Method and device for detecting tiny bearing surface defect by computer vision technology

A technology of computer vision and bearing surface, which is applied in the direction of optical testing of defects/defects, sorting, etc., can solve the problems of poor reliability and low efficiency, and achieve the effects of easy maintenance, simple device structure, and improved automation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

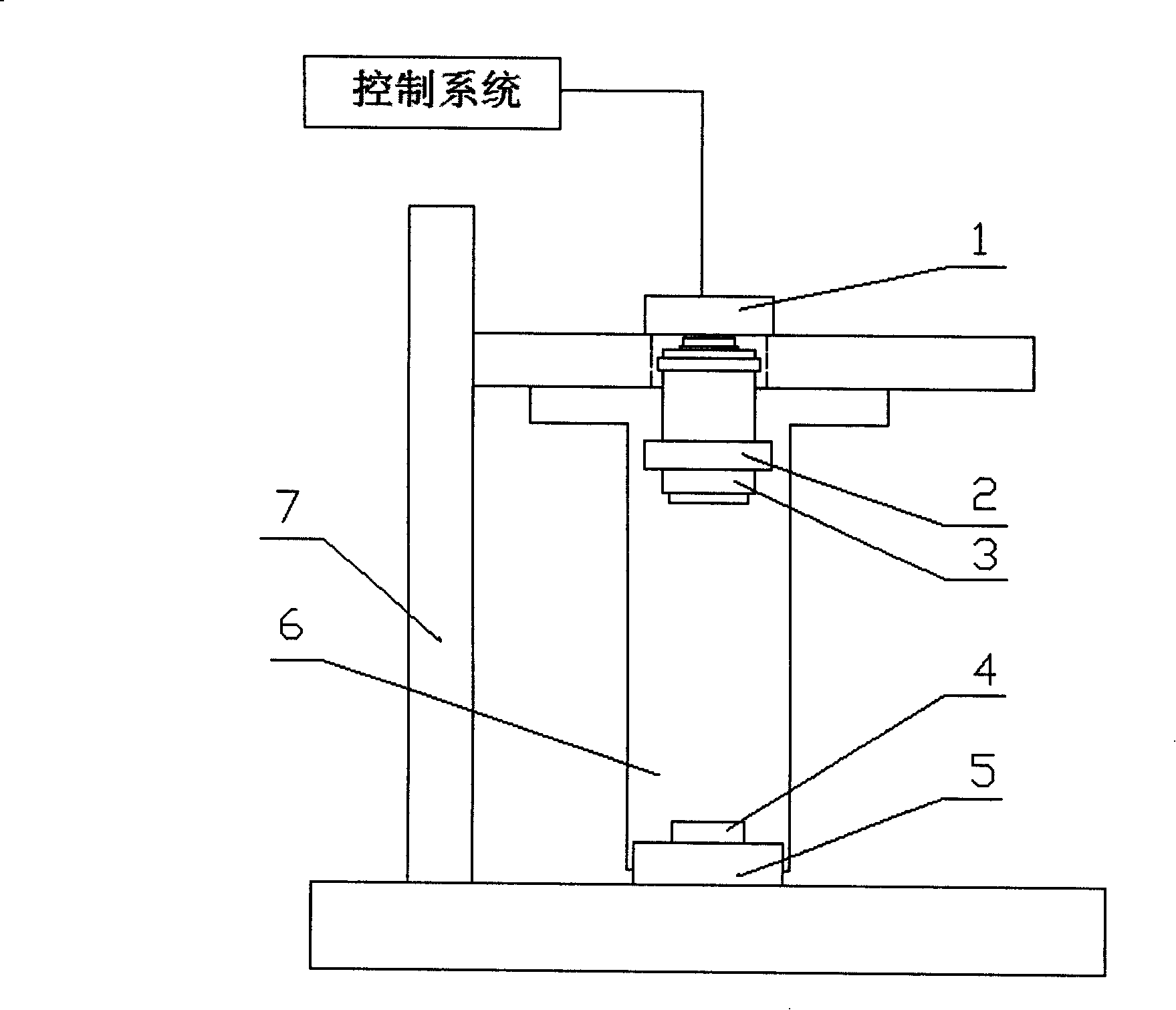

[0016] The device for detecting tiny bearing surface defects using computer vision technology is mainly composed of a digital camera (1) for taking images of the bearing surface, a light source for illuminating the bearing (2), a telecentric lens (3), a bracket for fixing the digital camera and light source (7), It is composed of a tiny bearing conveying device (5) for a rejecting mechanism, a dark box (6) for preventing external light interference, a computer control system for controlling the entire detection system, and the like.

[0017] Working principle and process: the micro-bearing surface defect detection system works online in the production line, and the micro-bearings (4) to be detected are placed on the automatic conveying line (5), and the automatic line is based on a certain beat requirement (4 seconds in the present invention) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com