Method for preparing semi-solid slurry of Al-Si-Cu alloy induced and inoculated by misch rare earth

A semi-solid slurry, al-si-cu technology, applied in the field of semi-solid slurry preparation, can solve problems such as easy to get involved in gas, inclusions, stirring dead zone, magnetic flux leakage, etc., to avoid harmful inclusions Produce, promote proliferation and refinement, and improve the effect of solidification environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

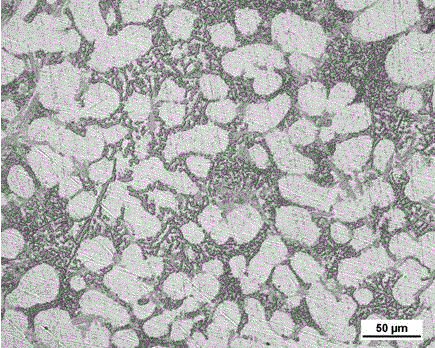

Image

Examples

Embodiment 1

[0017] (1) Put the Al-Si-Cu alloy ingot into a graphite crucible and overheat to 740°C to completely melt the aluminum block, then refining and removing slag.

[0018] (2) Add Al-5Pr-5Ce (that is, the mass fraction of Pr and Ce each account for 5wt.%) master alloy covered with aluminum foil paper into the melt of step (1), and the amount of master alloy added accounts for the total of the melt The weight percentage is 3wt.%, and then the furnace is heated to 760°C and kept for 15 minutes.

[0019] (3) Place the preheated ultrasonic horn probe in the melt and apply intermittent ultrasound to the melt. The interval between each ultrasound is 1s, the release time of each ultrasound is 2.0s, the ultrasound power is 1.0kw, and the ultrasound The frequency is 20kHz, and the ultrasound time is 3min.

[0020] (4) After the above-mentioned ultrasound is completed, let it stand for 8min when the temperature is lowered to 610℃, and then apply intermittent ultrasound to the melt again. The ultr...

Embodiment 2

[0022] (1) Put the Al-Si-Cu alloy ingot into a graphite crucible and overheat to 745°C to completely melt the aluminum block, then refining and removing slag.

[0023] (2) Add Al-5Pr-5Ce (that is, the mass fraction of Pr and Ce each account for 5wt.%) master alloy covered with aluminum foil paper into the melt of step (1), and the amount of master alloy added accounts for the total of the melt The weight percentage is 6wt.%, and then the furnace is heated to 765°C and kept for 18 minutes.

[0024] (3) Place the preheated ultrasonic horn probe in the melt, and apply intermittent ultrasound to the melt. The interval between each ultrasound is 2s, the release time of each ultrasound is 2.0s, the ultrasound power is 1.5kw, the ultrasound The frequency is 20kHz, and the ultrasound time is 4min.

[0025] (4) After the above-mentioned ultrasound is completed, the temperature is cooled to 595℃ with the furnace, and the temperature is kept for 9 minutes, and then intermittent ultrasound is a...

Embodiment 3

[0027] (1) Put the Al-Si-Cu alloy ingot into a graphite crucible and overheat to 750°C to completely melt the aluminum block, then refining and removing slag.

[0028] (2) Add Al-5Pr-5Ce (that is, the mass fraction of Pr and Ce each account for 5wt.%) master alloy covered with aluminum foil paper into the melt of step (1), and the amount of master alloy added accounts for the total of the melt The weight percentage is 9wt.%, and then the furnace is heated to 770°C for 20 minutes.

[0029] (3) Place the preheated ultrasonic horn probe in the melt, and apply intermittent ultrasound to the melt. The interval between each ultrasound is 2s, the release time of each ultrasound is 2.5s, the ultrasound power is 2.0kw, the ultrasound The frequency is 20kHz, and the ultrasound time is 5min.

[0030] (4) After the above-mentioned ultrasound is completed, the temperature is cooled to 585℃ with the furnace and kept for 10 minutes, and then intermittent ultrasound is applied to the melt again. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com