A high-strength, high-elasticity, high-plasticity nickel-based superalloy strip and its preparation process

A nickel-based superalloy and a preparation process technology, applied in the field of nickel-based superalloy preparation technology, can solve the problems of high strength, high plasticity and poor performance uniformity, and achieve the effects of improving resource utilization, excellent performance and broad industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

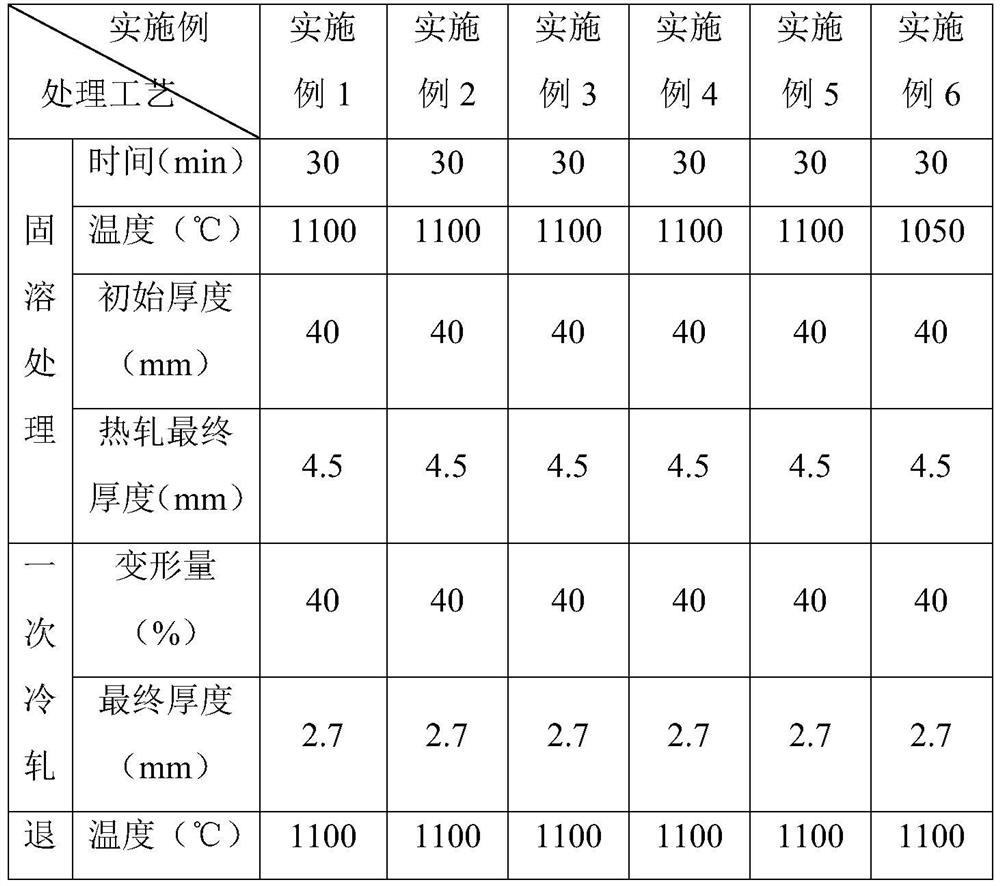

[0049] In this embodiment, GH4578 alloy is used as raw material.

[0050] The preparation process of a high-strength, high-elasticity and high-plasticity nickel-based superalloy strip provided in this embodiment includes the following steps: preparing a strip blank:

[0051] Alloy ingot smelting: Vacuum induction and electroslag remelting are used to complete alloy ingot smelting, and electroslag ingots with a diameter of 120mm are obtained; homogenization treatment: homogenization treatment is performed on alloy ingots, and the homogenization treatment time is 1180°C. The time is 40h for the initial mechanical grinding of the alloy ingot after the homogenization treatment;

[0052] Forging slab: Forging slab for the ingot after the initial mechanical grinding, and performing secondary mechanical grinding and initial edge wire cutting on the slab after forging slab, to obtain the slab required for hot rolling, with a thickness of 40mm;

[0053] Multi-fire hot rolling of slab...

Embodiment 2

[0081] The tensile strength of the finished strip in embodiment 2 is 1530MPa, the yield strength is 1354MPa, and the elongation is 15.0%. As can be seen, the finished strip has higher strength and lower elongation. Although the finished strip has good strength, its plasticity Poor, unable to meet the requirements of the finished strip for strength and plasticity at the same time; the tensile strength of the finished strip in Example 3 is 1298MPa, the yield strength is 1094MPa, and the elongation is 32.0%. The rate is high, and the finished strip has good plasticity, but the strength is low.

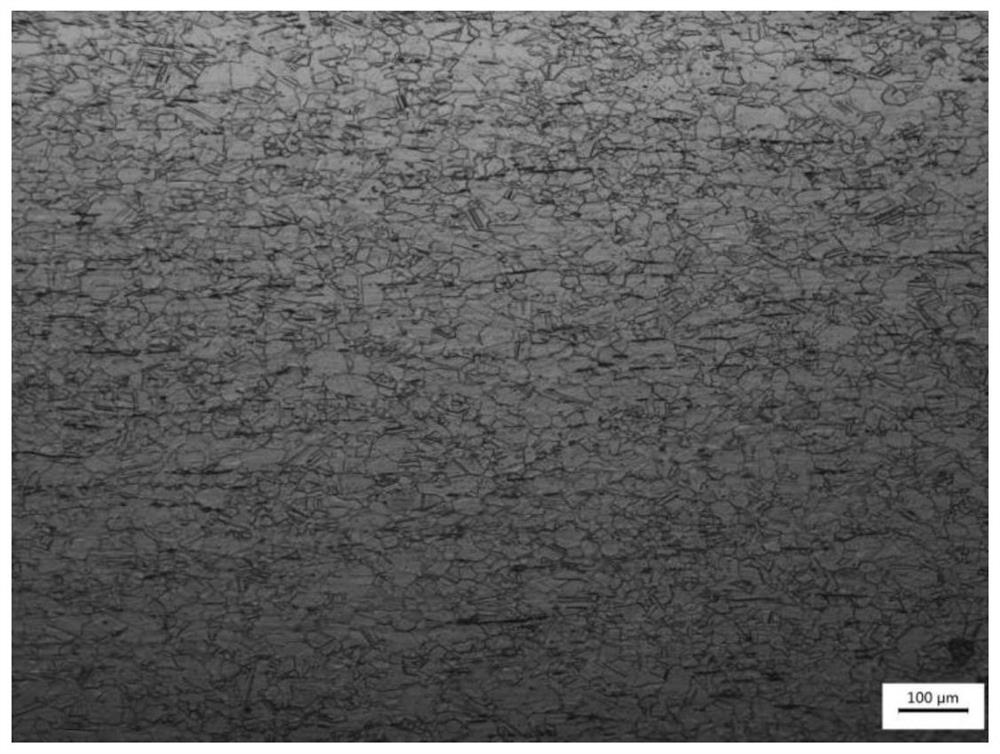

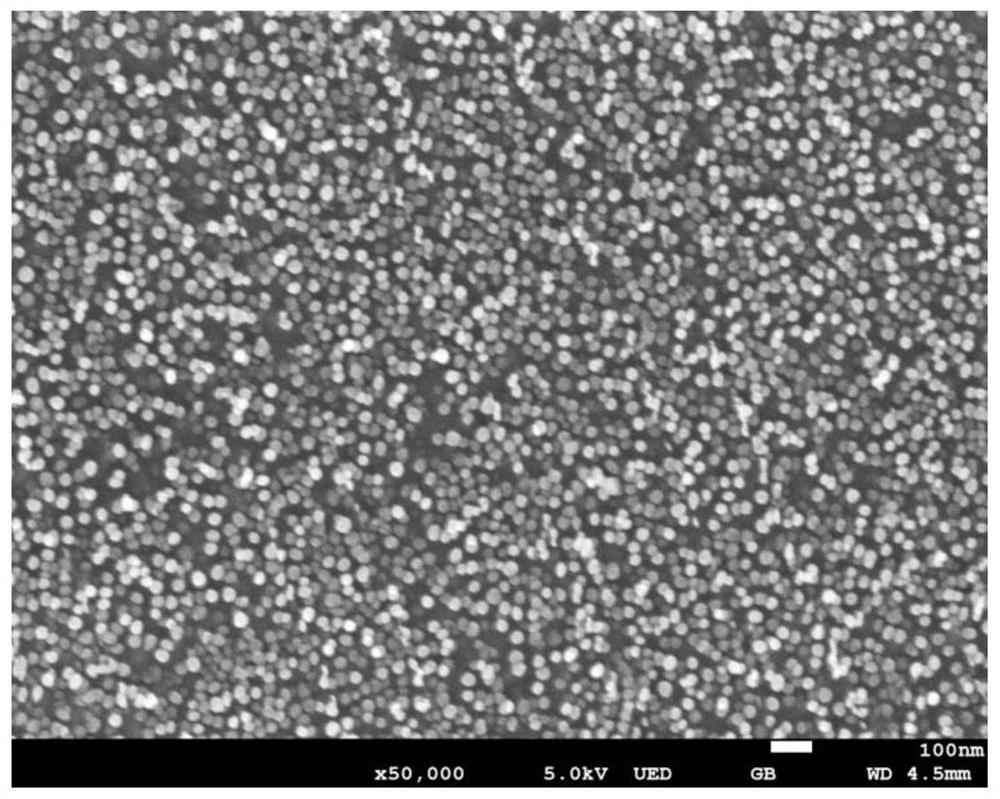

[0082] Contrasting Example 1 with Examples 2-3 shows that the comprehensive mechanical properties of the finished strip in Example 1 are better than those of Example 2-3, indicating that the continuous annealing temperature affects the comprehensive mechanical properties of the finished strip, the continuous annealing temperature is low, and the crystal The grain structure is fine, the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com