Prestress connecting device of railway prefabricated assembly type bridge pier

A prefabricated assembly and prestressed technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems affecting the normal use of bridge piers, reducing the durability of bridge piers and the overall service life of bridge piers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

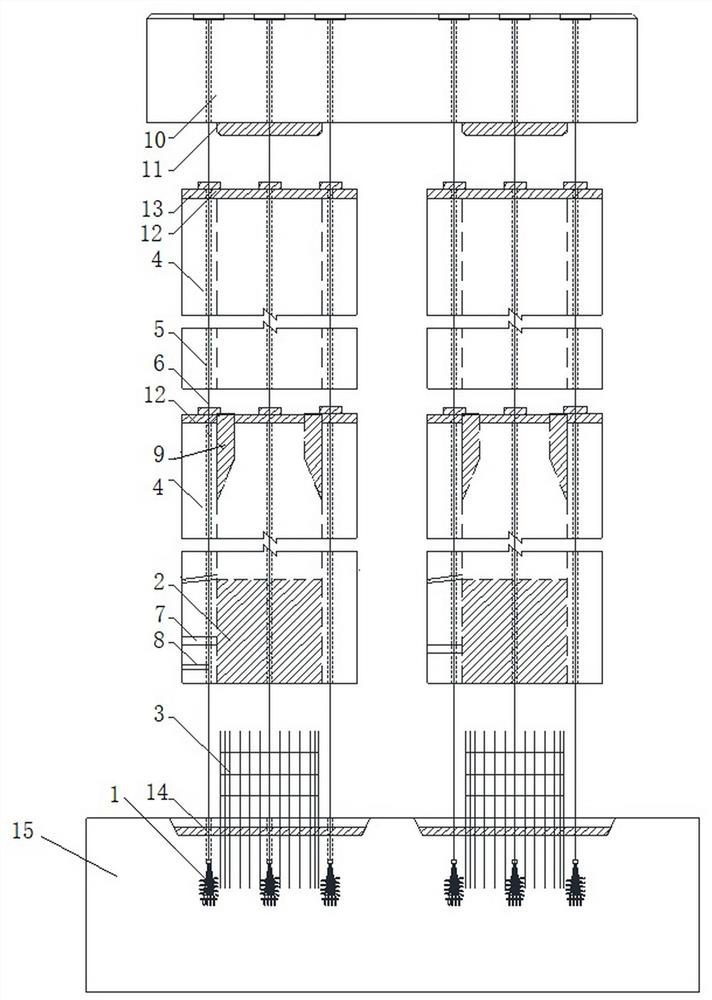

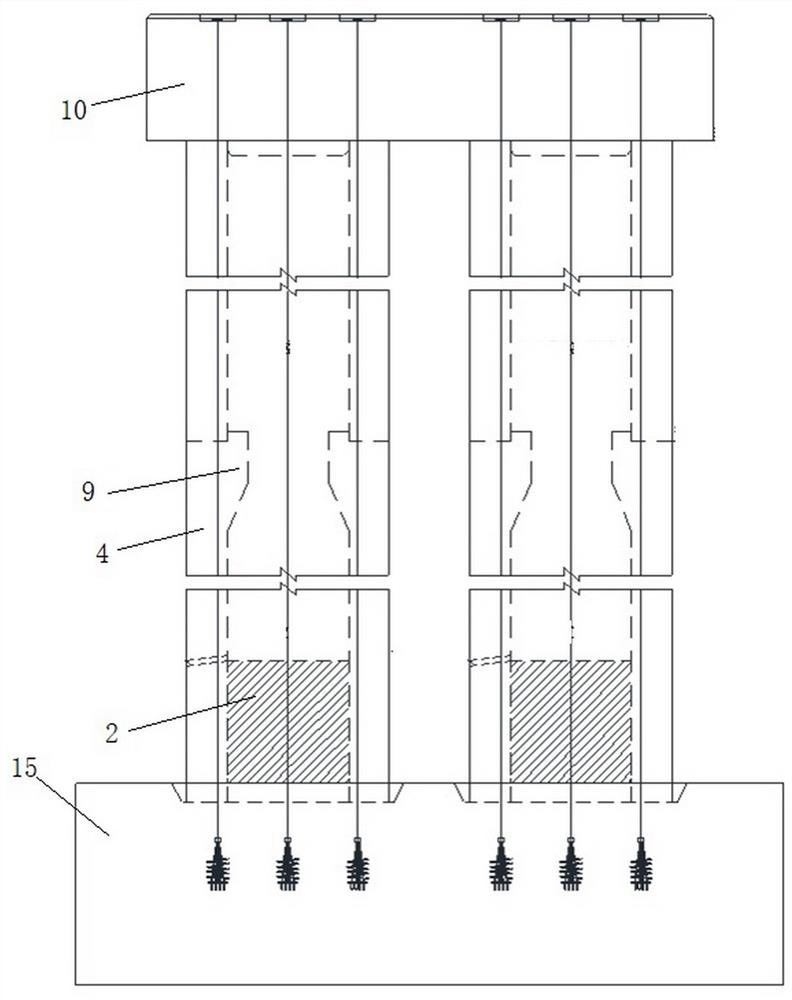

[0010] see figure 1 , figure 2 , a prestressed connection device for railway prefabricated bridge piers, comprising single-end tension anchors 1, cast-in-situ solid section concrete 2, pre-embedded steel bars 3, prefabricated hollow pier bodies 4, prestressed tunnels 5, and prestressed steel bars 6. Grouting hole 7, grouting hole 8, pier positioning falcon 9, prefabricated beam 10, beam positioning falcon 11, sealant 12, sealing gasket 13, mortar cushion 14, foundation 15. The pre-embedded steel bar 3 is pre-embedded in the foundation 15 corresponding to the part of the prefabricated hollow pier pier body 4 cast-in-situ concrete 2, and the single-end tension anchor 1 is pre-embedded in the foundation anchor hole after installing the prestressed steel bar 6, and is connected with a wire rope Prestressed steel bar 6, the first section of prefabricated hollow pier body 4 is placed flat, the steel wire rope is penetrated into the prestressed channel 5 on the bottom surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com