Method for producing hexafluoropropane oxide and coproducing perfluorovinyl ether

A technology of hexafluoropropylene oxide and perfluorovinyl ether is applied in the field of preparation of fluorine-containing fine chemicals, which can solve problems such as trouble and achieve the effect of avoiding pollution and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

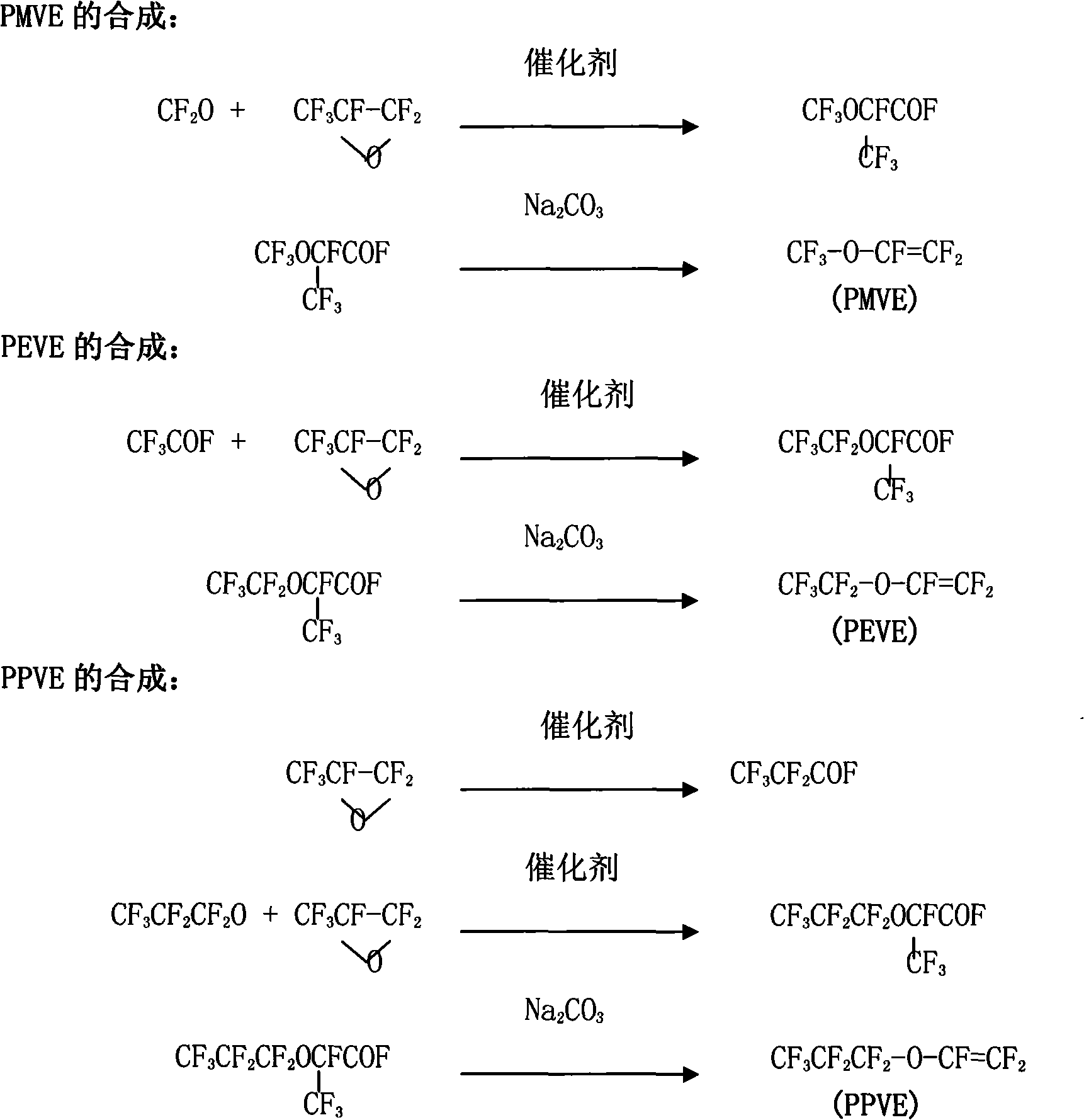

Method used

Image

Examples

preparation example Construction

[0020] 1. Preparation of mixed gas:

[0021] According to the prior art, hexafluoropropylene reacts with an oxidizing agent under certain conditions of temperature, pressure, solvent, etc. to obtain a mixed gas including hexafluoropropylene oxide, perfluoroacetyl fluoride, carbonyl fluoride and unreacted hexafluoropropylene and oxygen .

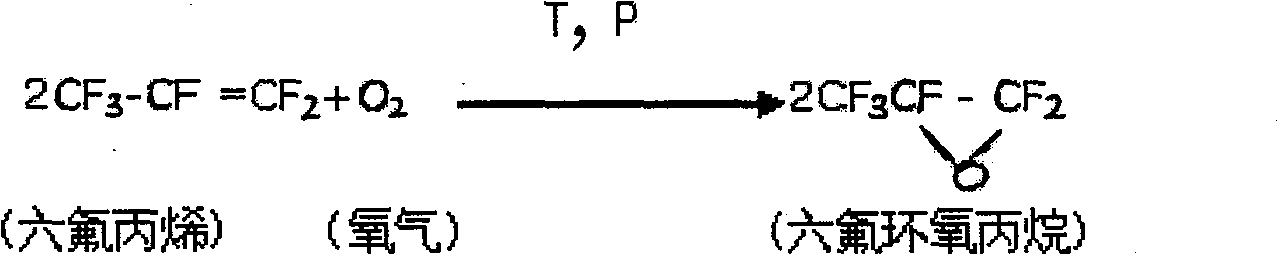

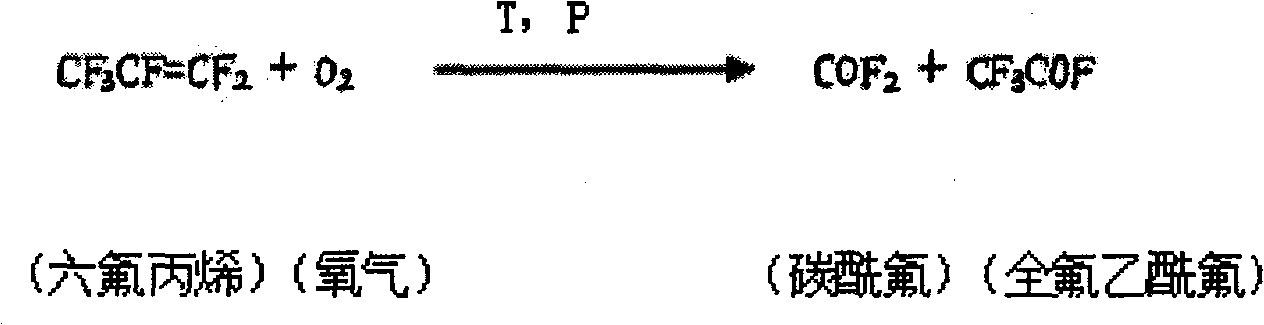

[0022] Main response:

[0023]

[0024] side effects:

[0025]

[0026] Oxygen and hexafluoropropylene are respectively placed in the oxygen barostat and hexafluoropropylene barostat through the regulating valve; the pressure of the oxygen and hexafluoropropylene barostat is controlled to be constant at 1.0-1.6Mpa; the oxygen and hexafluoropropylene are respectively passed through the regulating valve and The mass flow meter enters the mixer according to the mass ratio of hexafluoropropylene:oxygen of 5 to 9.4:1, and enters the reactor through the regulating valve. The ratio of the mass of the solvent in the reactor to the total mass ...

Embodiment 1

[0040] Oxygen and hexafluoropropylene are respectively in the oxygen barostat and hexafluoropropylene barostat through the regulating valve; the pressure of the oxygen and hexafluoropropylene barostat is controlled to be constant at 1.2Mpa; the oxygen and hexafluoropropylene are respectively through the regulating valve and the mass flow rate The meter enters the mixer according to the mass ratio of hexafluoropropylene: oxygen of 6.25: 1, and enters the reactor through the regulating valve, and the ratio of the quality of the solvent in the reactor to the total mass of the reactant hexafluoropropylene and oxygen is controlled at 8: 1. The temperature in the reaction kettle is 90°C and the pressure is 1.3Mpa, and the oxygen and hexafluoropropylene react at this temperature and pressure to obtain a mixed gas mainly containing hexafluorocyclopropane, carbonyl fluoride and perfluoroacetyl fluoride. In the mixed gas, 60.72% of hexafluoropropylene oxide, 11.8% of carbonyl fluoride, 2...

Embodiment 2

[0045] As described in Example 1, the difference is that oxygen and hexafluoropropylene enter the mixer through a regulating valve and a mass flow meter at a mass ratio of 7:1 hexafluoropropylene:oxygen, and the hexafluoropropylene oxide in the mixed gas is 60.47% , carbonyl fluoride 10.9%, perfluoroacetyl fluoride 19.38%, hexafluoropropylene 7%, oxygen 1.26%. Both are mass ratios.

[0046] The above-mentioned mixed gas is passed into the coarse fractionation tower, the light component separated from the coarse fractionation tower enters the rectifying tower, and the non-condensable gases such as oxygen are removed under the conditions of pressure 3.2MPa and top temperature -25 ℃ to obtain carbonyl Mixed gas mainly composed of fluorine and perfluoroacetyl fluoride, carbonyl fluoride 32%, perfluoroacetyl fluoride 66%, hexafluoropropylene oxide 1%, hexafluoropropylene 1%. Both are mass ratios.

[0047] The above-mentioned mixed gas mainly composed of carbonyl fluoride and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com