Device and method for testing contact angle and interfacial tension at ultrahigh pressure and high temperature

A technology of interfacial tension and testing method, applied in surface tension analysis, image data processing, special data processing applications, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

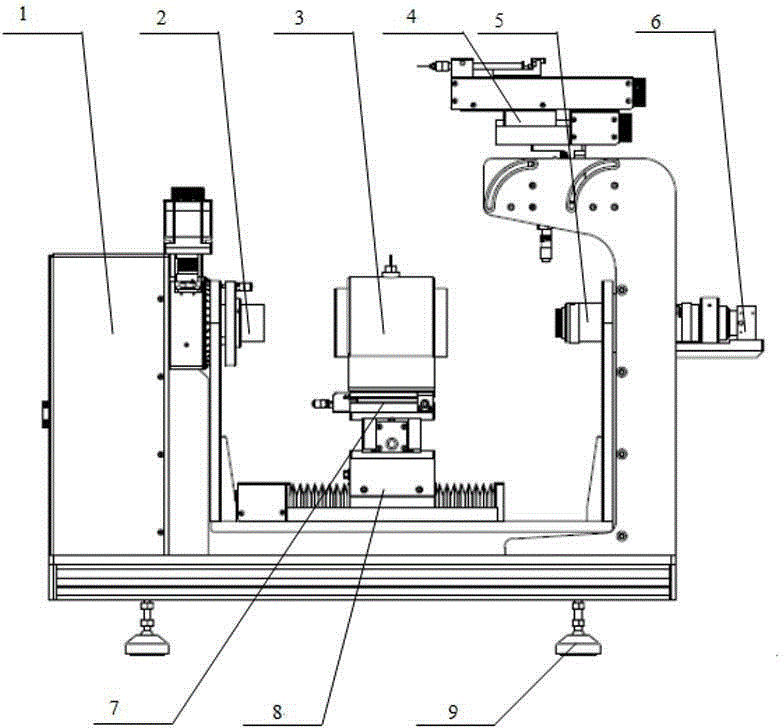

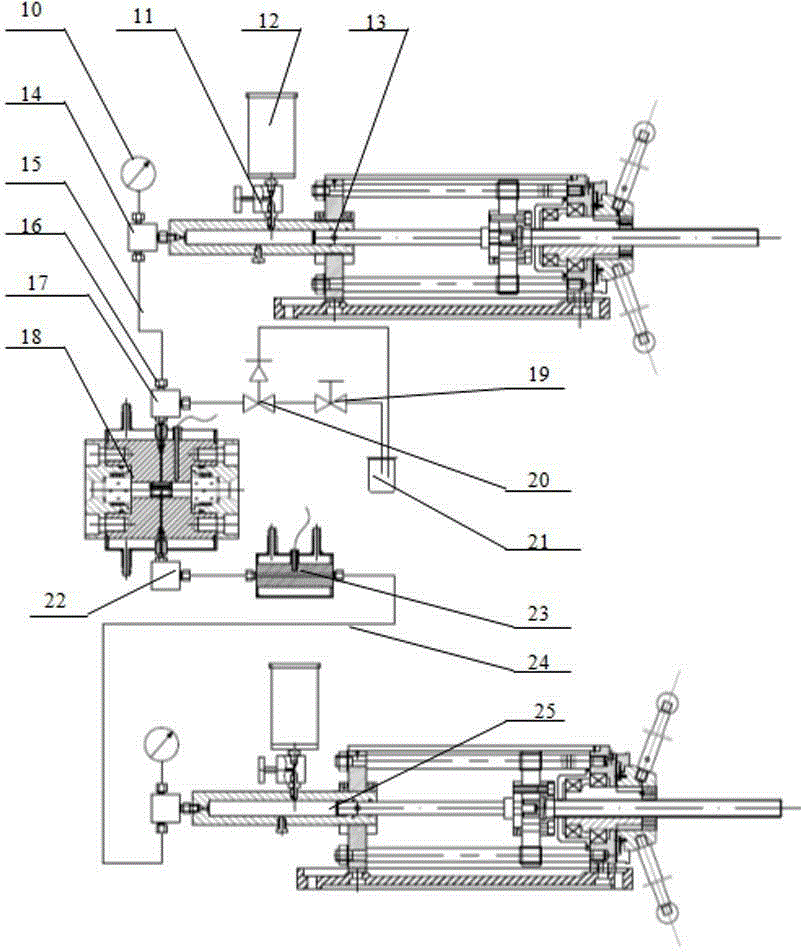

[0053] In order to achieve the purpose of high-precision testing of the contact angle and interfacial tension of the sticky sample system under the conditions of ultra-high pressure (maximum 100Mpa) and temperature control (maximum temperature 200 degrees), the specific implementation methods of this patent are as follows: (including stepping motor driver, motion control card, light source control circuit, etc.)

[0054] 1. Design a real droplet method test to correct the gravity system contact angle and interfacial tension value, including:

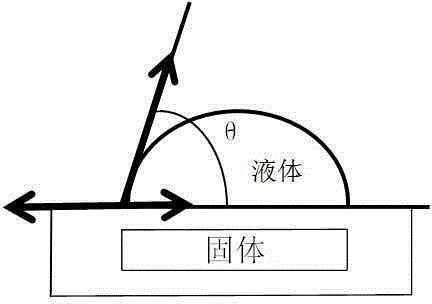

[0055] 1) Propose a discretized Young-Laplace equation system for sessiledrop, captivebubble or pendantdrop in side-view image analysis:

[0056] dx / ds=conθ(1)

[0057] dz / ds=sinθ(2)

[0058] dθ / ds=2 / R 0 +Cz-sinθ / x(3)

[0059] dV / ds=πx 2 sinθ(4)

[0060] dA / ds=2πx(5)

[0061] x(0)=z(0)=θ(0)=V(0)=A(0)=0(6)

[0062] C=Δρg / γ(7)

[0063] Where: θ is the contact angle, s is the arc length, R 0 is the radius of curvature at the verte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com