Non-slideway multi-module construction measuring method

A measurement method and multi-module technology, applied in the field of measurement, can solve the problems of overall structure accuracy deviation, installation fit deviation, affecting the combined installation of each module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

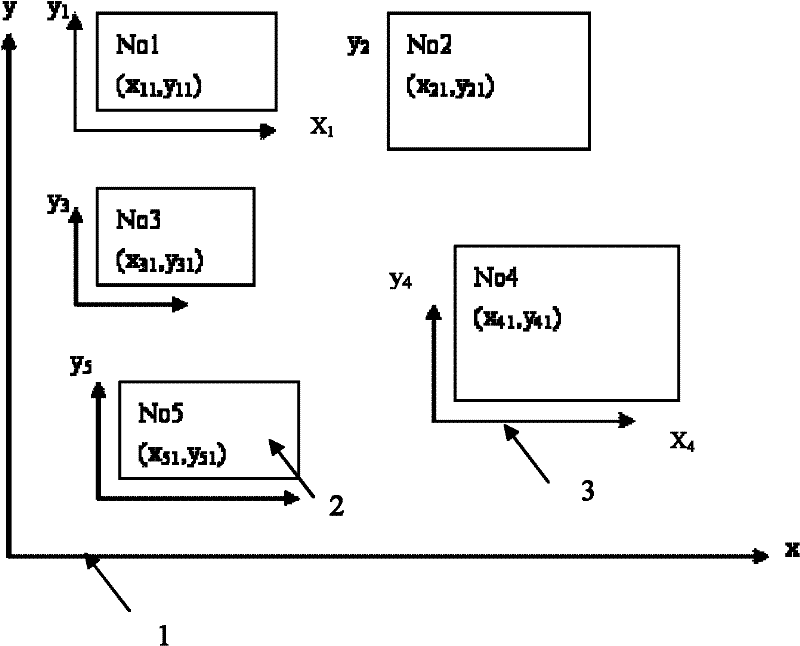

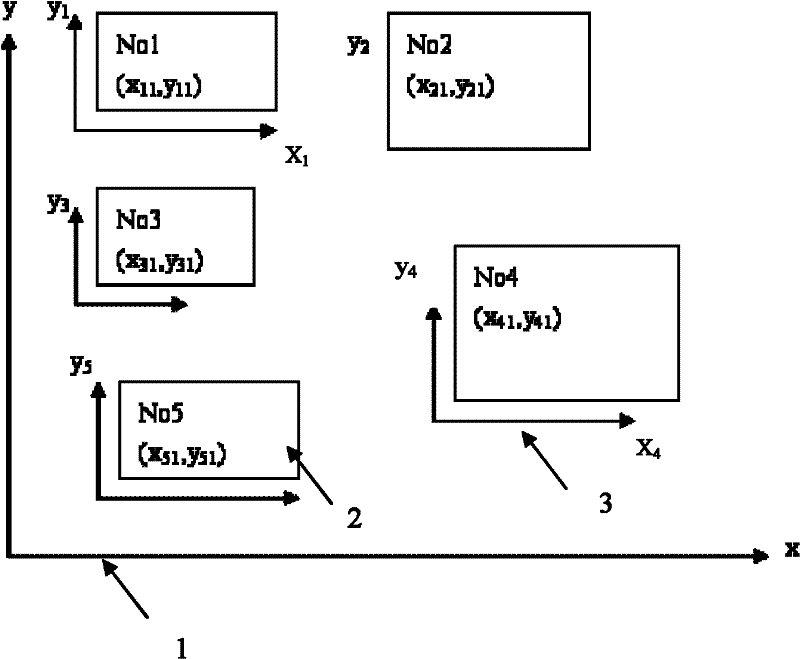

[0016] In the process of decomposing an overall structure into multiple modules, the following steps are used:

[0017] (1) Establish the reference coordinates of the construction site for the construction module of the overall structure; (2) Determine the reference coordinates of each sub-module; (3) Determine the location of each sub-module in the reference coordinates of each sub-module The relative coordinates in the site reference coordinates are used to obtain the coordinate position information of the components in each sub-module in the construction site reference coordinates; (4) According to the overall structure design size and error requirements, according to the information of the coordinate position of the components in each sub-module, determine The error requirements of each component.

[0018] After testing: in the reference coordinates of each sub-module, the allowable error of the module is obtained, and after the overall installation, the overall assembly accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com