Composite solvent in use for extracting, rectifying and separating arene and method of application

A compound solvent, extractive distillation technology, applied in extraction purification/separation, refined hydrocarbon oil, petroleum industry and other directions, can solve the problems of aromatics purity, difficult operation control, and tray efficiency decline, etc., to improve aromatics recovery rate, The effect of enhancing the solubility and reducing the amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

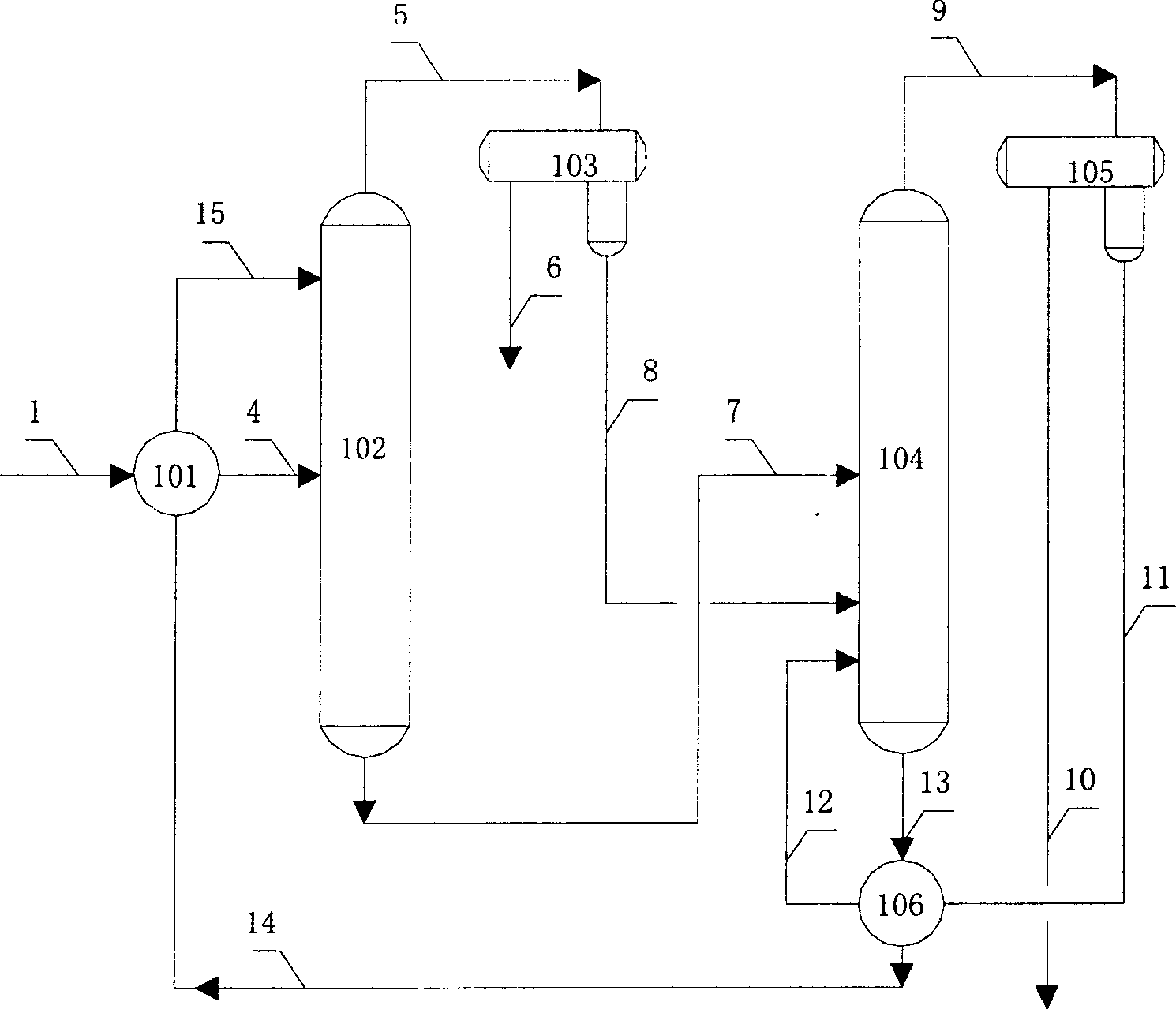

[0024] The C6-C7 fraction of reformed depentanized oil is used as the raw material, and its composition is listed in Table 1. according to figure 1 The shown process carries out extractive distillation to separate benzene and toluene, and the selective solvent used is the composite solvent of the present invention, wherein contains 84 mass % of sulfolane, 15 mass % of 1-methylnaphthalene and 1.0 mass % of water . The operating conditions of extractive distillation and solvent recovery tower are shown in Table 2, and the separation results are shown in Table 3.

example 2

[0026] The operation of extracting and rectifying separation of benzene and toluene was carried out according to the method of Example 1, except that the composite solvent used was 84 mass % sulfolane, 15 mass % diphenylmethane and 1.0 mass % water. The operating conditions of extractive distillation and solvent recovery tower are shown in Table 2, and the separation results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com