Composite segment

A technology of composite segment and concrete structure, applied in the field of composite segment, can solve the problems of limited application, high cost, difficult to change shape, etc., to achieve the effect of realizing the value of steel mold, reducing production cost and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

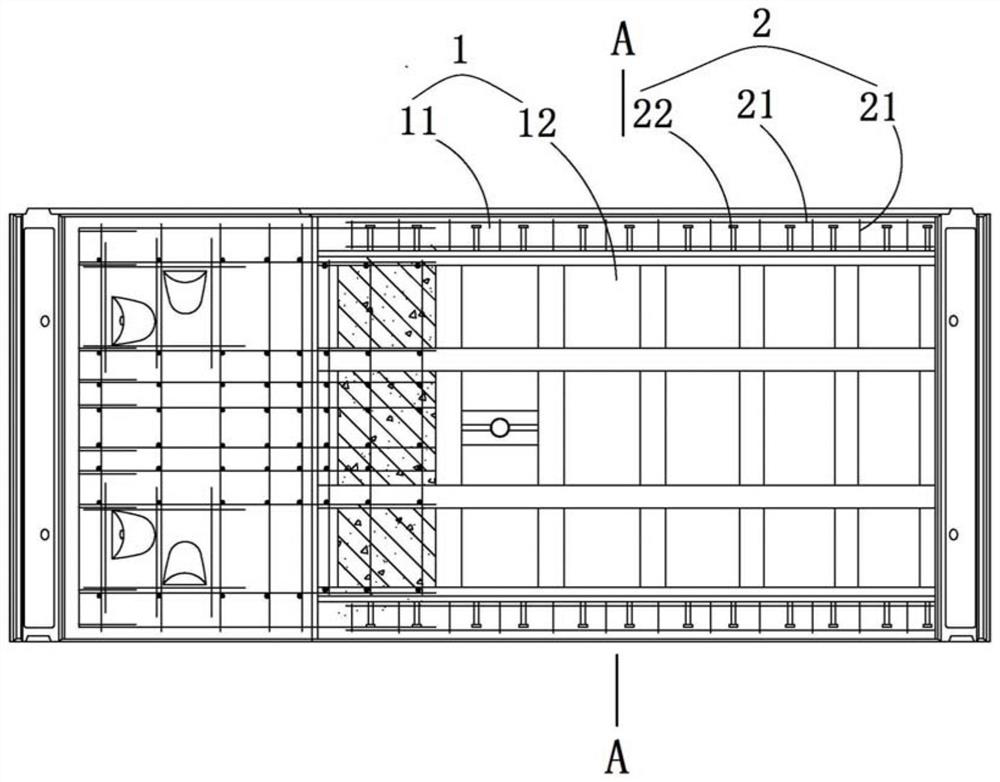

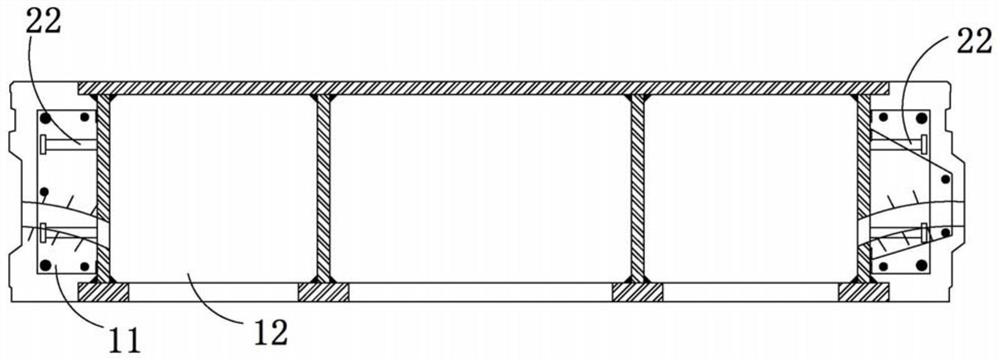

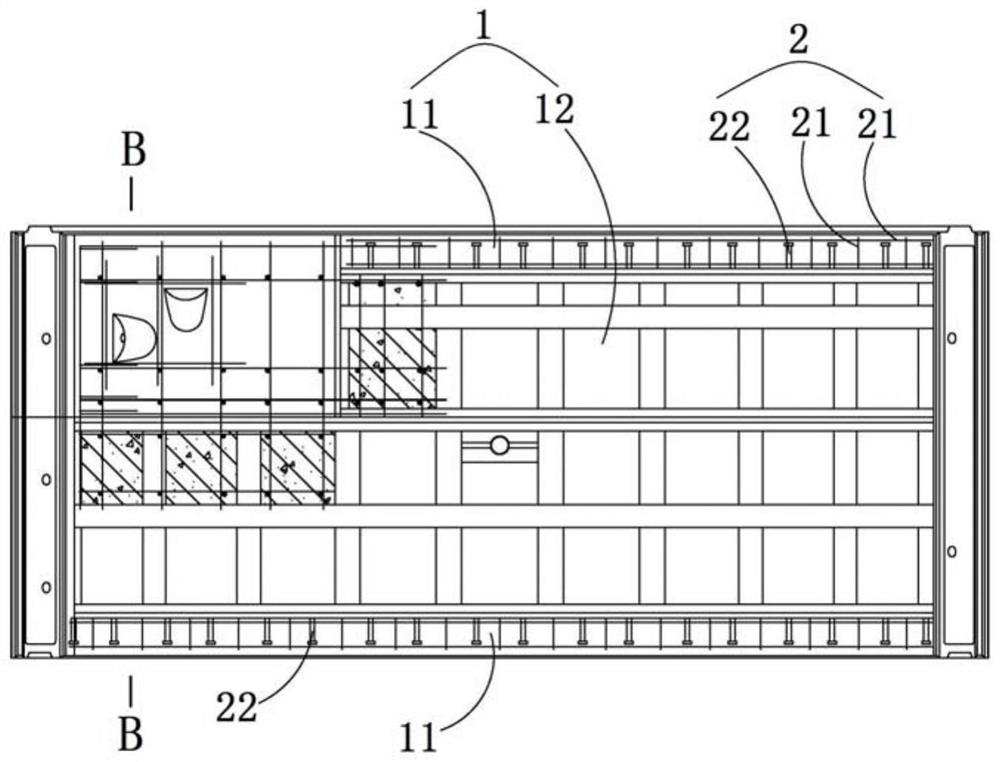

[0024] see Figures 1 to 4 As shown, the present invention provides a composite segment 1, which includes two concrete structures 11 arranged on both sides in the longitudinal direction and a steel structure 12 sandwiched between the two concrete structures 11, the steel structure 12 and the concrete structure 11 at the interface fixed with a connector 2 to connect the concrete structure 11 and the steel structure 12, the concrete structure 11 is the annular joint of the composite segment 1 for The assembled connection of the adjacent composite segments 1; the two concrete structures 11 are machinable concrete structures, one of the two concrete structures 11 is formed into a tenon (not shown in the figure), and the other of the two concrete structures 11 One is formed into a concave tenon (not shown in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com