Welding process method and flow for integrated frame of DDS structure operator rack

A welding process and structural operation technology, applied in the field of DDS structural manipulator frame integrated frame welding process, can solve the problem that the positioning of the tooling is difficult to prevent welding deformation, the coaxiality of the holes on the wallboard is difficult to ensure, and the parallelism of the two wallboards is difficult to solve. Guarantee and other issues, to achieve the effect of reasonable and reliable process installation route, fast and efficient completion of assembly, and optimization of equipment assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

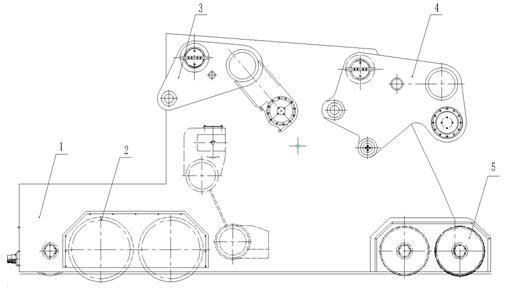

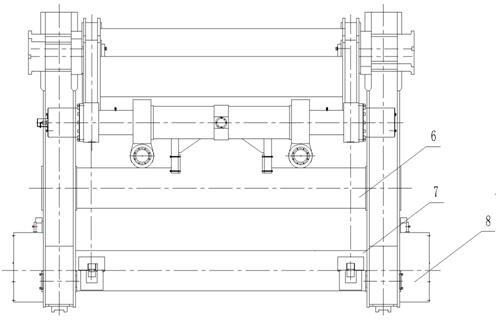

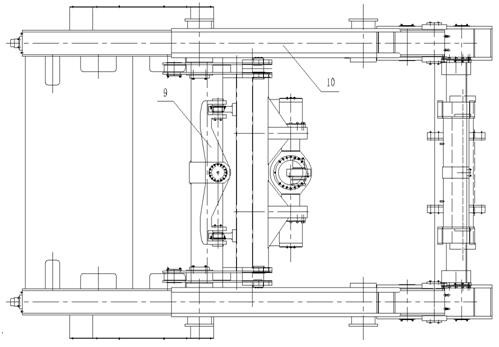

[0037] refer to Figure 1-3 , a DDS structure manipulator frame integrated frame welding process, the welding process adopts an integrated frame welding process, in the assembly process, when the left wall panel and the right wall panel are formed, the equipment parts, the front and rear turrets are used The modular one-piece assembly technology positions the left and right wall panels, and then welds the spacer tubes.

[0038] A process flow of a DDS structure manipulator frame integrated frame welding process method, comprising the following steps:

[0039] S1 First lift the left wall panel 1 and place it on the installation platform, adjust the left wall panel 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com