Niobium-alloying high-chromium cast iron grinding ball and production technology thereof

A high-chromium cast iron and niobium alloying technology, which is applied in the direction of metal processing equipment, process efficiency improvement, casting mold, etc., can solve the problems of poor performance, poor performance uniformity, and low cooling rate, so as to improve the comprehensive performance and structural performance Uniformity, improvement of tissue performance uniformity, and the effect of toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

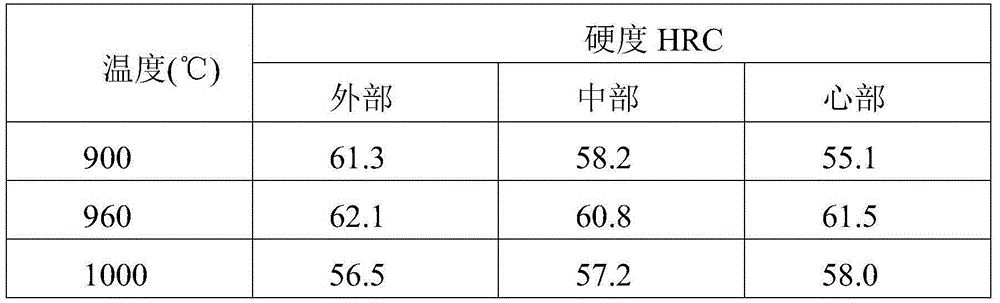

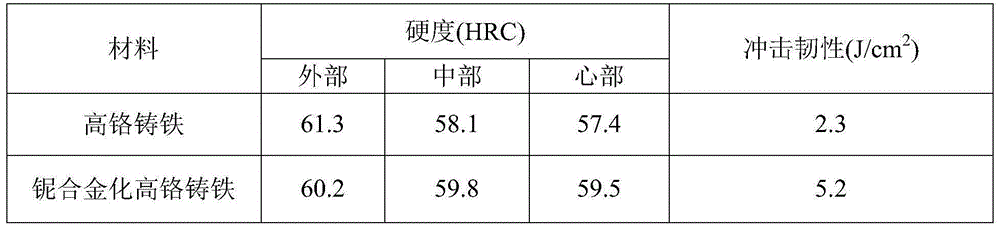

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to specific embodiments.

[0022] The niobium alloyed high chromium cast iron grinding ball according to the present invention has a chemical composition of C: 2.5-3.0%, Si: 0.3-0.8%, Mn: 0.6-1.0%, P: <0.1%, S : <0.1%, Cr: 14.0-16.0%, Nb: 0.1-0.2%, RE: 0.1-0.2%; the balance is Fe.

[0023] Carbon: Carbon content is the most significant factor affecting the structure and performance of high chromium cast iron. As the carbon content increases, the wear resistance increases, but the toughness of the alloy decreases. According to the actual wear conditions of the grinding balls, we control the carbon content in the range of 2.5%-3.0% by mass.

[0024] Chromium: It can be seen from the Fe-Cr-C alloy phase diagram that in order to ensure that the carbides are 7 C 3 The chromium content must be greater than 12%. Chromium is the main alloy, in addition to forming carbides with carbon, it is partially dissolved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com