Graphene reinforced aluminum matrix composite material and preparation method

A composite material and aluminum-based technology, applied in the field of composite materials, can solve the problems of poor graphene dispersion, low strengthening efficiency, poor interface bonding, etc., and achieve the effect of complete graphene structure, avoiding interface reaction and excellent material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a graphene-reinforced aluminum-based composite material and its preparation method. The preparation steps are as follows:

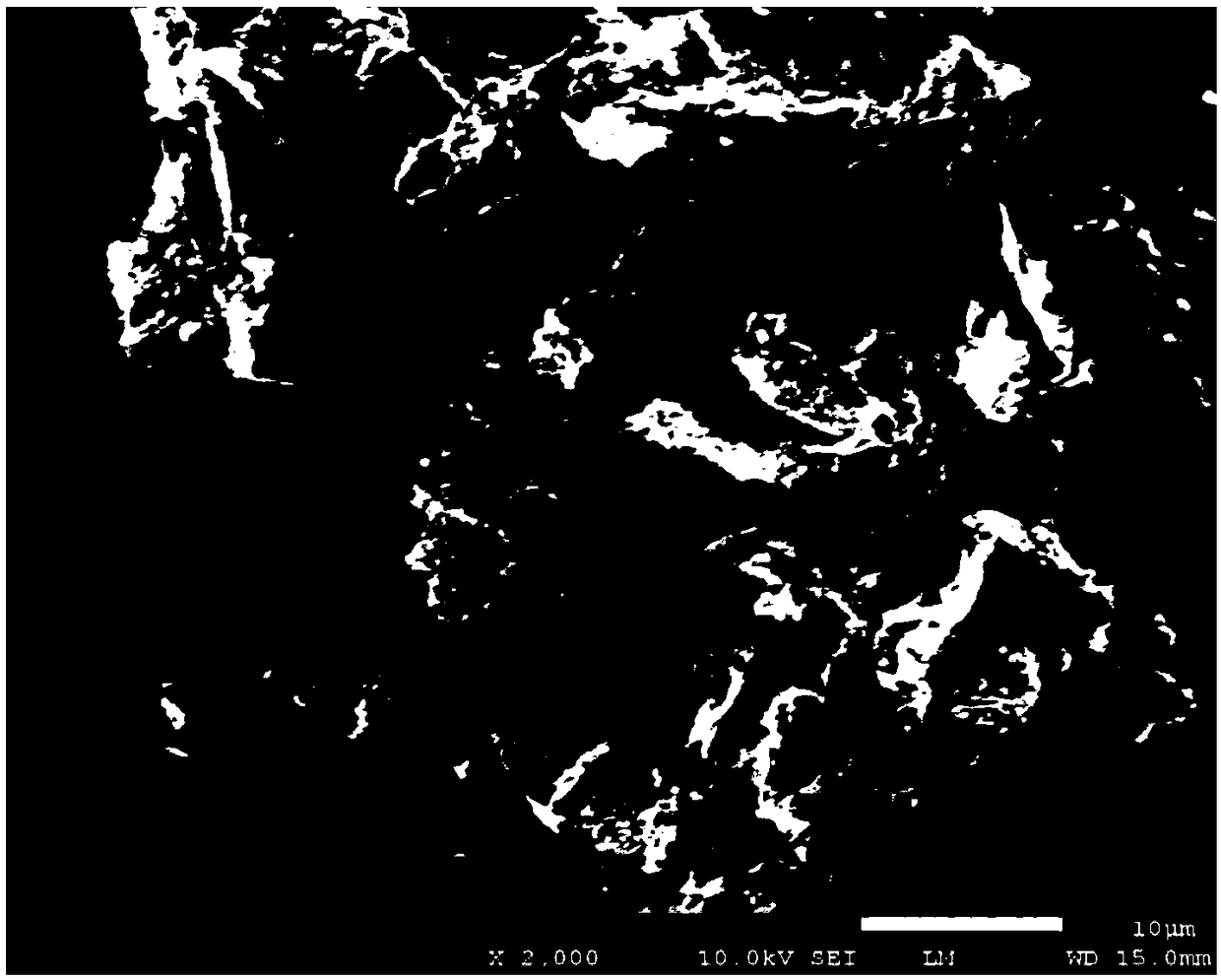

[0035] 1) Get 5g graphene and ultrasonically disperse in ethanol solution, carry out metal nickel-plating treatment to it in advance after freeze-drying; Prepared nickel-plated graphene is as attached figure 1 , the graphene is uniformly covered by the surface nickel layer.

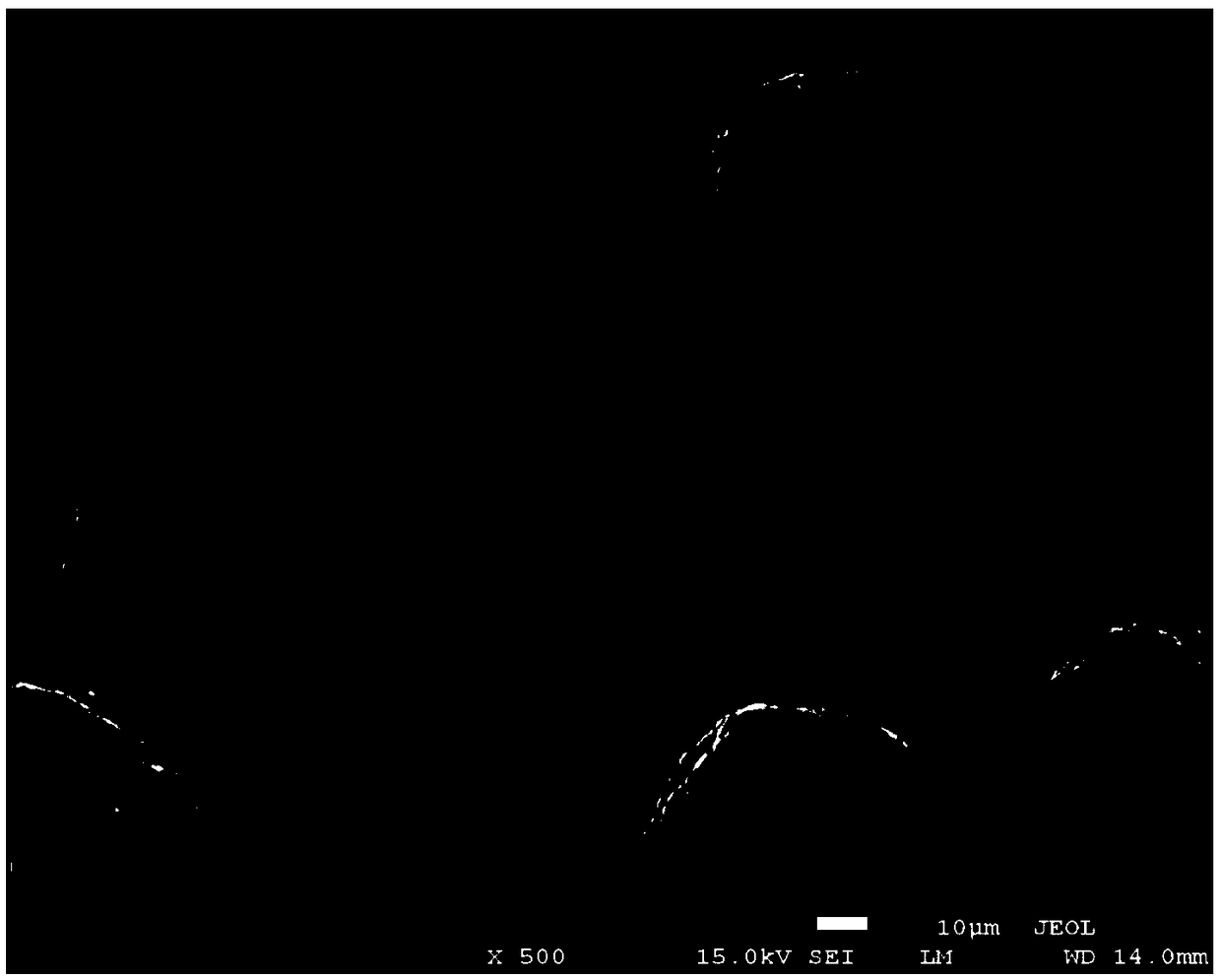

[0036] 2) Take 100g of industrial pure aluminum powder, the aluminum particle size is 80-120μm, ball mill it with nickel-plated graphene for 12h, and add 0.01g of stearic acid as a surfactant. The prepared mixed powder is as attached figure 2 , nickel-coated graphene is uniformly attached to the surface of aluminum-based powder.

[0037] 3) Put 400g of Al5wt.% Cu into the alumina crucible and heat until it melts, put the ultrasonic probe deep into the liquid surface and turn on the ultrasonic, mix the fine powder and send it into the melt with an external...

Embodiment 2

[0056] 1) Get 1g of graphene and ultrasonically disperse in ethanol solution, freeze-dry and carry out metal nickel plating to it in advance;

[0057] 2) Take 100g of industrial pure aluminum powder, the aluminum particle size is 80-120μm, and ball mill it with the nickel-plated graphene under the protection of argon for 24h, and add 0.01g of stearic acid as a surfactant;

[0058] 3) Put 400g of Al5wt.% Cu alloy into an alumina crucible and heat until it melts. Put the ultrasonic probe deep into the liquid surface and turn on the ultrasonic. Graphene fine powder is sent into the melt from the center hole of the ultrasonic probe under argon flow, and then obtained by air cooling. 0.2wt.% graphene reinforced aluminum matrix composite. During this process, the nominal ultrasonic power is 2000W, the melt temperature is controlled at 680°C-550°C, the flow rate of the mixed powder is 1-2g / min; the ultrasonic probe is cylindrical, and its interface size is The size of the central c...

Embodiment 3

[0073] This embodiment relates to a method for preparing a graphene-reinforced aluminum-based composite material, and the specific steps are as follows:

[0074] 1) Get 5g graphene and ultrasonically disperse in ethanol solution, after freeze-drying, carry out metal copper-plating treatment to it in advance;

[0075] 2) Take 100g of high-purity aluminum powder with an aluminum particle size of 60-100 μm, ball mill it with Cu-plated graphene for 12 hours, and add 0.01g of stearic acid as a surfactant;

[0076] 3) Put 400g of Al20wt.% Cu alloy into an alumina crucible and heat until it melts. Put the ultrasonic probe deep into the liquid surface and turn on the ultrasonic, mix the fine powder and send it into the melt with an external delivery tube under argon flow, and then air-cool to obtain 1wt. .% graphene-reinforced Al-based composites. During this process, the nominal ultrasonic power is 2000W, the melt temperature is controlled at 660°C-550°C, the flow rate of the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com