A kind of gh4282 nickel-based superalloy bar and its preparation method

A nickel-based superalloy, GH4282 technology, applied in the field of metal materials, can solve the problems of restricting product quality, coarse grains, poor uniformity, etc., and achieve the effect of improving the uniformity of structure and properties, the uniformity of grain structure, and the avoidance of coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

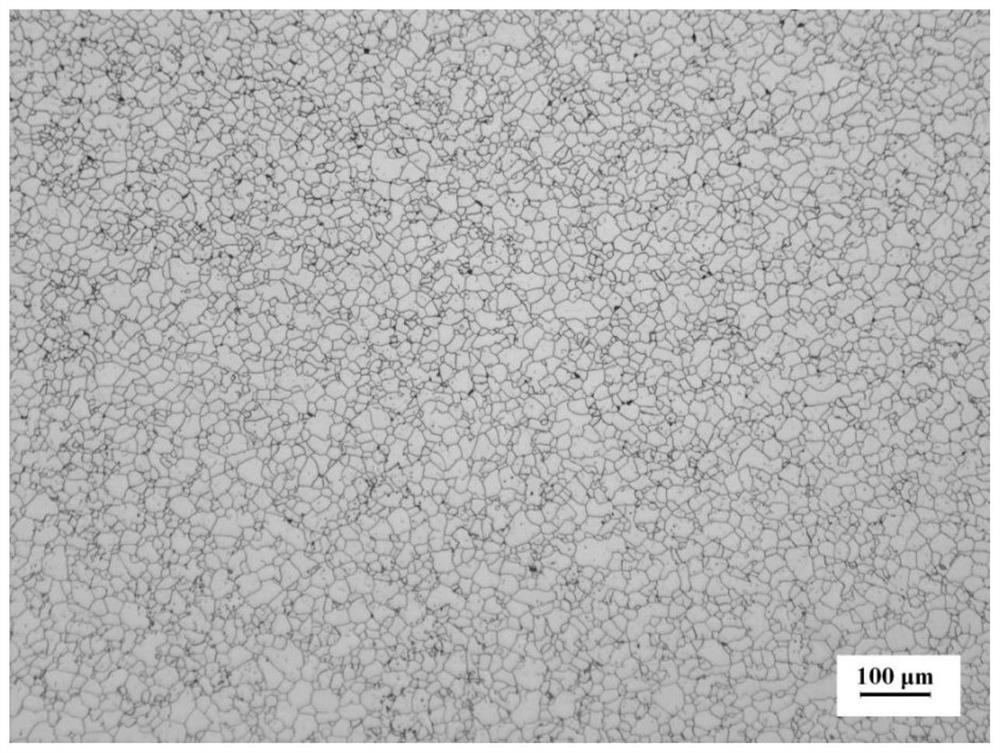

Embodiment 1

[0053] Prepare the GH4282 superalloy bar of Φ210mm, comprising the following steps:

[0054] S1. The GH4282 nickel-based superalloy ingot of Φ305mm that has been homogenized is compositely wrapped, and then the ingot is loaded in a furnace at a temperature of 650°C, and the temperature is raised to 1160°C at a heating rate of 70°C / h, and the temperature is kept for 3.5h. baked;

[0055] S2. Perform the first fire upsetting in the axial direction on the ingot after heat treatment in step S1. The specific operation is: firstly carry out the first continuous deformation at a constant speed with a deformation amount of 12%, and then stay for 4s and then increase it with 28% The deformation amount is carried out for the second deformation at a constant speed, and the final forging temperature is 1020°C;

[0056] Then return the billet to the furnace while it is hot and reheat it to 1160°C, keep it warm for 70 minutes, and take it out of the furnace to obtain the billet;

[0057] ...

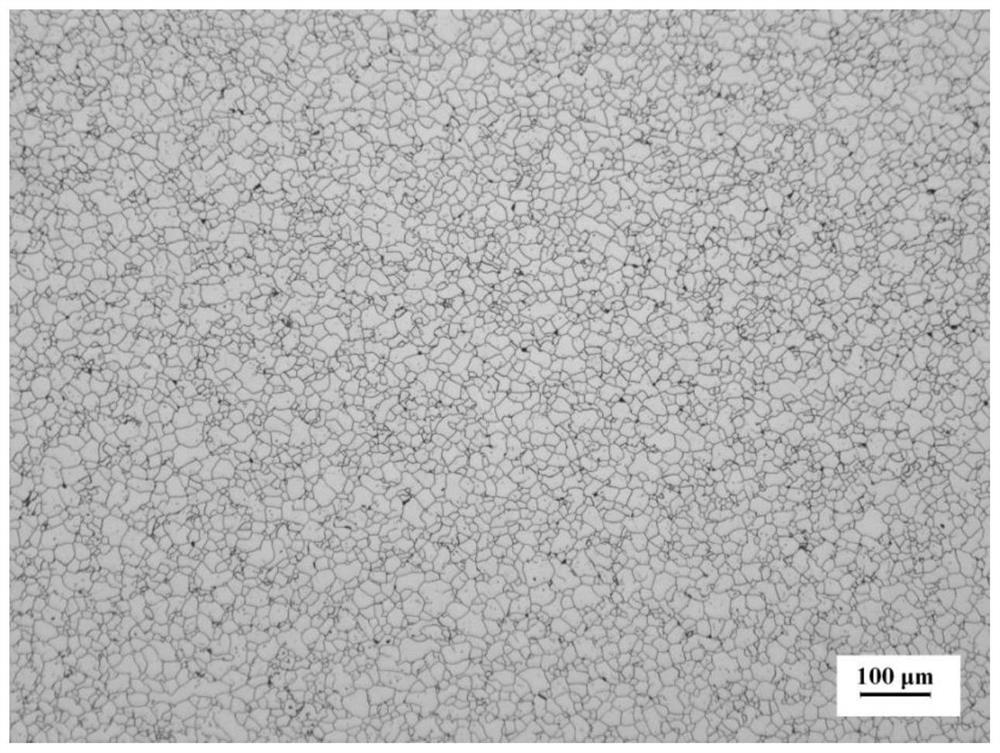

Embodiment 2

[0067] Prepare the GH4282 superalloy bar of Φ200mm, comprising the following steps:

[0068] S1. Composite sheath the homogenized Φ305mm GH4282 nickel-based superalloy ingot, then put the ingot in the furnace at 650°C, raise the temperature to 1165°C at a heating rate of 65°C / h, keep it for 4 hours, and take it out of the furnace ;

[0069] S2. Perform the first fire upsetting in the axial direction of the ingot after heat treatment in step S1. The specific operation is: firstly carry out the first continuous deformation at a constant speed with a deformation amount of 10%, and then stay for 3s, and then increase it by 30% The amount of deformation is carried out for the second deformation at a constant speed, and the final forging temperature is 1000°C;

[0070] Then return the billet to the furnace while it is hot and reheat it to 1165°C, keep it warm for 75 minutes, and then take it out of the furnace to obtain the billet;

[0071] Carry out a fire drawing on the billet p...

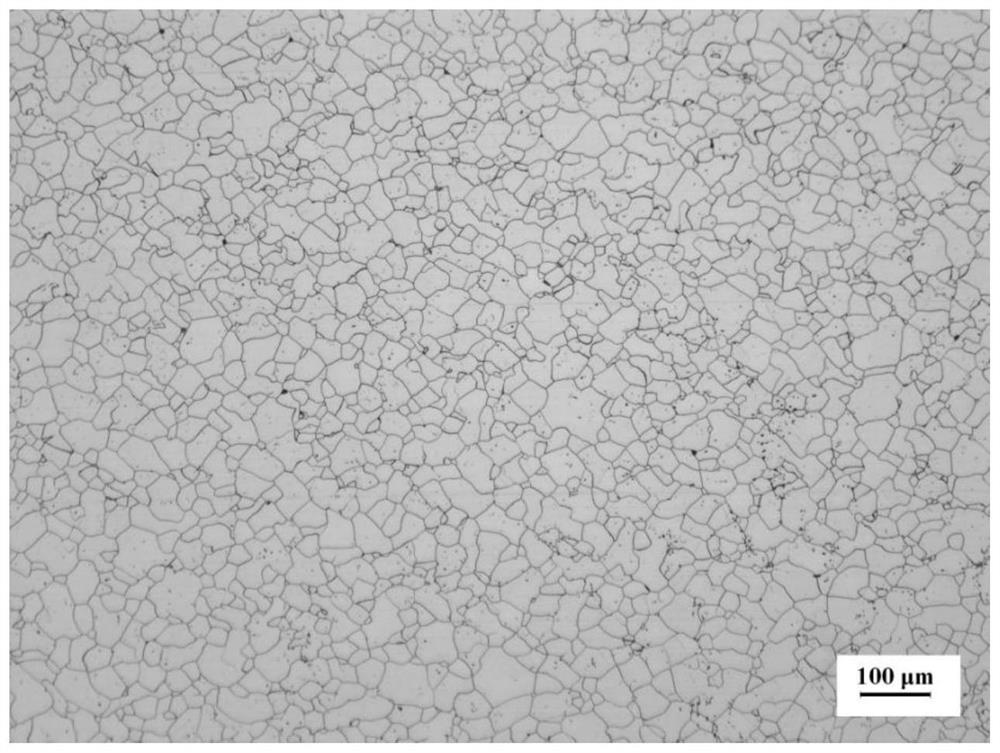

Embodiment 3

[0082] Prepare the GH4282 superalloy bar of Φ245mm, comprising the following steps:

[0083] S1. Composite sheath the homogenized Φ305mm GH4282 nickel-based superalloy ingot, then put the ingot in the furnace at 500°C, raise the temperature to 1140°C at a heating rate of 60°C / h, keep it warm for 2 hours, and take it out of the furnace ;

[0084] S2. Perform the first fire upsetting in the axial direction on the ingot after heat treatment in step S1. The specific operation is: firstly carry out the first continuous deformation at a constant speed with a deformation amount of 10%, and then stay for 3s, and then increase it by 20% The amount of deformation is carried out for the second deformation at a constant speed, and the final forging temperature is 1000°C;

[0085] Then return the billet to the furnace while it is hot and reheat it to 1140°C, keep it warm for 45 minutes, and then take it out of the furnace to obtain the billet;

[0086] Carry out a fire drawing on the bil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com