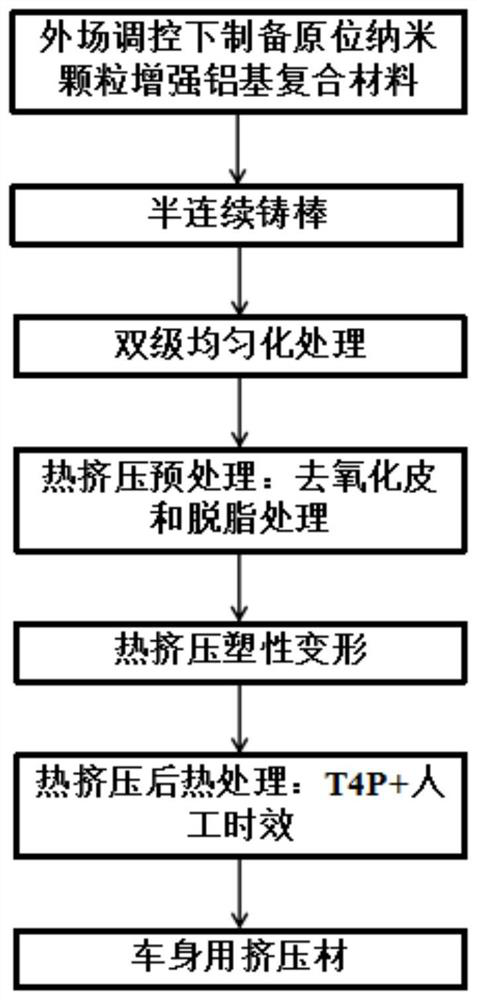

Extrusion process of in-situ nanoparticle-reinforced aluminum matrix composites for vehicle body

A composite material and nanoparticle technology, which is applied in the field of aluminum-based composite material processing, can solve the problems of unsatisfactory reinforced composite materials, easy aggregation of in-situ nanoparticles, and difficult size control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

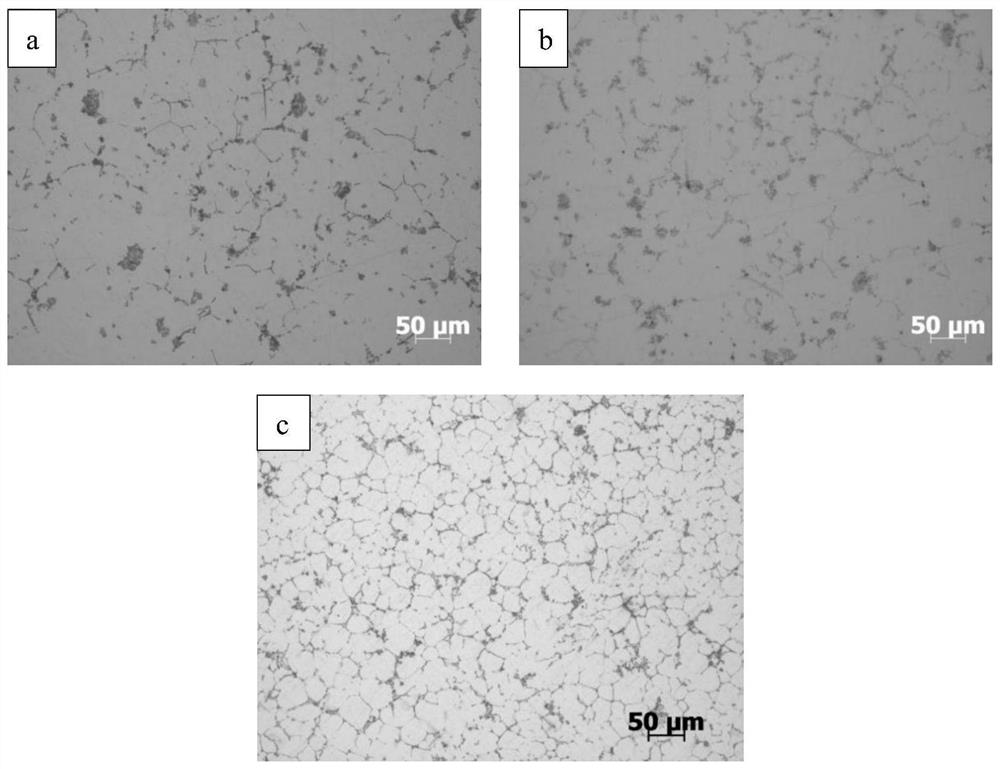

[0030] (1) In-situ preparation of composite materials: 2vol% ZrB with a diameter of 100 mm was prepared by the direct melt reaction method (DMR) and a copper crystallizer 2 / AA6111 composite material semi-continuous casting cast rod, generated ZrB 2 The average particle size of the particles is between 50nm and 80nm.

[0031] (2) Two-stage homogenization treatment: put the cast rod into a resistance furnace for two-stage homogenization annealing treatment at 470°C×3h+545°C×17h, and cool with the furnace.

[0032] (3) Extrusion deformation pretreatment: use 600-mesh sandpaper to remove the oxide skin on the surface of the sample after homogenization treatment, and polish it smoothly, then put the polished and smooth sample into acetone for degreasing treatment, and then wipe it off with alcohol cotton The oxide film on the surface was finally cleaned with ethanol and dried with a hair dryer before use.

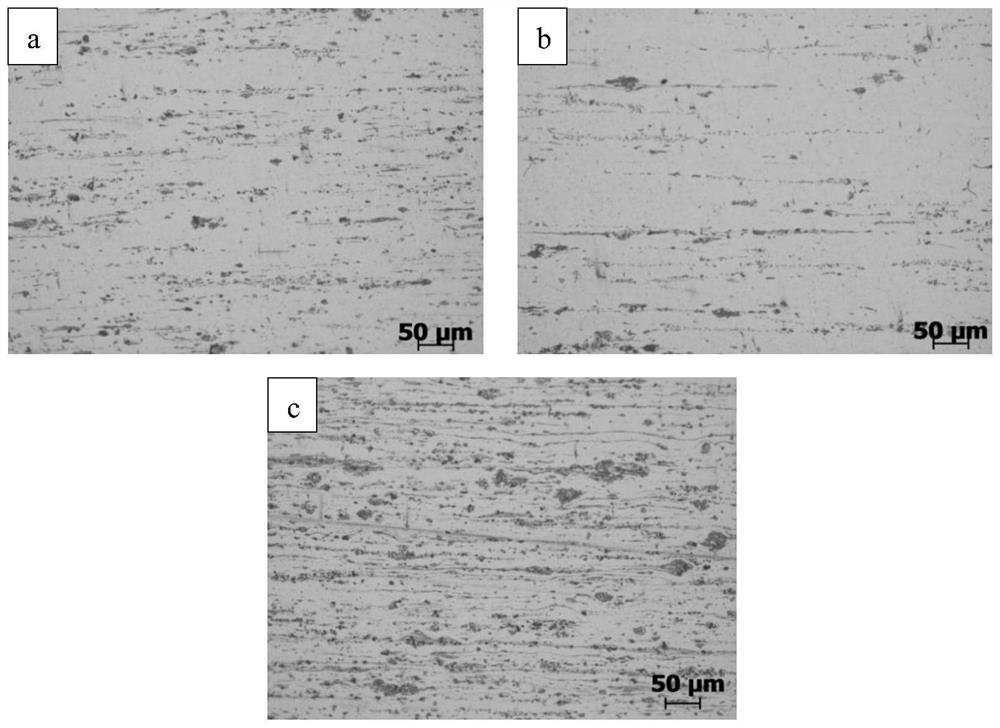

[0033] (4) Plastic deformation by hot extrusion: Put the pretreated cast...

Embodiment 2

[0036] The preparation method of the cast rod is basically the same as in Example 1, the difference is that: 1. the research object is different, and the present embodiment is 1vol%Al 2 o 3 / AA6111 aluminum matrix composites, the generated Al 2 o 3 The average particle size of the particles is 70nm-100nm. ②The two-stage homogenization treatment is different: 480℃×2h+540℃×18h. ③The hot extrusion process is different: the extrusion temperature of the cast rod is 400°C, the extrusion speed is 1.5m / min, and the extrusion ratio is 20:1. ④The heat treatment process is different: solution quenching is 550℃×1.5h, pre-aging is 160℃×5min, and artificial aging is 180℃×20min.

Embodiment 3

[0038] The preparation method of the cast rod is basically the same as in Example 1, the difference is that: 1. the research object is different, and the present embodiment is 3vol%TiB 2 / AA6016 Aluminum Matrix Composite, Generated TiB 2 The average particle size of the particles is 50-100nm. ②The two-stage homogenization treatment is different: 465℃×4h+555℃×16h. ③The hot extrusion process is different: the extrusion temperature of the cast rod is 500°C, the extrusion speed is 0.5m / min, and the extrusion ratio is 12:1. ④The heat treatment process is different: solution quenching is 540℃×2h, pre-aging is 160℃×5min, and artificial aging is 175℃×30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com