High-temperature alloy bar billet heating device and method for shaft forgings

A high-temperature alloy and heating device technology, applied in forging furnaces, furnace types, engine components, etc., can solve the problems of poor overall uniformity of forgings, and achieve the effects of short heating time and improved overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

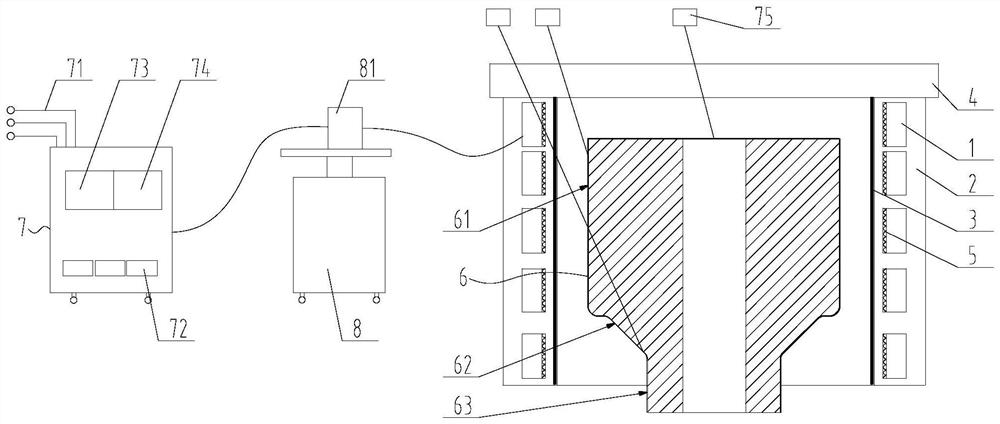

[0018] High-temperature alloy billet heating device for shaft forgings, such as figure 1 As shown, it includes a heating furnace, a controller 73, a temperature controller 74, a thermocouple 75 and a variable frequency power supply; the heating furnace includes an induction coil 1 and an insulating furnace wall 2 made of refractory cement, and the induction coil 1 is buried Inside the insulating furnace wall 2, an insulating lining 3 is laid on the inner surface of the insulating furnace wall 2; surrounded by the insulating lining 3, a cylindrical heating cavity with two ends penetrating is formed; Open zirconium-containing fiber cover plate 4; the thermocouple 75 is connected to the input port of the controller 73, and the output port of the controller 73 is connected to the input port of the temperature controller 74, and the temperature controller T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com