Diffusion welding process for heat exchanger core

A technology of heat exchanger and diffusion welding, which is applied in the direction of welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of large influence on the heating and cooling speed of diffusion welding, the decline of mechanical properties of joints, and the difficulty of obtaining clamping pressure, etc. Achieve excellent high temperature and high pressure resistance, reduce core deformation, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention provides a process method for diffusion welding of a core body of a stainless steel heat exchanger. Through the process method combined with self-made welding tooling, the quality of welded joints can be well improved, welding defects can be reduced, and the rate of finished products can be increased. At the same time, the invention also has a unique design for the structure of the heat exchanger core. The heat exchanger prepared by using the heat exchanger core has high heat exchange efficiency and compactness, can serve under high temperature and high pressure, and is suitable for special occasions to use.

[0038] Before explaining the diffusion welding process, it is necessary to introduce the structure of the heat exchanger core and the self-made welding tool in detail.

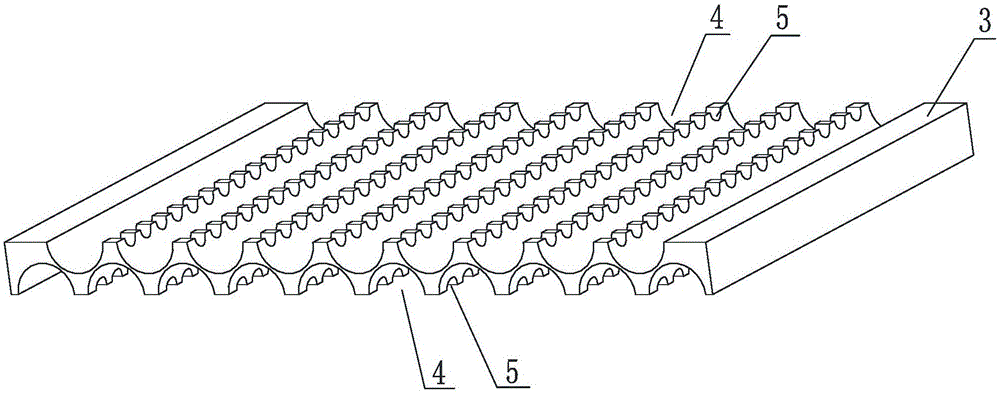

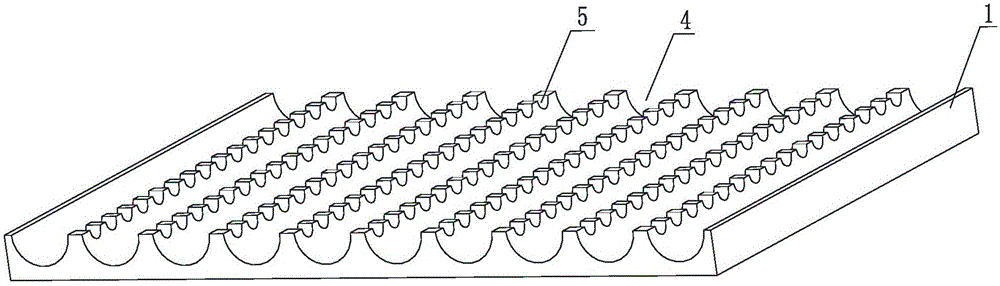

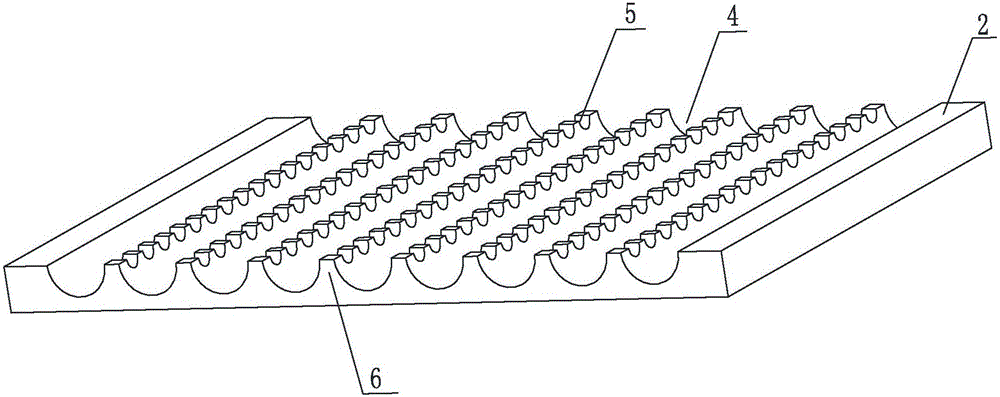

[0039] Such as Figure 1-4 As shown, a compact and high-efficiency heat exchanger core includes an upper metal cover plate 1 , a lower metal cover plate 2 and several intermediate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com