Glass sintered high temperature and high pressure sealing electric connector

A technology for electrical connectors and glass sintering, which is applied in the direction of connection, parts of connection devices, circuits, etc., can solve problems such as poor material matching, improve microcosmic bonding, reduce the possibility of air leakage, and high thermal expansion The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

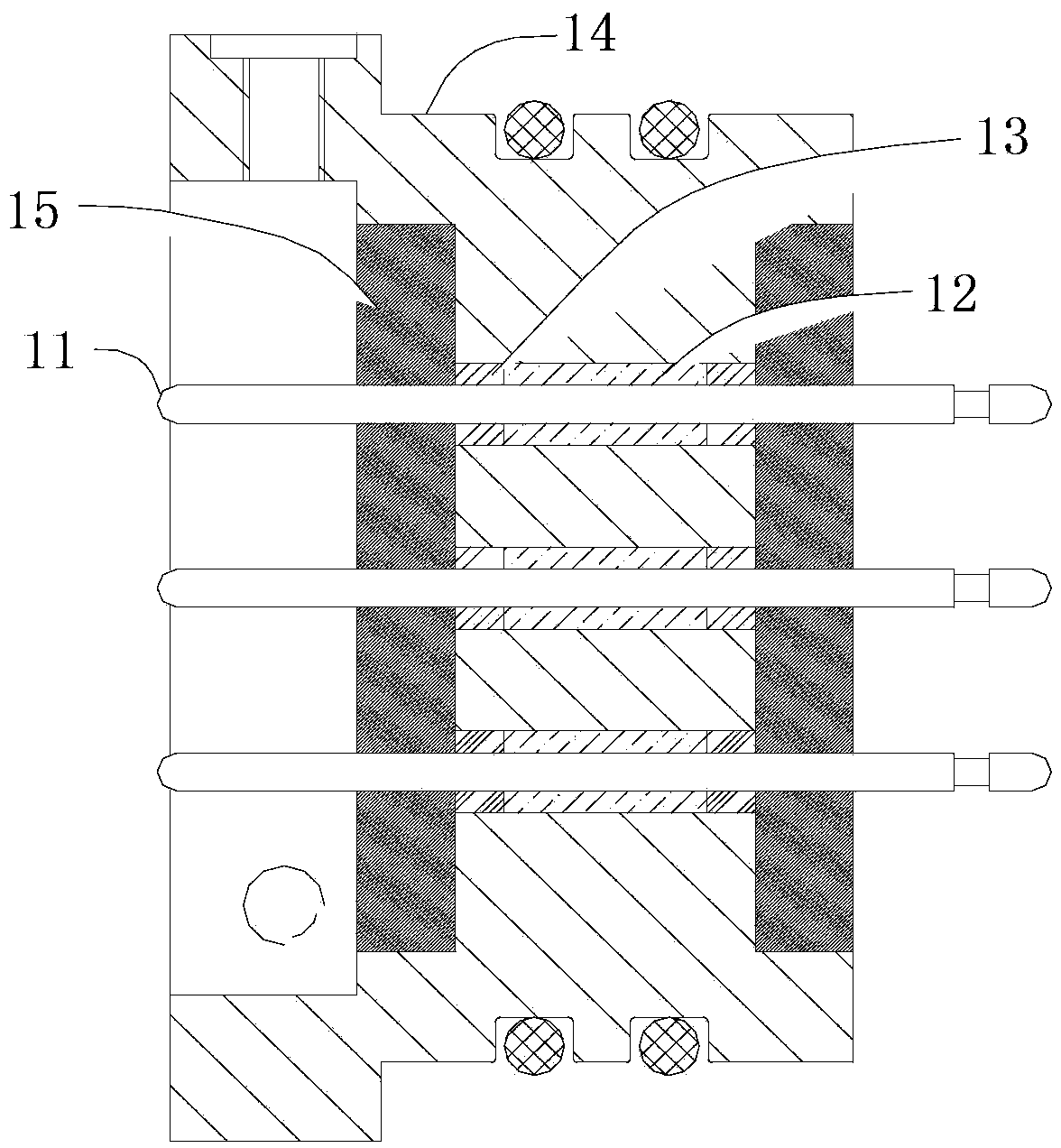

[0013] A glass sintered high-temperature, high-pressure sealed connector according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0014] by figure 1 A glass sintered electrical connector used in oil well logging is shown as an example for illustration. The high temperature and high pressure index of the connector can reach 175°C and 140MPa, and it can bear pressure at both ends. As shown in the figure, the connector includes a plurality of conductor pins 11 for transmitting current, surrounded by a glass insulator 12 and a ceramic insulator 13, and a metal shell 14 is arranged on the periphery of the glass insulator 12 and the ceramic insulator 13, the above components constitute Glass-metal sintered structure (before glass sintering, there is a sufficient gap between the ceramic insulator 13 and the metal shell 14, and the function of the ceramic insulator 13 is to increase the pressure bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com