Thixotropic plasticity forming method of metal-based composite material

A composite material and plastic forming technology, applied in the direction of metal processing equipment, etc., can solve the complex and difficult forming process of metal matrix composite materials, achieve the effects of reducing energy consumption, improving product quality, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Preheat the mold to 280°C, and spray lubricant in the mold cavity for later use. At the same time, the semi-solid SiC with a solid phase rate of 93% obtained by isothermal heat treatment P / AZ61 magnesium-based composite material is kept at 15°C above the solidus line for 30 minutes, and the above-mentioned blank is machined into Φ50×17.5mm, placed in a preheated mold, and thixotropic plastic forming is performed in a hydraulic die forging press.

Embodiment 2

[0015] Preheat the mold to 295°C, and spray lubricant in the mold cavity for later use. At the same time, the semi-solid B4Cp / YII2 aluminum-based composite material obtained by mechanical stirring method with a solid phase rate of 88% was kept at 25°C above the solidus line for 16 minutes, and the above blank was machined into Φ50×17.5mm and placed in a preheated In-die, thixoplastic forming in a hydraulic die forging press.

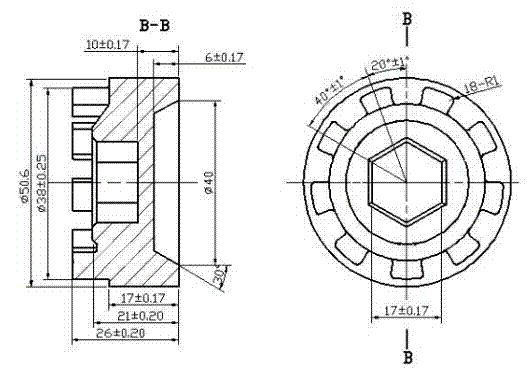

[0016] figure 1 The CAD drawing of the parts selected for the present invention, it can be seen from the figure that the part structure is complex, and nine 9mm high claws need to be formed on the peripheral surface, and the center is a round table and an inner hexagonal hole. It is required that the surface has no obvious defects after forging, and the convex The tooth part is fully formed.

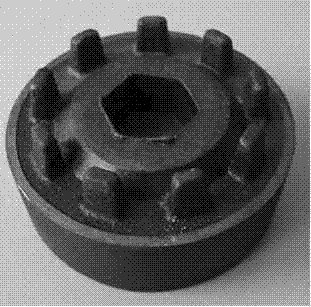

[0017] figure 2 For the composite gear parts obtained by thixotropic plastic forming in the present invention, it can be seen that the surface of the parts is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com