Axial laminated contact/noncontact combined sealing tape type conveyer plastic carrier roller

A belt conveyor and combined sealing technology, applied in the direction of conveyor objects, rollers, transportation and packaging, etc., can solve the problems of increased risk of quality management, adverse effects of residual stress, increased production processes, etc., and reduce quality. The effect of managing risks, improving labor productivity, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

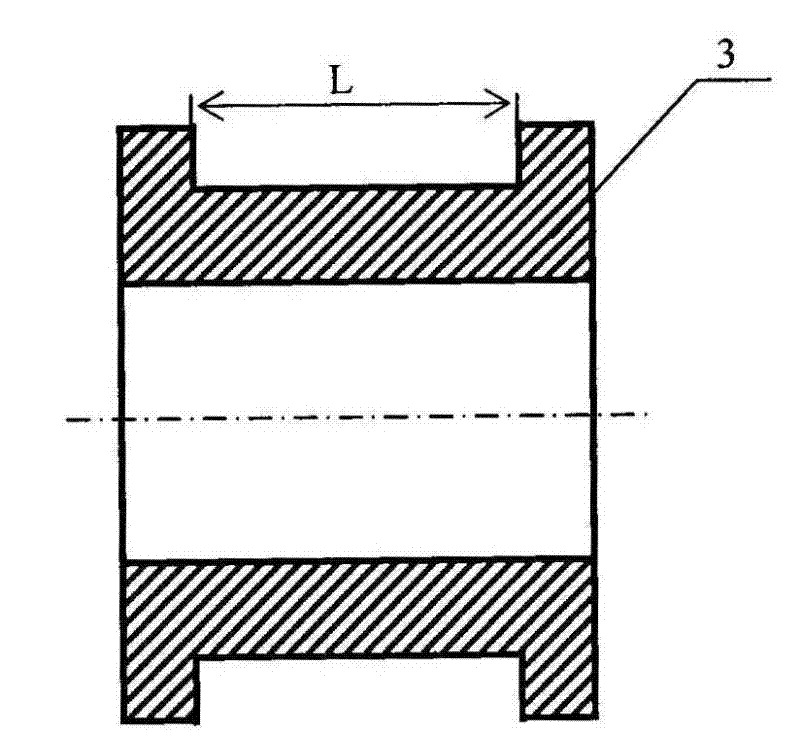

[0038] Such as figure 1 , Figure 7 , Figure 11 As shown, the plastic idler roller of the axial laminated contact / non-contact combined sealed belt conveyor in this embodiment includes an idler shaft 8, which is supported and sleeved on the bearing housing 2 by bearing housings 2 and 7 arranged at both ends of the shaft. The modified PVC roller body 1, and the axial laminated contact / non-contact combined seal sealed in the annular cavity between the bearing housing 2 and the idler shaft 8 through the end cover 4; the axial laminated contact / The non-contact combined seal is composed of an integral structure, a hollow cylindrical lamination seat 3 and an axial combined lamination group 6 installed in the sealing groove processed around the outer wall of the lamination seat; the laminations The seat 3 is combined with the idler shaft 8 in the form of interference fit, and the radial gap between the lamination seat 3 and the bearing seat 2 is a=0.5mm; the width of the sealing ...

Embodiment 2

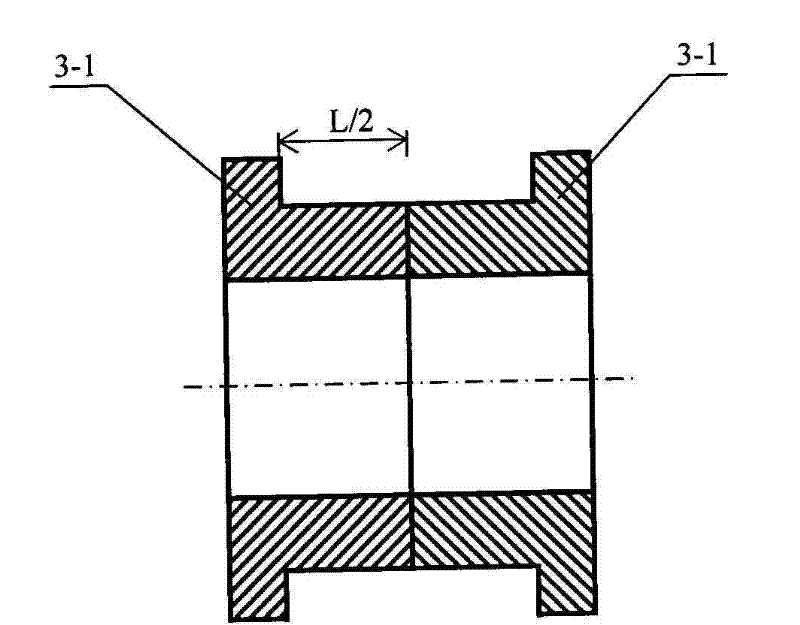

[0042] Such as Figure 5 , Figure 8 , Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that the axial laminated contact / non-contact combined seal is composed of a split-type, hollow cylindrical lamination seat 3-1 installed in a surrounding The lamination seat 3-1 is combined with the bearing seat 2 in the way of interference fit, and the lamination seat 3-1 is combined with the support The radial gap between the roller shafts 8 is a=0.4mm; the gap between the width of the sealing groove of the lamination seat 3-1 and the total length of the axially combined lamination group 6 is b=0.8mm; the axially combined type The lamination group 6 is composed of laminations with internal tension, and the radial gap with the bottom of the sealing groove of the lamination seat is c=0.4mm, and it is interference fit with the roller shaft 8.

Embodiment 3

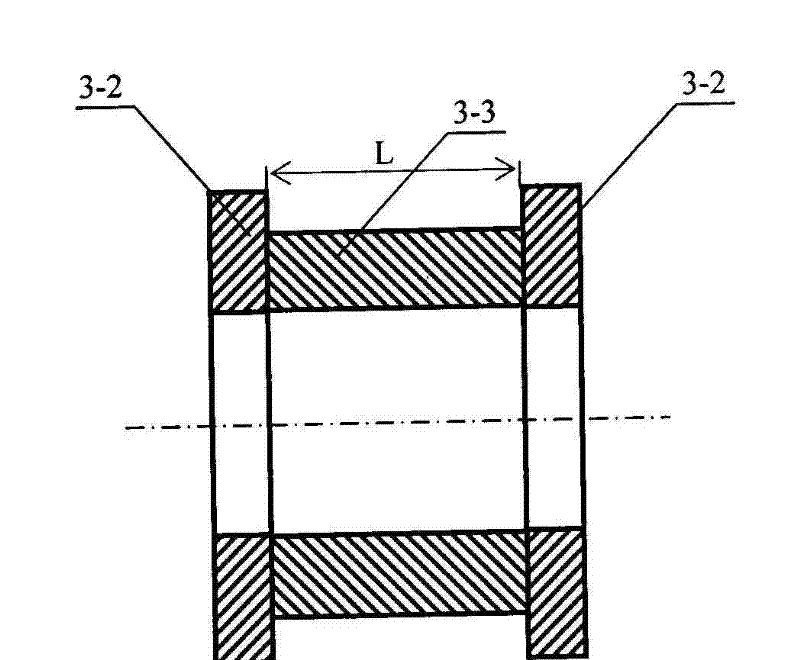

[0044] Such as image 3 , Figure 9 , Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that: the axial laminated contact / non-contact combined seal is a laminate seat 3-2, 3-3 of a separate structure composed of upper, middle and lower rings It is composed of an axial combined lamination group 6 installed in the sealing groove around the outer wall of the lamination seat; the lamination seat is combined with the roller shaft 8 in an interference fit manner, and the lamination seat and the bearing seat The radial gap between them is a=0.5mm; the gap between the width of the sealing groove of the lamination seat and the total length of the axial combined lamination set 6 is b=1mm; the axial combined lamination set 6 is composed of It is composed of inner and outer tension laminations arranged at intervals, wherein the outer tension laminations are in interference fit with the bearing seat and the radial gap between the lamination seat sealing groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com