High-quality nickel-chromium-iron-based high-temperature alloy plate and preparation method thereof

A technology of iron-based superalloys and superalloys, applied in metal rolling, manufacturing tools, heat treatment equipment, etc., can solve problems such as poor surface quality, difficulty in meeting design and use requirements, low dimensional accuracy, etc., and achieve good uniformity of structure and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present application provides a method for preparing a high-quality nickel-chromium-iron-based superalloy sheet, which specifically includes the following steps: slab preparation, cold rolling, solution treatment of finished products, and surface treatment;

[0047] Wherein, cold rolling: cold-rolling the prepared slab to obtain a cold-rolled sheet; the cold-rolling includes intermediate-fire sub-cold rolling and final-fire sub-cold rolling; in each sub-fire cold rolling, the cold rolling deformation of each pass Distribute the deformation amount of the fire evenly;

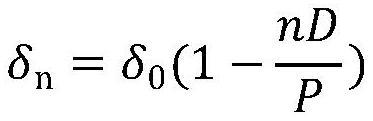

[0048] The calculation method of sheet thickness after cold rolling for each fire is as follows:

[0049]

[0050] Among them, δn represents the thickness after the nth cold rolling of the fire; δ 0 Represents the initial thickness of the sheet before the cold rolling of the fire; n is the number of the fire of the fire; D is the deformation of the fire; P is the number of cold rolling passes per fi...

Embodiment 1

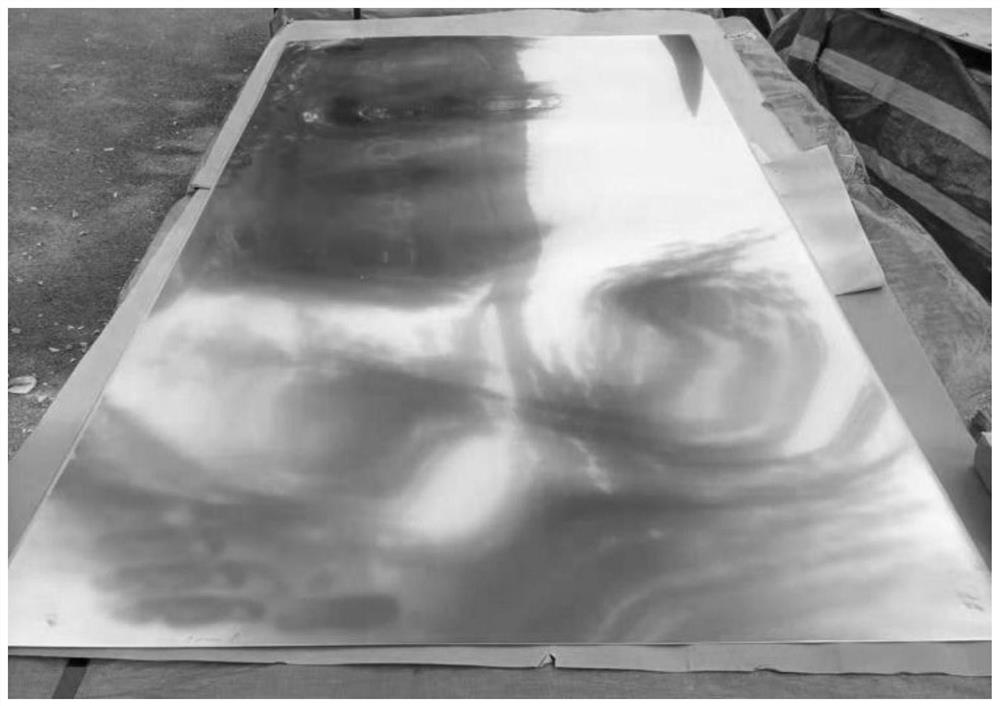

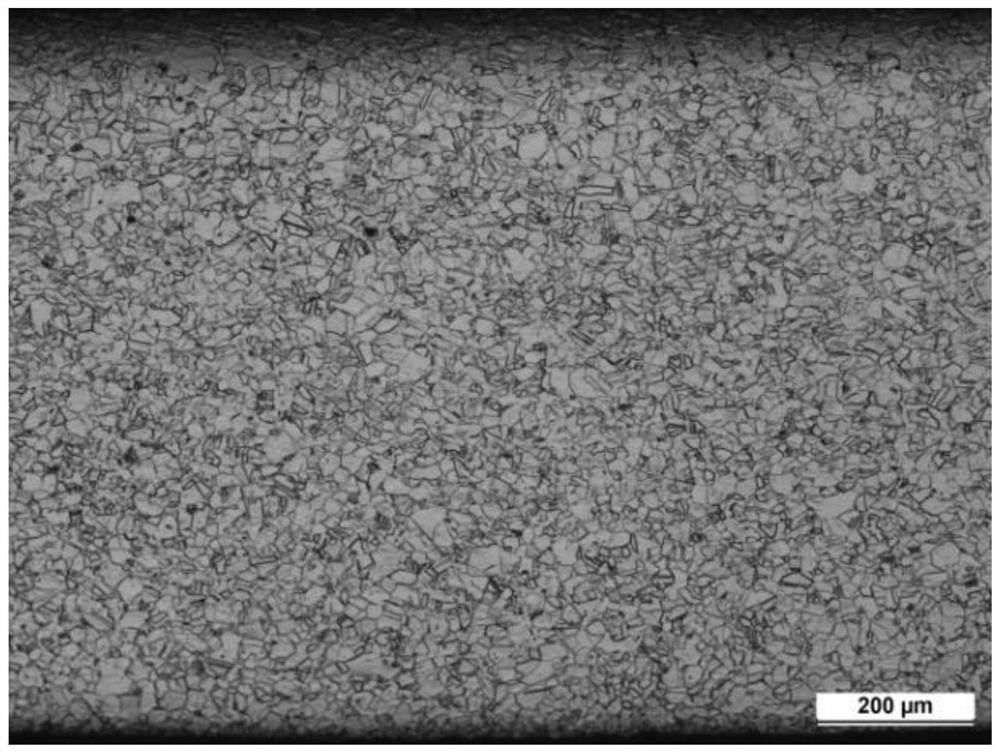

[0081] This embodiment provides a high-quality nickel-chromium-iron-based superalloy plate.

[0082] This high quality nickel-chromium-iron based superalloy sheet contains the following compositions: C 0.012%, Si 0.08%, Mn 0.021%, Cr 18.0%, Ni 54.0%, Mo 3.0%, Nb 5.1%, Ti 0.98%, Al 0.49%, Co 0.15%, Cu 0.02%, P 0.0065%, S 0.0005%, O 0.0006%, N 0.0070%, B 0.003%, Mg 0.0005%, Ta≤0.05%, and the balance is Fe.

[0083] The preparation method of the high-quality nickel-chromium-iron-based superalloy plate specifically includes the following steps:

[0084] 1. Vacuum induction melting: The raw materials are smelted and poured into ingot A in a vacuum induction melting furnace.

[0085] 2. Remelting: The ingot A obtained in step 1 is subjected to vacuum self-consumption remelting to obtain the ingot B.

[0086] 3. Homogenization heat treatment

[0087] The ingot B obtained in step 2 is subjected to homogenization heat treatment, and the ingot after the homogenization heat treatment ...

Embodiment 2

[0114] This embodiment provides a high-quality nickel-chromium-iron-based superalloy plate.

[0115] This high quality nickel-chromium-iron based superalloy sheet contains the following compositions: C 0.025%, Si 0.06 / %, Mn 0.018%, Cr 18.9%, Ni 53.65%, Mo 2.99%, Nb 5.09%, Ti 1.02%, Al 0.59%, Co 0.11%, Cu 0.02%, P 0.0059%, S 0.0004%, O 0.0005%, N 0.0068%, B 0.0030%, Mg 0.0004%, Ta < 0.05%, and the balance is Fe.

[0116] The preparation method of the high-quality nickel-chromium-iron-based superalloy plate specifically includes the following steps:

[0117] 1. Vacuum induction melting: The raw materials are smelted and poured into ingot A in a vacuum induction melting furnace.

[0118] 2. Remelting: The ingot A obtained in step 1 is subjected to vacuum self-consumption remelting to obtain the ingot B.

[0119] 3. Homogenization heat treatment

[0120] The ingot B obtained in step 2 is subjected to homogenization heat treatment, and the ingot after the homogenization heat tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com