FPC component mounting process

A component and patch technology, which is applied in the field of FPC component patch technology, can solve the problems of falling off solder joints, the welding performance cannot reach the ideal index, dead lights, etc., and achieves the effect of strengthening thrust and ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

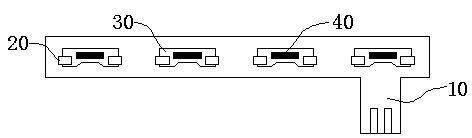

[0026] Such as Figure 1-2 Show.

[0027] S1. Fixing, fixing the back of the FPC board on the positioning fixture, the optical camera detects the circuit and position of the FPC board, and prepares for the welding of the components 30 .

[0028] S2. Glue printing. After the optical camera detects the FPC board 10 correctly, paste the first stencil plate (not shown) on the front of the FPC board 10 , and perform stencil printing on the FPC board 10 through the glue dispensing station 40 .

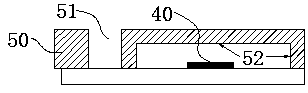

[0029] S3, solder paste printing, the second stencil 50 is placed above the first stencil, and the second stencil is provided with a mesh 51 and an empty groove 52 at the position corresponding to the dispensing position 40, so that the solder paste 20 Missing printing to the preset position of the FPC board 10.

[0030] S4. Mounting, sending the FPC board 10 after the solder paste 20 printing step into the placement machine, and the placement machine accurately installs the components 30 ...

Embodiment 2

[0040] Such as Figure 1-2 Shown:

[0041] S1. Fixing, fixing the back of the FPC board on the positioning fixture, the optical camera detects the circuit and position of the FPC board, and prepares for the welding of the components 30 .

[0042] S2. Glue dispensing. After the optical camera detects the FPC board 10 correctly, the glue dispenser dispenses glue at the preset position of the FPC board 10 .

[0043] S3, solder paste printing, the second stencil is placed on the side where the glue is printed, and the second stencil is provided with an avoidance groove 52 at the position corresponding to the dispensing position 40, so that the solder paste can be missed printed on the FPC board 10 default position.

[0044] S4. Mounting, sending the FPC after the solder paste 20 printing step into the placement machine, and the placement machine accurately installs the components 30 to the fixed position of the FPC board 10 .

[0045] S5. Curing, sending the mounted circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com