Compact porous positioning tool

A hole positioning and compact technology, applied in the mechanical field, can solve the problems of inability to reach the central area to confirm the installation accuracy in time, the positioning accuracy is not ideal, and the labor intensity is high, so that the insertion and removal process is easy and convenient, and the concentricity is satisfied The effect of assembly precision requirements and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

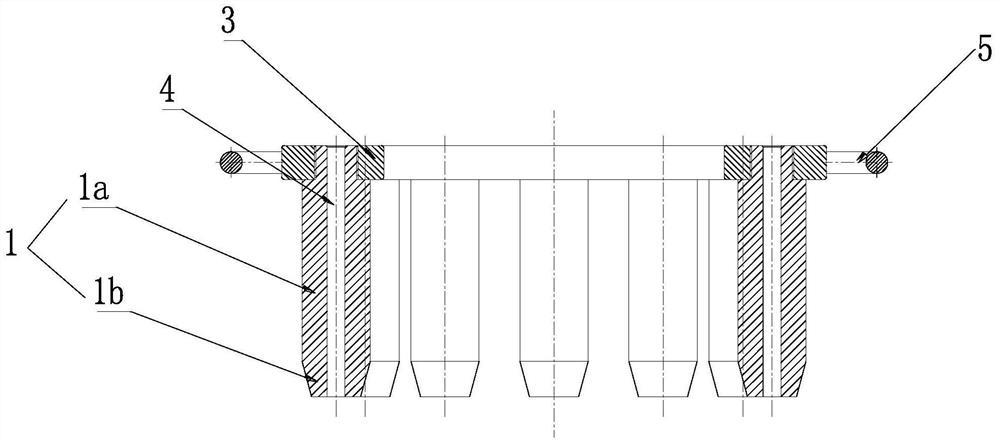

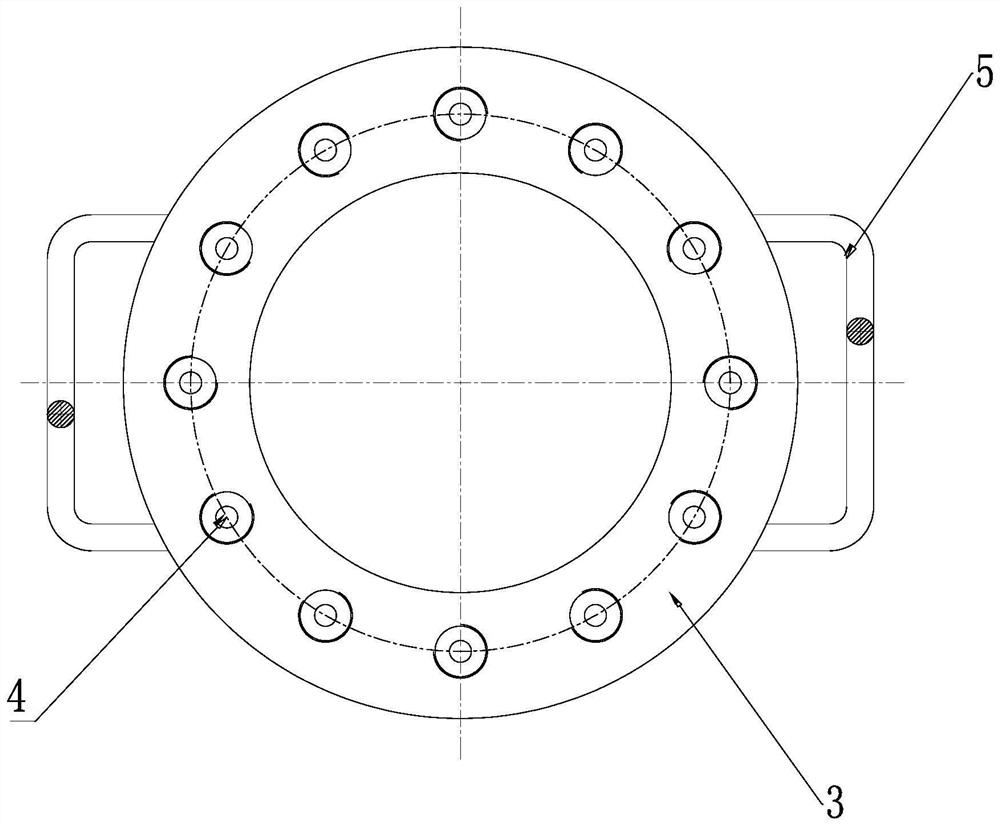

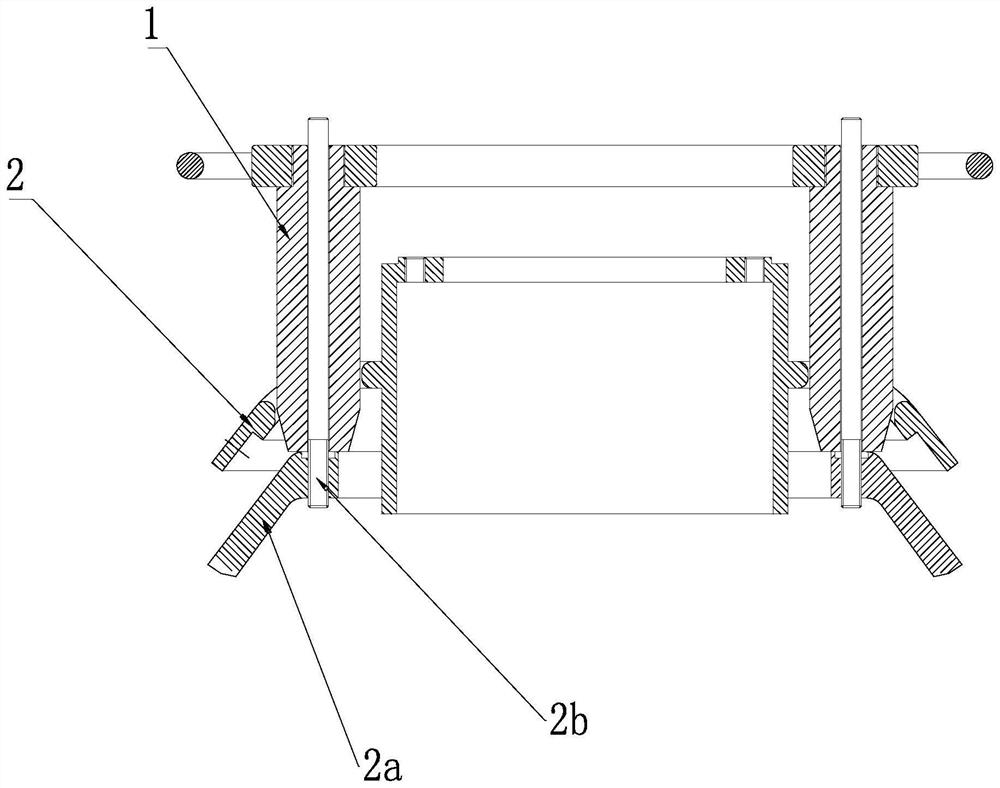

[0036] like Figure 1-5 shown, a compact multi-hole positioning tool comprising:

[0037] The positioning pin shaft 1, the outer diameter of the positioning pin shaft 1 matches the inner hole of the conical cylinder structure of the upper workpiece 2, the positioning pin shaft 1 is provided with a plurality of, and the plurality of positioning pin shafts 1 are connected together in the positioning on the mounting ring 3, and the axial length of the positioning pin 1 is not less than the stacking height of the upper workpiece 2 and the lower workpiece 2a stacked;

[0038] The shaft hole 4 is provided through the positioning pin shaft 1 along the axial direction of the positioning pin shaft 1 , and the inner diameter of the shaft hole 4 matches the diameter of the anode column 2b arranged on the lowermost workpiece.

[0039] The anode column can be screwed into the inner cylinder of the lowermost workpiece by threading, and finally a nut is installed on the outer thread provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com