Sand mould vacuum pressure casting technology and equipment

A technology of vacuum pressure casting and sand moulding, which is used in the field of high density production, can solve the problems of long production cycle, poor structural stability of cold-worked materials, deformation of parts, etc., and achieves the effect of ensuring cleanliness and avoiding shrinkage and thermal cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

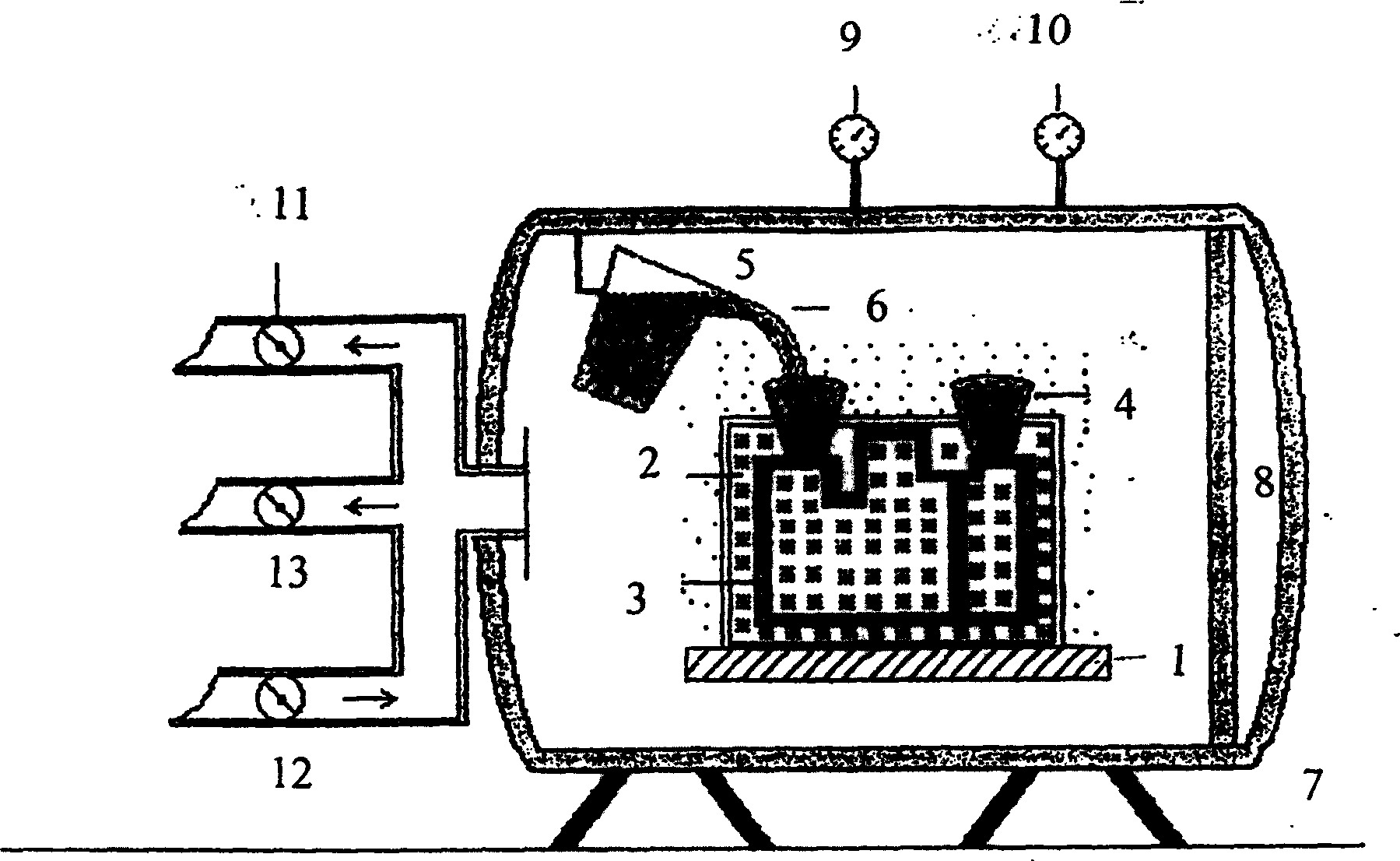

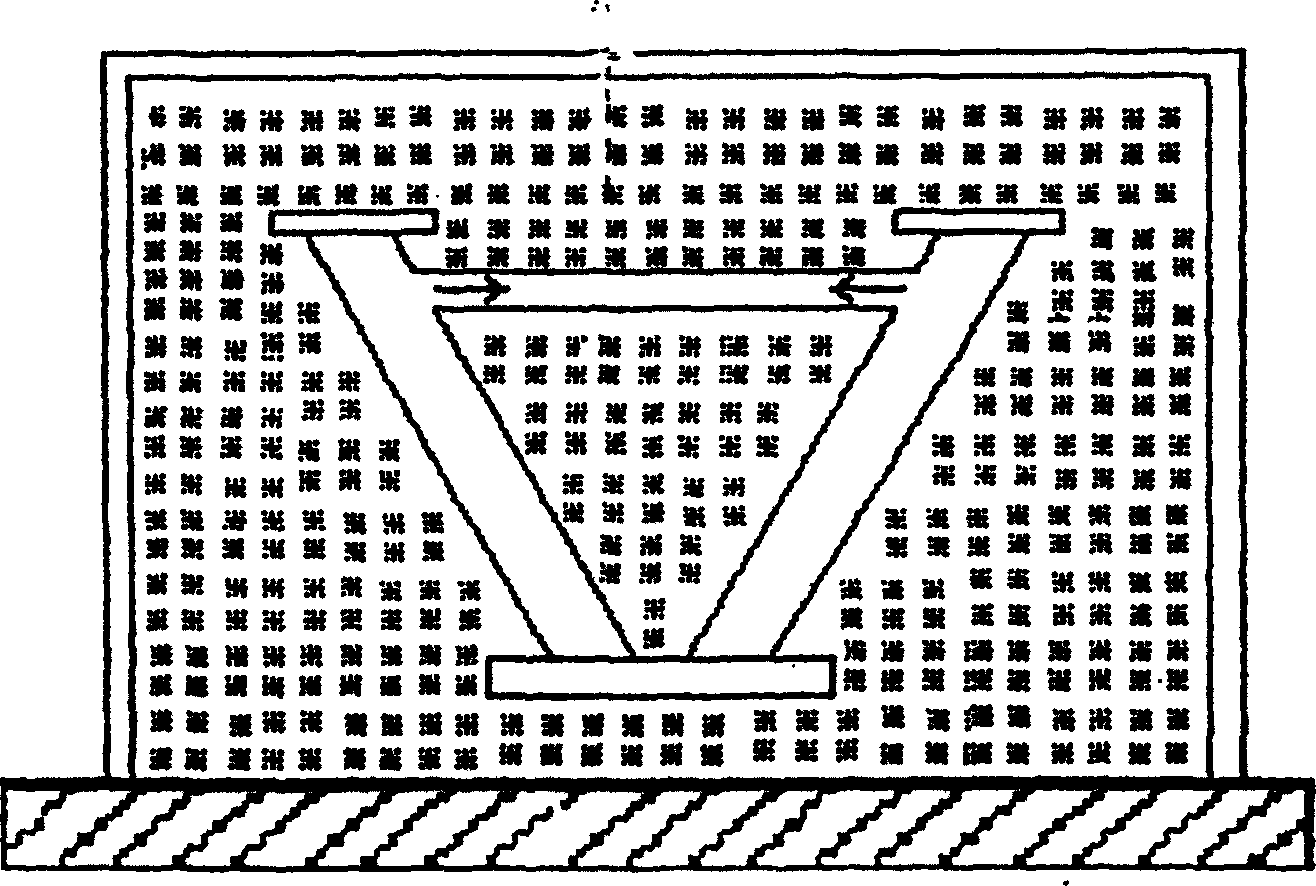

[0027] exist Figure 1 , Molding: Use quartz sand as the raw material of the sand mold, mix it with high-strength no-hardening resin, shape, repair, and temperature aging. The shape can withstand a pressure difference of ±1 MPa, and the temperature is aged for 8 hours. The casting tank is equipped with a pressure gauge 9, a vacuum negative pressure gauge 10, a vacuum valve 11, a pressure valve 12 and an exhaust valve 13. The vacuum valve is connected to the vacuum through the vacuum tube 14. Tank 15 and vacuum pump 16 are connected, pressure valve 12 is connected with pressure tank 18 and air compressor 19 through pressurized pipe 17, vacuum tank is equipped with pressure gauge 20, and pressure tank is equipped with safety valve 21 and pressure gauge 22.

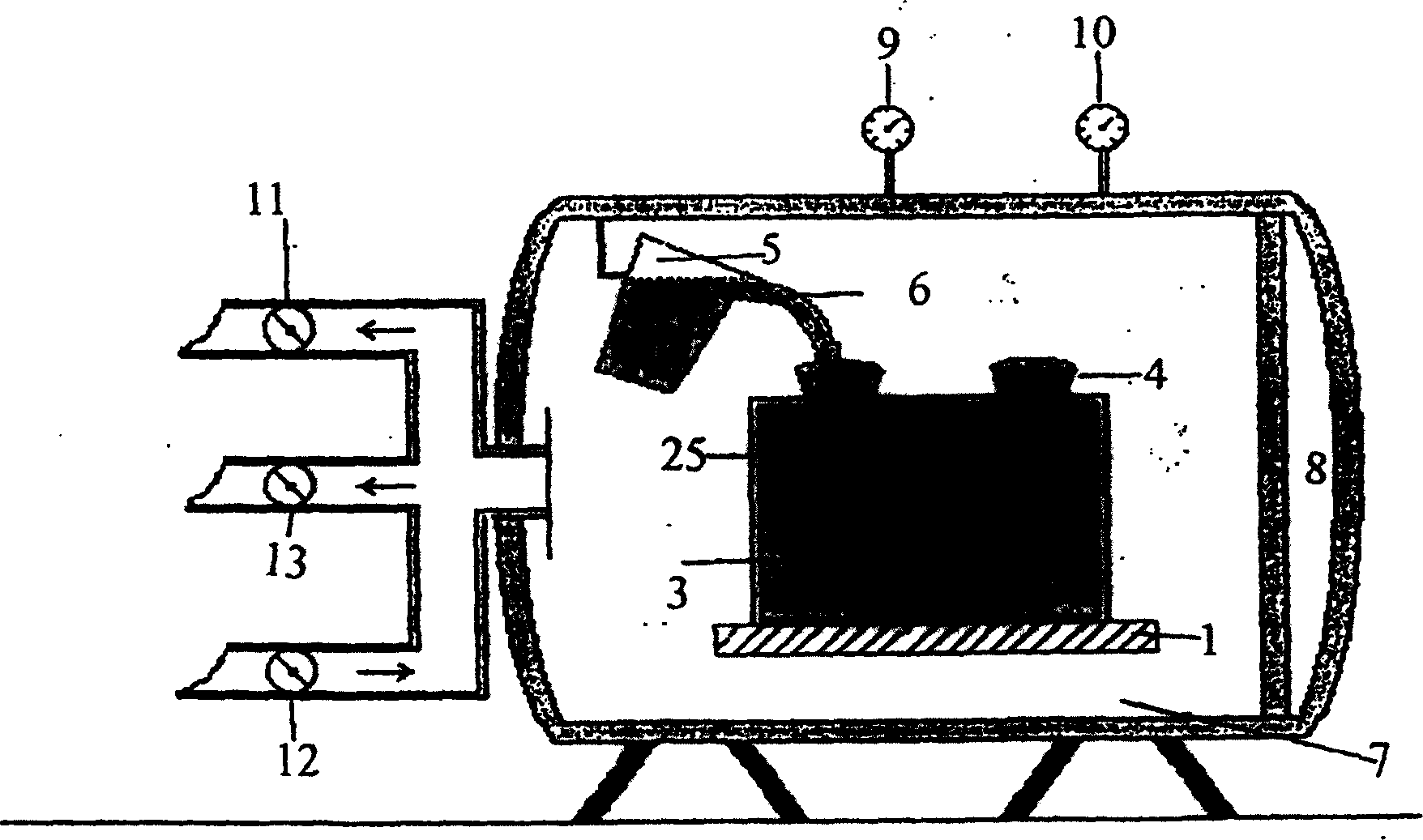

[0028] exist Figure 5 , put the sand mold base 1 into the casting tank 7, fix the sand mold 2 and close the mold. The ladle 15 is hung on the casting frame 24, the casting cup and the pouring cup 4 are installed, the refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com