Optical cable casing pipe forming processing device

A molding processing and casing technology, applied in optics, light guides, optical components, etc., can solve the problems of production speed influence, complex process conditions, and inability to effectively control excess length, etc., to increase production speed, ensure production quality, and ensure traction effect and the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

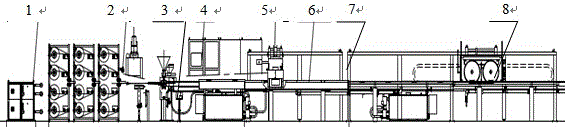

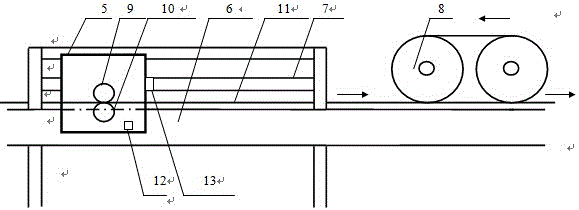

[0016] Including water-blocking yarn pay-off rack 1, optical fiber pay-off rack 2, extruder and sleeve forming die 3, main control system 4, cooling water tank 6, and traction device 8, between the optical fiber pay-off rack and sleeve forming die A doubling mode is arranged between them, which is used for doubling the optical fiber and water-blocking yarn; the cooling water tank 6 is installed between the casing forming mold and the pulling device, and the pulling along the optical cable casing 11 between the cold and hot water tank and the pulling device The auxiliary traction device is installed in the direction, and the auxiliary traction device includes a traction bracket 5, and upper and lower traction wheels 9, 10 are installed on the traction bracket, and the upper and lower traction wheels constitute a pair of synchronously reversed traction whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com