Molybdenum and molybdenum alloy material sintering method and application thereof

A sintering method and molybdenum alloy technology, applied in the field of powder metallurgy, can solve the problems of lack, consumption of free atoms, merger and growth, etc., to achieve the effect of improving work efficiency, reducing heating rate, and avoiding uneven macrostructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1. Preparation of single weight 7kg board by passivating Mo-0.6La alloy powder

[0080] The present embodiment provides a molybdenum and molybdenum alloy material sintering method, comprising the following steps:

[0081] Step 1: Take 7.7kg Mo-0.6La alloy powder and The forged molybdenum balls are put into the 17L ball milling tank of the GH-17L three-dimensional motion high-efficiency mixer; set the ball milling procedure of "total ball milling time is 10h, after each ball milling time is 2.5h, the equipment is suspended for 1h"; The speed of the ball mill is greater than or equal to 30rpm;

[0082] After the ball milling, the molybdenum powder and the molybdenum balls are separated by a -10 mesh sieve, then the molybdenum powder is passed through a -100 mesh sieve to remove the molybdenum ball debris, and finally, the molybdenum powder is sieved with a -200 mesh, and the material under the sieve is taken as the passivated molybdenum powder;

[0083] Step 2:...

Embodiment 2

[0096] Example 2: Preparation of Passivated Pure Molybdenum Powder Molybdenum billet

[0097] With embodiment 1, the difference is, in this embodiment, weigh 18kg pure molybdenum powder and The forged molybdenum balls are put into the 50L ball milling tank of the GH-50L three-dimensional motion high-efficiency mixer; the ball mill is divided into 4 stages for 8 hours; the molybdenum powder and the molybdenum ball are separated by a -10 mesh sieve, and then the molybdenum powder is passed through - Molybdenum balls were removed by a 100-mesh sieve, and finally sieved with -200-mesh, and the material under the sieve was taken as passivated molybdenum powder; A compact with a single weight of 17kg;

[0098] In the ZTL-250 intermediate frequency sintering furnace, heat up and keep warm according to the following process:

[0099]

[0100] get After sintering the billet, it is forged at 1280°C to And 950 ℃ × 0.5h stress relief annealing.

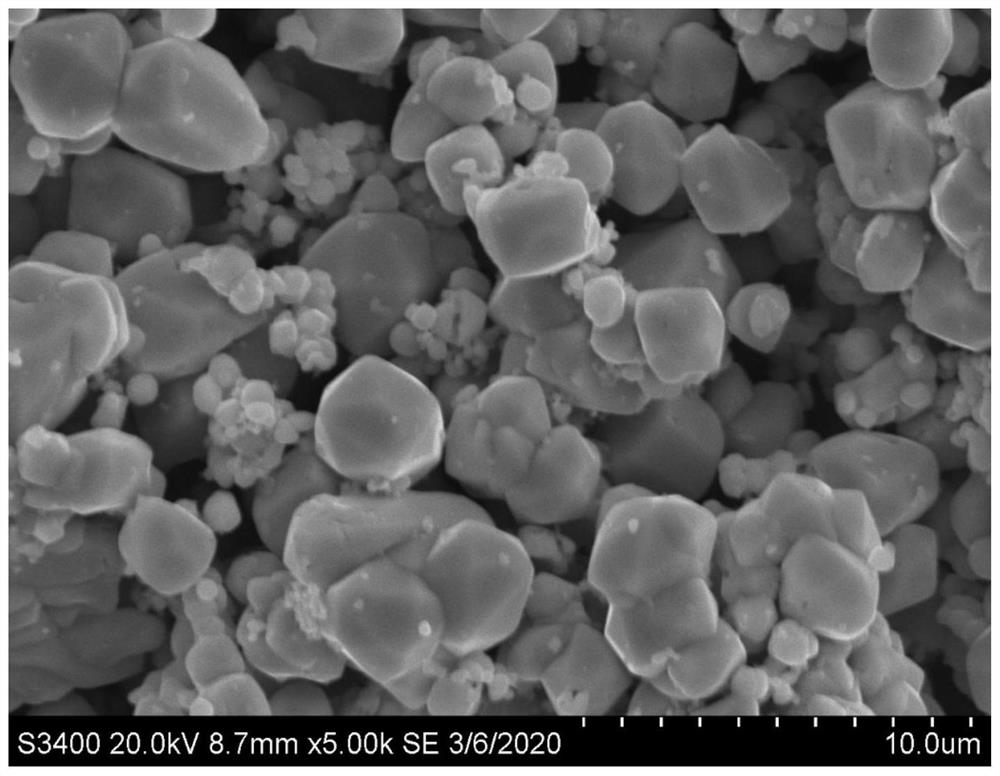

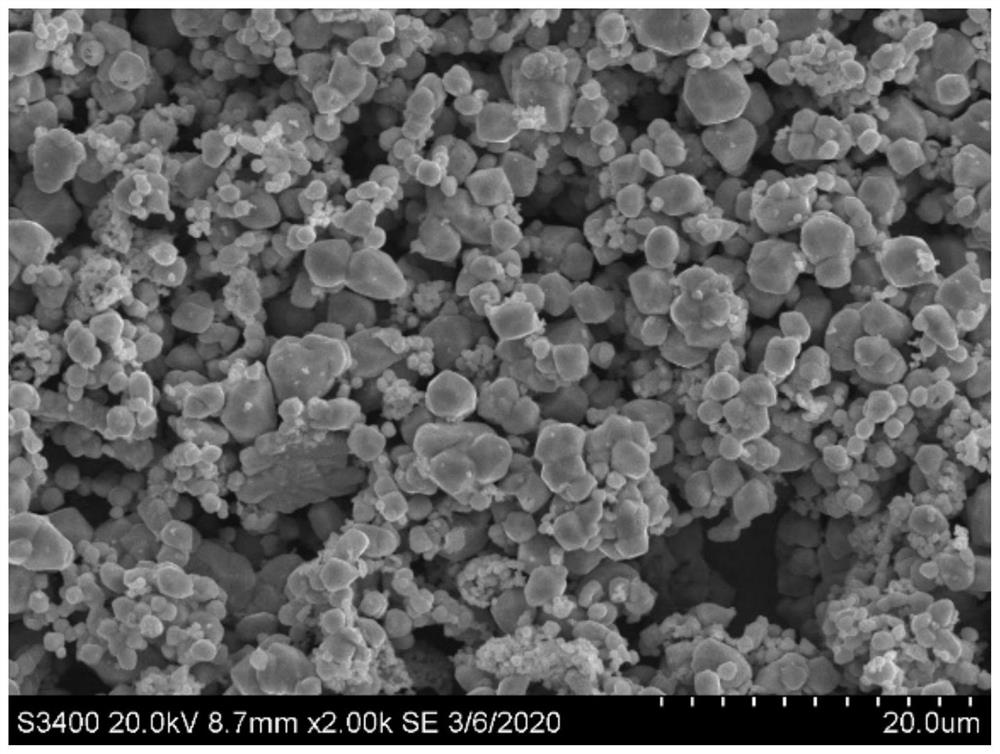

[0101] The particle morpholo...

Embodiment 3

[0102] Example 3: Hydrogen reduction of Mo-0.6La alloy powder to prepare a slab with a single weight of 6.4kg

[0103] The same as Example 1, the difference is that the raw material Mo-0.6La alloy powder in this example is not passivated, and hydrogen is directly passed into it for heating and sintering.

[0104] Specifically include: using a movable steel mold with a rubber sleeve seal, the size of the precisely formed green compact is 40×158×158mm, and the density is 6.35g / cm 3 , sintering process:

[0105]

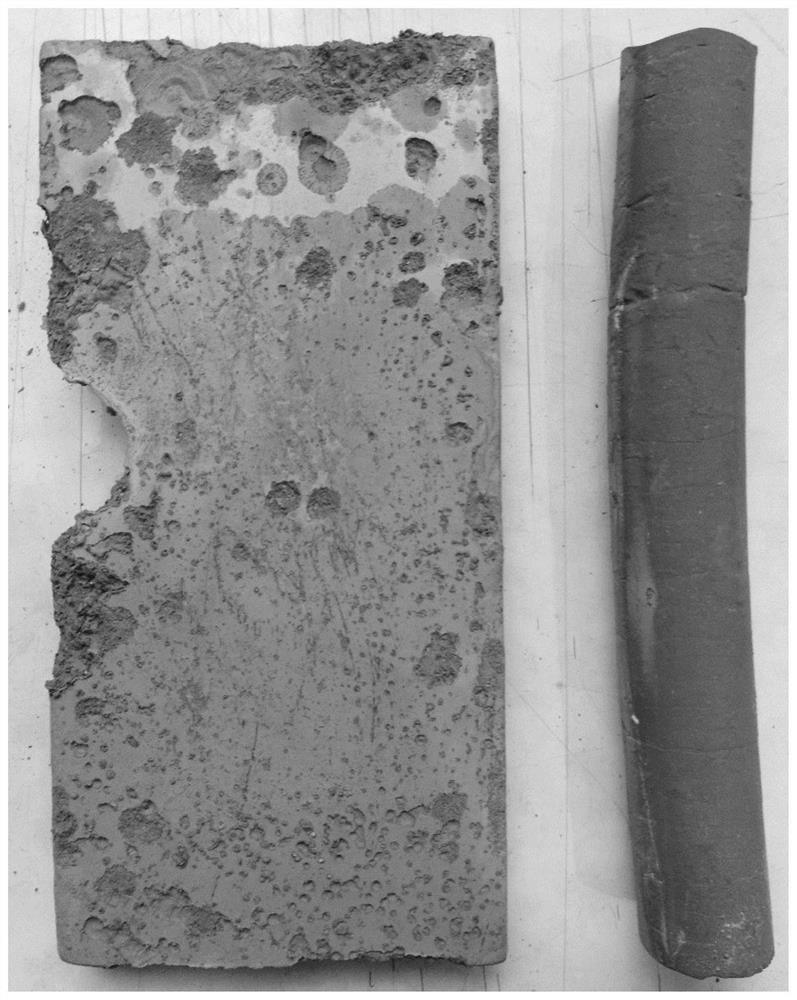

[0106] The size of the sintered blank is 33×138×138mm and the density is 9.7g / cm 3 . In the process of rolling the size of the basic bidirectional equal deformation to 3 × 450 × 450 mm, the edge is complete ( Figure 12 ), as-rolled metallographic Figure 13 shown, showing an isotropic rolling structure. The room temperature tensile strength, yield strength and elongation after fracture of the 950℃×0.5h annealed state of the two samples are 741MPa, 678MPa, 12%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com