Prefabricated assembly type comprehensive pipe gallery and assembling method thereof

A comprehensive pipe gallery and prefabricated assembly technology, applied in water conservancy projects, artificial islands, underwater structures, etc., to achieve the effects of ensuring processing accuracy and quality, shortening the construction period, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

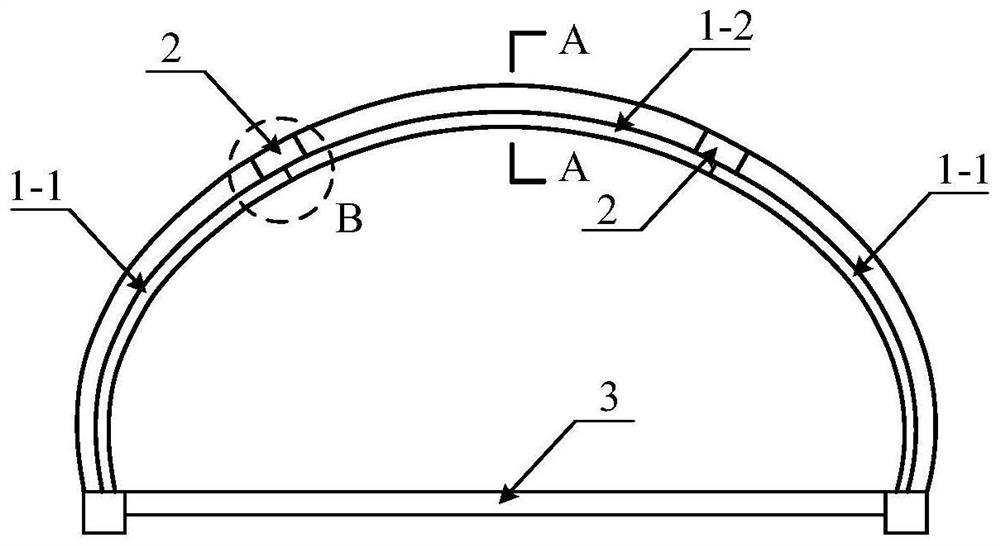

[0032] Attached below Figure 1~6 , to describe the implementation of the present invention in detail.

[0033] Such as figure 1 As shown, a prefabricated integrated pipe gallery using ultra-high toughness cement-based composite materials includes the following components: prefabricated parts, including two forms: bottom prefabricated part 1-1, top prefabricated part 1-2; super high toughness The connecting layer 2 formed by cast-in-place cement-based composite materials; the concrete base 3 .

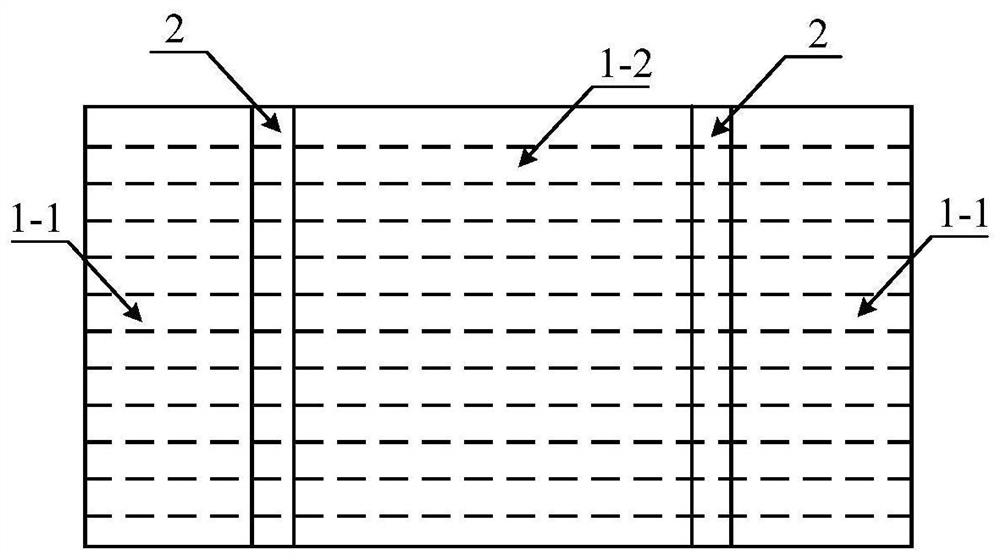

[0034] Such as figure 1 , figure 2 As shown, the comprehensive pipe gallery structure is composed of prefabricated parts, a connecting layer 2 formed by cast-in-place ultra-high toughness cement-based composite materials, and a concrete base 3; figure 2 As shown, the preforms include a bottom preform 1-1 and a top preform 1-2. The processing of prefabricated parts is completed in the factory and transported to the construction site for assembly.

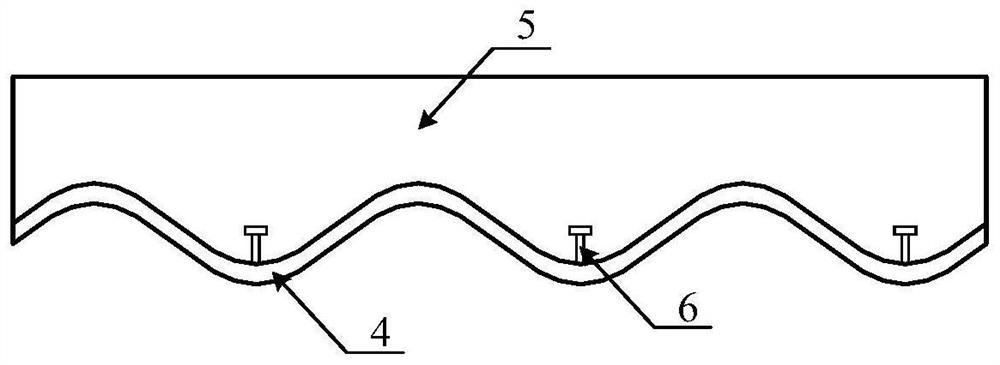

[0035] Such as Figure 1~2 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com