A rolling method for weakening the anisotropy of tc4 titanium alloy sheet

An anisotropic, titanium alloy technology, applied in metal rolling and other directions, can solve the problems of long production process, serious edge cracking, low yield and other problems, and achieve good surface quality, small anisotropy, and degree of fragmentation. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

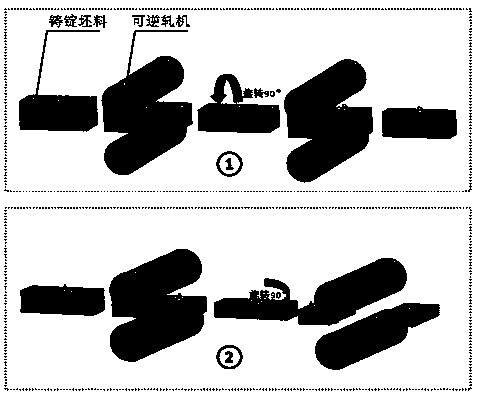

[0023] A rolling method to weaken the anisotropy of TC4 titanium alloy sheet, the forming process is as figure 1 As shown, the specific steps are as follows:

[0024] (1) The material of this example is Ti-6Al-4V (TC4) titanium alloy. The phase transition point of TC4 titanium alloy was measured, and the phase transition point temperature of the alloy was measured to be 980° C. by differential scanning calorimetry (DSC).

[0025] (2) Heat the cuboid TC4 titanium alloy ingot to 1020°C and keep it warm for 20 minutes.

[0026] (3) The heated cuboid ingot is subjected to two-fire hot rolling, and the first fire rolling process is: the rolling speed is 1.4m / s

[0027] , the cumulative rolling pass is 10 times, and the cumulative deformation is about 72%. First, the first pass is rolled along the length direction, and then the billet is rotated 90° along the length direction and reversely rolled for the second pass, namely Width and thickness commutation, such as figure 1 As sho...

Embodiment 2

[0034] A rolling method to weaken the anisotropy of TC4 titanium alloy sheet, the forming process is as figure 1 As shown, the specific steps are as follows:

[0035] (1) The material of this example is Ti-6Al-4V (TC4) titanium alloy. The phase transition point of TC4 titanium alloy was measured, and the phase transition point temperature of the alloy was measured to be 980° C. by differential scanning calorimetry (DSC).

[0036] (2) Heat the cuboid TC4 titanium alloy ingot to 990°C and keep it warm for 30 minutes.

[0037] (3) The heated cuboid ingot is subjected to two-fire hot rolling, and the first fire rolling process is: the rolling speed is 1.25m / s

[0038] , the cumulative rolling pass is 9 times, and the cumulative deformation is about 73%; firstly, the first pass is rolled along the length direction, and then the billet is rotated 90° along the length direction and reversely rolled for the second pass (ie Width and thickness reversing), repeat this process once, a ...

Embodiment 3

[0045] A rolling method to weaken the anisotropy of TC4 titanium alloy sheet, the forming process is as figure 1 As shown, the specific steps are as follows:

[0046] (1) The material of this example is Ti-6Al-4V (TC4) titanium alloy. The phase transition point of TC4 titanium alloy was measured, and the phase transition point temperature of the alloy was measured to be 980° C. by differential scanning calorimetry (DSC).

[0047] (2) Heat the cuboid TC4 titanium alloy ingot to 1050°C and keep it warm for 25 minutes.

[0048] (3) The heated cuboid ingot is subjected to two-fire hot rolling. The first fire rolling process is as follows: the rolling speed is 1.1m / s, the cumulative rolling passes are 8 times, and the cumulative deformation is about 67%. First roll the first pass along the length direction, then rotate the billet 90° along the length direction and roll the second pass in reverse (ie width and thickness reversal), repeat this process once, and roll 5 passes in tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com