Adaptive flexible guiding-type assembling platform

An assembly platform and self-adaptive technology, applied in metal processing, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

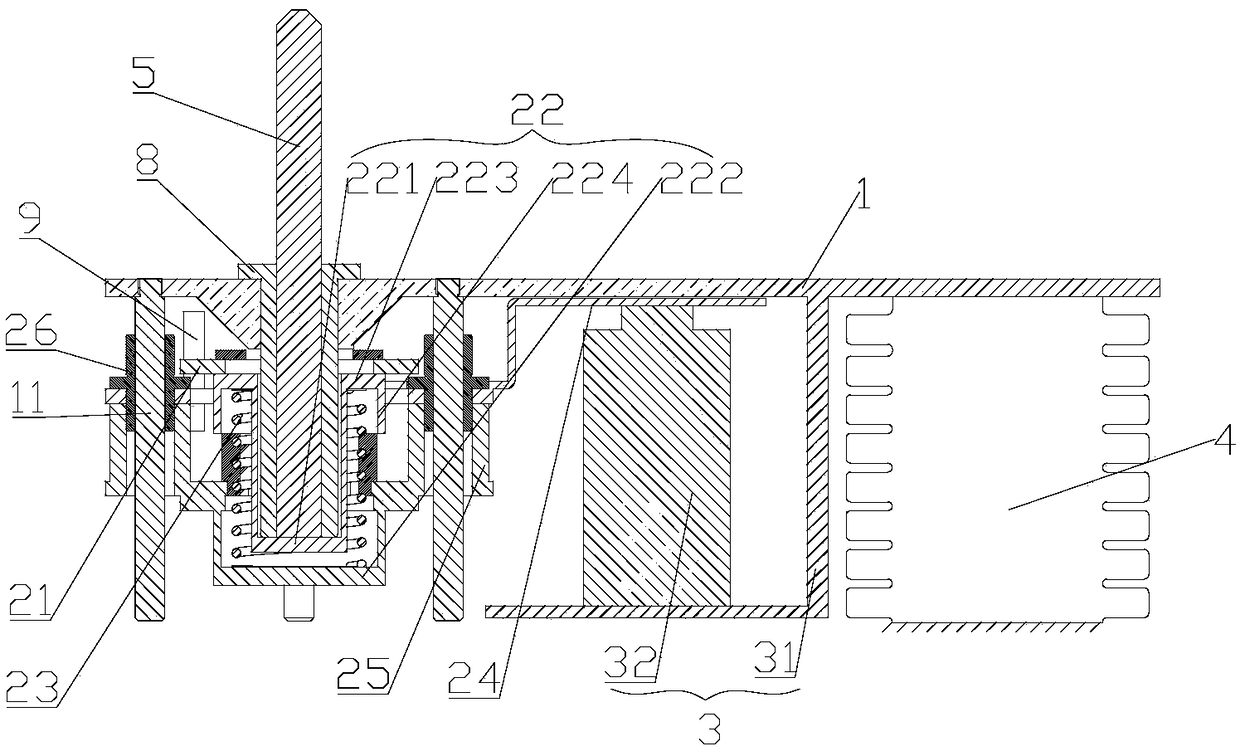

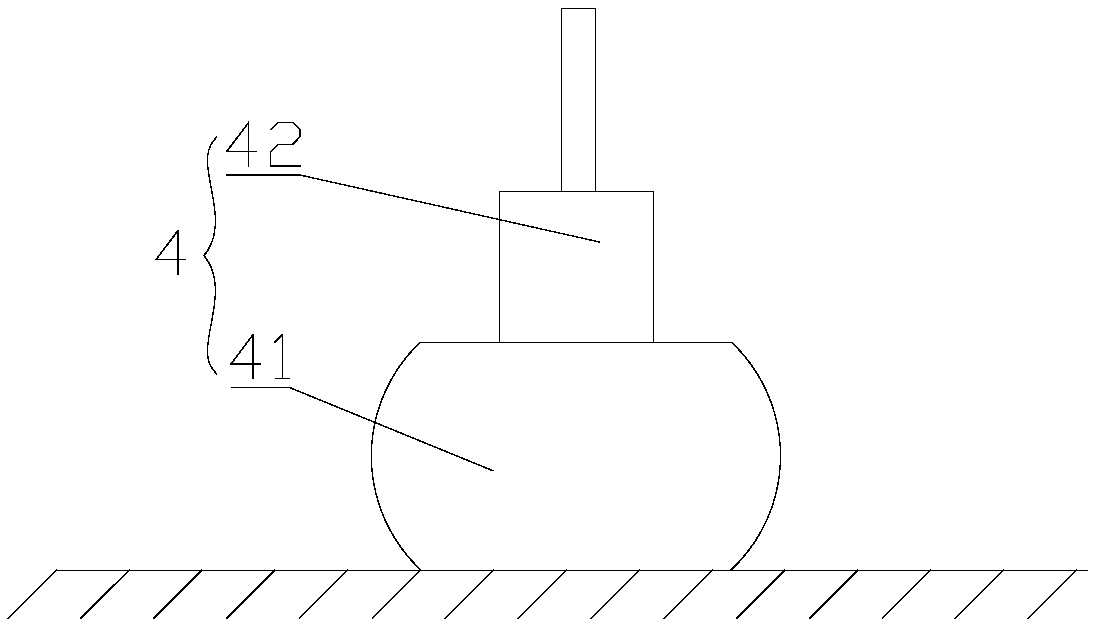

[0024] refer to figure 1 , this embodiment discloses an adaptive flexible guiding assembly platform, which includes a storage platform 1 , a force transmission mechanism 2 , a support mechanism 3 and a jacking device 4 .

[0025] The storage table 1 is provided with a guide hole (not marked in the figure), and a guide pin 5 is pierced in the guide hole, and the guide pin 5 is used for guiding and positioning during the assembly process.

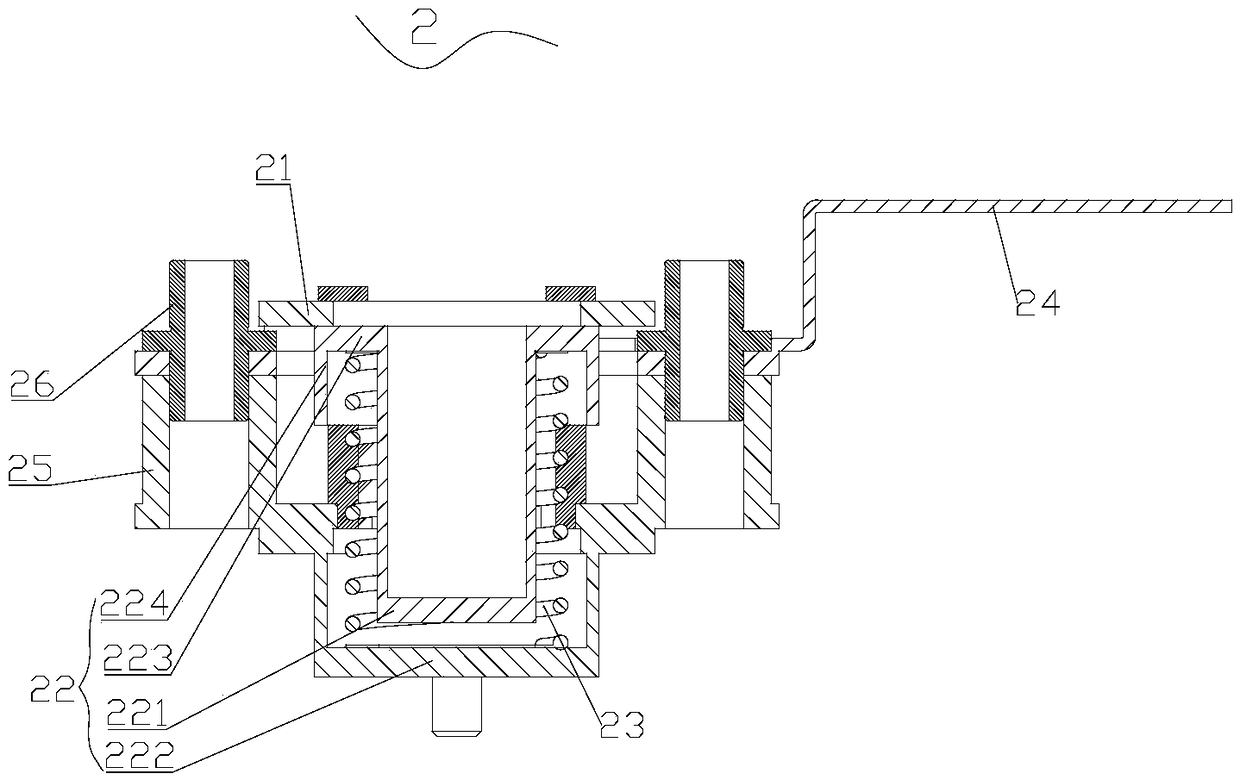

[0026] refer to figure 2 , the force transmission mechanism 2 includes a connecting plate 21 , a force transmission cylinder 22 , an elastic member 23 and a force transmission plate 24 . The connecting plate 21 is sheathed on the guide pin 5 and located under the storage table 1 . The force transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com