Method and system for transporting and loading bulk materials in storage yard

A conveying system and technology for bulk materials, applied in the direction of continuous material flow weighing equipment, loading/unloading, measuring devices, etc. Good vibration isolation effect, the effect of reducing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

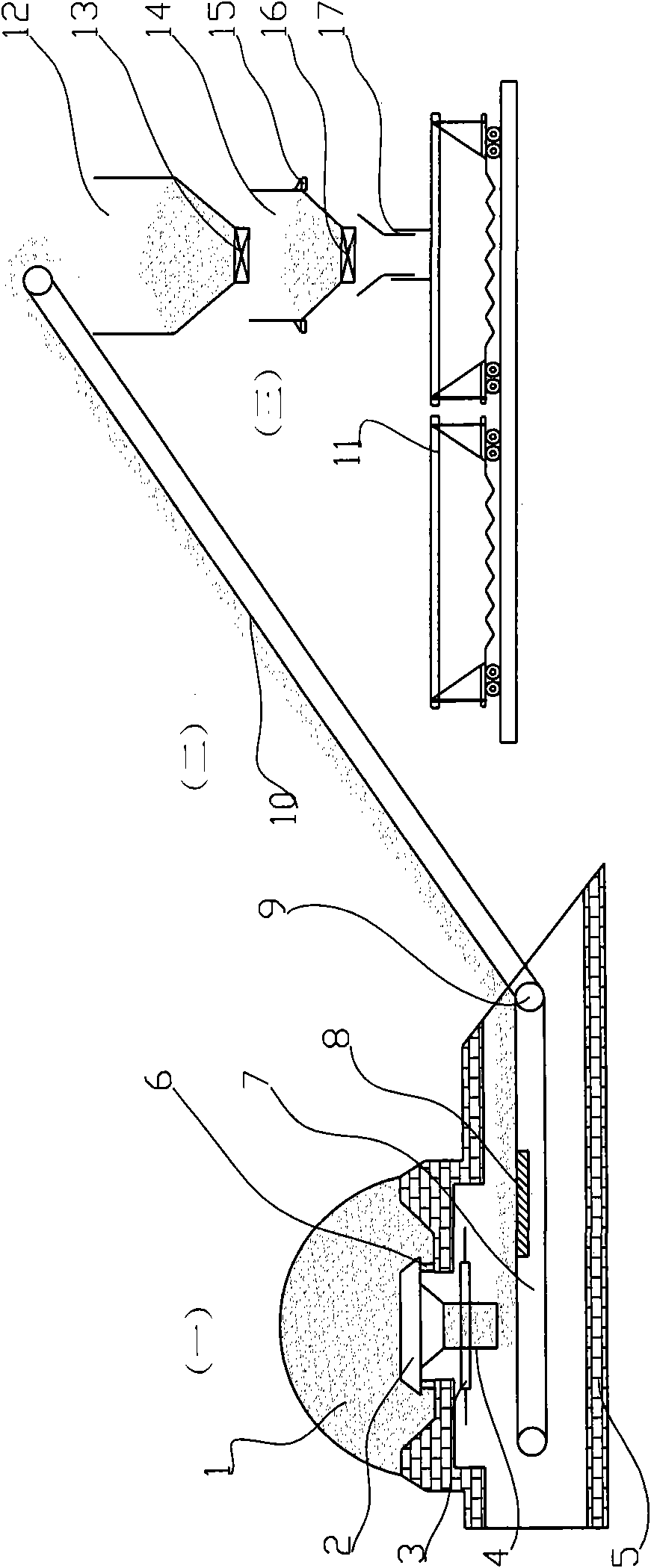

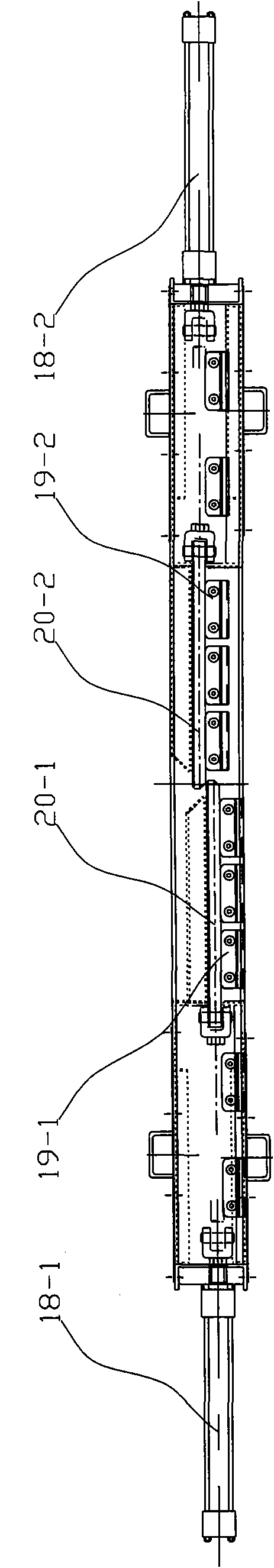

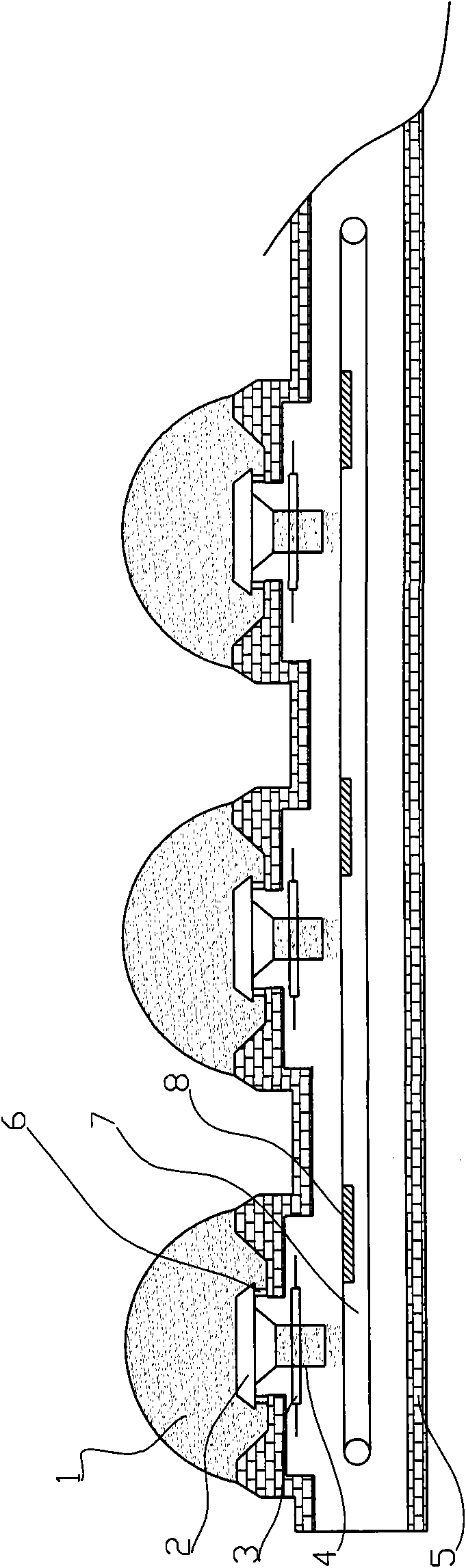

[0037] Such as figure 1 , figure 2 As shown: the yard conveying system (1) includes a set of disc vibrating hopper 2 installed above the underground tunnel 5, a rubber shock absorber 6 is arranged between the disc vibrating hopper 2 and the concrete foundation, and the disc vibrating hopper 2 is placed below The connected low clearance flow control gate 3 is used to accurately control the falling amount of the material 1 in the yard. The low headroom flow control gate includes a gate 20-1 and a gate 20-2, and the lower parts of the gate 20-1 and the gate 20-2 are respectively equipped with a slide block 19-1, a slide block 19-2, and a slide block 19-2. 1. The material of the slider 19-2 is a plastic alloy slider with a small friction coefficient and a long service life. The ejector rod connection. A discharge chute 4 is connected below the low-clearance flow control gate 3 for conveying the material falling from the disc vibrating hopper 2 to the underground belt 7 .

[0...

Embodiment 2

[0044] Such as image 3 As shown, the bulk materials 1 in three storage yards are arranged in a line, and a disc vibrating hopper 2 is installed below each storage yard. Others are the same as embodiment 1.

[0045] When the present embodiment is in use, when only transporting the material of one stockyard, it is only necessary to open the disc vibrating hopper 2 below one stockyard.

[0046] When transporting materials from two or three stockyards, open the disc vibrating hopper 2 under the stockyard to be transported, and the materials are conveyed to the accurate and fast quantitative loading system (3) through the belt conveying system (2), and then After the accurate and rapid quantitative loading system (3), it is loaded onto the transportation means such as trains or automobiles, and the online batching is completed.

[0047] The present invention is not limited to the above embodiments. For example, in order to enhance the material conveying capacity, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com