information label film

An information label and film technology, applied in the field of label film, can solve the problem of easy generation of oil pollution on the surface of the label film, and achieve the effect of preventing oil pollution, blocking migration and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

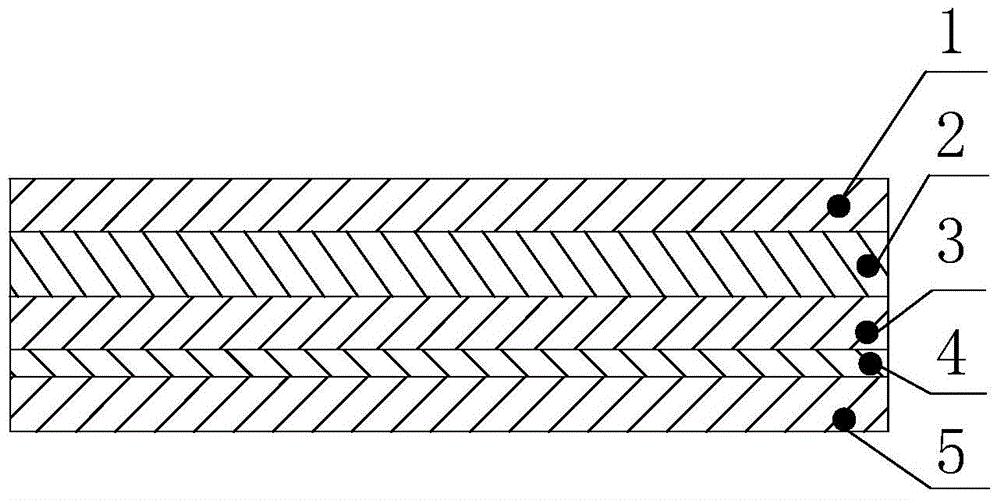

[0026] Such as figure 1 As shown, the information label film is composed of a coating 1, a PET film 2, an aluminum layer 3, an adhesive layer 4, and a substrate 5, which are sequentially arranged as an integrated structure;

[0027] The material of the coating is mixed by matrix, reactive diluent, deionized water, defoamer, leveling agent and wetting and dispersing agent, and the parts by weight of each raw material are: 16 parts of matrix, 10 parts of reactive diluent , 9 parts of deionized water, 0.3 parts of defoamer, 0.4 parts of leveling agent, 0.4 parts of wetting and dispersing agent;

[0028] The thickness of the coating is 0.5-1 μm; the thickness of the PET film is 45-50 um; the thickness of the aluminum layer is 401-500 angstroms; the substrate is a release film.

[0029] The matrix is an acrylate copolymer; the reactive diluent is -β-hydroxyethyl methacrylate (HEMA); the defoamer is a silicone defoamer; the leveling agent is Acrylic ester leveling agent; the wet...

Embodiment 2

[0055] Such as figure 1 As shown, the information label film is composed of a coating 1, a PET film 2, an aluminum layer 3, an adhesive layer 4, and a substrate 5, which are sequentially arranged as an integrated structure;

[0056] The material of the coating is mixed by matrix, reactive diluent, deionized water, defoamer, leveling agent and wetting and dispersing agent. The parts by weight of each raw material are: 35 parts of matrix, 30 parts of reactive diluent , 25 parts of deionized water, 0.4 parts of defoamer, 0.6 parts of leveling agent, 0.6 parts of wetting and dispersing agent;

[0057] The thickness of the coating is 0.5-1 μm; the thickness of the PET film is 45-50 um; the thickness of the aluminum layer is 401-500 angstroms; the substrate is release paper (existing release paper).

[0058] The base is an acrylate copolymer; the reactive diluent is 1,6-hexanediol diacrylate (HDDA); the defoamer is a silicone defoamer; the leveling agent It is a phosphate-modified...

Embodiment 3

[0069] Such as figure 1 As shown, the information label film is composed of a coating 1, a PET film 2, an aluminum layer 3, an adhesive layer 4, and a substrate 5, which are sequentially arranged as an integrated structure;

[0070] The material of the coating is composed of matrix, reactive diluent, deionized water, defoamer, leveling agent and wetting and dispersing agent. The parts by weight of each raw material are: 40 parts of matrix, 32 parts of reactive diluent , 30 parts of deionized water, 0.5 parts of defoamer, 0.7 parts of leveling agent, 0.8 parts of wetting and dispersing agent;

[0071] The thickness of the coating is 0.5-1 μm; the thickness of the PET film is 45-50 um; the thickness of the aluminum layer is 401-500 angstroms; and the substrate is a release film.

[0072] The base is an acrylate copolymer; the reactive diluent is butyl glycidyl ether (660); the defoamer is a polyether defoamer; the leveling agent is a silicone fluid Leveling agent; Described we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com