Porous nano carbon fiber material, lithium battery cathode material and cathode plate

A technology of carbon nanofibers and composite cathode materials, applied in the field of electrochemistry, can solve problems such as rapid capacity decay, and achieve the effects of reducing solvent solubility, uniform distribution, and less demanding operation and environmental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 high surface area carbon nanofiber material

[0054] Dissolve 8% by mass of polyacrylonitrile (PAN) / polymethyl methacrylate (PMMA) (7:3, mass ratio) powder in 92% by mass of N-N dimethylformamide (DMF) , Stir vigorously at 60°C for 24h to obtain a homogeneous polymer solution. The solution is subjected to electrospinning under the action of a high-voltage direct current power supply with a voltage of 20kV. The electrospinning obtained above was pre-oxidized at 280°C for 2 hours, and the heating rate was controlled at 10°C / min. The pre-oxidized electrospinning was carbonized at a high temperature in a tube furnace with nitrogen as a protective gas, and carbonized at 1200°C for 1 hour. Finally, Porous nano-carbon fiber material: the length is about 8μm, the diameter is 200nm, and the interior contains a microporous structure with a pore size of about 10nm.

Embodiment 2

[0055] The preparation of embodiment 2 high surface area carbon nanofiber material

[0056] Dissolve 10% by mass of poly(acrylonitrile-styrene) P(AN-St) (AN:St=8:2, molar ratio) powder in 90% by mass of N-N dimethylformamide (DMF ), vigorously stirred at 60°C for 24h to obtain a homogeneous polymer solution. The solution is subjected to electrospinning under the action of a high voltage DC power supply with a voltage of 10kV. The electrospinning obtained above was pre-oxidized at 160°C for 4 hours, and the heating rate was controlled at 10°C / min. The pre-oxidized electrospinning was carbonized at a high temperature in a tube furnace with nitrogen as a protective gas, and carbonized at 600°C for 3 hours. Finally, Porous nano-carbon fiber material: the length is about 6 μm, the diameter is 150 nm, and the interior contains a microporous structure with a pore size of about 8 nm.

Embodiment 3

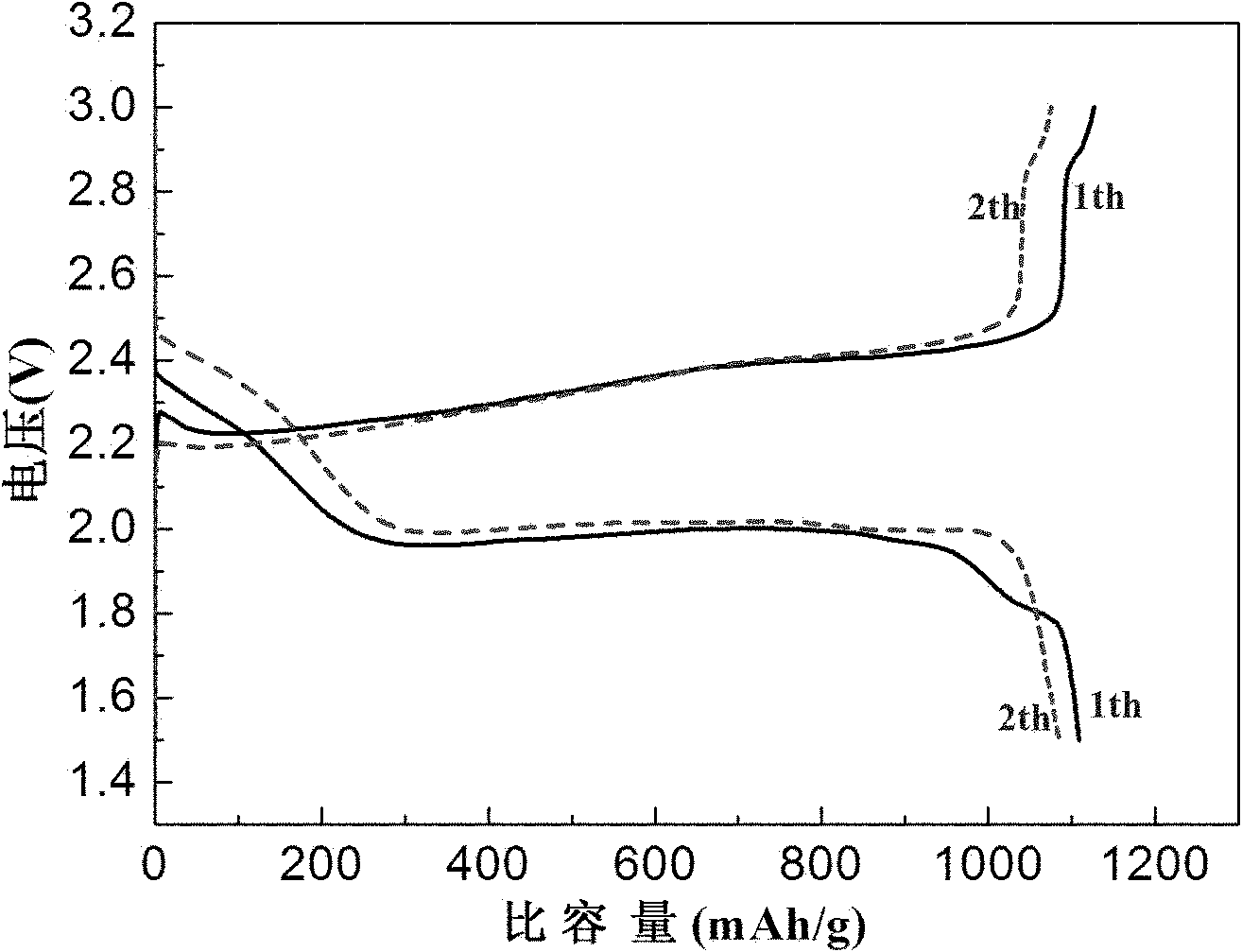

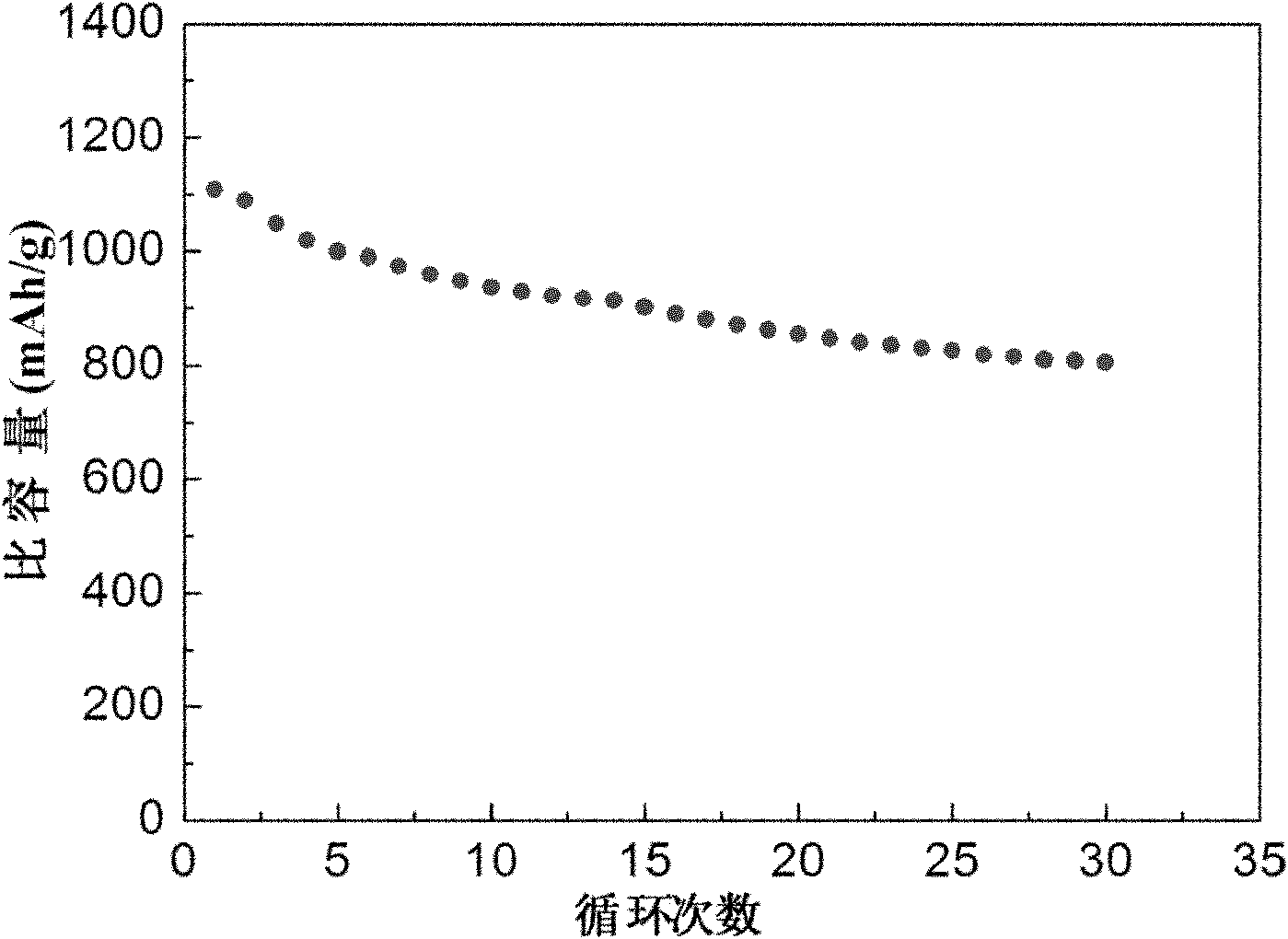

[0057] Example 3 Preparation of Elemental Sulfur / Porous Nano-Carbon Fiber Composite Positive Electrode Material for Lithium Batteries

[0058] The porous nano-carbon fiber material of Example 1 was used to prepare elemental sulfur / porous nano-carbon fiber composite cathode material.

[0059] Dissolve 1 g of sodium sulfide in 20 mL of deionized water to prepare a sodium sulfide solution. Add 1.23g of sublimated sulfur powder to the above sodium sulfide solution for reaction, stir at 25°C for 3 hours until the sulfur powder is completely dissolved, and brown-red sodium polysulfide (Na 2 S x ) solution, and filtered. Dissolve 0.182g of the surfactant cetyltrimethylammonium bromide (CTAB) in 100mL of deionized water, adjust to pH>8 with 0.1mol / L NaOH solution, and mix the filtered sodium polysulfide solution with 0.3 g porous nano-carbon fiber material was simultaneously added to deionized water containing surfactant CTAB, and then ultrasonically stirred for 60 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com