A preparation method of a porous lithium ion electrode sheet with high energy density and a lithium ion battery

A technology with high energy density and lithium ions, which is applied in the field of preparation of porous lithium ion pole pieces, can solve the problems that the thickness of the energy density pole piece is not proportional, unfavorable Li+ extraction and intercalation, lithium ion capacity density is not up to standard, etc., to achieve good ionization The effect of conductivity, simple pore-forming method, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

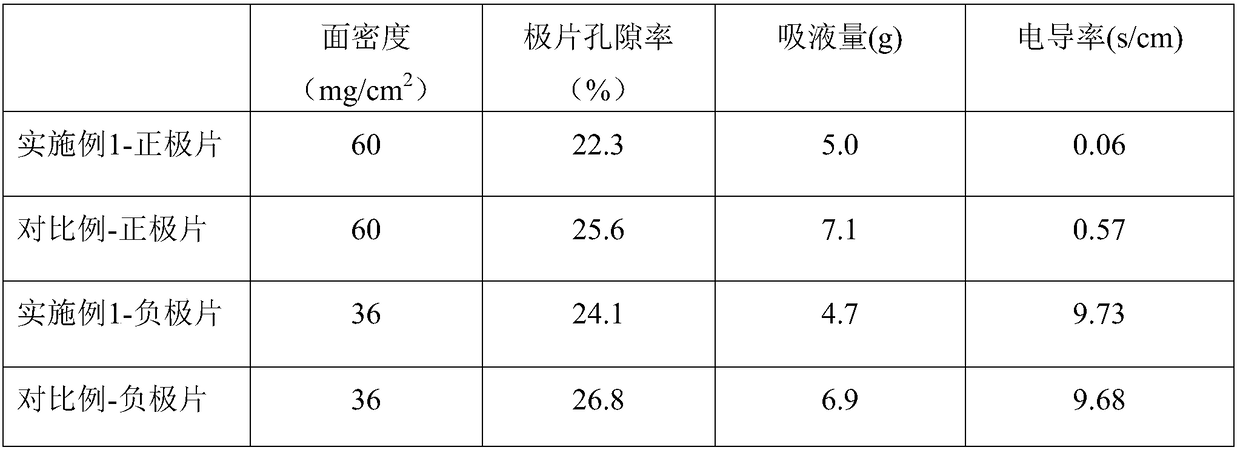

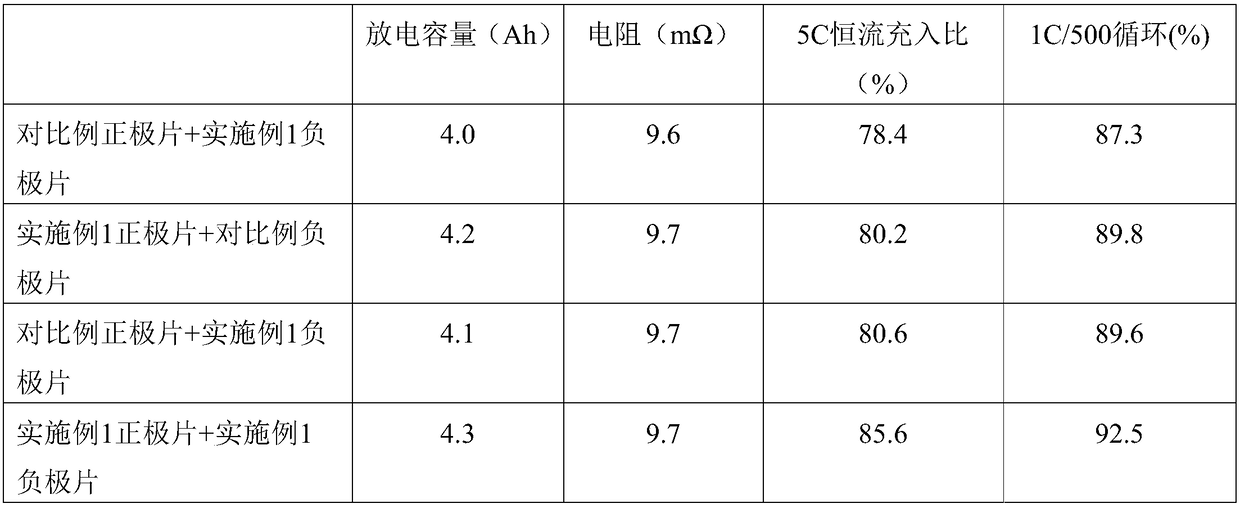

[0040] Put N-methylpyrrolidone and binder (polyvinylidene fluoride) into a double planetary dynamic mixer to prepare glue, add positive active material and positive electrode conductive agent to the glue and mix evenly to obtain a uniform Stable positive electrode slurry (wherein the weight and number ratio of positive electrode active material, conductive agent and binder is 97.3:1.2:1.5), after adding negative electrode active material and negative electrode conductive agent to the glue solution and mixing evenly, a uniform and stable Negative electrode slurry, (wherein the weight and number ratio of negative electrode active material, conductive agent, and binder is 96:1.0:3.0) the prepared slurry is coated on the electrode current collector by spraying or roller coating, The surface density of positive electrode coating is 60mg / cm 2 , negative electrode surface density is 38mg / cm 2 , bake to remove the solvent and moisture absorbed in the air, after the electrode sheet is...

Embodiment 2

[0042]Put the N-methylpyrrolidone and the binder (polyvinylidene fluoride) into the double planetary power mixer to prepare the glue solution, add the positive electrode active material and the positive electrode conductive agent to the glue solution and mix them evenly to obtain a uniform solution. Stable positive electrode slurry (wherein, the weight ratio of positive electrode active material, conductive agent and binder is 97.5:1.0:1.5), after adding negative electrode active material and negative electrode conductive agent to the glue solution and mixing evenly, a uniform and stable slurry is obtained. Negative electrode slurry (wherein, the weight ratio of negative electrode active material, conductive agent, and binder is 96.5:1.2:2.3), and the prepared slurry is applied on the electrode current collector by spraying or roller coating, The surface density of positive electrode coating is 60mg / cm 2 , the negative sheet density is 38 mg / cm 2 , bake to remove the solvent ...

Embodiment 3

[0044] Put the N-methylpyrrolidone and the binder (polyvinylidene fluoride) into the double planetary power mixer to prepare the glue solution, add the positive electrode active material and the positive electrode conductive agent to the glue solution and mix them evenly to obtain a uniform solution. Stable positive electrode slurry (wherein, the weight ratio of positive electrode active material, conductive agent and binder is 97:1.5:1.5), after adding negative electrode active material and negative electrode conductive agent to the glue solution and mixing evenly, a uniform and stable slurry is obtained. Negative electrode slurry (wherein, the weight ratio of negative electrode active material, conductive agent, and binder is 97:0.75:2.25), and the prepared slurry is applied on the electrode current collector by spraying or roller coating, The surface density of positive electrode coating is 60mg / cm 2 , the negative sheet density is 38 mg / cm 2 , bake to remove the solvent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com