Method for preparing alloy semi-solid thixotropic blank by continuously extruding elementary substance mixed powder

A mixed powder, semi-solid technology, applied in the field of material processing, can solve the problems of high processing cost, high cost, large thermal shock of the mold, etc., and achieve the effect of reducing production cost and cycle, reducing mold material requirements, and improving mold life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

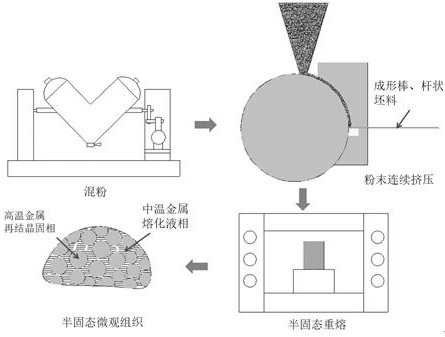

[0026] The semi-solid billets prepared in this experiment are copper-aluminum semi-solid billets (Cu -10wt% Al), and the binary alloy powders used are aluminum powder with a purity of 99.7% (particle size is 200 mesh) and copper with a purity of 99.8%. powder (grain size is 200 mesh)

[0027] (1) Fully mix copper powder and aluminum powder with a mass ratio of 9:1 on a V-type powder mixer, and the mixing time is 30 minutes.

[0028] (2) Preheat the mold of the CONFORM continuous extrusion machine, the preheating temperature is 400°C, and the holding time is 30 minutes.

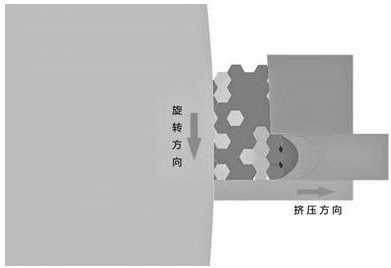

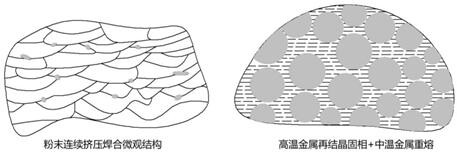

[0029] (3) Pour the mixed powder into the extrusion wheel groove of the CONFORM powder continuous extrusion machine. The extrusion wheel speed is 4rpm. The mixed powder is continuously fed to the mold cavity for accumulation, and the extrusion wheel continues to rotate. Under the action of friction Next, the powder is crushed and welded, and the bar is formed from the die mouth.

[0030] (4) Cut off the rod,...

Embodiment 2

[0034] The semi-solid billets prepared in this experiment are titanium-aluminum semi-solid billets (Al-8wt%Zn), and the binary alloy powders used are aluminum powder with a purity of 99.5% (particle size is 200 mesh), and zinc with a purity of 99.5%. Powder (particle size is 200 mesh).

[0035] (1) Fully mix aluminum powder and zinc powder on a V-type powder mixer with a mass ratio of 9.2:0.8, and the mixing time is 60 minutes.

[0036] (2) Preheat the mold of the CONFORM powder continuous extrusion machine, the preheating temperature is 400°C, and the holding time is 30 minutes.

[0037] (3) Pour the mixed powder into the extrusion wheel groove of the CONFORM powder continuous extrusion machine. The extrusion wheel speed is 7rpm. The mixed powder is continuously fed to the mold cavity for accumulation, and the extrusion wheel continues to rotate. Under the action of friction Next, the powder is crushed and welded, and the bar is formed from the die mouth.

[0038] (4) Cut o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com