degassing and impurity removing; conducting online grain refinement treatment; conducting online degassing and filtering treatment; conducting ultrasonic vibration andsemi-continuous casting; conducting homogenizing treatment on a cast rod; heating the cast rod, and conducting extrusion molding; drawing and straightening the cast rod; and conducting artificial aging treatment. According to the preparation method, through optimization design of the preparation process and parameters of the aluminum alloy extrusion rod and by inhibiting growth of recrystallized grains and eliminating the defects of coarse grain ring structures of the extrusion rod, the extrusion rod can have the fine and uniform grain structure, the homogeneity of the structure performance ofthe extrusion rod is improved, and the aluminum alloy extrusion rod has the excellent mechanical performance and machinability.

Owner:广东领胜新材料科技有限公司

Extremely thick quenched and tempered rack steel plate for 785 MPa level ocean platform and preparation method

The invention discloses an extremely thick quenched and tempered rack steel plate for a 785 MPa level ocean platform and a preparation method. The steel plate comprises the chemical components in percent by weight: 0.08-0.15% of C, 0.60-1.55 of Mn, 0.10-0.50% of Si, 0.002-0.005% of S, 0.005-0.015% of P, 2.7-4.0% of Ni, 0.40-1.00% of Cr, 0.30-0.70% of Mo, 0.10-0.40% of Cu, 0-0.080% of Nb, 0-0.10% of V, 0-0.08% of Ti, 0.02-0.08% of Al, 0.0008-0.0015% of B and the balance Fe and other inevitable impurities. By adopting a low C and high Ni-Cr-Mo alloyed and Nb, V and Ti microalloyed component system, the yield strength is greater than or equal to 795 MPa, the tensile strength is greater than or equal to 865 MPa, the -60 DEG C Charpy V-shaped notch impact energy is greater than or equal to 140J, Z is greater than or equal to 35%, and the maximum thickness is 100 mm, and the extremely thick quenched and tempered rack steel plate can be used for manufacturing a rack for the ocean platform. The extremely thick quenched and tempered rack steel plate for the 785 MPa level ocean platform with high hardenability and high toughness further has a characteristic of low yield ratio, and is widerin application range, higher in structural safety and suitable for a working environment in an extremely low-temperature sea area.

Owner:NORTHEASTERN UNIV LIAONING

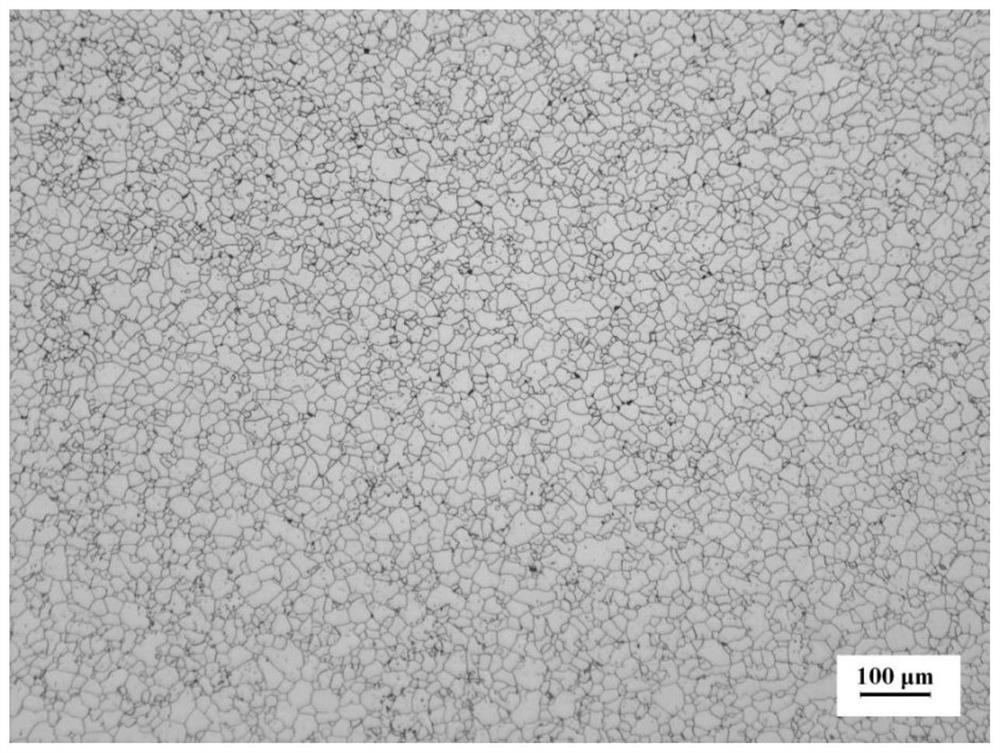

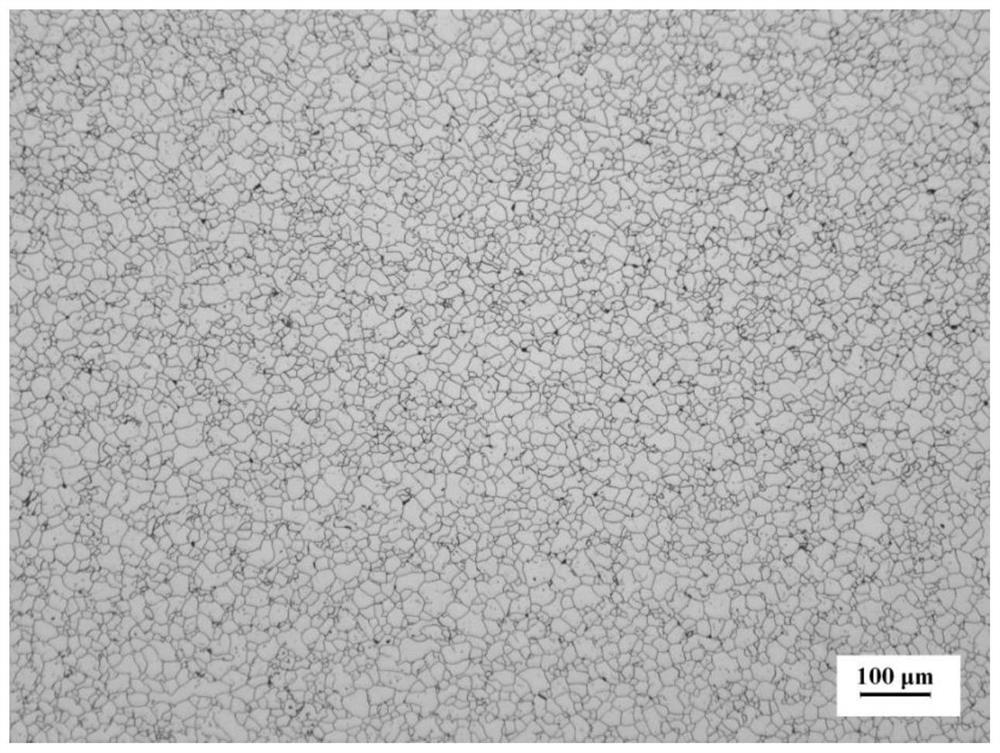

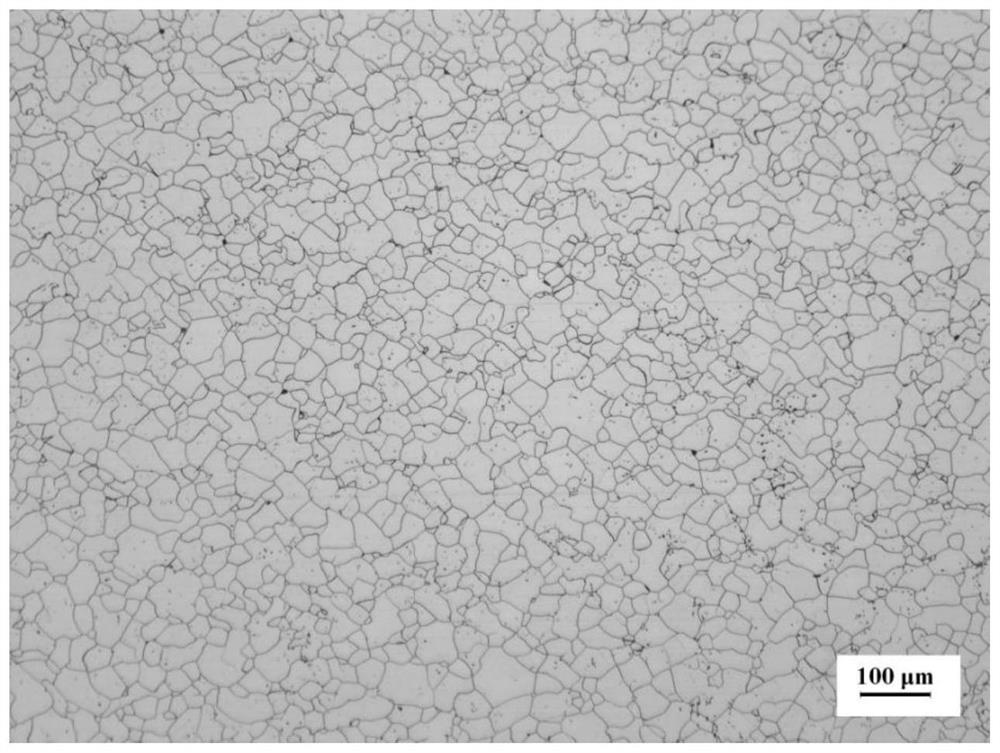

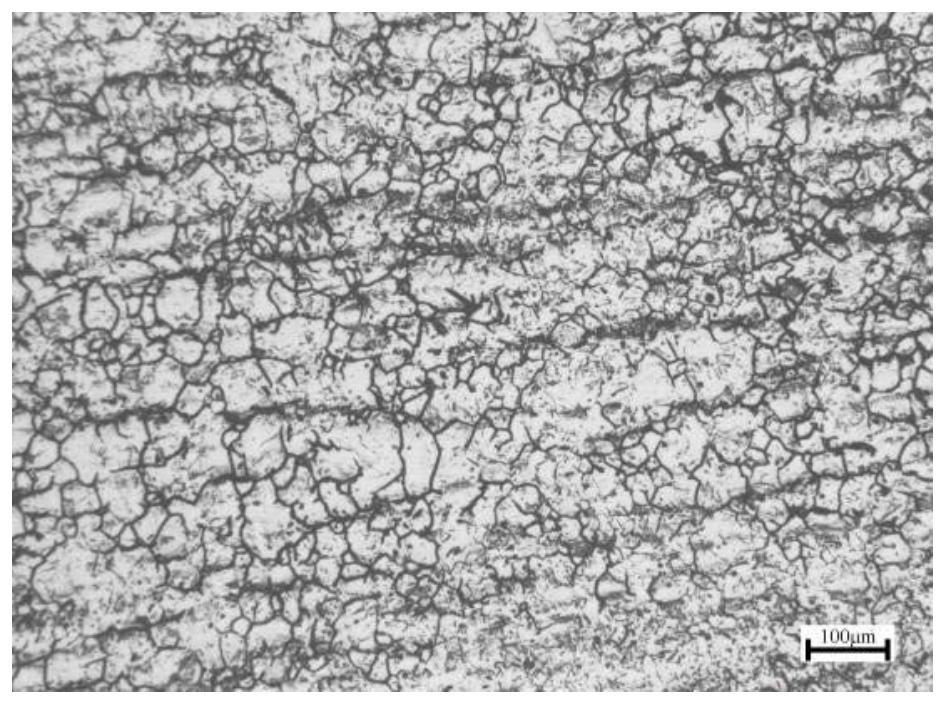

GH4282 nickel-based high-temperature alloy bar and preparation method thereof

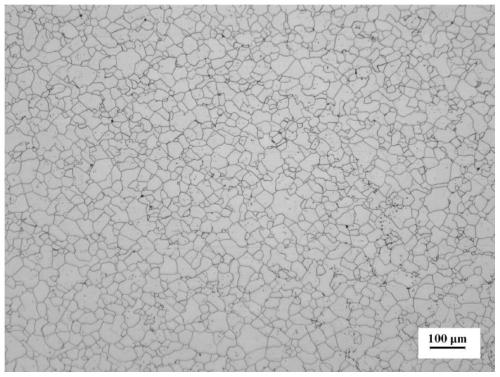

ActiveCN111118423AUniform fine grain structureImprove tissue performance uniformityTemperingIngot casting

The invention discloses a GH4282 nickel-based high-temperature alloy bar and a preparation method thereof, and solves the technical problems of coarse grain size and poor uniformity of an existing GH4282 alloy bar. The preparation method comprises the following steps: S1, heating a GH4282 nickel-based high-temperature alloy ingot casting; S2, carrying out primary upsetting and tempering on the ingot casting in the axial direction to obtain a blank, and carrying out primary hot drawing and tempering on the blank in the direction perpendicular to the axial direction; S3, carrying out secondary upsetting and tempering on the blank in the axial direction, and then carrying out secondary hot drawing and tempering in the direction perpendicular to the axial direction; S4, carrying out three-timeupsetting and tempering on the blank in the axial direction, and then carrying out three-time drawing and tempering in the direction perpendicular to the axial direction to obtain a bar blank; and S5, tempering the bar blank in the step S4, and then performing one-fire-diameter forging forming to obtain the GH4282 nickel-based high-temperature alloy bar. The invention further discloses the GH4282nickel-based high-temperature alloy bar prepared by the method. The GH4282 nickel-based high-temperature alloy bar has the advantage that the structure uniformity of the GH4282 nickel-based high-temperature alloy bar can be effectively improved, so that the performance of the GH4282 nickel-based high-temperature alloy bar is improved.

Owner:BEIJING CISRI GAONA TECH +1

Method for producing 8CrV2 hot-rolled sheet steel

InactiveCN101792883AImprove uniformityImprove tissue performance uniformityTemperature control deviceMetal rolling arrangementsSlagSheet steel

The invention provides a method for preparing high-quality 8CrV2 hot-rolled sheet steel based on continuous casting and continuous rolling processes of sheet billets. The method mainly comprises the technical processes of smelting, refining, continuous casting of sheet billets, soaking, hot continuous rolling, cooling and coiling. The superheat degree T(superheat) of molten steel is greater than 30 DEG C and less than or equal to 45 DEG C, the charging temperature T(charging) of casting billets is greater than or equal to 900 DEG C and less than or equal to 1050 DEG C, the finishing temperature T(finishing) is greater than or equal to 850 DEG C and less than or equal to 950 DEG C, the coiling temperature T(coiling) is greater than or equal to 550 DEG C and less than or equal to 630 DEG C, and the pulling speed S(pulling) of continuous casting is greater than or equal to 3.5m / min and less than or equal to 5.5m / min; covering slag is used for casting; and the molten steel comprises the following chemical components: 0.70-0.80 of C, 0.20-0.45 of Si, 0.60-0.90 of Mn, less than or equal to 0.025 of P, less than or equal to 0.025 of S, 0.30-0.60 of Cr and 0.02-0.08 of V. The 8CrV2 hot-rolled sheet steel prepared by the method of the invention reduces the segregation, loosen and cracks of the casting billets, and has the characteristics of uniform structure property and high fatigue resistance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

High-strength magnesium alloy extruded profile and manufacturing method thereof

PendingCN113832371AFacilitates local temperature regulationHigh temperature control accuracyMetallurgyIngot

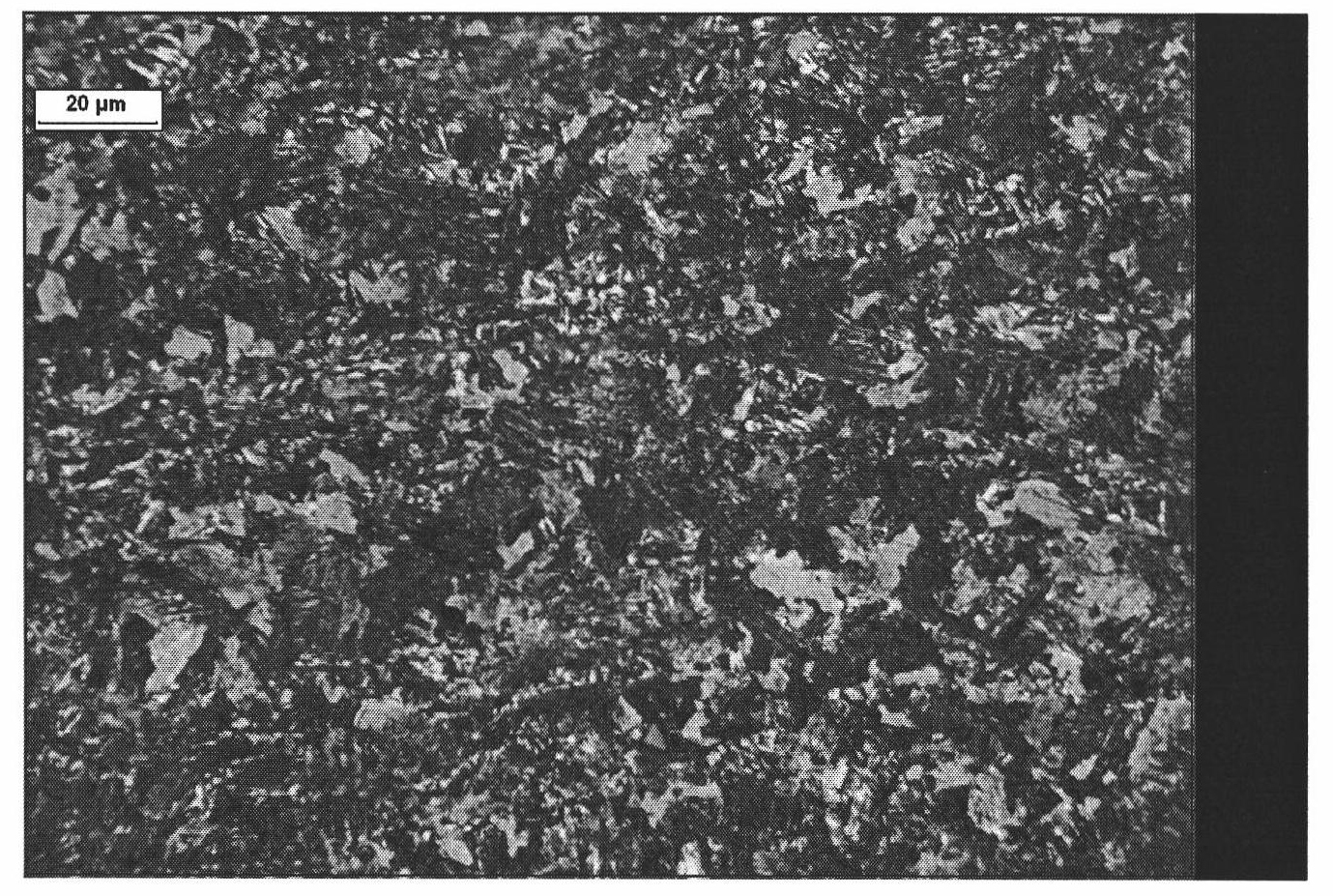

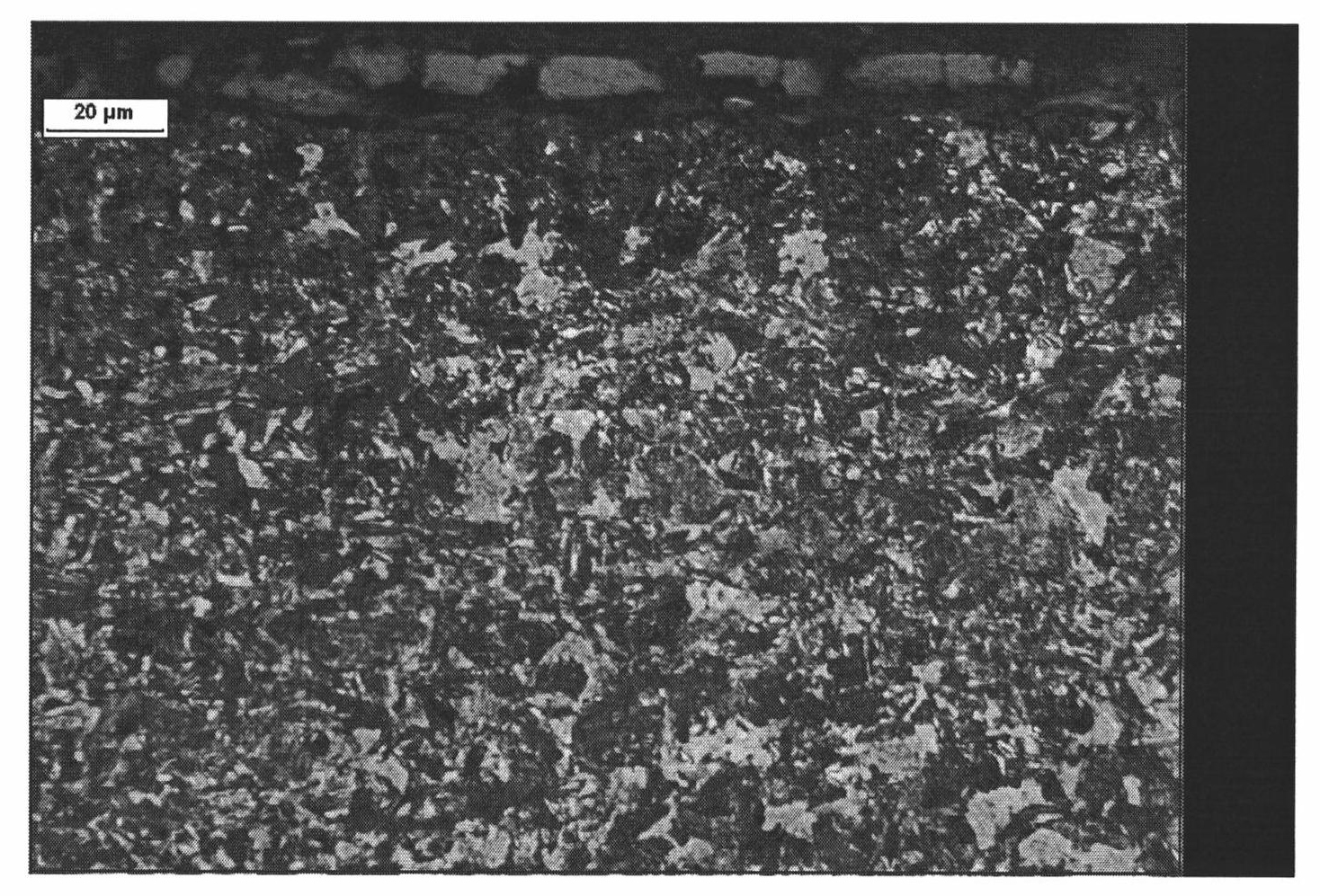

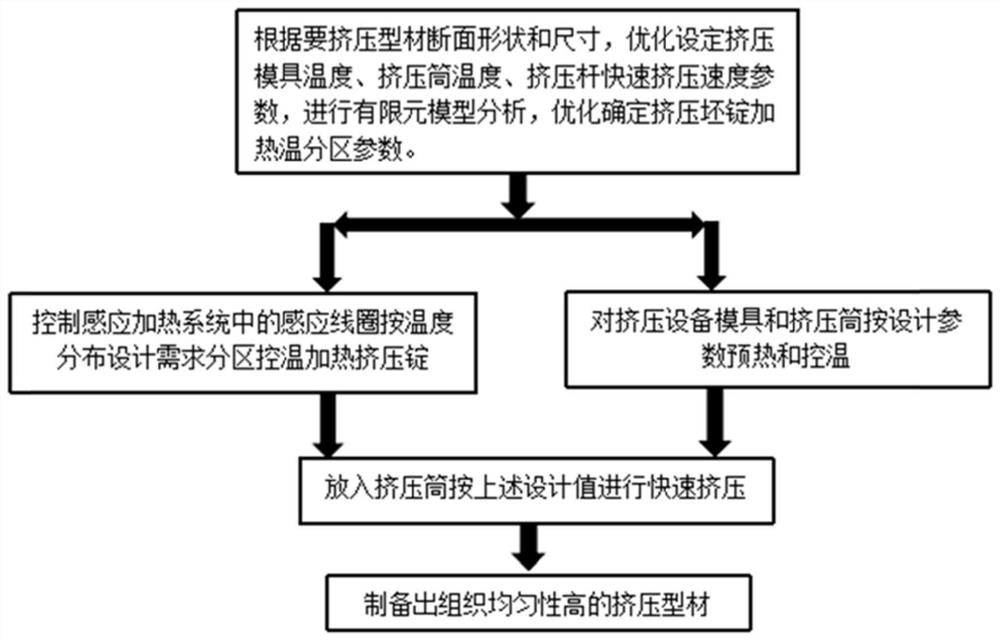

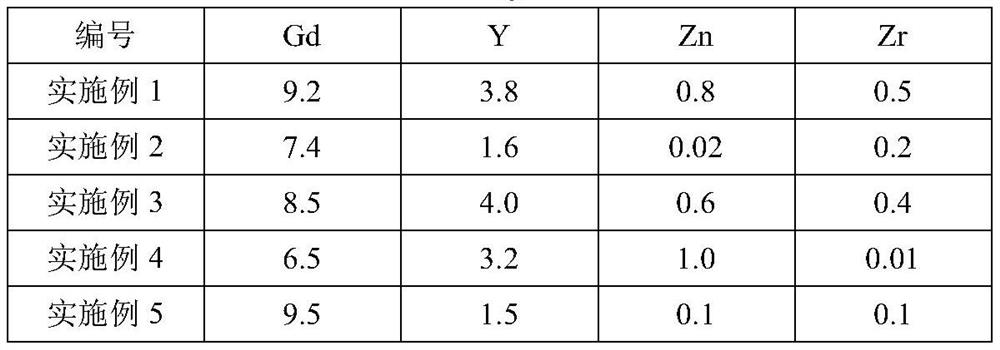

The invention discloses a high-strength magnesium alloy extruded profile. The high-strength magnesium alloy extruded profile comprises the following chemical elements in percentage by mass besides Mg: 6.5-9.5% of Gd; 1.5-4.0% of Y; 0.02-1.0% of Zn; and 0.01-0.5% of Zr. Correspondingly, the invention also discloses a manufacturing method of the high-strength magnesium alloy extruded profile, the manufacturing method comprises the following steps that an extruded ingot is prepared; the temperature distribution of the extruded ingot in each direction is determined based on finite element simulation software; an induction heating system is adopted to heat the extruded ingot according to the temperature distribution; and the heated extruded ingot is immediately placed in a preheated extrusion cylinder and an extrusion die to be extruded. The high-strength magnesium alloy extruded profile has good structure property uniformity, is excellent in performance and high in product quality, and has good popularization prospects and application values.

Owner:BAOSHAN IRON & STEEL CO LTD

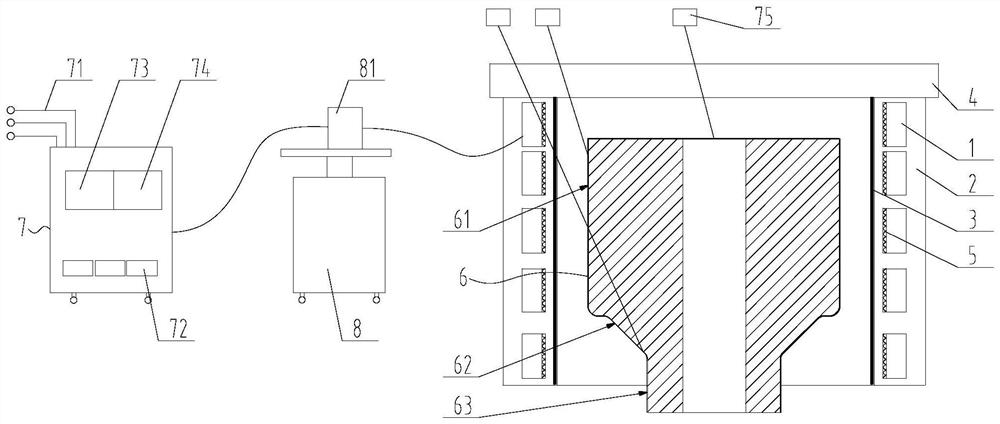

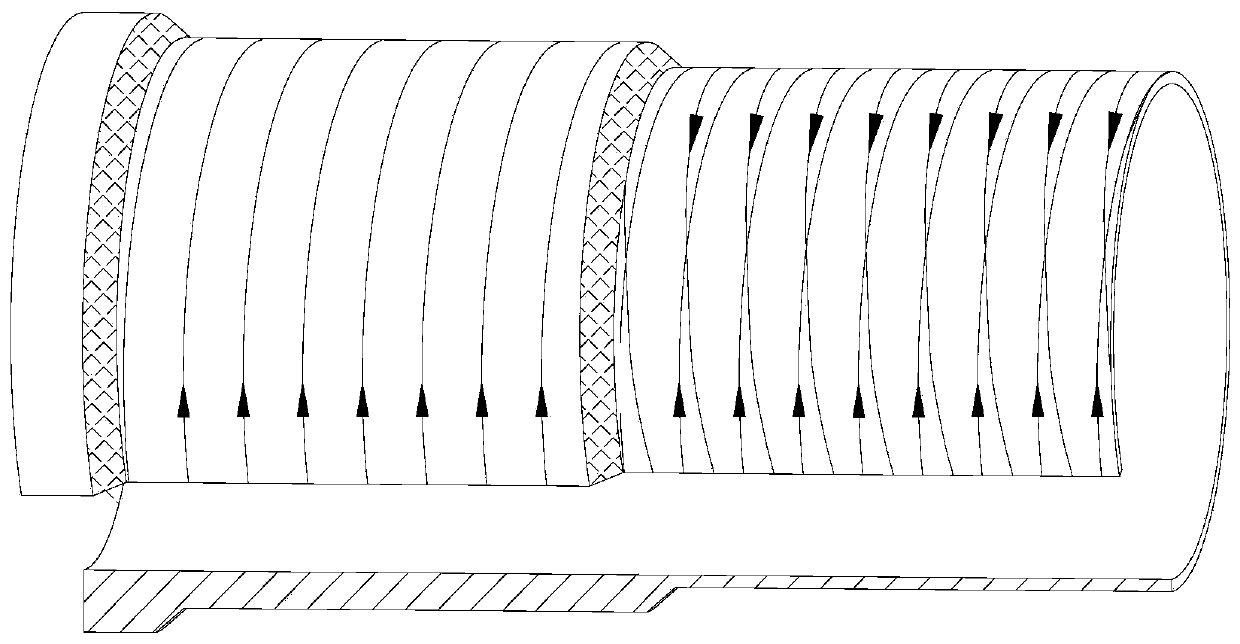

High-temperature alloy bar billet heating device and method for shaft forgings

ActiveCN112355230AImprove efficiencyShort heating timeIncreasing energy efficiencyEngine componentsThermodynamicsHeating furnace

The invention discloses a high-temperature alloy bar billet heating device and method for shaft forgings, belongs to the field of material forming and control, and aims to achieve independent controlover local structures of the forgings and improve the uniformity of overall assemblies of the forgings. The heating device comprises a heating furnace, a controller, a temperature controller, a temperature measuring galvanic couple and a variable-frequency power supply, wherein an input port of the controller is connected with the temperature measuring galvanic couple; an output port of the controller is connected with an input port of the temperature controller; an output port of the temperature controller is connected with the variable-frequency power supply; and the variable-frequency powersupply supplies power to an induction coil in the heating furnace. According to the heating method, the core surface temperature difference is controlled to be smaller than or equal to 5 DEG C, the temperature of a bar billet transition area is gradually decreased to the normal temperature from the large end to the small end, and discharging is conducted when the core temperature reaches the settemperature. According to the high-temperature alloy bar billet heating device and method for shaft forgings provided by the invention, electromagnetic induction heating is adopted, local deformationof a rod blank is controlled, the proper heating temperature is matched according to forging deformation at all positions, the heating range is accurately controlled, the local structure performance of a forging is independently controlled, and the uniformity of the overall structure performance of the forging is improved.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

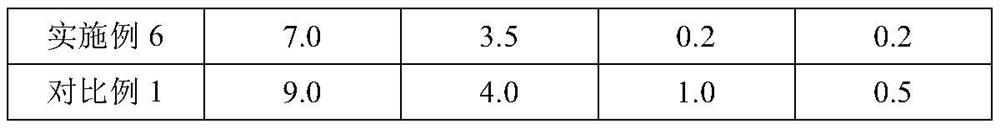

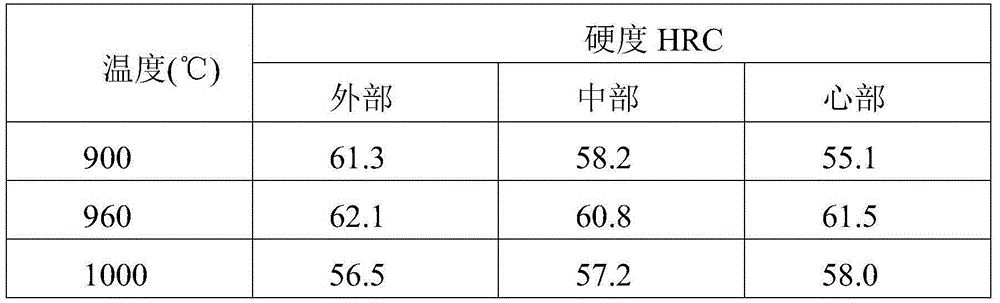

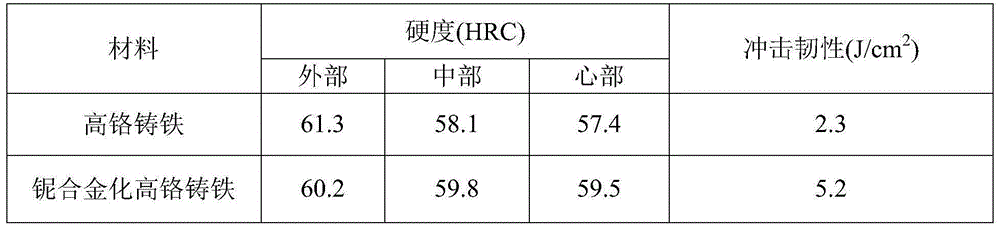

Niobium-alloying high-chromium cast iron grinding ball and production technology thereof

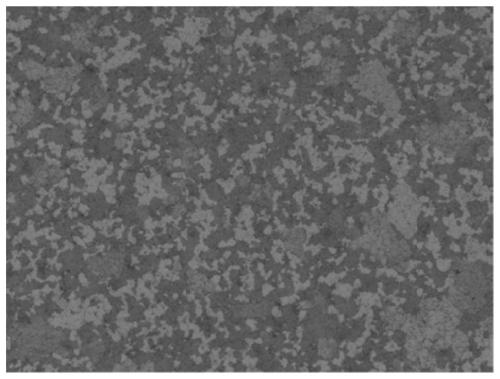

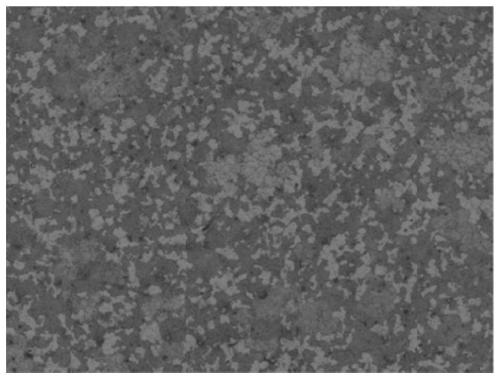

InactiveCN105177405AImprove tissue performance uniformityImprove performance uniformityFoundry mouldsFoundry coresNiobium alloyMetal mold

The invention relates to a niobium-alloying high-chromium cast iron grinding ball and a production technology thereof, and belongs to the field of new materials. The niobium-alloying high-chromium cast iron grinding ball is prepared from, by mass ratio, 2.5% to 3.0% of C, 0.3% to 0.8% of Si, 0.6% to 1.0% of Mn, smaller than 0.1% of P, smaller than 0.1% of S, 14.0% to 16.0% of Cr, 0.1% to 0.2% of Nb, 0.1% to 0.2% of RE and the balance Fe. According to the material performance, the use conditions and the problems of high-chromium white cast iron, a one-mold-multi-piece metal mold local-sand-covering grinding ball production technology is adopted, niobium alloying and rare earth modification are adopted, the structure of the high-chromium white cast iron is refined, the structural performance uniformity of the high-chromium white cast iron is improved, and the overall performance and the structural performance uniformity of the grinding ball are further improved through a semicontinuous decentralized quenching technology. Compared with a common high-chromium white cast iron grinding ball, the niobium-alloying high-chromium white cast iron grinding ball manufactured with the technology has the beneficial effects that the structure is refined, tenacity is greatly improved, and the abrasion resistance is better.

Owner:HEZE BAIHUI CASTING

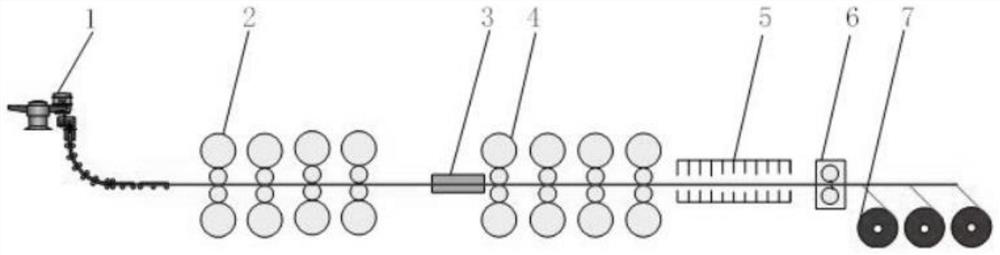

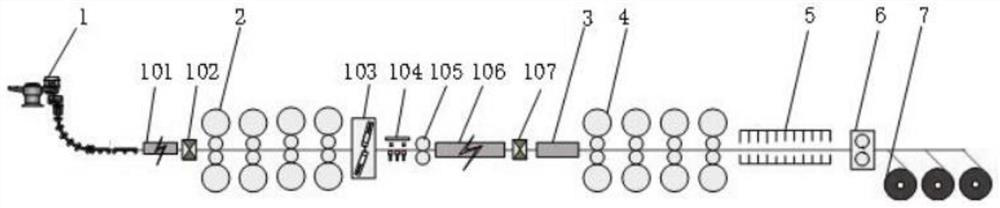

Continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystal and production method

PendingCN114273425AProlong the transition timeExtension of timeTemperature control deviceWork treatment devicesProduction lineSlow cooling

The invention belongs to the technical field of metallurgical processes and equipment, and relates to a continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystals and a control method. The invention discloses a continuous casting and rolling production line capable of avoiding ferrite rolling mixed crystals. The continuous casting and rolling production line comprises a continuous casting machine, a roughing rolling unit, an intermediate billet heat preservation device, a finishing rolling unit, an after-rolling cooling device, a high-speed flying shear and a coiling unit which are sequentially arranged along a rolling line. A rolled piece heating device, a descaling device, an accident handling device, an intermediate billet cooling device and the like can be arranged on the production line according to needs. The intermediate billet heat preservation device is arranged in front of a finishing mill group, the temperature of the intermediate billet when reaching an inlet of the intermediate billet heat preservation device is controlled to be below the ferrite phase change temperature, the heating temperature of the intermediate billet heat preservation device is controlled, the intermediate billet is subjected to heat preservation or slow cooling in the device, the austenite-ferrite phase change time is prolonged, and the production efficiency is improved. And phase change is fully carried out, mixed crystals caused by double-phase rolling are avoided, and the structure property uniformity of a ferrite rolled product is improved.

Owner:CISDI ENG CO LTD +1

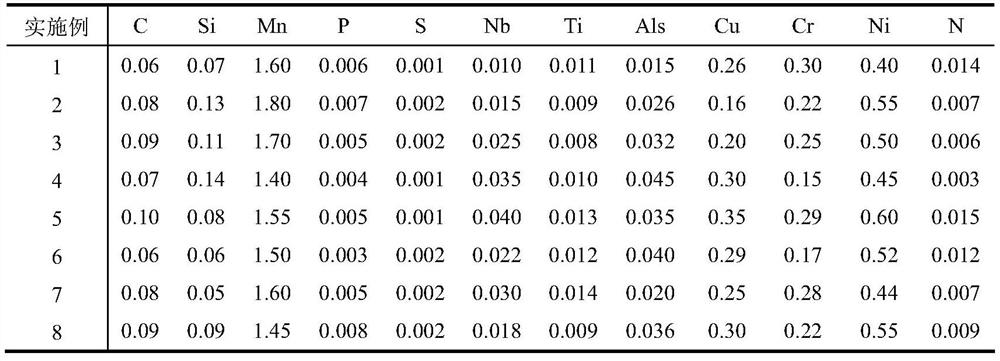

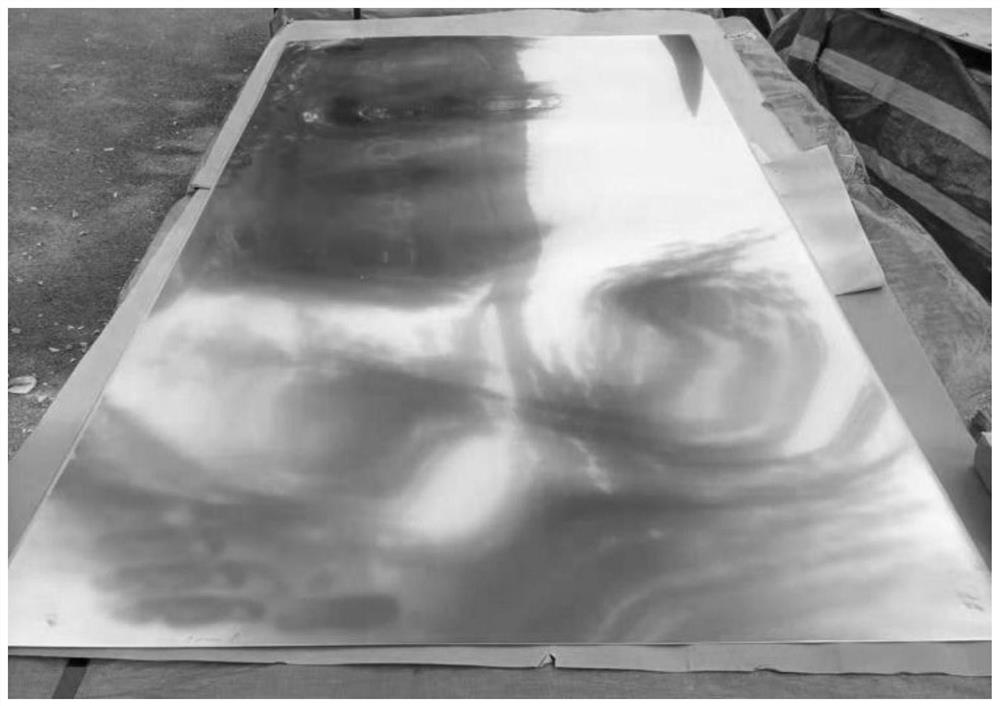

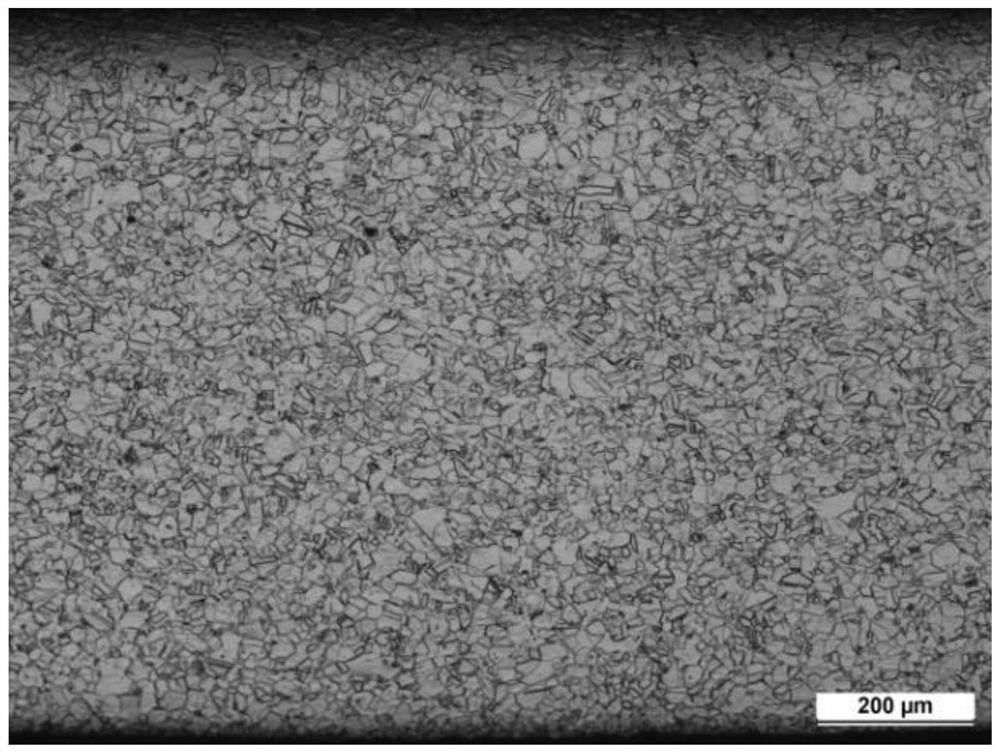

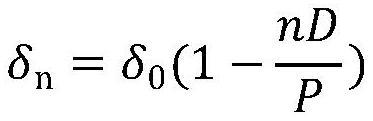

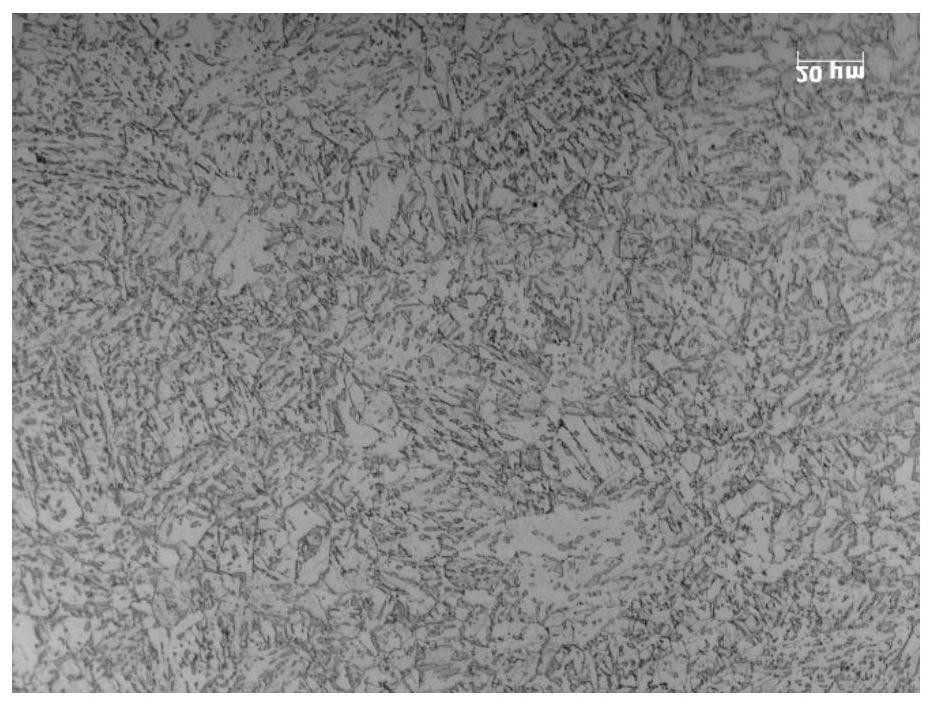

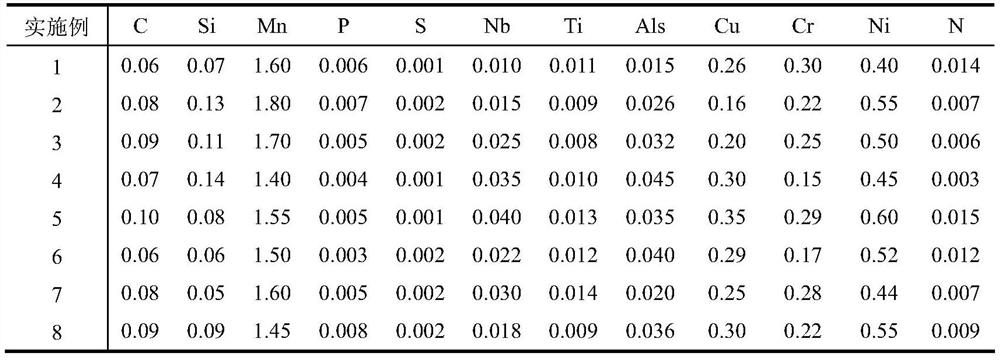

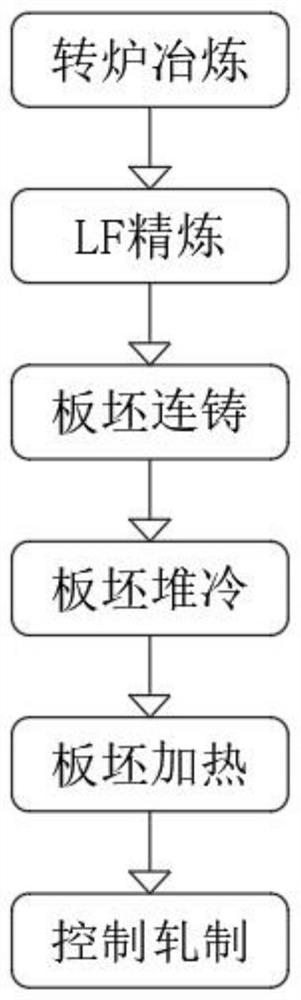

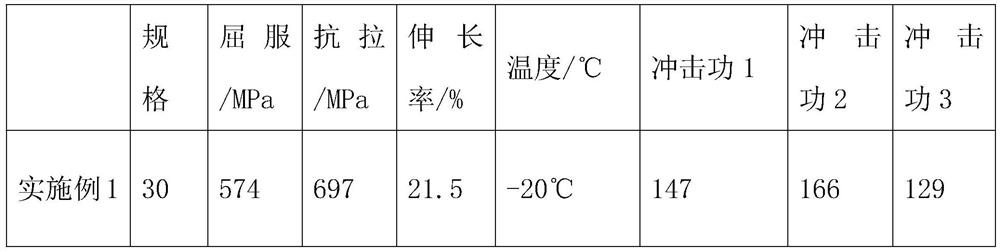

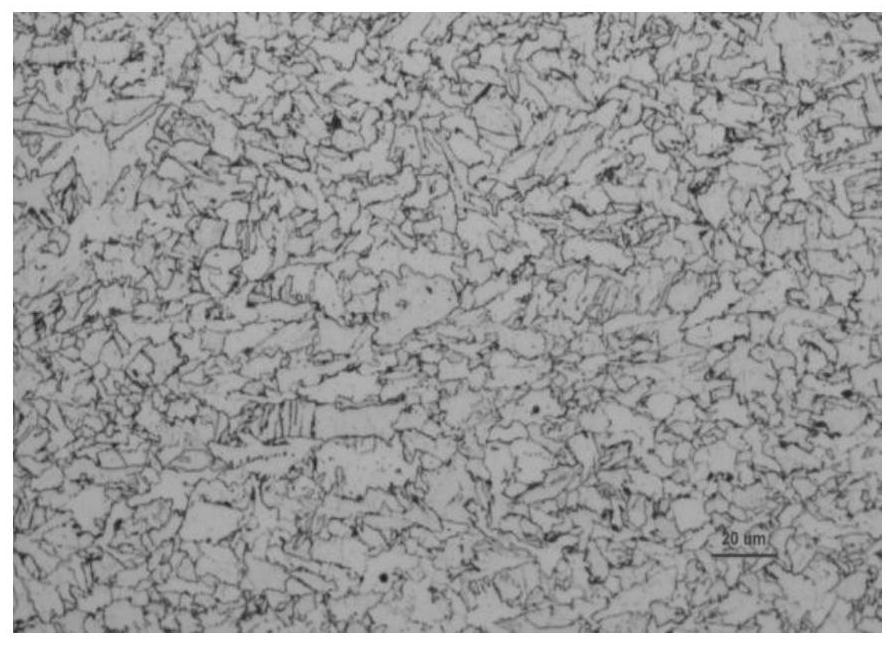

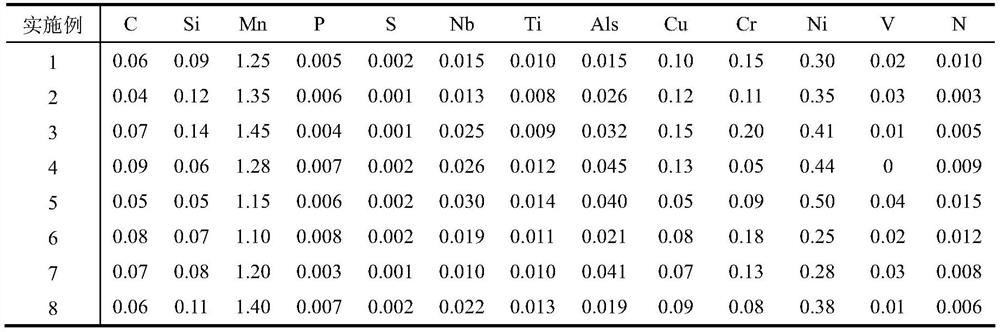

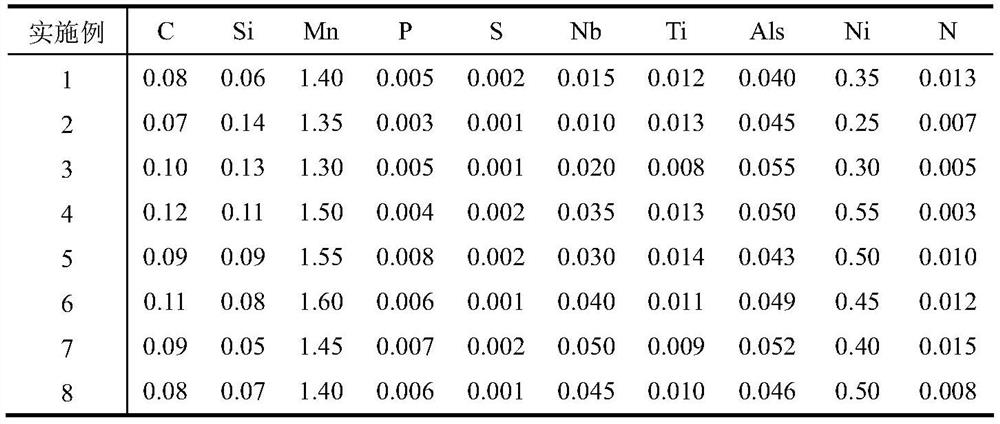

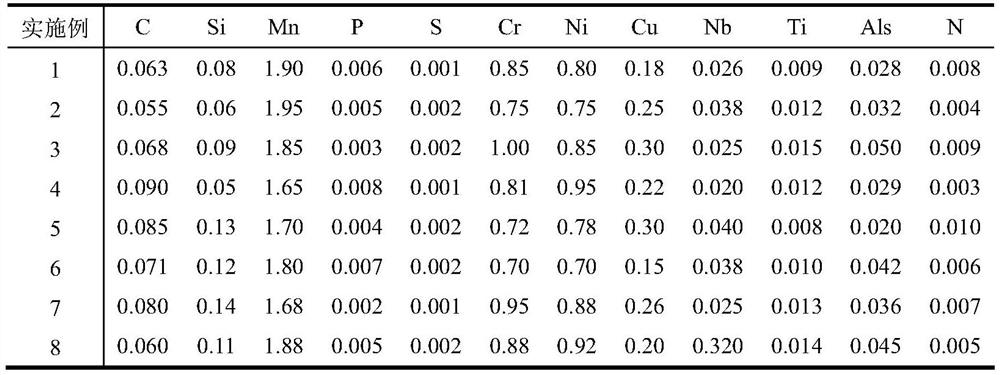

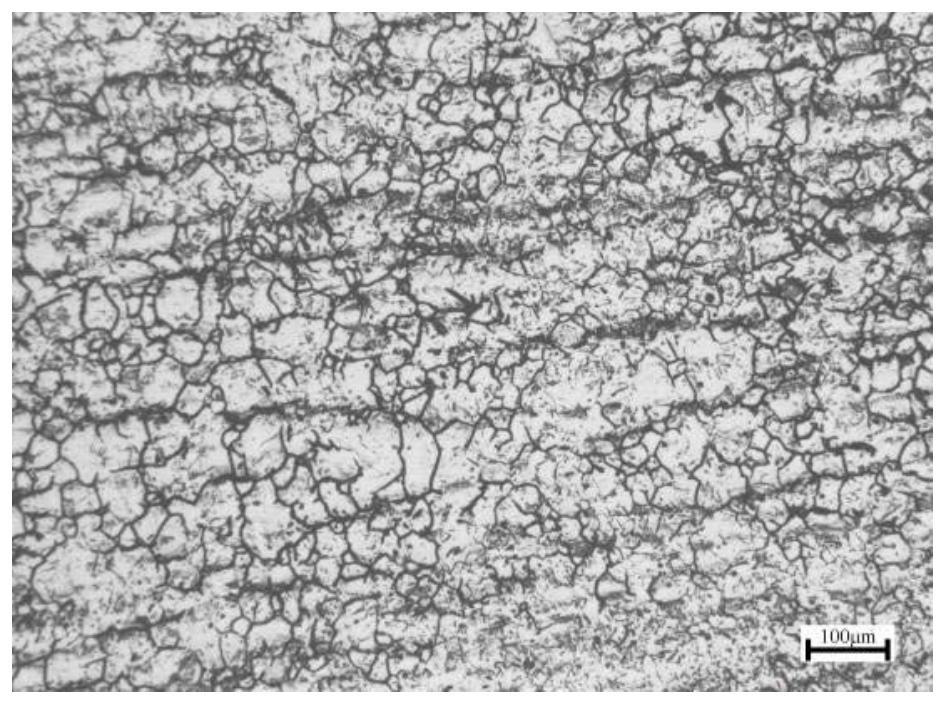

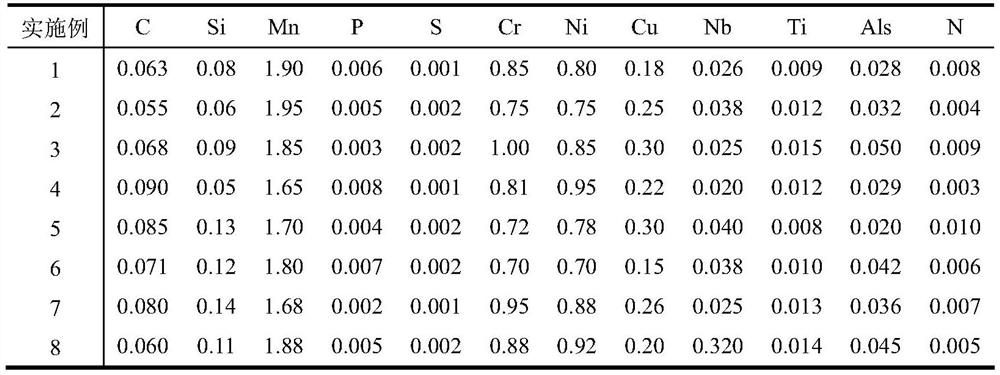

Large-thickness quenched and tempered FO460 ship steel plate and manufacturing method thereof

The invention discloses a large-thickness quenched and tempered FO460 ship steel plate and a manufacturing method of the large-thickness quenched and tempered FO460 ship steel plate. The steel plate comprises the following chemical elements in percentage by mass: C: 0.06%-0.10%; Si: 0.05%-0.14%; Mn: 1.40%-1.80%; S: less than or equal to 0.002%; P: less than or equal to 0.008%; Als: 0.015%-0.045%; N: 0.003%-0.015%; Nb: 0.01%-0.04%; Cu: 0.16%-0.35%; Ni: 0.30%-0.60%; Cr: 0.15%-0.30%; Ti: 0.008%-0.014%; and the balance of Fe and inevitable impurities. The technical requirements of the ship steel plate in severe and harsh ocean environments can be met.

Owner:ANGANG STEEL CO LTD

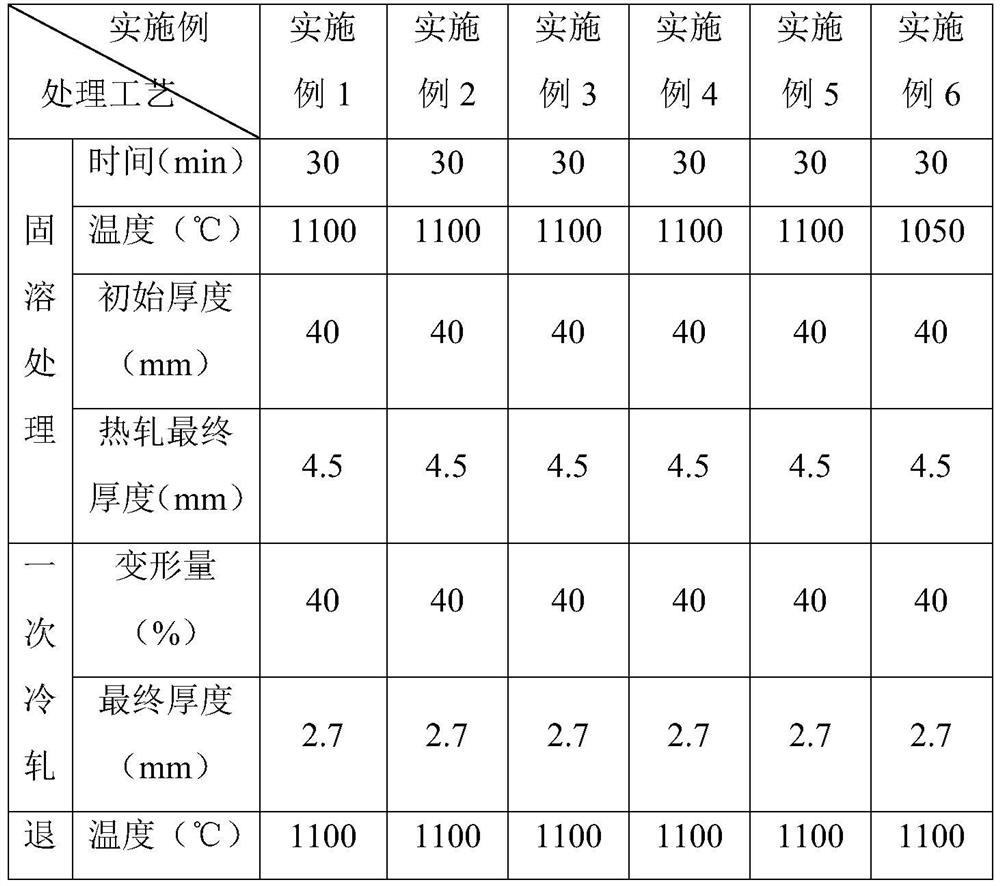

High-quality nickel-chromium-iron-based high-temperature alloy plate and preparation method thereof

ActiveCN114540730AImprove surface qualityImprove tissue performance uniformityEfficient propulsion technologiesFurnace typesSolution treatmentNichrome

The invention relates to the technical field of high-temperature alloy materials, and particularly discloses a high-quality nickel-chromium-iron-based high-temperature alloy plate and a preparation method thereof. The preparation method of the high-temperature alloy plate comprises the following steps of preparation of a plate blank, cold rolling, solution treatment of a finished product and surface treatment. Wherein cold rolling is conducted, specifically, a prepared plate blank is subjected to cold rolling, and a cold-rolled plate is obtained; solution treatment is conducted on a finished product, specifically, the cold-rolled plate is subjected to solution treatment, and the plate subjected to solution treatment is obtained; surface treatment: carrying out acid and alkali washing and surface oil grinding on the plate subjected to solution treatment to obtain a surface-treated plate; the surface oil grinding mode is single-face grinding; and controlling the total thickness reduction of the plate after surface treatment to be less than or equal to 1% of the thickness of the cold-rolled plate. The high-temperature alloy plate prepared by the preparation method provided by the invention has high thickness precision and high surface quality at the same time.

Owner:BEIJING CISRI GAONA TECH +3

A kind of ultra-high-strength tempered eh690 extra-thick steel plate and its manufacturing method

Owner:ANGANG STEEL CO LTD

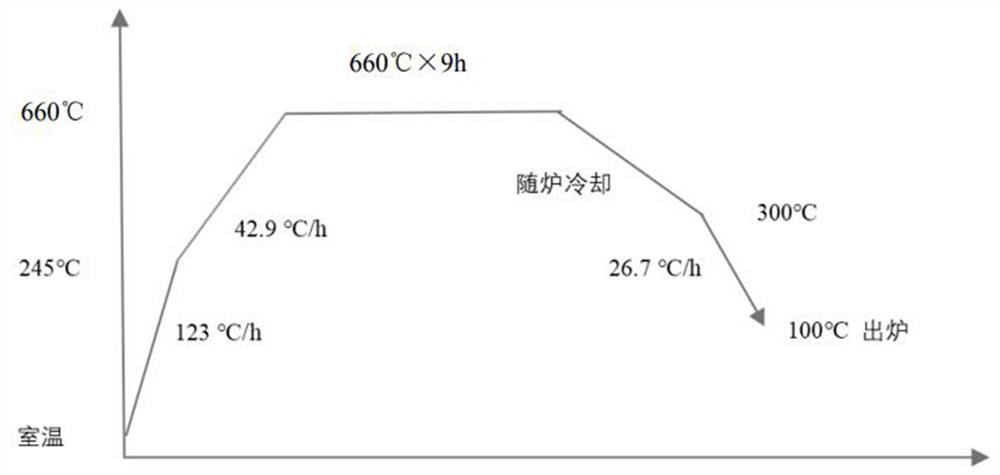

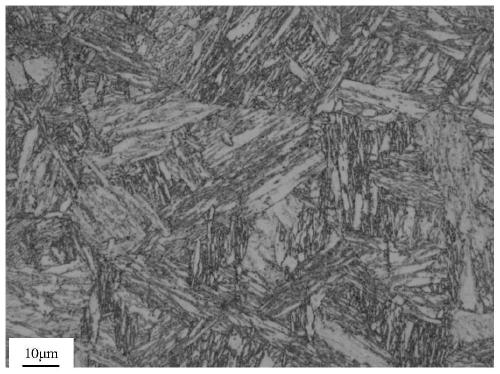

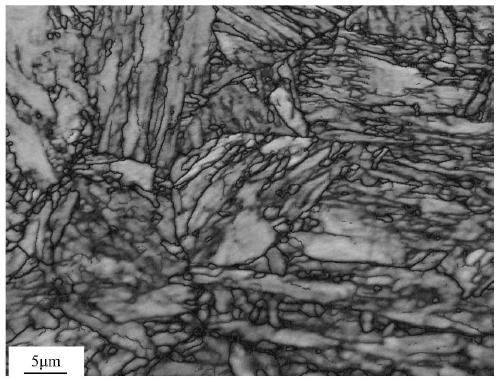

Cover annealing method for high-Cr-Si alloyed hot-formed steel

The invention belongs to the technical field of heat treatment, and particularly relates to a cover annealing method for high-Cr-Si alloyed hot-formed steel. Aiming at the problems of low yield, large performance fluctuation and the like caused by poor structure property uniformity after coiling of high-hardenability high-Cr-Si alloyed hot-formed steel, limited martensitic structure bending properties after hot forming, and unstable processes of acid pickling welding, uncoiling blanking and hot forming processes, the invention provides the cover annealing method for improving uniformity and bending properties of high-Cr-Si alloyed high-hardenability hot-rolled hot-formed steel. According to the invention, after cover annealing, structure uniformity of a hot-formed steel coil is greatly improved, internal stress is reduced, a performance difference between the head and tail of the steel coil and the coil center is reduced, uncoiling buckling is improved, and the material loss of the edge and the head and tail is reduced. In addition, in a cover annealing process, a decarburized layer with certain thickness can be generated on a surface of the steel coil containing the components provided by the invention under the reduction action of high-temperature hydrogen, so that bending properties of hot-formed steel manufactured through subsequent hot forming processing are improved.

Owner:NORTHEASTERN UNIV +1

A cross-spinning strengthening method for magnesium alloy thin-walled cylindrical parts

The invention relates to the field of cylindrical part reinforcing methods, in particular to a cross-spinning reinforcing method of a magnesium alloy thin-walled cylindrical part, and aims to solve the problem that a magnesium alloy thin-walled cylindrical part prepared by a traditional magnesium alloy spinning process is prone to generating obvious anisotropy, so that the circumferential tensilestrength of the magnesium alloy thin-walled cylindrical part is lower than the axial tensile strength of the magnesium alloy thin-walled cylindrical part. The cross-spinning reinforcing method comprises the following steps of 1, fixing a magnesium alloy blank and carrying out preheating; 2, preheating the magnesium alloy blank to a spinning temperature; 3, starting a spinning machine to carry outstrong spinning; 4, changing the rotating direction of a core shaft of the spinning machine, carrying out preheating, spraying lubricants, and carrying out next-pass strong spinning; and 5, repeatingstep 4 until the magnesium alloy thin-walled cylindrical part with the target size is obtained. The cross-spinning reinforcing method can be used for the spinning forming process of the magnesium alloy thin-walled cylindrical part, and is capable of effectively improving the circumferential mechanical property of the part formed by spinning.

Owner:HARBIN INST OF TECH

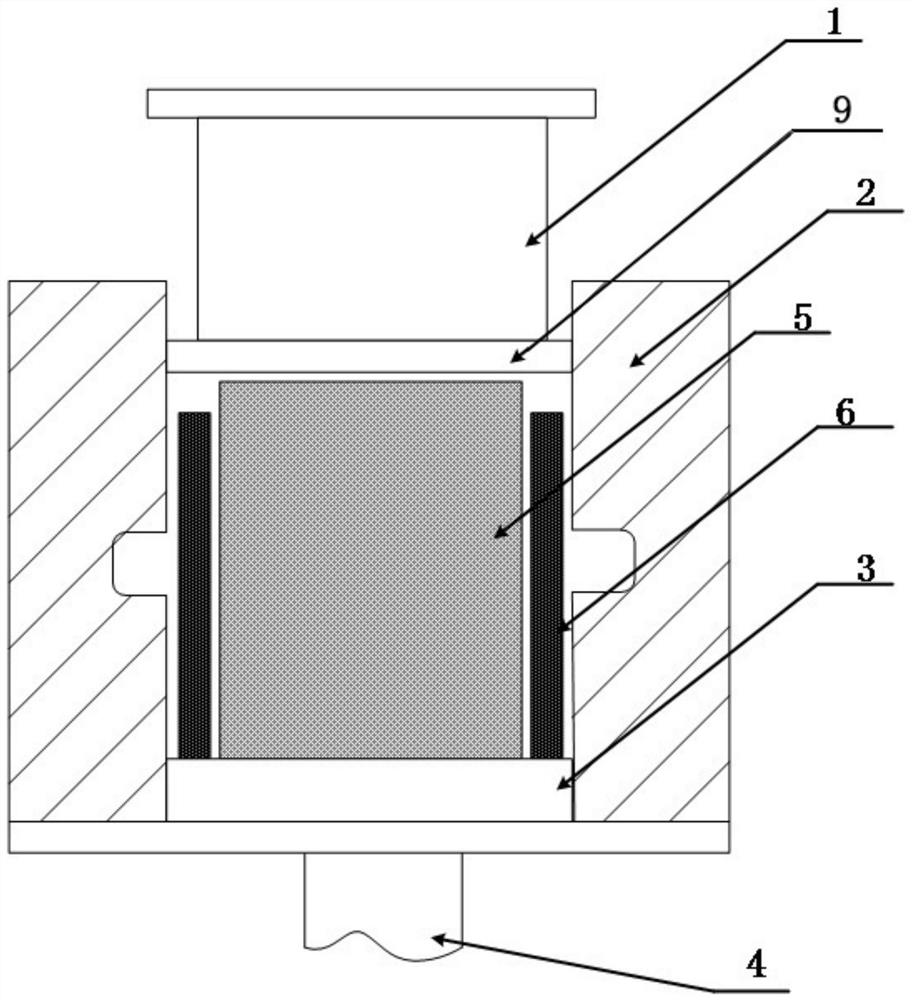

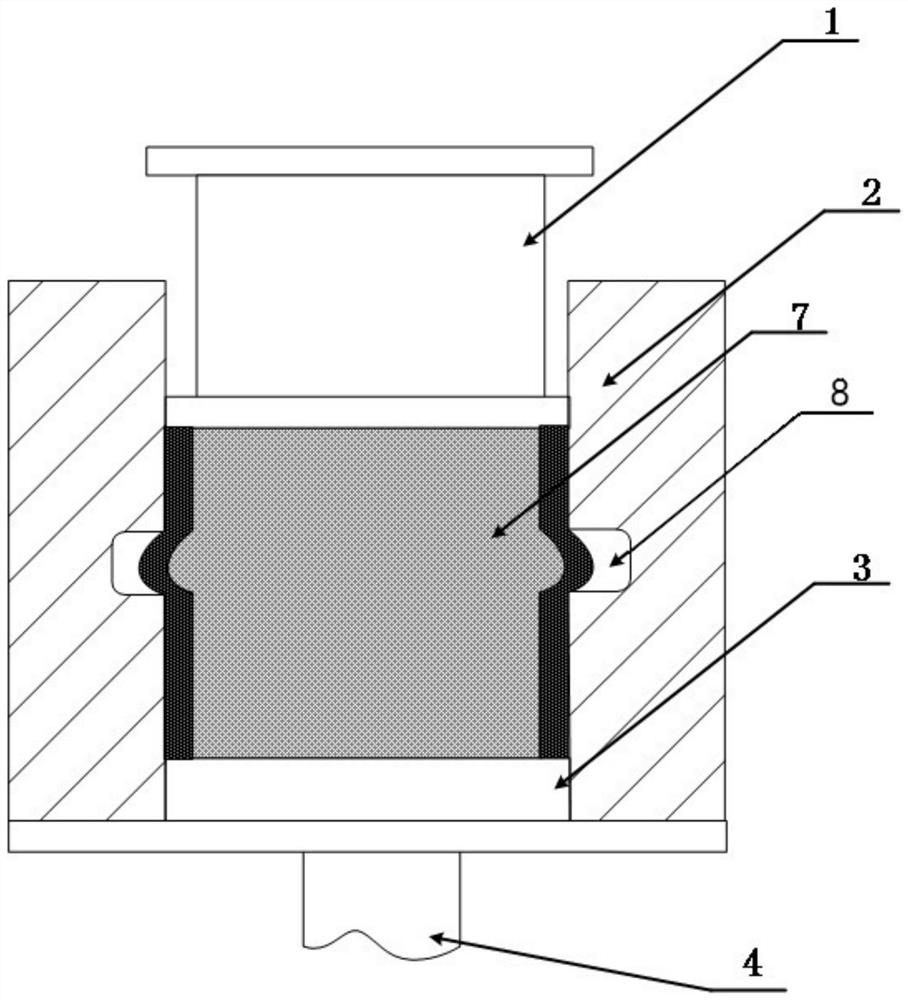

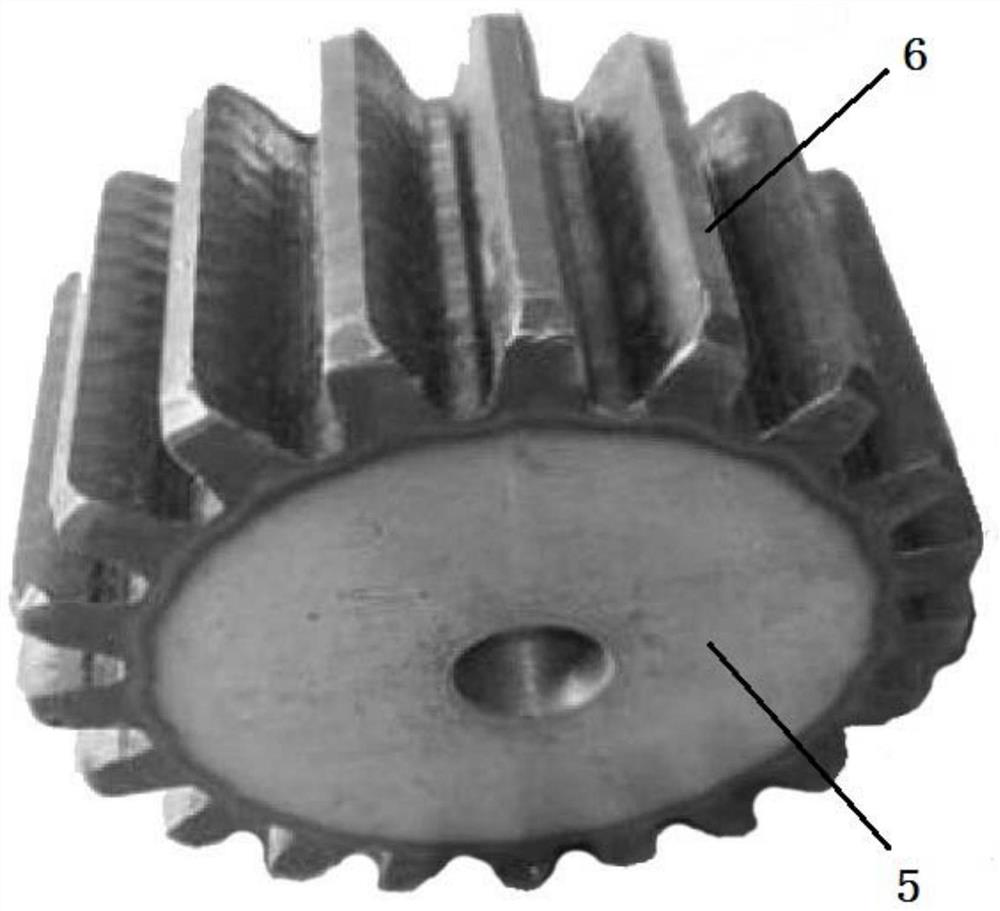

Thixotropic soft core composite forging forming method for aluminum-steel bimetal component

ActiveCN109807272BForming accuratelyGood thixotropic fluidityForging/hammering/pressing machinesSemi solidUltimate tensile strength

The invention discloses a thixotropic soft core composite forging molding method for an aluminum-steel bimetallic component. Firstly, an aluminum alloy core body and a steel sleeve of a certain size and shape are made, and the aluminum alloy core body is heated and kept in a semi-solid state. The sleeve is heated to a thermoplastic state, and the aluminum alloy core and steel sleeve are quickly introduced into the mold and assembled to complete the composite forging. Utilizing the good fluidity of the aluminum alloy in the semi-solid state, the coordinated deformation of the aluminum alloy core and the steel sleeve is realized, making the molding of the composite component more precise; in addition, using the liquid phase part in the semi-solid aluminum alloy core and the steel The set reaction forms a stable interface with high bonding strength. Realize the metallurgical combination of aluminum-steel double-metal coordinated deformation and reliable interface, and effectively integrate the high-performance advantages of steel and the lightweight advantages of aluminum alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

A large-thickness quenched and tempered FO460 marine steel plate and its manufacturing method

The invention discloses a large-thickness quenched and tempered FO460 steel sheet for ships and a manufacturing method thereof. C: 0.06% to 0.10%; Si: 0.05% to 0.14%; Mn: 1.40% to 1.80%; S: ≤ 0.002%; P : ≤0.008%; Als: 0.015%~0.045%; N: 0.003%~0.015%; Nb: 0.01%~0.04%; Cu: 0.16%~0.35%; Ni: 0.30%~0.60%; Cr: 0.15%~ 0.30%; Ti: 0.008% to 0.014%; the balance is Fe and inevitable impurities. It can meet the technical requirements of marine steel plates in harsh and harsh environments.

Owner:ANGANG STEEL CO LTD

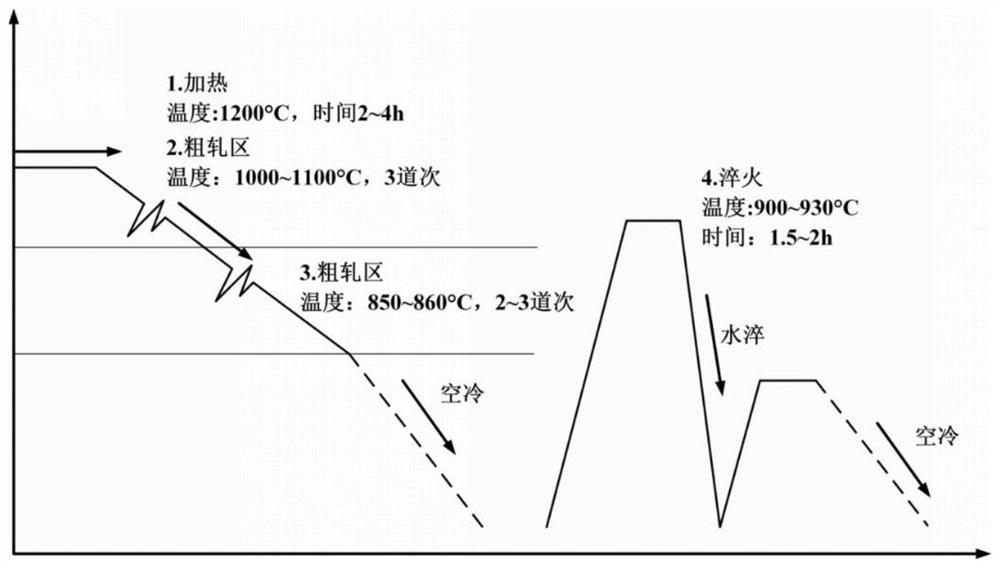

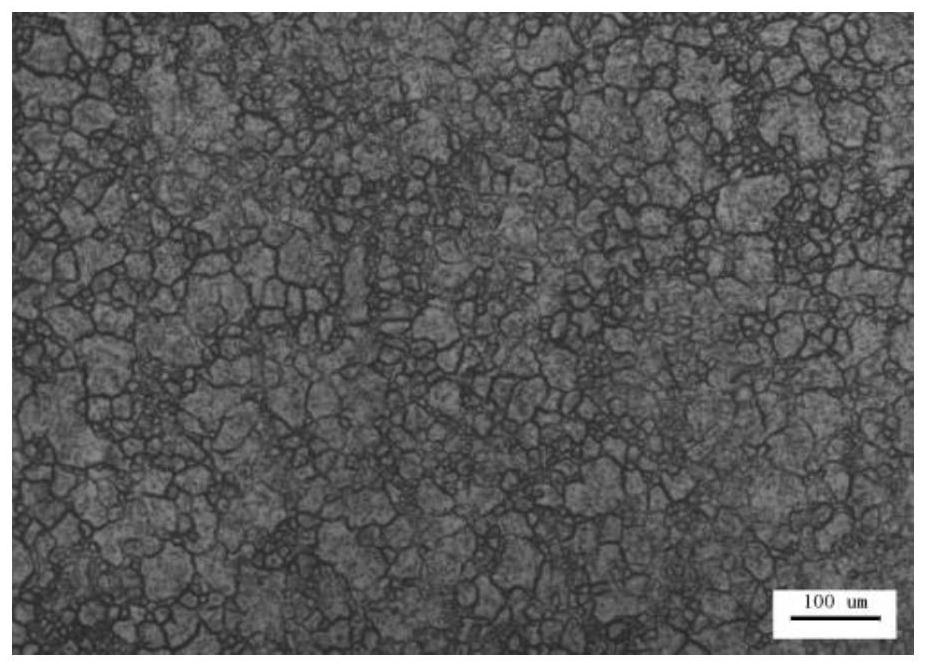

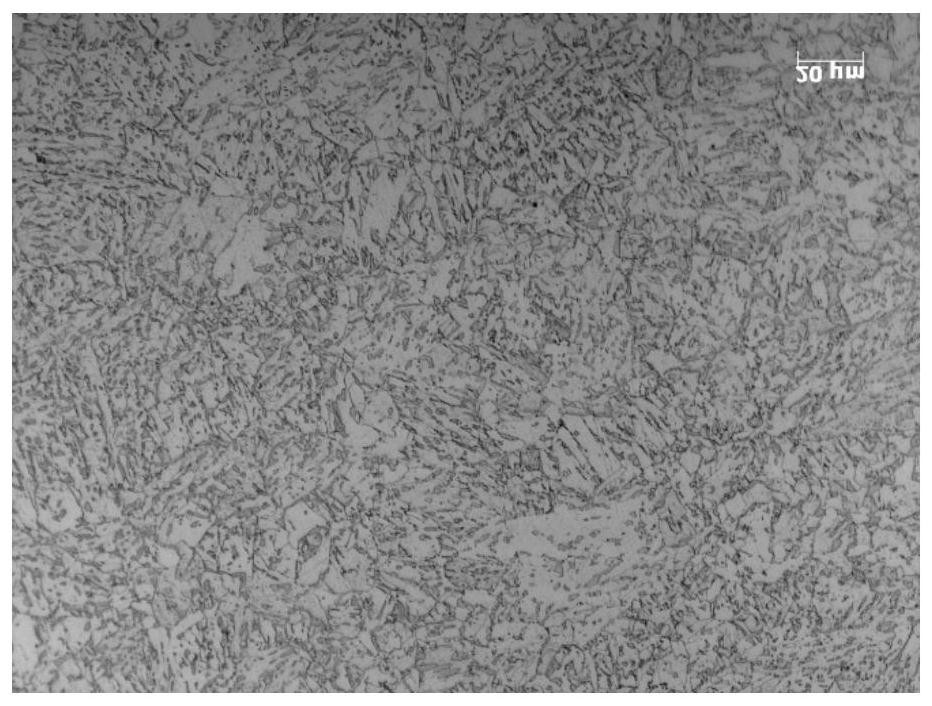

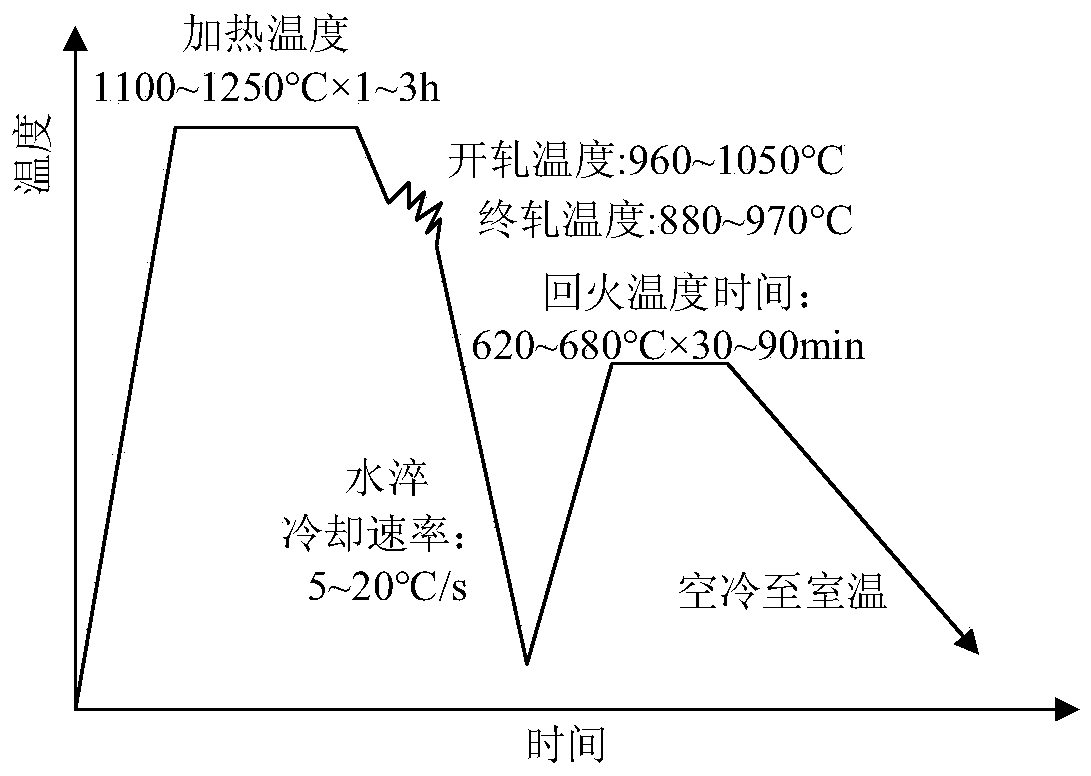

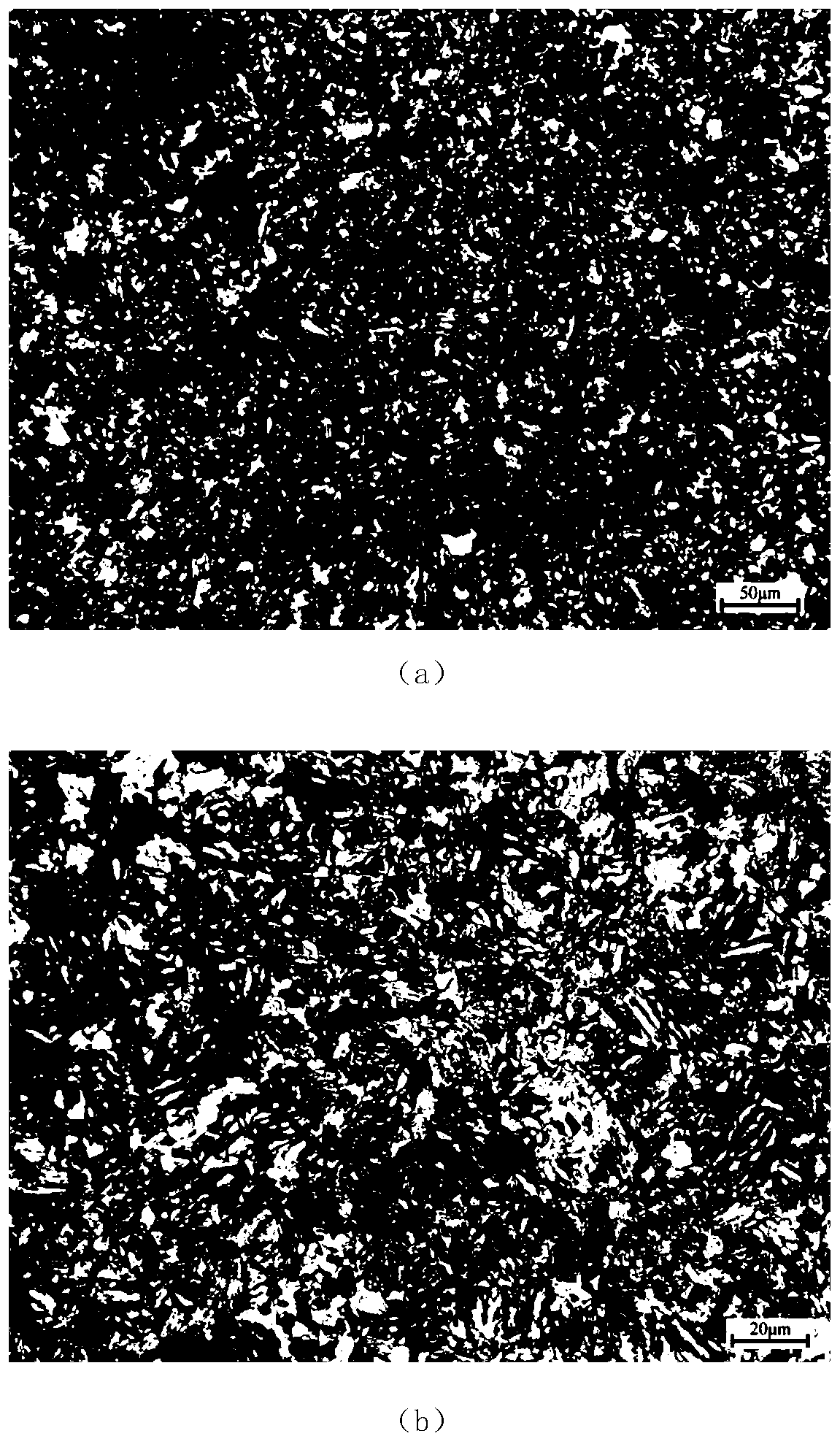

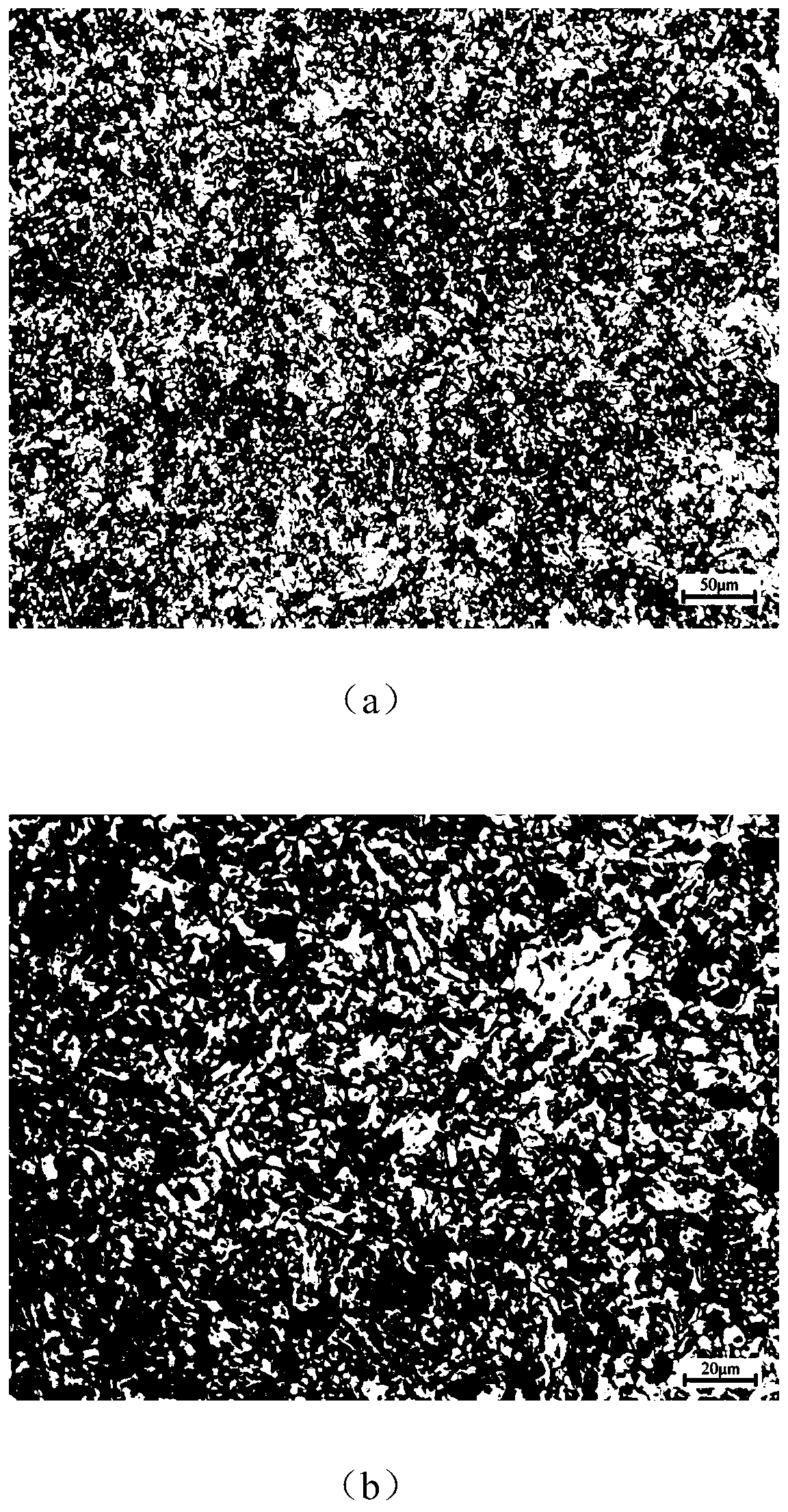

VN microalloyed steel for coal mine hydraulic support and preparation method of VN microalloyed steel

PendingCN114657346AImprove toughnessImprove tissue performance uniformityFurnace typesHeat treatment furnacesAustenite grainThick plate

The invention discloses VN microalloying steel for a coal mine hydraulic support and a preparation method thereof.The VN microalloying steel is prepared from, by mass, 0.15%-0.18% of C, 0.20%-0.40% of Si, 1.3%-1.5% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S, smaller than or equal to 0.050% of Al, smaller than or equal to 0.0120% of N, 0.015%-0.020% of Nb, 0.040%-0.060% of V and the balance Fe and unavoidable elements. Compared with a traditional process, under the condition that the original austenite grain size of an extra-thick plate is large, VN precipitates are formed in deformation-induced austenite in the rolling process, and a controlled cooling process is combined, so that the production process of the steel for the 550MPa-grade coal mine hydraulic support is achieved. And the needle-shaped ferrite structure with good obdurability is obtained, the structure property uniformity of the plate is greatly promoted, and the process route has extremely high feasibility.

Owner:ANYANG IRON & STEEL +1

820mpa class large thickness ship steel plate and its manufacturing method

ActiveCN113186460BLow costImprove purityTemperature control deviceFurnace typesMetallurgySteel plates

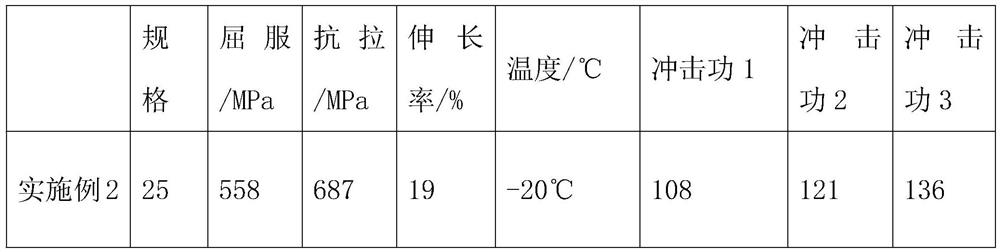

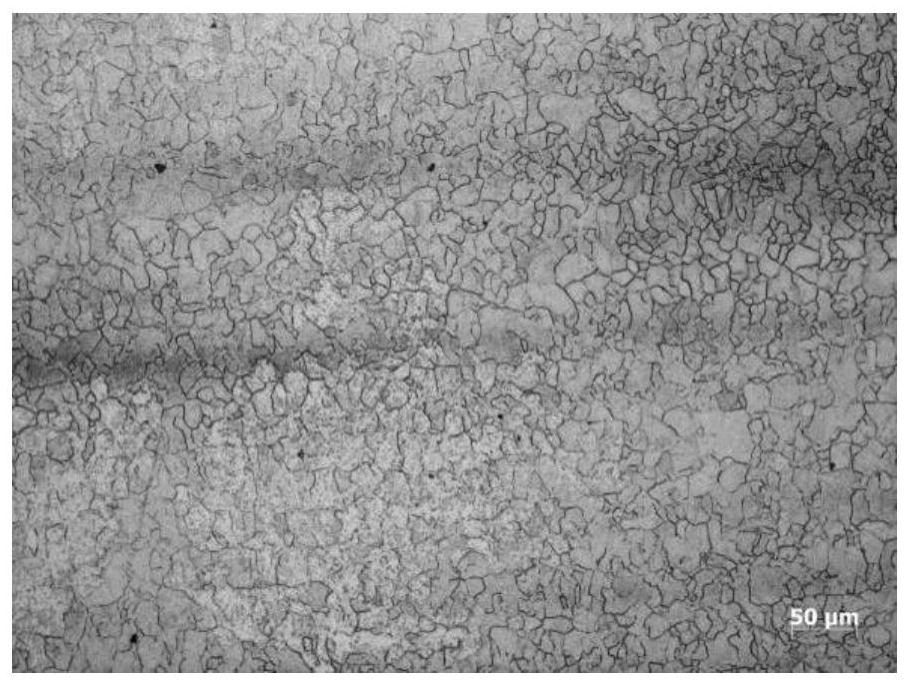

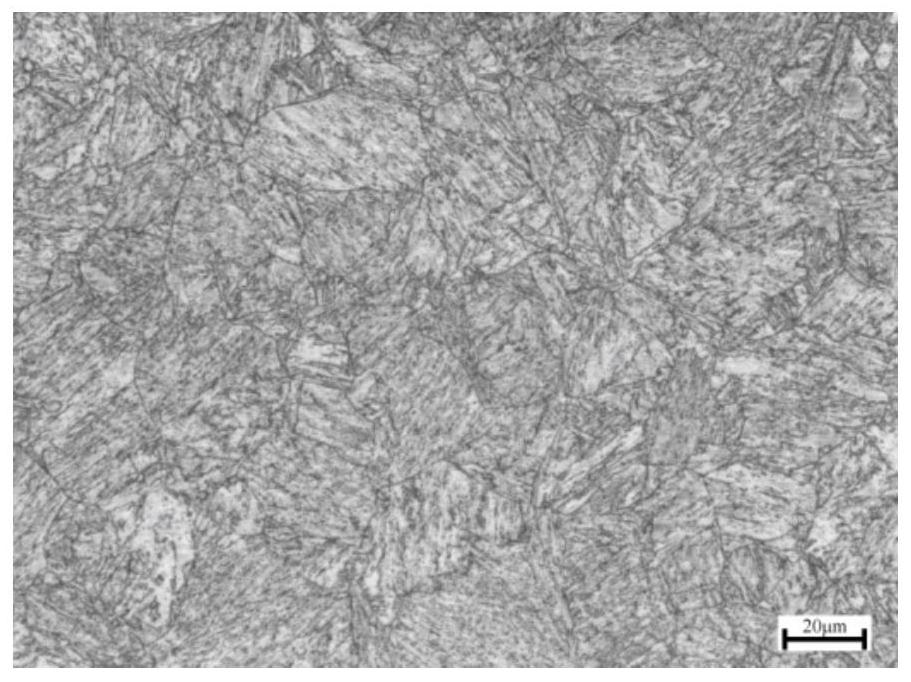

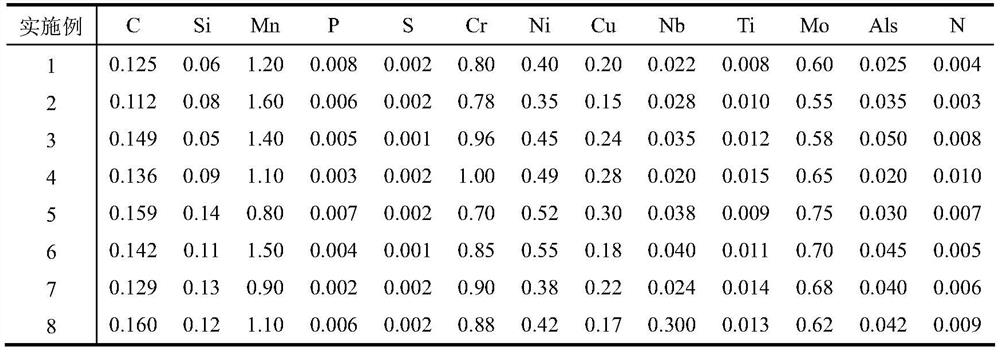

The invention discloses an 820MPa grade large-thickness ship steel plate, C: 0.11%-0.16%; Si: 0.05%-0.14%; Mn: 0.80%-1.60%; S: ≤ 0.002%; P: ≤ 0.008%; Als : 0.02% to 0.05%; N: 0.003% to 0.010%; Ni: 0.35% to 0.55%; Cr: 0.70% to 1.00%; Mo: 0.55% to 0.75%; Nb: 0.02% to 0.04%; Cu: 0.15 %~0.30%; Ti: 0.008%~0.015%; the balance is Fe and inevitable impurities, Cu / Ni≤0.9. It can meet the technical requirements of marine steel plates in harsh and harsh environments.

Owner:ANGANG STEEL CO LTD

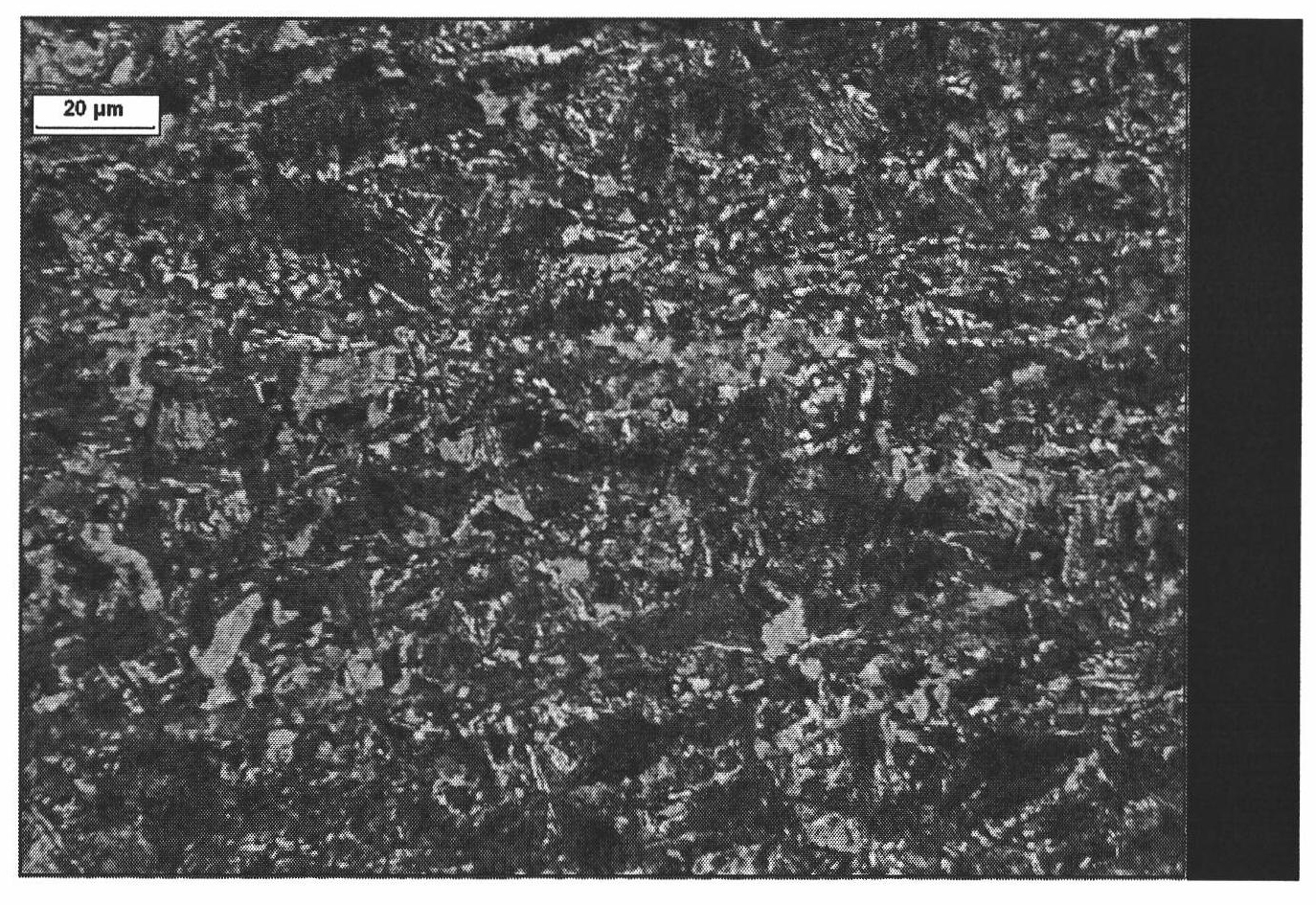

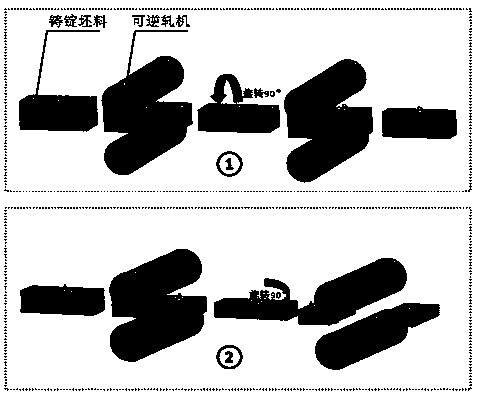

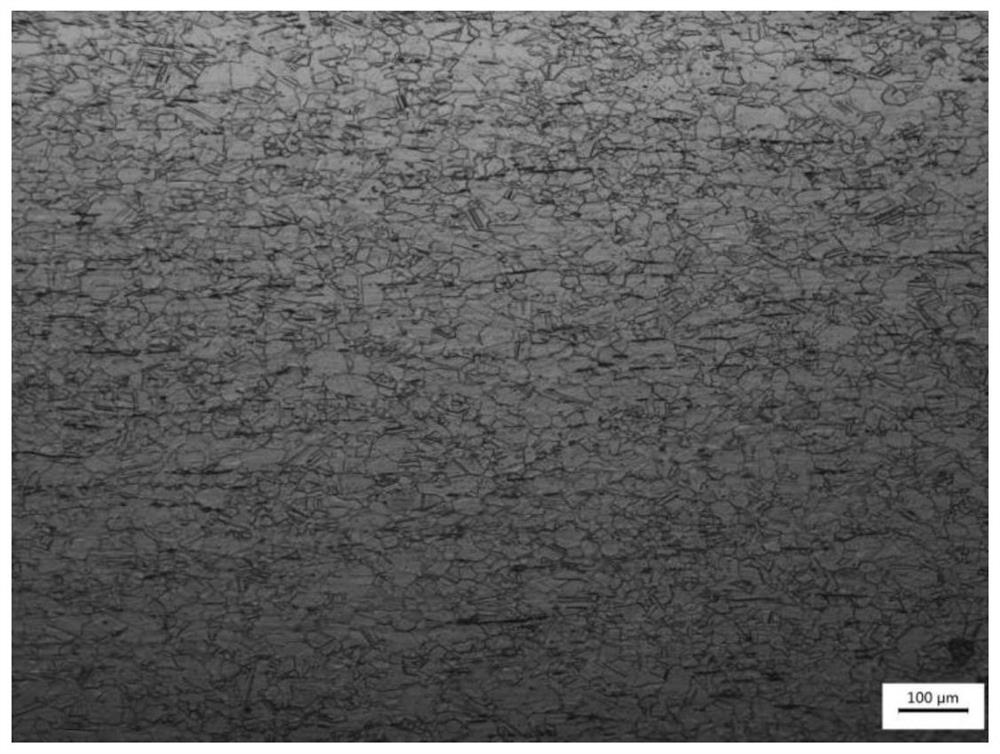

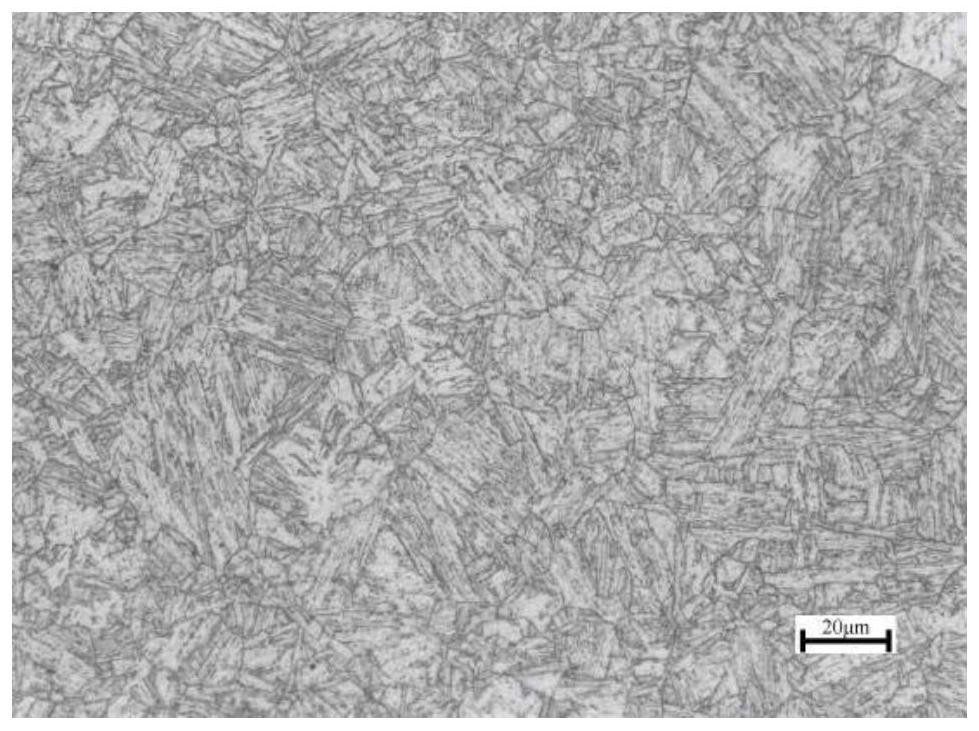

A rolling method for weakening the anisotropy of tc4 titanium alloy sheet

ActiveCN108994077BReduce anisotropyImprove qualityMetal rolling arrangementsManufacturing cost reductionTitanium alloy

The invention discloses a rolling method for weakening the anisotropy of a TC4 titanium alloy plate, and belongs to the field of plastic forming. According to the method combining multi-directional rolling and heat treatment, on one hand, the anisotropy of the TC4 titanium alloy plate can be reduced or weakened, so that the uniformity of the tissue performance is improved, and the high-quality TC4titanium alloy plate is obtained; and on the other hand, the technological process is shortened, the energy consumption is reduced, the manufacturing cost is reduced, finally the TC4 titanium alloy plate with high quality and low cost is obtained, and then the application field of the TC4 titanium alloy plate is enlarged.

Owner:重庆大江杰信锻造有限公司

Vl4-4l marine steel plate with good low temperature toughness and its manufacturing method

The invention discloses a VL4-4L steel plate for ships with good low temperature toughness and a manufacturing method thereof. C: 0.04%-0.09%; Si: 0.05%-0.14%; Mn: 1.10%-1.45%; S: ≤0.002%; P: ≤0.008%; Als: 0.015% to 0.045%; N: 0.003% to 0.015%; Nb: 0.01% to 0.03%; Cu: 0.05% to 0.15%; Cr: 0.05% to 0.20%; Ni: 0.25% ~0.50%; V: 0%~0.04%; Ti: 0.008%~0.014%; the balance is Fe and inevitable impurities. It can meet the technical requirements of marine steel plates in harsh and harsh environments.

Owner:ANGANG STEEL CO LTD

A kind of gh4282 nickel-based superalloy bar and its preparation method

ActiveCN111118423BUniform fine grain structureImprove tissue performance uniformityTemperingIngot casting

The invention discloses a GH4282 nickel-based high-temperature alloy bar and a preparation method thereof, and solves the technical problems of coarse grain size and poor uniformity of an existing GH4282 alloy bar. The preparation method comprises the following steps: S1, heating a GH4282 nickel-based high-temperature alloy ingot casting; S2, carrying out primary upsetting and tempering on the ingot casting in the axial direction to obtain a blank, and carrying out primary hot drawing and tempering on the blank in the direction perpendicular to the axial direction; S3, carrying out secondary upsetting and tempering on the blank in the axial direction, and then carrying out secondary hot drawing and tempering in the direction perpendicular to the axial direction; S4, carrying out three-timeupsetting and tempering on the blank in the axial direction, and then carrying out three-time drawing and tempering in the direction perpendicular to the axial direction to obtain a bar blank; and S5, tempering the bar blank in the step S4, and then performing one-fire-diameter forging forming to obtain the GH4282 nickel-based high-temperature alloy bar. The invention further discloses the GH4282nickel-based high-temperature alloy bar prepared by the method. The GH4282 nickel-based high-temperature alloy bar has the advantage that the structure uniformity of the GH4282 nickel-based high-temperature alloy bar can be effectively improved, so that the performance of the GH4282 nickel-based high-temperature alloy bar is improved.

Owner:BEIJING CISRI GAONA TECH +1

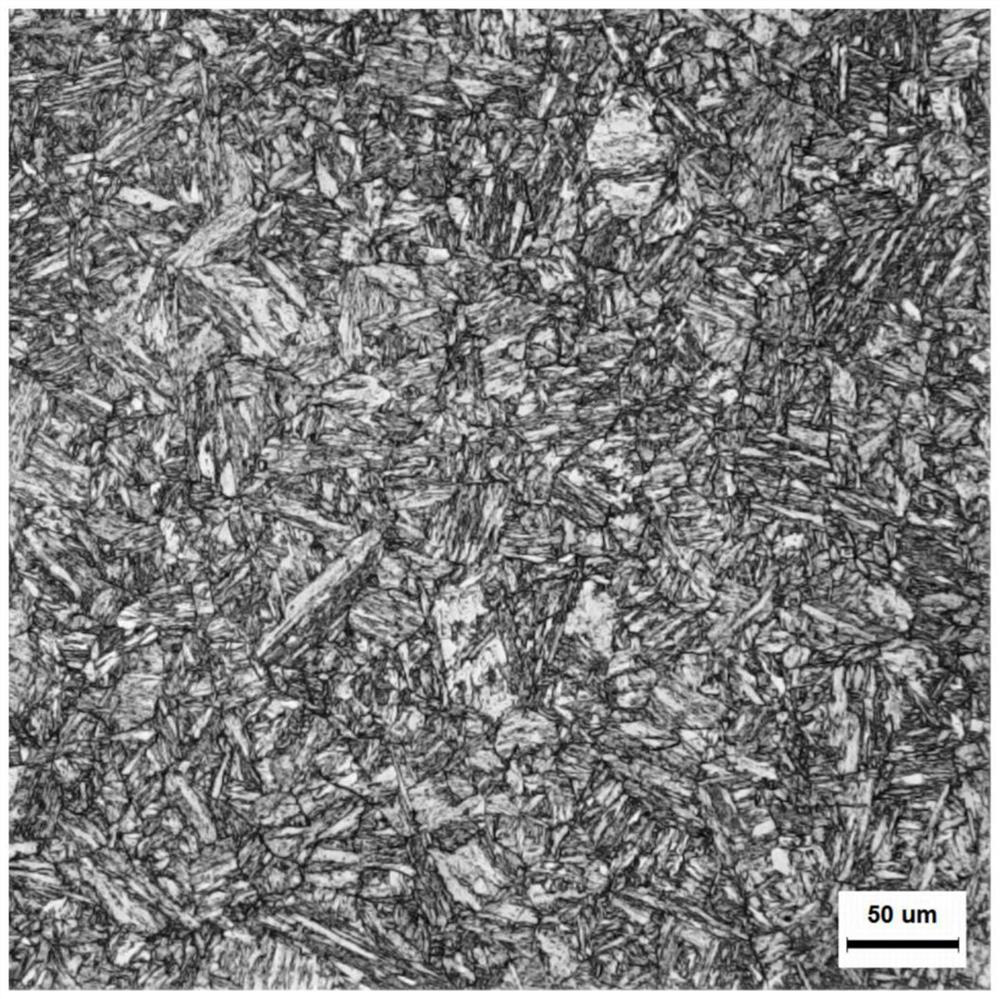

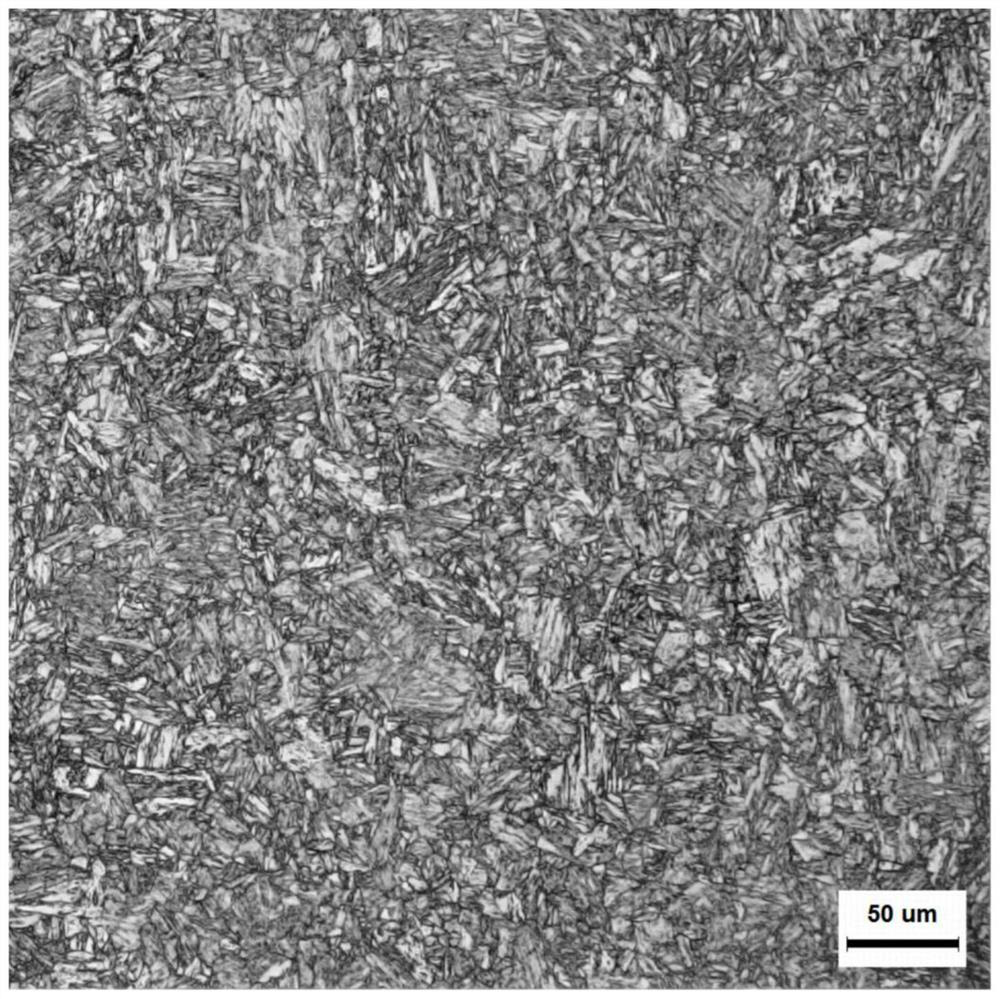

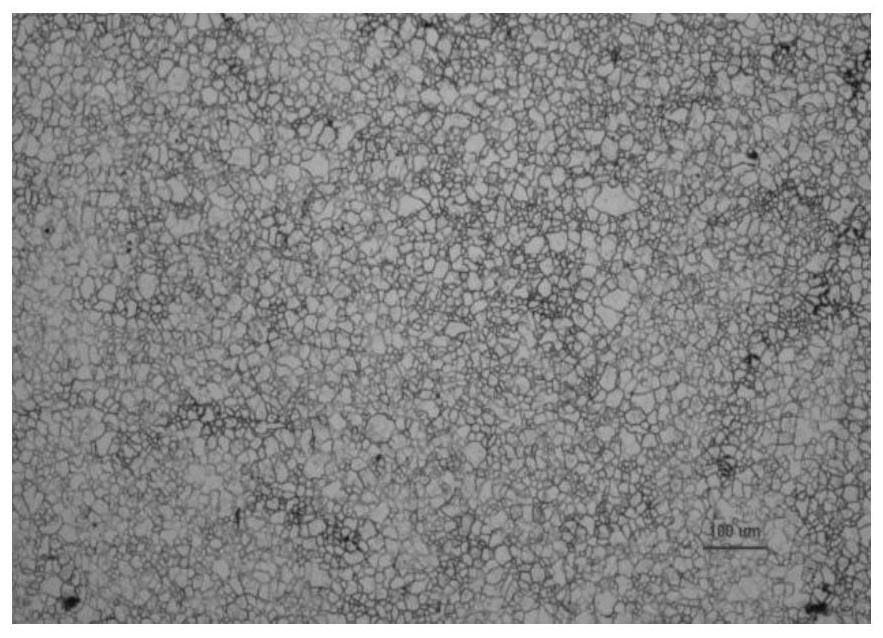

Ti microalloyed medium manganese steel plate for offshore platform and preparation method thereof

A Ti microalloyed medium manganese steel medium plate for marine platforms and a preparation method thereof, which is characterized in that its chemical composition in weight percentage is: C: 0.03~0.1%, Mn: 4.0~8.0%, Ti: 0.02~ 0.10%, Si: 0.10~0.40%, S: <0.005%, P: <0.005%, Al: 0.02~0.05%, Cr: 0.10~0.40%, Ni: 0.10~0.30%, Mo: 0.10~0.40%, Cu: 0.10~0.30%, the rest is Fe and other unavoidable impurities; preparation method: 1) Forge the Ti micro-alloyed medium-manganese steel medium-thick plate alloy ingot for the offshore platform into a billet, heat it with the furnace and keep it warm, to obtain The heated billet; 2) perform multi-pass hot rolling on the heated billet to obtain a hot-rolled plate and then quench it; 3) place the quenched medium-thick plate into a furnace for heating and insulation, and air-cool to room temperature to obtain the medium-thick plate. The structure of manganese steel medium-thick plate is a dual-phase structure of tempered martensite and fine reverse-transformed austenite.

Owner:NORTHEASTERN UNIV LIAONING

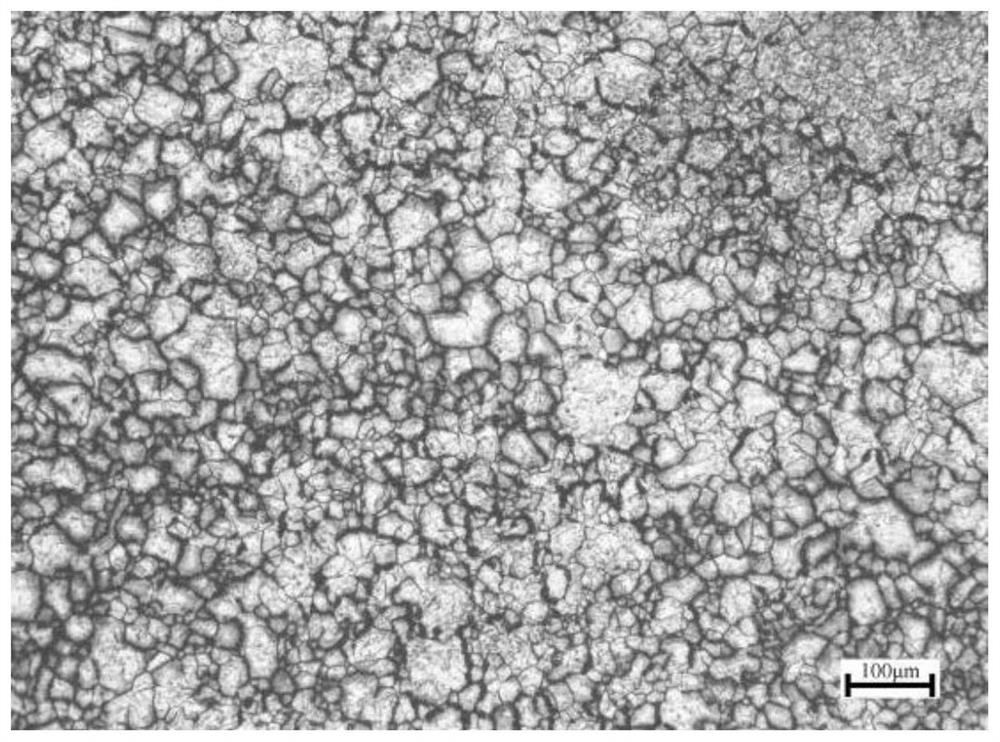

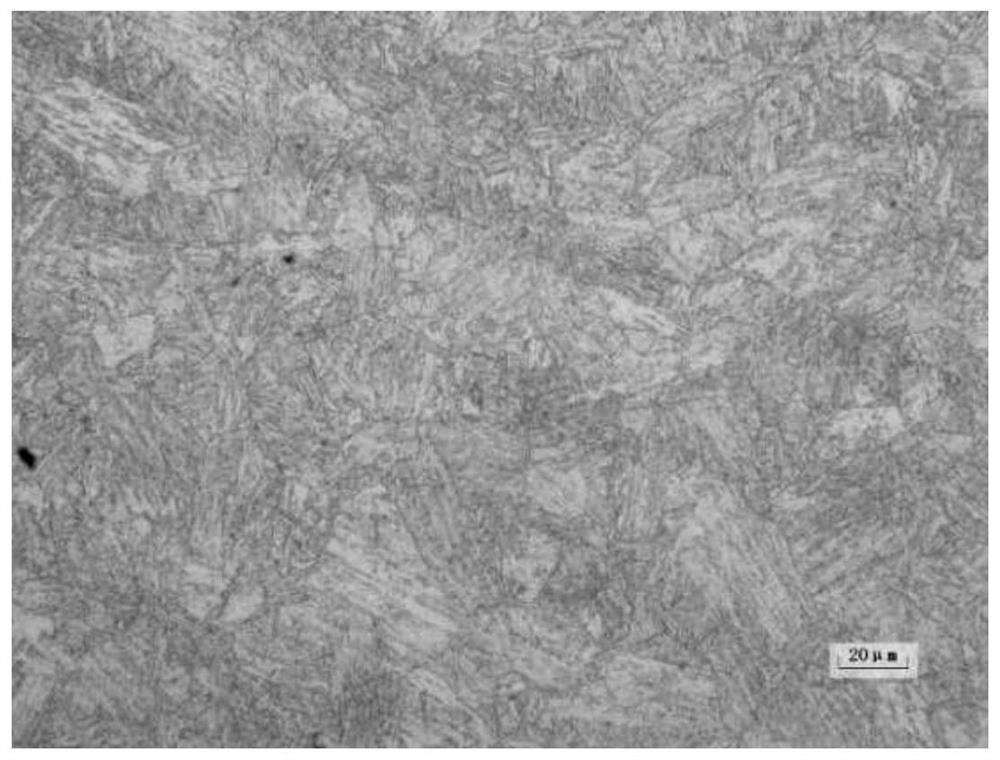

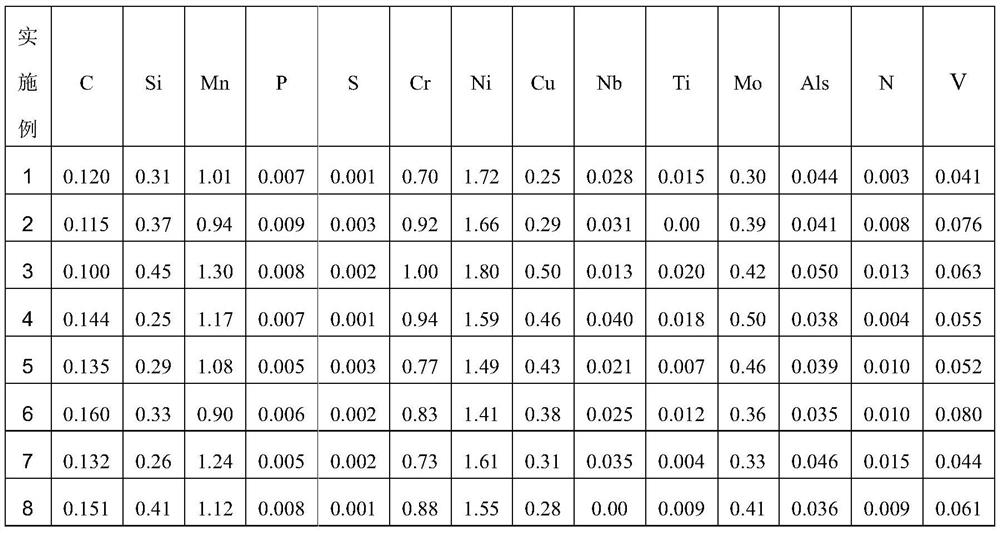

Quenched and tempered eh550 extra-thick steel plate for marine engineering and its manufacturing method

The invention discloses a modified EH550 super-thick steel plate for marine engineering and a manufacturing method thereof. The steel contains 0.08% to 0.15% of C, 0.20% to 0.55% of Si, 0.80% to 1.35%of Mn, less than or equal to 0.01% of P, less than or equal to 0.03% of S, 0.04% to 0.08% of V, 0.015% to 0.45% of Als, 0.003-0.015% of N, 0.50-0.90% of Ni, 0.20-0.40% of Cr, 0.002-0.03% of Mo, 0.02%to 0.05% of Nb, 0.20-0.40% of Cu, less than or equal to 0.04% of Ti, and the balance of Fe and unavoidable impurities. The method employs two-stage controlled rolling, the first-stage rolling temperature is 1100-1150 DEG C, the one-stage finishing rolling temperature is 990-1130 DEG C, the second-stage rolling temperature is 700-780 DEG C, and the final rolling temperature is 680-750 DEG C. The heat treatment method of quenching before sub-quenching is used, and after quenching, the steel plate is tempered, and the steel plate having a thickness of 80-100 mm is obtained. The impact toughnessof a core is more than 200J, and the comprehensive performance is uniform at different positions.

Owner:ANGANG STEEL CO LTD

A high-strength, high-elasticity, high-plasticity nickel-based superalloy strip and its preparation process

ActiveCN112813369BImprove tissue performance uniformityImprove surface qualityContinuous annealingSuperalloy

The application relates to the technical field of nickel-based superalloy preparation technology, and specifically discloses a high-strength, high-elasticity and high-plasticity nickel-based superalloy strip and its preparation technology. The preparation process includes the following steps: preparing a strip; primary cold rolling: performing a cold rolling on the strip; water-cooling annealing: performing water-cooling annealing on the strip after the primary cold rolling; Secondary cold rolling; continuous annealing: the strip after secondary cold rolling is subjected to continuous annealing treatment; three times cold rolling: the strip after continuous annealing is subjected to three cold rolling to obtain finished strip. The nickel-based superalloy strip produced by the preparation process of this application has excellent grain size, good matching of the number of γ′ strengthening phases, good uniform structure and performance, and has both high strength and high plasticity; the preparation process is simple and has significant promotion Value.

Owner:BEIJING CISRI GAONA TECH +1

A kind of large thickness FH40 shipbuilding steel plate and its manufacturing method

ActiveCN113174537BLow costImprove purityRoll force/gap control deviceTemperature control deviceMetallurgyMaterials science

The invention discloses a large-thickness FH40 shipbuilding steel plate with excellent aging impact toughness and a manufacturing method thereof. C: 0.07%~0.12%; Si: 0.05%~0.14%; Mn: 1.30%~1.60%; S: ≤0.002%; P: ≤0.008%; Als: 0.040%~0.055%; N: 0.003%~0.015 %; Nb: 0.01% to 0.05%; Ni: 0.25% to 0.55%; Ti: 0.008% to 0.014%; the balance is Fe and inevitable impurities. It can meet the technical requirements of marine steel plates in harsh and harsh environments.

Owner:ANGANG STEEL CO LTD

Extrusion process of in-situ nanoparticle-reinforced aluminum matrix composites for vehicle body

ActiveCN108796404BImprove tissue performance uniformityImprove strong plasticityThermal dilatationMULTIPLE DISLOCATIONS

The invention relates to the field of aluminum base composite material processing, in particular to an extrusion process for a vehicle body in-situ nanoparticles enhancing aluminum base composite material. The vehicle body in-situ nanoparticles enhancing aluminum base composite material synthesized in situ under the outer field control is used as a research object, the casting defects such as holes and loosening are eliminated by adopting the hot extrusion plasticity, so that the texture is refined and dense, the extruded grains are uniform and small, and the mechanical properties are obviously improved; meanwhile, under the action of the extrusion pressure, the agglomeration particles are dispersed and dispersed in a matrix, the bonding force with the matrix is higher, a lot of dislocation is generated, a high-density dislocation mesh is formed, and dislocation enhancement is produced accordingly. The T4P+ artificial aging heat treatment of the follow-up extrusion material can eliminate the thermal residual stress caused by the different thermal expansion coefficients of nanoparticles and matrix in the process of the hot extrusion, the plasticity of the vehicle body extrusion material is further improved, and the vehicle body in-situ nanoparticles enhancing aluminum base composite material extrusion material which can replace the steel plate is obtained.

Owner:JIANGSU UNIV

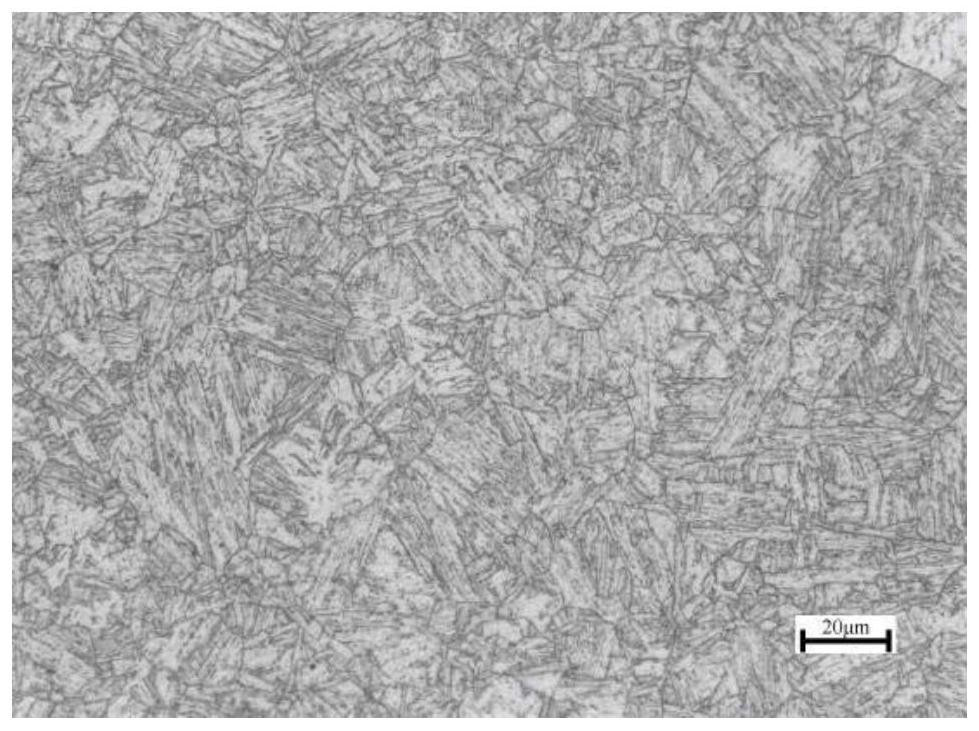

720MPa-grade large-thickness ship steel plate and manufacturing method thereof

The invention discloses a 720MPa-grade large-thickness ship steel plate. The 720MPa-grade large-thickness ship steel plate is manufactured from the following chemical components in percentage by mass: 0.055% to 0.09% of C, 0.05% to 0.14% of Si, 1.65% to 1.95% of Mn, less than or equal to 0.002% of S, less than or equal to 0.008% of P, 0.02% to 0.05% of Als, 0.003% to 0.010% of N, 0.70% to 0.95% of Ni, 0.70% to 1.00% of Cr, 0.02% to 0.04% of Nb, 0.15% to 0.30% of Cu, 0.008% to 0.015% of Ti, and the balance of Fe and inevitable impurities. The technical requirements of severe and harsh ocean environments on a marine steel plate can be met.

Owner:ANGANG STEEL CO LTD

720mpa class large thickness ship steel plate and its manufacturing method

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com