Non-contact electric energy transmission system based on Z-source inverter and phase-shifted control method of transmission system

A technology of power transmission system and impedance source, which is applied in the direction of conversion equipment with intermediate conversion to AC, which can solve problems such as load work and achieve the effect of preventing current backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

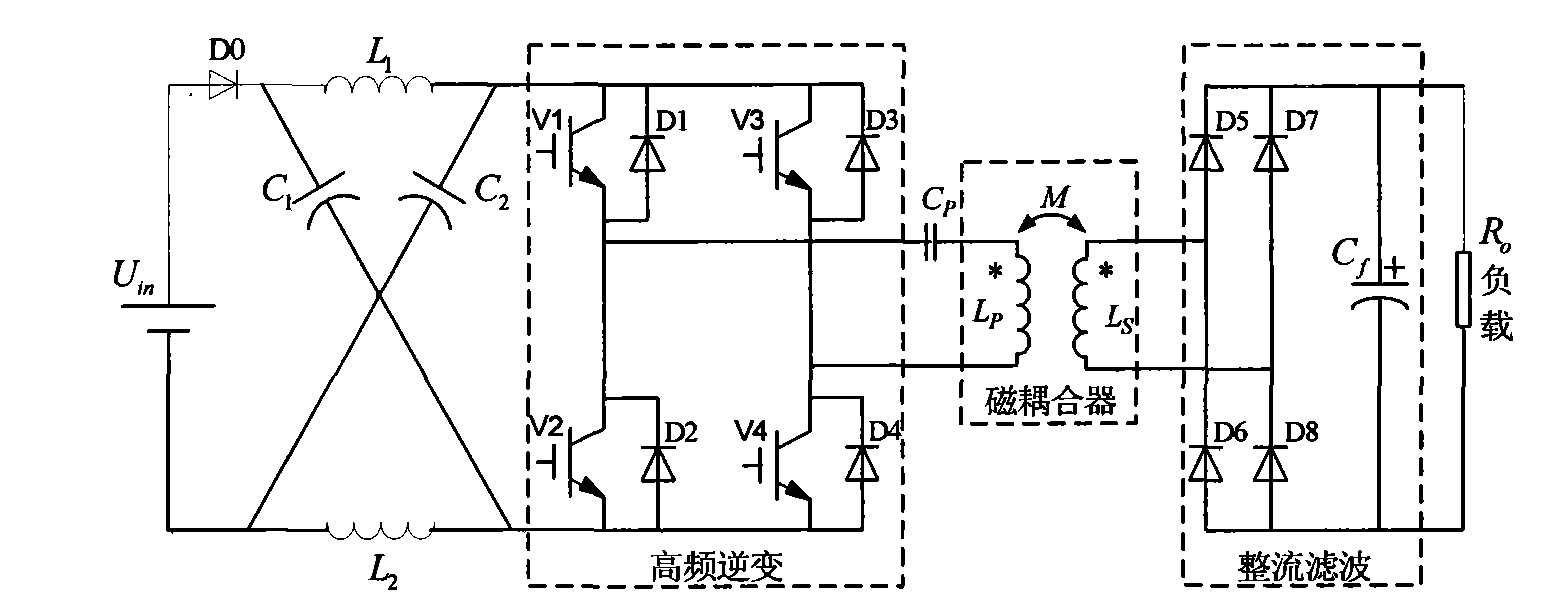

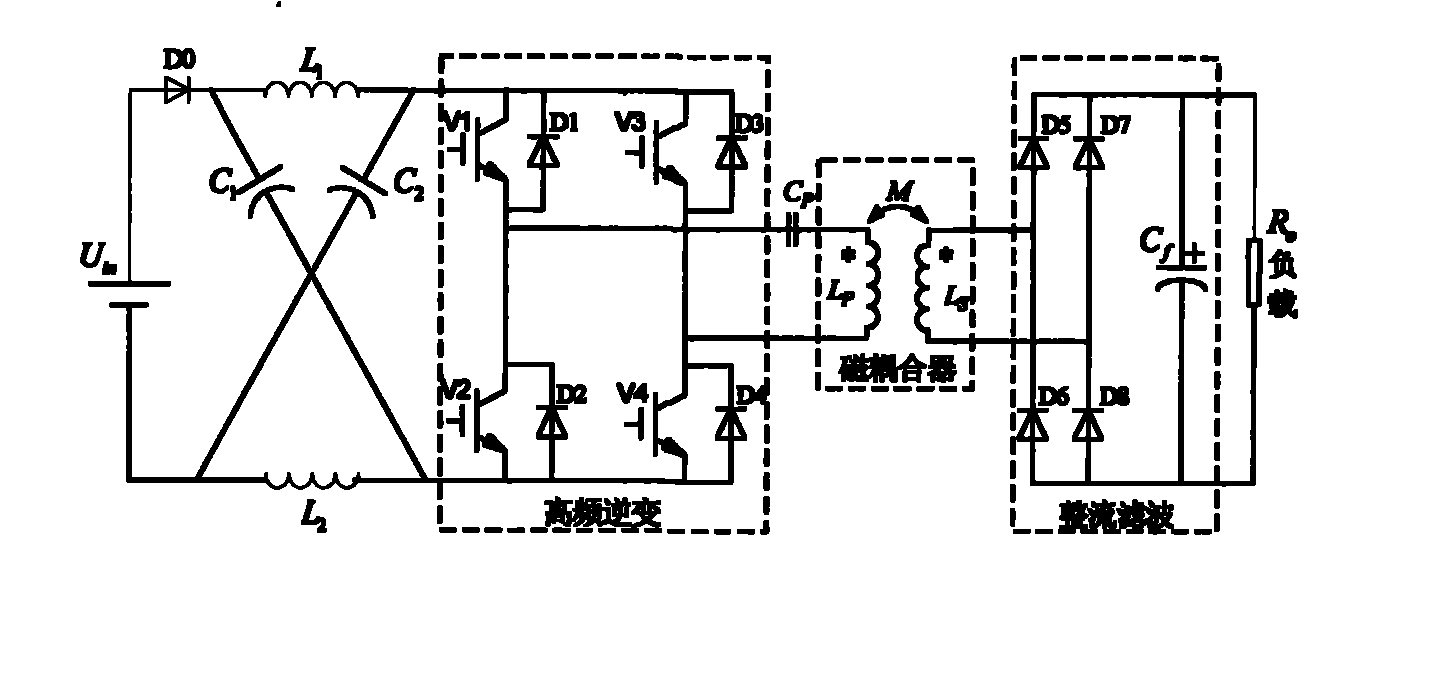

[0013] Such as figure 1 As shown, the figure is a topology diagram of a non-contact power transmission system based on an impedance source inverter. In this circuit diagram, the circuit is divided into sending and receiving parts by the coupler. The sending part includes the input DC power supply, which can be obtained by rectifying and filtering the AC grid; the impedance source network, which enables the inverter bridge arm to withstand instantaneous short circuit and open circuit, increases system reliability, and introduces direct zero vector and Open circuit zero vector, so as to provide the possibility of step-up and step-down for the inverter. In addition, in order to prevent the backflow of current, a diode must be connected in series after the voltage source; the high-frequency inverter circuit is used to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com