Stirring-friction-based crack repair method

A friction stir and repair method technology, applied in the field of defect repair, can solve the problems of repeated cracks, high labor intensity and high repair cost, and achieve the effects of low repair cost, economical and environmental protection, and simple repair process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

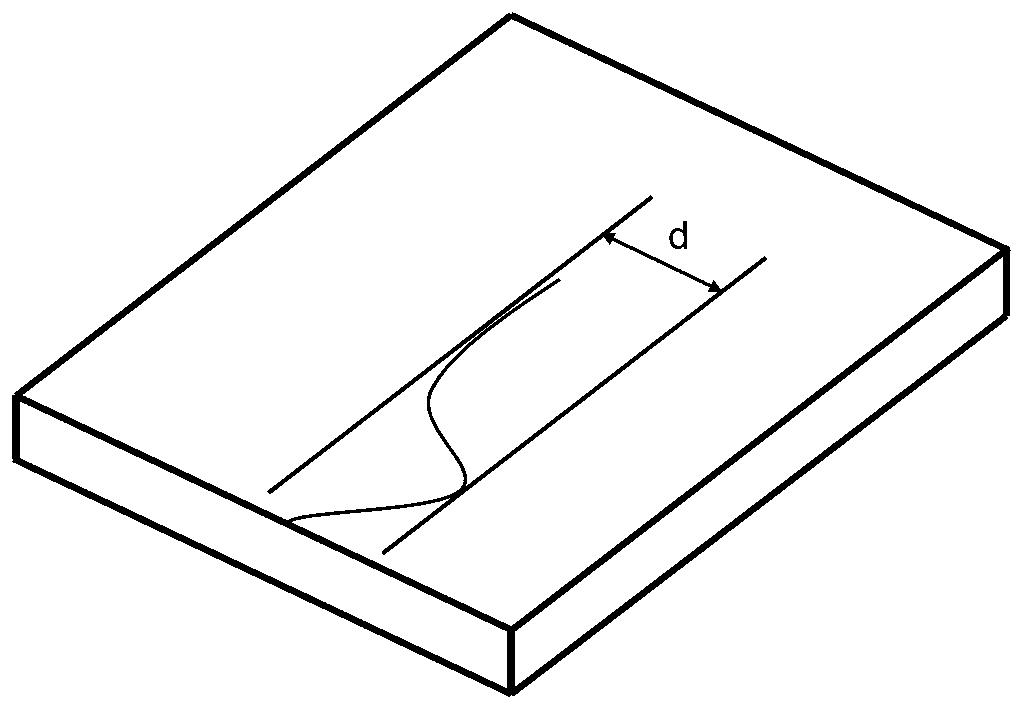

[0028] The repair of long straight cracks on the surface of 6 mm thick 6063-T6 aluminum alloy plate, the crack depth is 1 mm, and the length is 150 mm. The specific steps are as follows:

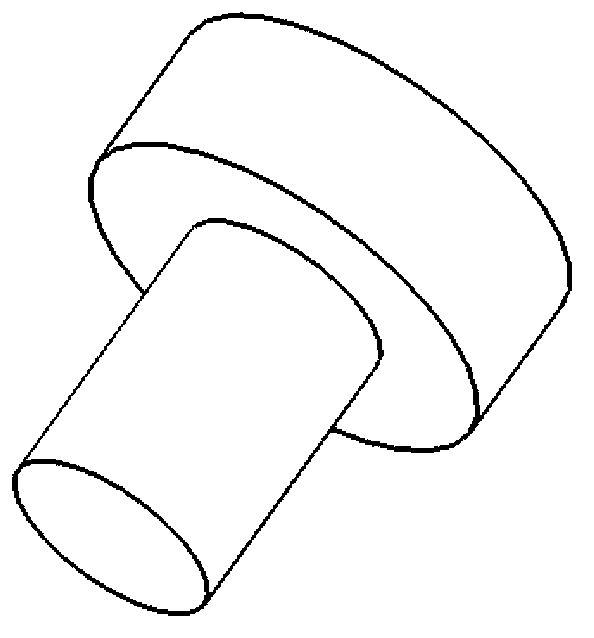

[0029] 1. Select ordinary tool steel as the tool material for friction stir repair without stirring needles, such as image 3 , The shaft shoulder diameter is designed to be 5mm, and quenched and tempered after processing.

[0030] 2. Use sandpaper to polish the surface around the crack to remove scale and surface dirt.

[0031] 3. Rigidly fix the parts to be repaired on the workbench of the friction stir welding machine in the Key Discipline Laboratory of National Defense Digital Manufacturing of Shenyang Aerospace University.

[0032] 4. Select the rotation speed of the repair tool to be 1000 rpm, the travel speed to be 100 mm / min, the pressing amount of the shaft shoulder to be 0.2 mm, and the inclination angle of the main shaft to be 3 degrees, so that the repair tool runs from the begi...

Embodiment 2

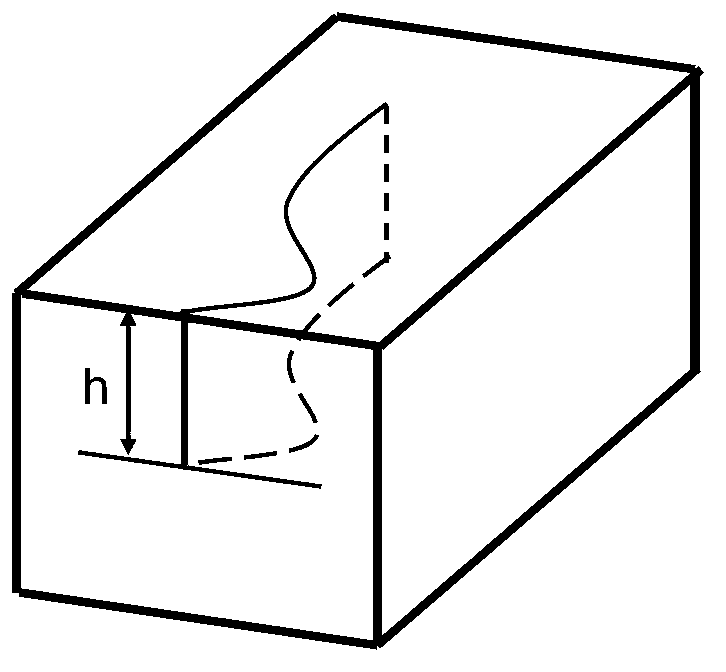

[0036] 4 mm thick 2A12-T4 aluminum alloy plate through crack repair, crack depth 3 mm, length 100 mm, the specific steps are as follows:

[0037] 1. Select ordinary tool steel as the friction stir repair tool material, and use a tapered and threaded stirring needle, such as Figure 4 , length 3.5mm, average diameter 3mm, surface turning shallow thread, shaft shoulder diameter design 10mm, quenching and tempering treatment after processing.

[0038] 2. Use sandpaper to polish the surface around the crack to remove scale and surface dirt.

[0039] 3. Rigidly fix the parts to be repaired on the workbench of the friction stir welding machine in the Key Discipline Laboratory of National Defense Digital Manufacturing of Shenyang Aerospace University.

[0040] 4. Select the rotation speed of the repair tool to be 1200 rpm, the travel speed to be 80 mm / min, the pressing amount of the shoulder shoulder to be 0.5 mm, and the inclination angle of the main shaft to be 3 degrees, so that ...

Embodiment 3

[0044] The difference from Example 1 is:

[0045] 15mm thick 6063-T6 aluminum alloy thick plate 5mm through crack repair, the repair tool form is a tapered thread with a stirring pin, the average diameter of the stirring pin is 5mm, the length is 6mm, and the shaft shoulder diameter is 20mm. Before repairing, add 6063 aluminum wire with a diameter of 1.5mm along the crack, and then repair the crack. The process parameters are as follows: the rotation speed is 1500 rpm, the travel speed is 60 mm / min, and the pressing amount of the shoulder is 1mm. After the repair is completed, carry out Deburring and flashing treatment, and T6 heat treatment for repaired parts.

[0046] The 6063-T6 aluminum alloy plate repaired by this process method has no cracks and other defects through X-ray and fluorescence inspection.

[0047] For alloys such as aluminum and magnesium, ordinary tool steel should be used as the repair tool material; for steel and titanium alloy high melting point materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com