Lime-titania type nuclear power nickel base covered electrode coating and preparation method thereof

A nickel-based electrode, nuclear power technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., to achieve the effects of arc stability, excellent electrode operation performance, and excellent welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

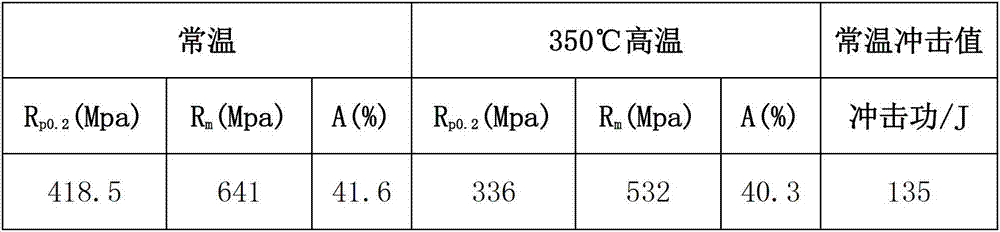

Embodiment 1

[0036] The titanium-calcium type nuclear power nickel-based electrode coating of this embodiment is formed by mixing solid components and liquid components, and the addition quality of the liquid components is 20% to 25% of the solid component quality; wherein

[0037] The solid components are mixed by the following raw materials in weight percentage: marble: 20%, fluorite: 9%, artificial rutile: 35%, titanium dioxide: 2%, feldspar: 3%, metal manganese: 10%, titanium iron : 5%, Soda Ash: 0.5%, CMC: 0.5%, Nickel Powder: 1%, Metal Chromium: 6%, Ferroniobium: 5%, Ice Crystal Powder: 2% and Cr 2 o 3 Powder: 1.0%. Among them, the Ti content in ferro-titanium is 27%-28%, and the Nb content in ferro-niobium is 52-55%.

[0038] The liquid component is potassium-sodium water glass with a potassium-sodium ratio of 3:1 at 40 to 42 Be' at 20°C.

[0039] After mixing the raw materials of the solid component evenly in proportion, sift through a 40-mesh sieve to obtain a dry powder of the...

Embodiment 2

[0041] The titanium-calcium type nuclear power nickel-based electrode coating of this embodiment is formed by mixing solid components and liquid components, and the addition quality of the liquid components is 20% to 25% of the solid component quality; wherein

[0042]The solid components are mixed by the following raw materials in weight percentage: marble: 16%, fluorite: 6%, artificial rutile: 39%, titanium dioxide: 3%, feldspar: 4%, metal manganese: 8%, titanium iron : 5%, Soda Ash: 0.5%, CMC: 0.5%, Nickel Powder: 1%, Metal Chromium: 6%, Ferroniobium: 5%, Ice Crystal Powder: 5% and Cr 2 o 3 Powder: 1.0%.

[0043] The liquid component is potassium-sodium water glass with a potassium-sodium ratio of 3:1 at 40 to 42 Be' at 20°C.

[0044] The electrode coating preparation method of this embodiment is the same as that of embodiment 1.

Embodiment 3

[0046] The titanium-calcium type nuclear power nickel-based electrode coating of this embodiment is formed by mixing solid components and liquid components, and the addition quality of the liquid components is 20% to 25% of the solid component quality; wherein

[0047] The solid components are mixed by the following raw materials in weight percentage: marble: 12%, fluorite: 8%, artificial rutile: 42%, titanium dioxide: 3%, feldspar: 3%, metal manganese: 12%, titanium iron : 3%, Soda Ash: 0.5%, CMC: 0.5%, Nickel Powder: 2%, Metal Chromium: 6%, Ferroniobium: 5%, Ice Crystal Powder: 4% and Cr 2 o 3 Powder: 1.0%.

[0048] The liquid component is potassium-sodium water glass with a potassium-sodium ratio of 3:1 at 40 to 42 Be' at 20°C.

[0049] The electrode coating preparation method of this embodiment is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com