A method for preparing bimetal composite ingot by using solidified liquid cavity

A technology of composite ingot and coagulation liquid, which is applied in the field of preparing bimetallic composite ingot by using coagulation liquid cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

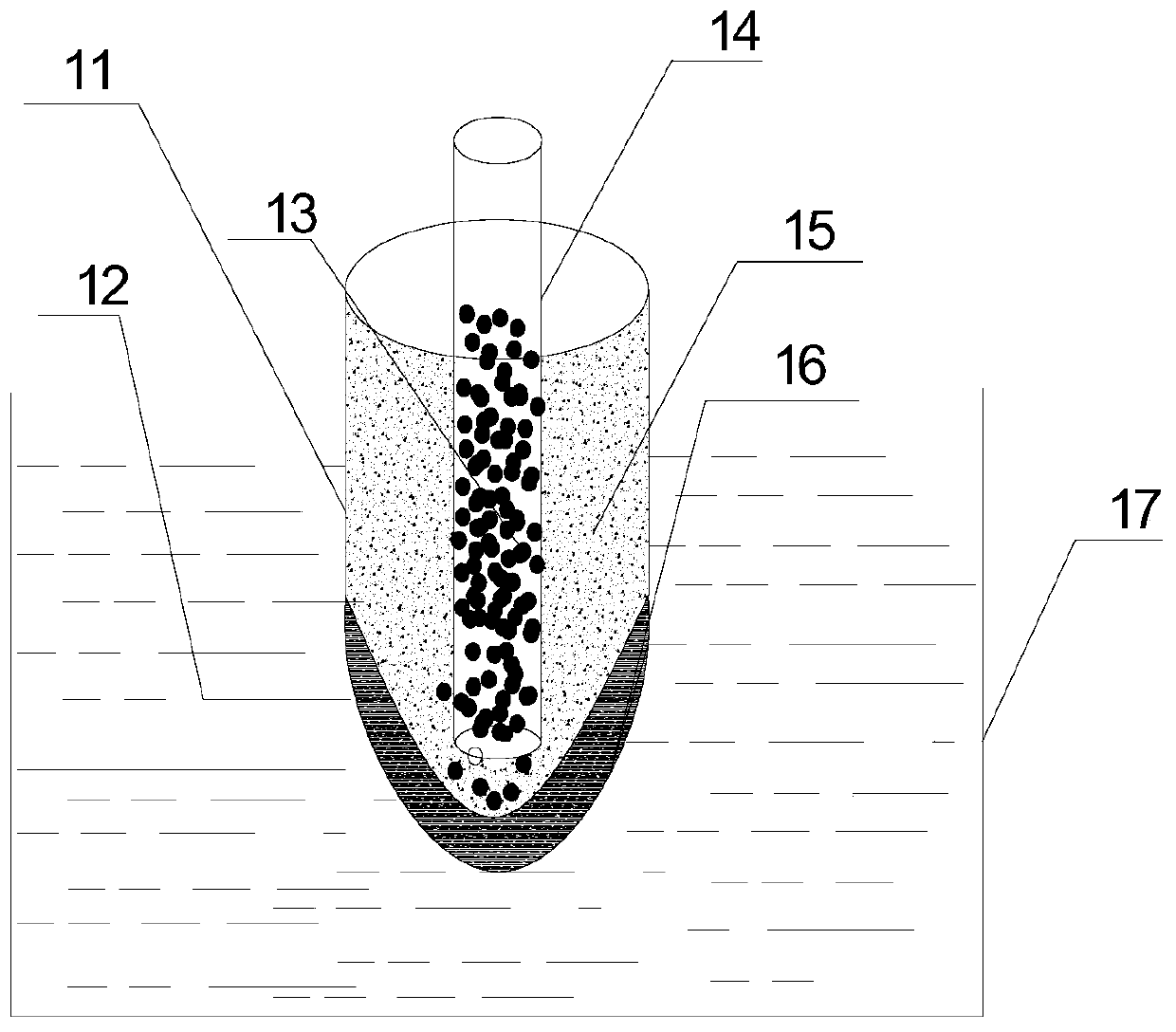

[0016] The invention provides a method for preparing a bimetallic composite ingot by using a solidification liquid cavity, comprising the following steps:

[0017] a) cooling the inverted cone crucible containing the liquid first metal melt, so that the first metal melt forms a solidification liquid cavity;

[0018] b) adding a second metal semi-solid slurry into the solidification liquid cavity, and obtaining a bimetallic composite ingot after solidification;

[0019] The first metal melt and the second metal semi-solid slurry are selected from different metals.

[0020] The invention firstly cools the inverted cone crucible containing the liquid first metal melt, so that the first metal melt forms a solidification liquid cavity. When the inverted cone crucible containing the liquid first metal melt is cooled, under the action of rapid heat conduction of the cooling medium, the liquid first metal melt in contact with the inner wall of the inverted cone crucible rapidly nucle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com