VN microalloyed steel for coal mine hydraulic support and preparation method of VN microalloyed steel

A coal mine hydraulic and micro-alloying technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high equipment requirements, high cost, and high alloy addition, and achieve the effect of promoting the uniformity of structure and properties and strong feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

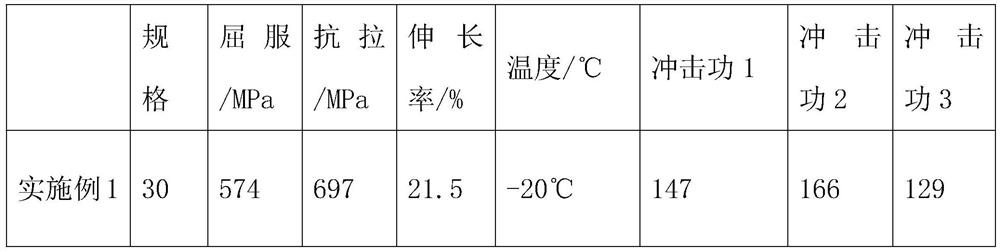

Embodiment 1

[0041] A VN microalloyed coal mine hydraulic support steel and a preparation method thereof are prepared from the following raw materials according to the mass percentage: C: 0.16%, Si: 0.24%, Mn: 1.45%, P: 0.015%, S: 0.004 %, Al: 0.05%, N: 0.0079%, Nb: 0.018%, V: 0.042%, and the rest are Fe and unavoidable elements.

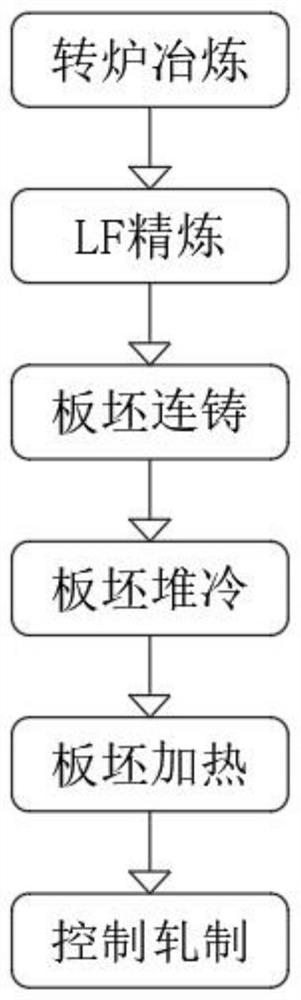

[0042] A kind of VN microalloying steel for production of coal mine hydraulic support and preparation method thereof, the chemical composition of the steel plate and its mass percentage are shown in Table 1, and the process steps of the production method of the steel plate for coal mine hydraulic support include:

[0043] Converter smelting: The raw materials are introduced into the smelting furnace for smelting, and the first billet is prepared, and the tapping C≥0.06% and P≤0.015% are controlled to avoid slag during the tapping process;

[0044] LF refining: white slag is carried out on the blanks in the first blank, and the white slag is kept for more than 15...

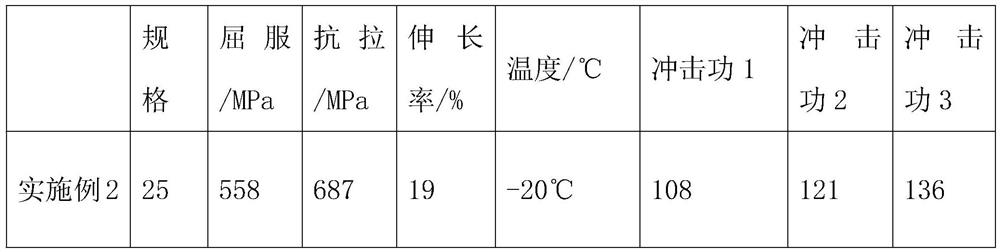

Embodiment 2

[0056] A VN micro-alloyed coal mine hydraulic support steel and a preparation method thereof are prepared from the following raw materials according to the mass percentage: C: 0.15%, Si: 0.24%, Mn: 1.43%, P: 0.017%, S: 0.005 %, Al: 0.006%, N: 0.0085%, Nb: 0.019%, V: 0.044%, and the rest are Fe and unavoidable elements.

[0057] A kind of VN microalloying steel for coal mine hydraulic support and preparation method thereof, the chemical composition of the steel plate and its mass percentage are shown in Table 3, and the process steps of the steel plate for coal mine hydraulic support production method include:

[0058] Converter smelting: the raw materials are introduced into the smelting furnace for smelting, and the first billet is prepared, and the tapping C≥0.06% and P≤0.015% are controlled to avoid slag during the tapping process;

[0059] LF refining: white slag is carried out on the blanks in the first blank, and the white slag is kept for more than 15 minutes, and the c...

Embodiment 3

[0071] A VN microalloyed coal mine hydraulic support steel and a preparation method thereof are prepared from the following raw materials according to the mass percentage: C: 0.17%, Si: 0.24%, Mn: 1.44%, P: 0.018%, S: 0.006 %, Al: 0.006%, N: 0.0090%, Nb: 0.020%, V: 0.044%, the rest are Fe elements and unavoidable elements,

[0072] A kind of VN microalloying steel for coal mine hydraulic support and preparation method thereof, the chemical composition of the steel plate and its mass percentage are shown in Table 5, and the process steps of the steel plate for coal mine hydraulic support production method include:

[0073] Converter smelting: the raw materials are introduced into the smelting furnace for smelting, and the first billet is prepared, and the tapping C≥0.06% and P≤0.015% are controlled to avoid slag during the tapping process;

[0074] LF refining: white slag is carried out on the blanks in the first blank, and the white slag is kept for more than 15 minutes, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com