Machine-vision-based rapid detection device and detection method for medium and small module gears

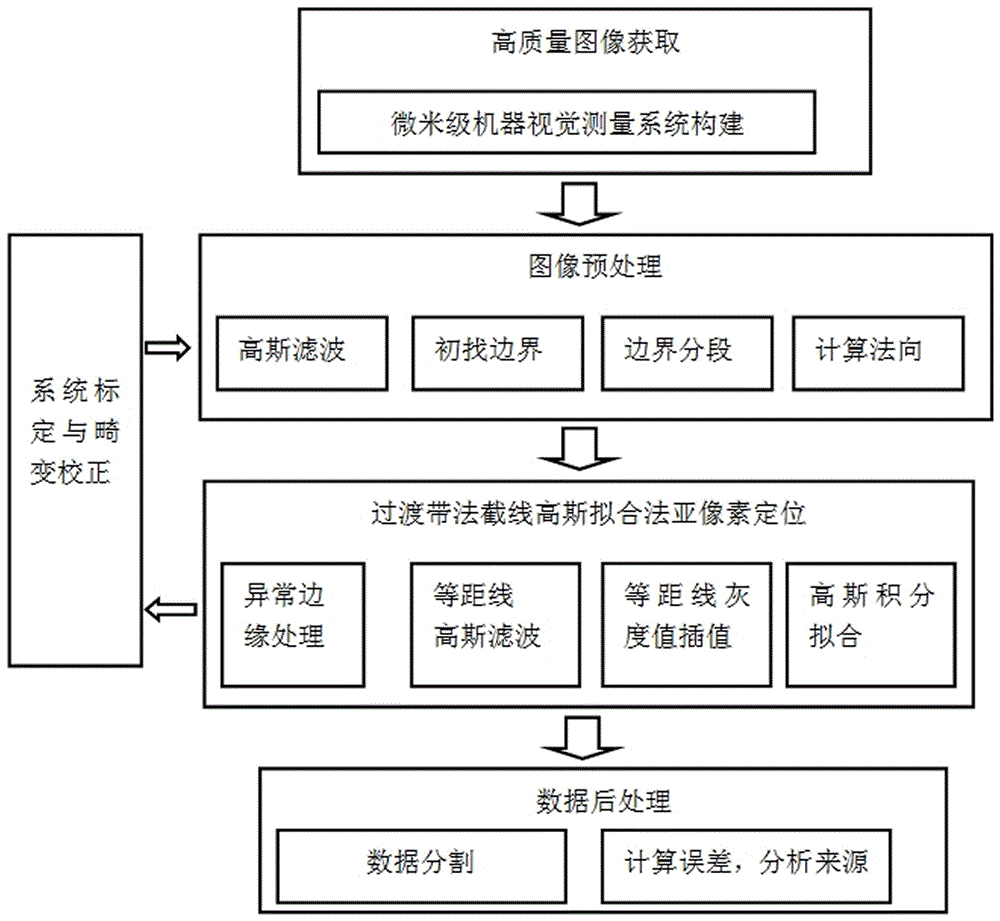

A machine vision, medium and small modulus technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to detect large gears, unsuitable for pinion detection, insufficient high-precision detection of gears, etc., to achieve simple operation and interface. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

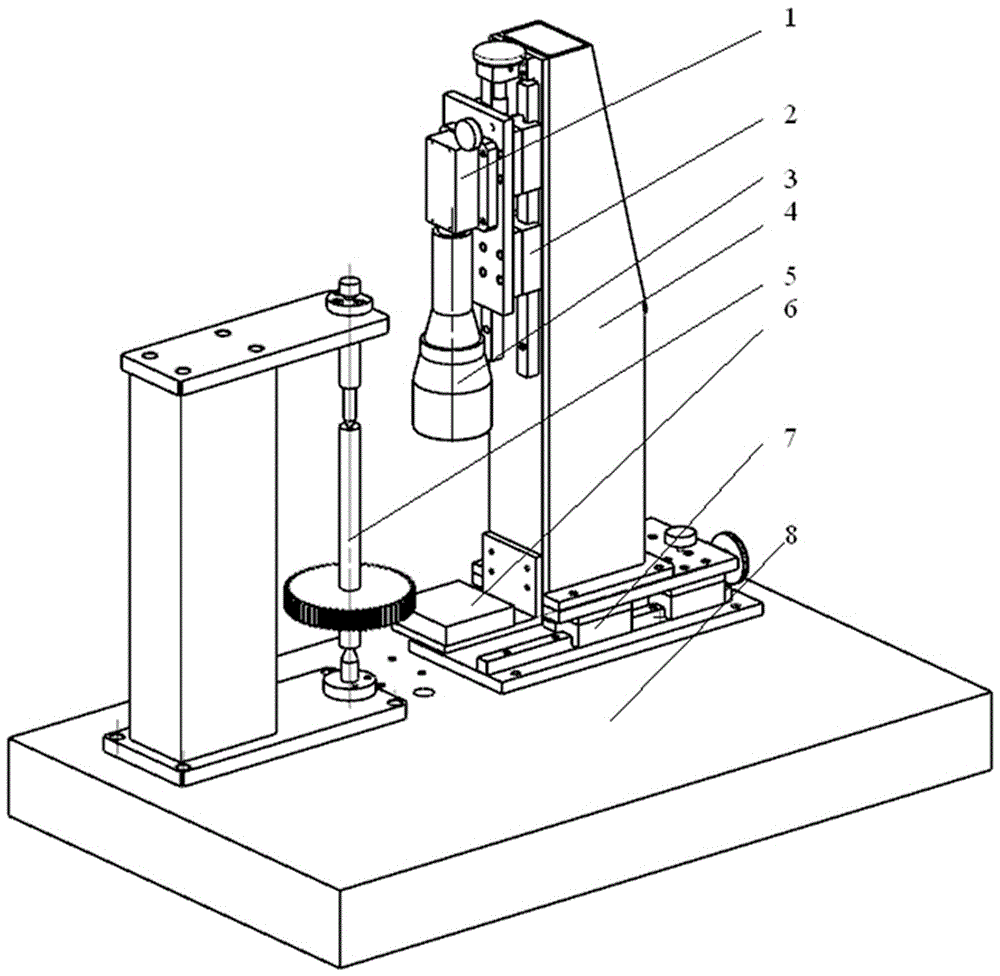

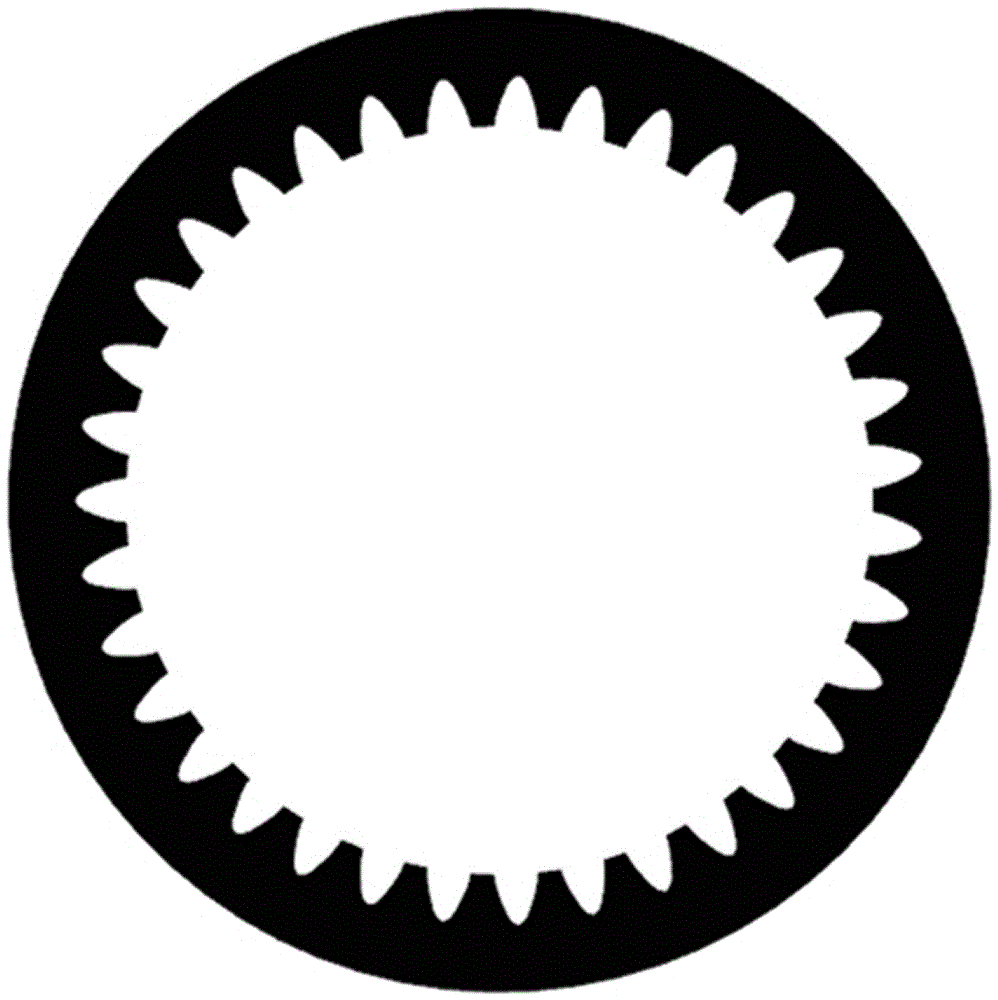

[0032] combined with figure 1As shown, the present invention is a kind of medium and small modulus gear fast detection device based on machine vision, and its main points of structure are: comprise marble platform 8, described marble platform 8 is provided with visual measuring system; Said visual measuring system comprises industrial camera 1 , telecentric lens 3, parallel light source 6, the industrial camera 1 is connected with the telecentric lens 3; the marble platform 8 also includes an object distance adjustment mechanism 2, a column 4, a horizontal adjustment mechanism 7, and a double top gear positioning mechanism 5. The column 4 is vertically arranged on the horizontal adjustment mechanism 7, and the object distance adjustment mechanism 2 is arranged on one side of the column 4; the industrial camera 1 is installed on the object distance adjustment mechanism 2, and the parallel light source 6 Set on the horizontal adjustment mechanism 7, the parallel light source 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com