Lithium titanate coated cathode and lithium ion battery using cathode

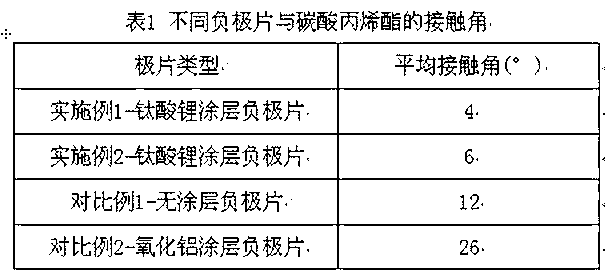

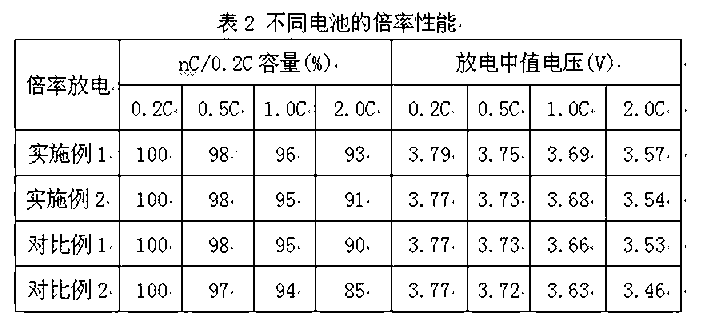

A lithium-ion battery and lithium titanate technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as poor wettability of electrolyte, loss of battery power characteristics, and low surface of nano-alumina materials. Achieve good electrolyte wettability, rate performance and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Slurry preparation for lithium titanate coating:

[0039] Prepare water-based glue with 1% CMC, 2.8% SBR and deionized water. Add 96.2% nano-lithium titanate into the glue, stir with a high-speed disperser, and disperse at a high speed for 3 hours at a shear rate of 2500 rpm to form a slurry with a solid content of 40%.

[0040](2) Preparation of positive electrode:

[0041] Dissolve 94% lithium cobaltate, 3% conductive agent and 3% polyvinylidene fluoride (PVDF) in N-methyl-2-pyrrolidone (NMP) to make positive electrode slurry. Coat the slurry on the aluminum foil, dry, roll, cut into 51×551mm, and weld the aluminum lug at one end.

[0042] (3) Preparation of negative electrode:

[0043] Dissolve graphite, 3% conductive agent and 4% PVDF in NMP to make negative electrode slurry. Coat the slurry on the copper foil, dry and roll. The lithium titanate slurry prepared in step 1 is coated on both sides of the negative electrode sheet by gravure coating, and then dr...

Embodiment 2

[0049] Prepare water-based glue with 3% CMC, 7% SBR and deionized water. Add 90% nano-lithium titanate into the glue, stir with a high-speed disperser, and disperse at a high speed for 3 hours at a shear rate of 2500rpm to form a slurry with a solid content of 40%. Other materials and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Single side thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com