Galvanized steel sheet lap-over laser welding method

A technology of laser welding and galvanized steel sheet, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., it can solve the problems of difficult to ensure the consistency of gaps, difficult to be uniform and uniform, and wave deformation of thin plates. The effect of low production cost, stable welding quality and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

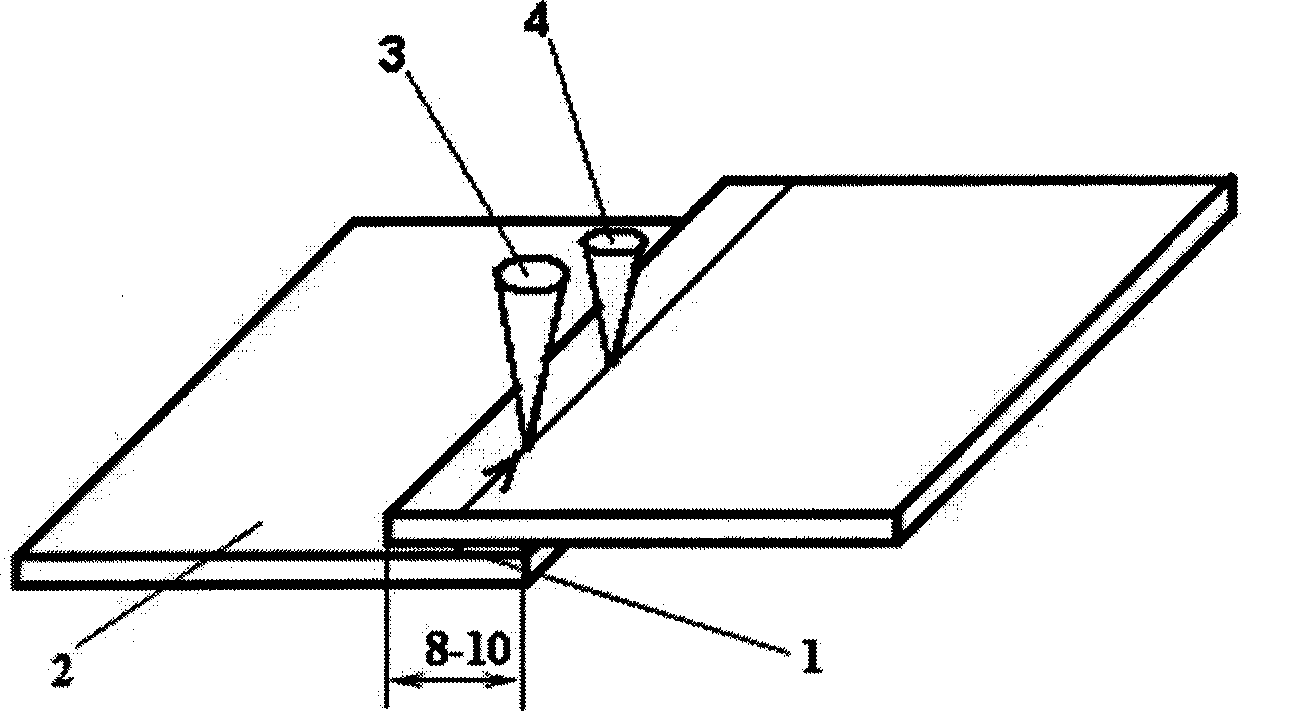

[0027] Embodiment 1 Nd: YAG laser lap welding of DP600 double-sided hot-dip galvanized steel sheet

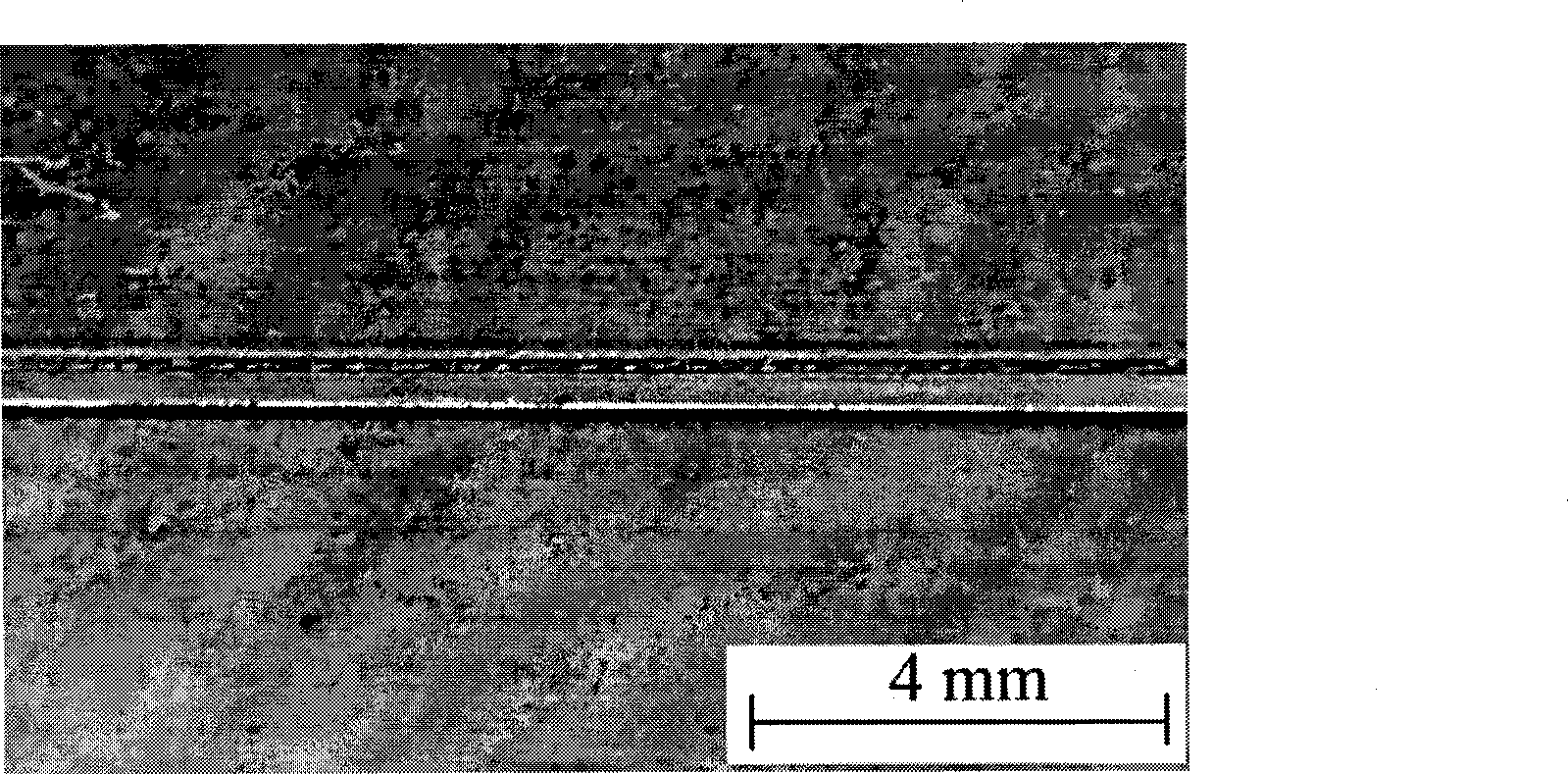

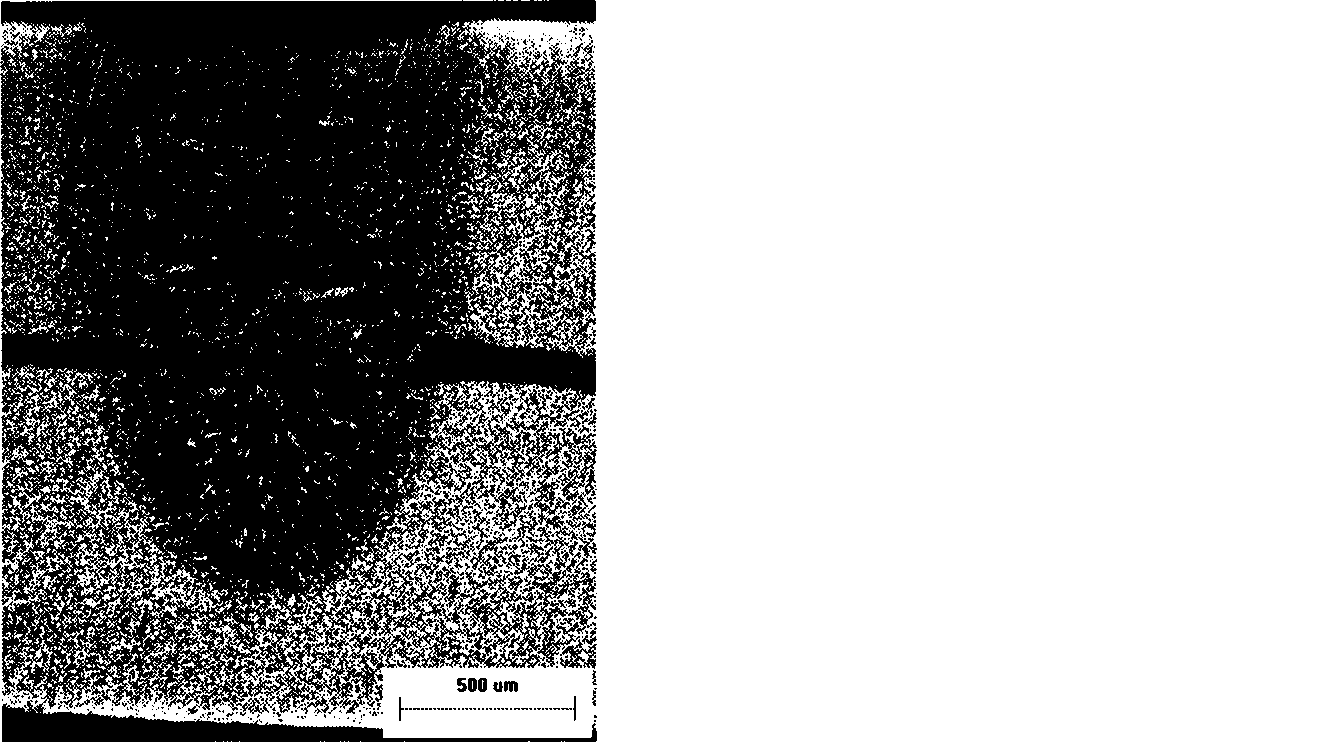

[0028] The thickness of the plate is 1mm, and the thickness of the double-sided galvanized layer is 0.01mm. The overlapping amount is 10mm, using Al-Sn foil with a width of 8mm, the power of the first laser beam is 2KW, the power of the second laser beam is 3KW, the focus diameter is 0.5mm, the welding speed is 4m / min, and there is no spatter on the surface after welding ( figure 2 ), the weld has no porosity and lack of meat ( image 3 ). The tensile and shear load per unit length of the welded joint reaches 650N / mm.

Embodiment 2

[0029] Example 2 CO of HSLA450 double-sided hot-dip galvanized steel sheet 2 laser lap welding

[0030] The thickness of the plate is 1mm, and the thickness of the double-sided galvanized layer is 0.01mm. The overlapping amount is 8mm, using Al-Sn foil with a width of 8mm, the power of the first laser beam is 3KW, the power of the second laser beam is 4KW, the focus diameter is 0.5mm. The welding speed is 7m / min. There is no spatter on the surface after welding ( Figure 4 ), the weld has no porosity and lack of meat ( Figure 5 ). The tensile and shear load per unit length of the welded joint reaches 480N / mm.

[0031] The manufacturing method of the Al-Sn alloy foil used in examples 1 and 2 is as follows:

[0032] 1. Melt the aluminum ingot at 700-720°C in a resistance crucible furnace;

[0033] 2. Add the prepared tin ingot, and after it melts evenly, lower the temperature to 520-550°C to pour.

[0034] 3. Pouring with a metal mold to achieve rapid solidification.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com